Transocean’s Deepwater Thalassa features the world’s first hybrid-powered drill floor. (Source: Transocean)

Atlantic Canada comprises the three Maritime Provinces—Nova Scotia, New Brunswick and Prince Edward Island—and the province of Newfoundland and Labrador. These provinces are using their collective ocean-based history as a foundation for taking ocean resource development to the next level, spearheading research and introducing industry-leading technologies that have the potential to change offshore operations.

Not surprisingly, Newfoundland, which has the longest history of active offshore E&P, has more oil and gas R&D initiatives than the other provinces. Some of the funding for these efforts comes from organizations like Petroleum Research Newfoundland and Labrador (PRNL), a not-for-profit entity that is maximizing the impact of research by investing money contributed by operating companies with an interest in the province’s offshore. More than CA $500 million has been invested by the industry in local research, education and training since 2004.

PRNL CEO Alan Clarke believes there is great promise in the technologies being developed in the region. “We have one of the most complex environments on earth, and what we learn and develop here can be taken around the world,” he said.

Finding and funding opportunities was one of the drivers for PRNL’s decision to participate in another ocean technology development initiative called the Ocean Supercluster. The supercluster brings together Canada’s ocean-related businesses, researchers and technologists in a range of disciplines to develop solutions to global challenges related to sustainability, reducing carbon footprint and improving energy efficiency. As the single largest funder of the program, PRNL is investing CA $30 million over five years.

“We see opportunities to partner with companies in other sectors,” said PRNL COO Dave Finn. “Diversity is critical to achieving our goals.”

Like-minded universities, businesses and government entities in the region are joining forces through the Ocean Supercluster to develop technologies to address a range of environmental, operational and manpower challenges.

Simulation and modeling

The Marine Institute, part of Memorial University of Newfoundland (MUN) in St. John’s, is creating specialized curricula to prepare students to take on offshore jobs. A simulation training program offered in the School of Ocean Technology is a case in point.

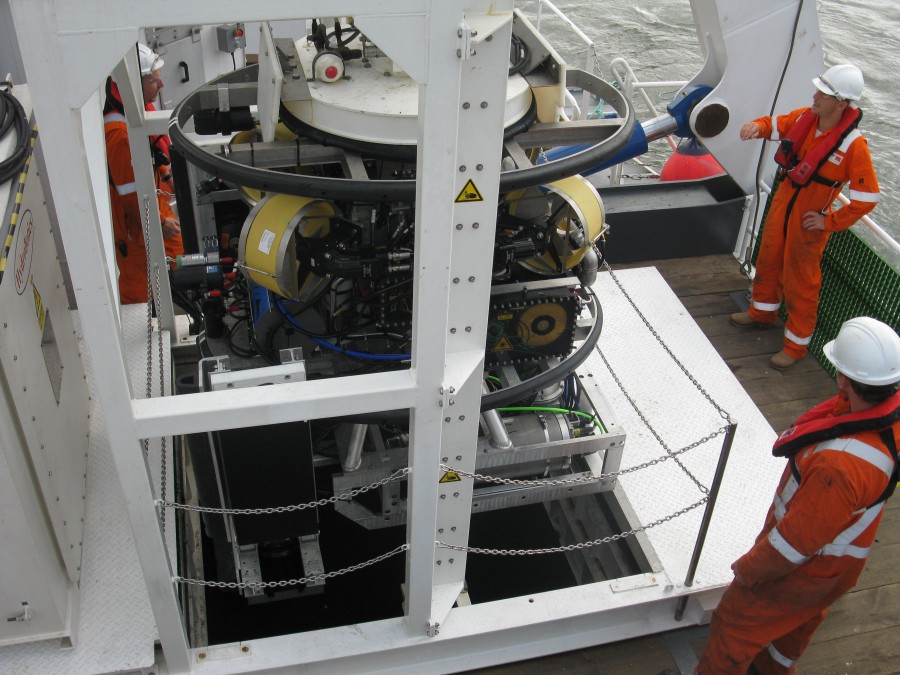

Housed in the Marine Institute, the ROV simulation center places students in a virtual marine environment in which they train to operate work class ROVs. According to Paul Brett, head of the school, this laboratory is unique in the world, providing simulation suites that allow students to fly and co-pilot ROVs as part of a program that also includes learning to maintain and service the equipment. Once they have mastered simulation, students put in 320 hours onboard a vessel before receiving certification. Those who complete the course enter the workforce with operational competencies that allow them to immediately add value.

