Like cholesterol in blood vessels, asphaltenes create problems without treatment. One economical way to prevent asphaltene deposition is to add an asphaltene dispersant. Conventional asphaltene dispersants include dodecylbenzene sulfonic acid (DDBSA) and alkyl phenol formaldehyde (PF) resins in aromatic solvents. The organic acid group provides a barrier around the asphaltene colloids by bonding with the asphaltene’s heteroatomic groups through an acid-base interaction while the long alkyl chain is attracted to the oil phase.

Both DDBSA and PF resins are hazardous to human health and the environment. With more restricted regulatory requirements, especially for offshore operations, the flow assurance industry is looking for new and nontoxic asphaltene dispersants. Flowsolve 150 (FS150) and Flowsolve 250 AF (FS250AF), developed by Croda Inc., are free of benzene, toluene, ethylbenzene and xylene (BTEX) asphaltene dispersants produced from bio-based and nontoxic resources.

The BTEX-free asphaltene dispersants are synthesized from sustainable and biodegradable raw materials in a mineral or bio-based oil. The molecular weight distribution of the dispersants is controlled by the reagent ratios, reaction temperature and time. Both dispersants are designed to achieve a balance between the hydrophobic chain, which provides steric hindrance between the asphaltene colloids and the polar groups that give multiple interaction points for bonding and absorption to the asphaltenes. Both dispersants contain only carbon, hydrogen and oxygen, and no heteroatoms. This molecular formula poses no threat to refinery catalysts.

Dispersal testing

The performance of the BTEX-free asphaltene dispersants was tested according to the procedure specified by ASTM D7061-06 with the Turbiscan optical scanning device. The scanner uses a pulsed infrared light source (850 nanometers) and a detector on opposing sides of a sample vial. The crude oil was diluted with toluene then added to heptane, which caused the asphaltenes to flocculate and sediment (Figure 1). This ASTM method provides a quantitative and rapid laboratory measurement of asphaltene precipitation in a crude oil sample.

In this test, the crude oil (1 mL) was diluted with toluene (6 mL) then mixed with an overhead stirrer at room temperature for at least 3 hours. The crude oil/toluene solution (2 mL) was added to heptane (23 mL) and hand mixed to form the blank test sample. The dispersant was dissolved in toluene (1 wt% stock solution) then added to the crude oil mixture at either 25 ppm, 50 ppm or 100 ppm dosing rates. The crude oil mixture was decanted into a glass vial then transferred into the Turbiscan sample chamber heated at 35 C (95 F).