Training through simulation also is the foundation of the safety programs offered by Virtual Marine. The company provides a range of virtual reality (VR) performance simulation and training courses, including lifeboat simulation complete with real-feel freefall and motions that simulate navigation scenarios, incorporating variables for the time of day, sea state and weather to enable users to experience an emergency firsthand. An ice-management simulator enables testing for emergency evacuations from offshore platforms in ice-infested water, featuring ice floes and hull/ice interaction for multiple vessels. The company also has developed a fast-response boat rescue simulator that can be used with a VR headset.

While these initiatives focus on VR for people, others use facilities to create real-world scenarios that allow assets to be tested in conditions that simulate operational environments. One of these is the ice tank test facility, operated by the National Research Council of Canada on the MUN campus.

One of the largest such facilities in the world, the tank can grow ice 2.5 mm/hr to a maximum thickness of 200 mm in conditions to -25 C (-13 F). The facility can model ice sheets 76 m by 12 m (250 ft by 39 ft) grown under controlled conditions and simulate all types of full-scale ice conditions, including grey ice and multiyear ice as well as level ice, drifting pack ice, columnar ice and ice ridges. A variable speed carriage can tow models through the ice at speeds to 4 m/sec

(13 ft/sec) with a towing force of up to 60 kN to evaluate vessel and structure performance.

Simulation efforts at the Bedford Institute of Oceanography (BIO) in Dartmouth, Nova Scotia, the largest ocean research station in Canada, are addressing a range of subjects that includes how oil behaves in water. At BIO, Rod Doane, a physical scientist at the Centre for Offshore Oil, Gas and Energy Research, manages a program that is evaluating the effectiveness of remediation measures for oil spills.

Doane and his team use an outdoor wave tank, simulating real-world events using seawater, freshwater and brackish water in ambient weather conditions from April to December to learn more about how surface spills act under different conditions. By varying the size and concentration of droplets, researchers are studying dispersion, adhesion to sediment and weathering of oil over time due to the sun, air, current and evaporation. They also are evaluating how microbes can be used to degrade hydrocarbons in water.

Acoustics and visualization

“Listening” under water is another discipline in which Atlantic Canada is taking the lead.

GeoSpectrum in Dartmouth, Nova Scotia, designs and manufactures integrated, end-to-end acoustic systems, specializing in underwater applications. The company focuses on transducer design and software systems, including products that support environmental surveys ahead of seismic programs and others used to improve communication with AUVs and ROVs.

According to GeoSpectrum President Paul Yeatman, in-house experts excel at developing purpose-built equipment for unique applications. “What we do best is look at the overall picture of requirements and design from there,” he said.

Ocean Sonics is another Nova Scotia enterprise investing to improve underwater sound measurement quality. The company has developed small, lightweight hydrophones with batteries that allow deployment and data gathering for up to three days in a range of applications.

Finding better ways to gather and communicate data also is at the heart of Kraken Robotic Systems Inc. in Newfoundland. The company designs and develops advanced sensors, software and underwater robotics for unmanned maritime vehicles and is recognized as a world leader in the use of synthetic aperture sonar, an underwater imaging technology that produces ultrahigh-resolution imagery.

According to Kraken President and CEO Karl Kenny, the foundational technology improves optical quality using acoustics. “It uses a real aperture and synthesizes it to make it think it is 50 times bigger, which means that at a distance of 300 m (~1,000 ft), we can see things at 3-cm (< 1-in.) resolution,” he explained.

The technology allows a 3-D picture of a physical asset to be developed in extremely high detail, providing a clear picture of components. “This capability is valuable in operations like decommissioning,” Kenny said.

The technology delivers value for asset integrity management as well. “If I’m able to gather data over time and can compare results over time, I can detect changes that indicate where structures are exhibiting fatigue, corrosion and potential fracture points.”

Kraken is conducting research, funded in part by PRNL, to determine how these technologies can improve operations in the offshore environment in Atlantic Canada. “There is an advantage in designing for a harsh environment like offshore Newfoundland,” Kenny said, “because if it works here, it will work anywhere.”

Another St. John’s-based company, PanGeo Subsea Inc., specializes in high-resolution 3-D acoustic imaging that has wide-ranging offshore applications. One of its technologies is the Sub-Bottom Imager, which enables detailed visualization below the seafloor. Originally developed to image buried pipelines, this technology has been used offshore Europe to image small-diameter buried cables employed in wind farms as well as more unusual applications, including visualizing buried bronze canons on an 18th-century shipwreck site.

According to Co-founder and CEO Moya Cahill, the company continues to innovate and has plans for this technology to operate on seabed crawler vehicles and AUVs. The value in technology development is clear, Cahill said. “Technology is something we can export, and it’s something we do really well here in Newfoundland.”

Leading technology development

Aspin Kemp & Associates in Prince Edward Island has exported technology in the form of the world’s first DNV-certified system to operate in Class 3 dynamic position closed bus configuration. This technology was used to develop the first hybrid drill floor system, which was deployed on Transocean’s Deepwater Thalassa in 2015 and was selected for installation on four additional newbuild deepwater drillships. The high-reliability power plant uses a combination of direct current bus control, energy storage and controller infrastructure to reduce the impact on drilling process drives resulting from power disturbances, allowing drives to be decoupled and driven completely independently of their controllers.