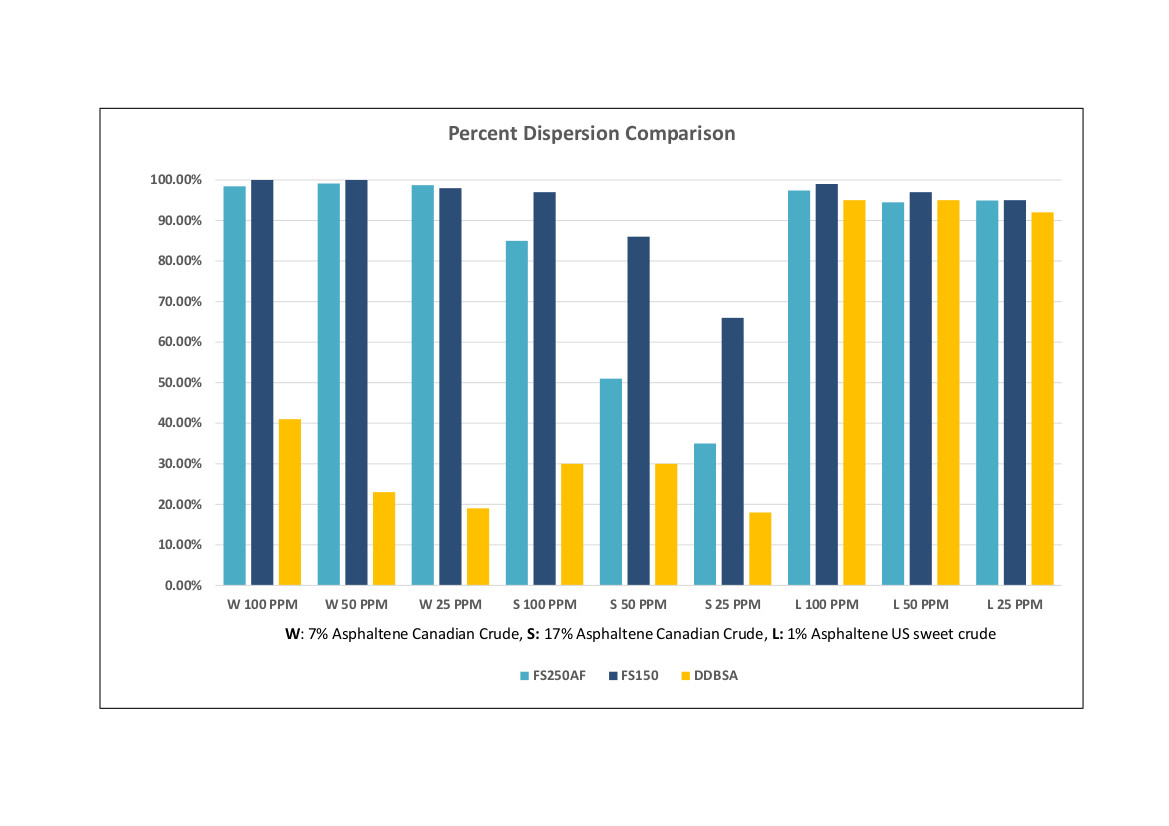

The rate of precipitation was monitored by vertically scanning the sample vial every minute for 15 minutes, then evaluating the increase in transmittance through a defined section of the oil sample (10 mm to 50 mm) over time. The asphaltene dispersion is evaluated with three different crude oils produced in Canada and the U.S. and compared with DDBSA. As shown in Figure 2, the BTEX-free asphaltene dispersants provide about 100% dispersion for the three crude oils at 50 ppm to 100 ppm.