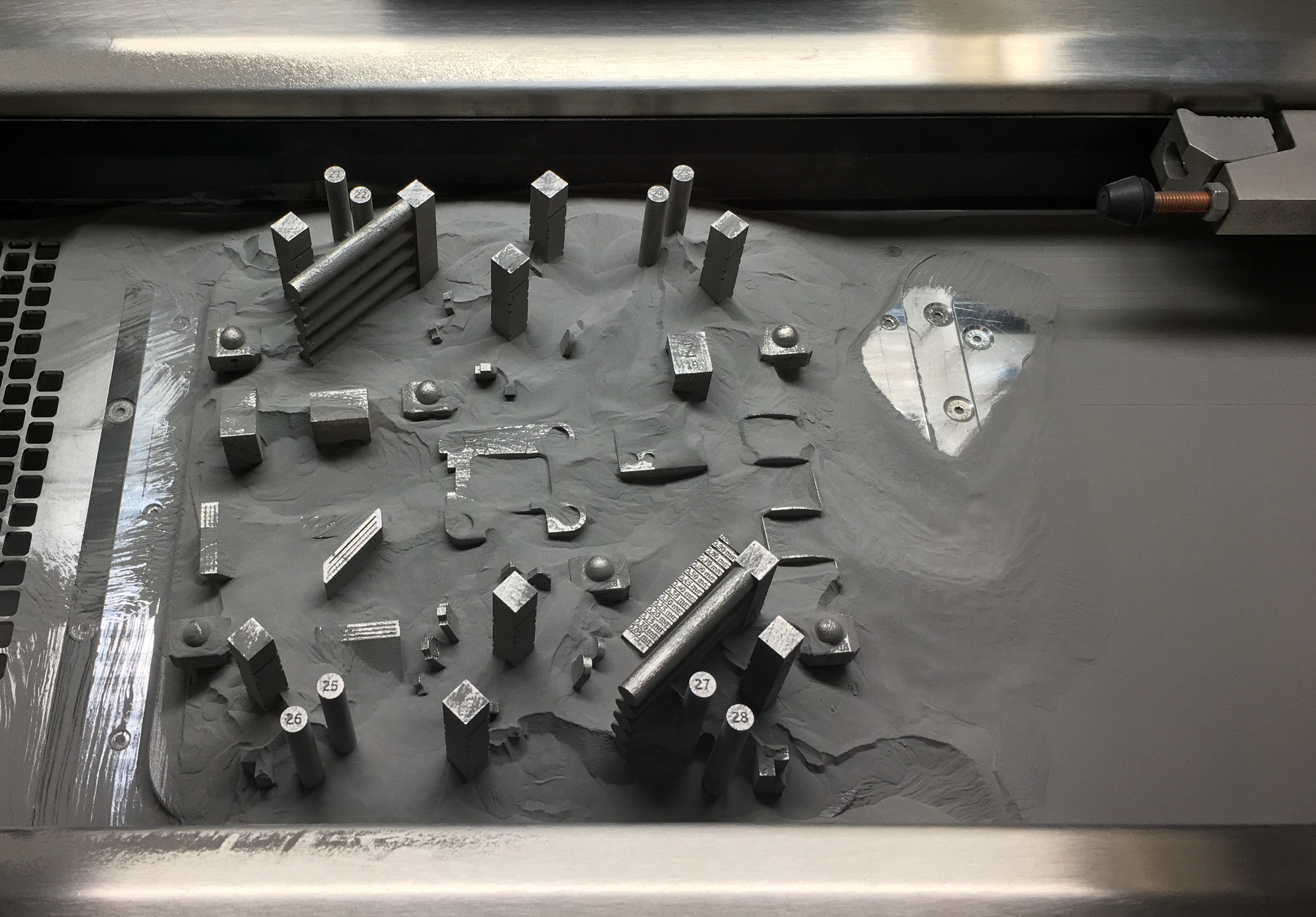

Other groundbreaking work is underway at the University of New Brunswick, where additive manufacturing research is delivering interesting results for high-entropy alloys. Researchers at the university are evaluating components built on site under different loading conditions, testing the tensile strength and corrosion resistance and determining fracture characteristics using macro to nano scale analysis methods.

While university researchers focus on new methods for producing physical parts, visionaries at T4G are finding ways to extract value from data. One of the near-term challenges being undertaken is creating a digital twin of the Grand Banks offshore Newfoundland, where E&P activities that began in the 1980s have led to multiple ongoing developments. Using data from a range of sources on a Microsoft platform, T4G plans to build a model of the Grand Banks before, during and after development, using data gathered throughout the process to feed back into the digital twin.

Exporting technology

Atlantic Canada has long been known for its harsh environment and the technologies that enable offshore E&P developments in exacting conditions, but regional investment in technology development could provide more reasons to take a closer look at this region.

The creation of the Ocean Supercluster provides a forum for collaboration among stakeholders across disciplines and industries in pursuit of innovative solutions, and many players in the area already are pushing the boundaries of what is possible.

For more information, contact Jennifer Presley at jpresley@hartenergy.com.

Recommended Reading

Exxon, Chevron Tapping Permian for Output Growth in ‘24

2024-02-02 - Exxon Mobil and Chevron plan to tap West Texas and New Mexico for oil and gas production growth in 2024, the U.S. majors reported in their latest earnings.

CEO: Coterra ‘Deeply Curious’ on M&A Amid E&P Consolidation Wave

2024-02-26 - Coterra Energy has yet to get in on the large-scale M&A wave sweeping across the Lower 48—but CEO Tom Jorden said Coterra is keeping an eye on acquisition opportunities.

NGL Growth Leads Enterprise Product Partners to Strong Fourth Quarter

2024-02-02 - Enterprise Product Partners executives are still waiting to receive final federal approval to go ahead with the company’s Sea Port Terminal Project.

Permian E&P Midway Energy Partners Secures Backing from Post Oak

2024-02-09 - Midway Energy Partners will look to acquire and exploit opportunities in the Permian Basin with backing from Post Oak Energy Capital.

Matador Resources Announces Quarterly Cash Dividend

2024-04-18 - Matador Resources’ dividend is payable on June 7 to shareholders of record by May 17.