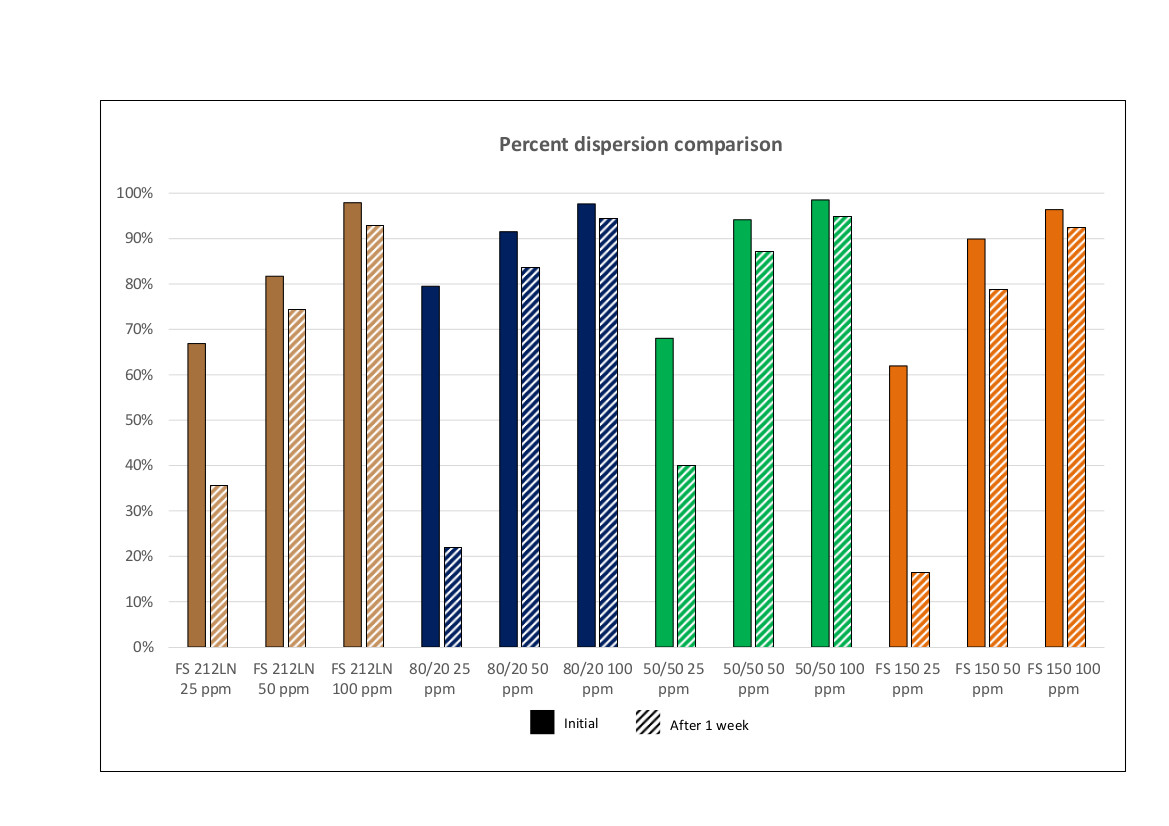

It is well known that aromatic solvents usually provide synergy for asphaltene dispersants and wax inhibitors. It is important to find out if BTEX-free asphaltene dispersants are compatible with aromatic solvents and their related flow assurance agents. Flowsolve 212LN (FS212LN) is a 50% active asphaltene dispersant in aromatic 150 solvent and not DDBSA chemistry. It was mixed with FS150 at a 50:50 and 80:20 ratio to check the compatibility. The asphaltene dispersion was tested in a heavy Canadian crude oil (Table 1).

|

FS212LN/FS150 ratio |

100:0 |

80:20 |

50:50 |

0:100 |

|

25 ppm |

66.8% |

79.5% |

68% |

61.9% |

|

50 ppm |

81.7% |

91.5% |

94.1% |

89.9% |

|

100 ppm |

96.4% |

97.6% |

98.5% |

96.4% |

TABLE 1. Asphaltene dispersion percentage of aromatic solvent asphaltene dispersant (FS212LN), BTEX free asphaltene dispersant (FS150) and their blends at 50:50 and 80:20 ratio in a Canadian heavy crude oil are listed. (Source: Croda Inc.)

As shown in Table 1, BTEX-free asphaltene dispersants are compatible with the aromatic solvent asphaltene dispersant and perform equally. There is even a synergistic effect for certain ratios. The dispersion was checked after a week for long-term stability. The BTEX-free asphaltene dispersant provides the same long-term stability as the aromatic solvent dispersant (Figure 3). The 25-ppm dosage is underdosed and cannot prevent long-term precipitation. FS150 also is mixed with a wax inhibitor based on PF resin in aromatic solvent FlowSolve 130LN (FS130LN) at a 50:50 ratio. As shown in Table 2, when underdosed, blends show a negative effect; when properly dosed, chemistries are compatible.

|

FS130LN/FS150 ratio |

100:0 |

50:50 |

0:100 |

|

25 ppm |

-2.3% |

32.6% |

65.9% |

|

50 ppm |

-0.7% |

47.6% |

85.9% |

|

100 ppm |

10.4% |

86.7% |

96.6% |

TABLE 2. Asphaltene dispersion percentage of a wax inhibitor based on PF resin in FS130LN, FS150 and their blends at 50:50 in a Canadian heavy crude oil are listed. (Source: Croda Inc.)

Cold centrifuge testing was carried out as an initial screening tool for formulation stability to determine if FS150 is suitable for umbilical use. The sample is centrifuged at 3,000 rpm at less than 4 C (39 F) continuously for seven days. After seven days, no gelling or sedimentation occurred. Isothermal and isobaric testing was then carried out, and FS150 was found to be stable up to a pressure of 10,000 psi and down to a temperature of 4 C.

The BTEX-free asphaltene dispersants are manufactured from renewable and nontoxic materials to meet strict regulatory requirements. They are compatible with conventional flow assurance agents and perform similarly to known asphaltene dispersants in aromatic solvents.