Facilities operate in the desert of Bahrain, Middle East. (Source: Philip Lange/Shutterstock.com)

The Abu Dhabi International Petroleum Exhibition and Conference (ADIPEC) is scheduled for Nov. 11-14 in the United Arab Emirates. ADIPEC is expected to host 145,000-plus visitors, more than 2,200 exhibiting companies, over 1,000 expert speakers and more than 160 conference sessions.

Last year $17.99 billion worth of business was concluded at the event, according to the ADIPEC website. “ADIPEC is a place to learn about new innovative technologies, share information and unlock the possibilities of our collective future,” the website stated.

The following is a sampling of some of those innovations that will be showcased at ADIPEC this year.

Editor’s note: The copy herein is contributed from service companies and does not reflect the opinions of Hart Energy.

Frames for pipeline transmission and high-pressure injection applications

Ariel Corp. will showcase its complete range of standard reciprocating compressors including the KBK and KBT frames released in 2018. These compressors have proven to be a great success all over the world with more than 150 compressors sold in the past 15 months (as of Sept. 3). Regionally, the KBK and KBT compressors are operating in Pakistan, Iraq and Egypt with more expected to go into operation in the United Arab Emirates, Oman, Bahrain and Kuwait in 2020. Ariel sees a strong market for high-speed reciprocating compressors in the Middle East and Africa regions. Customers in the regions are moving forward with a focus on budget and lead time for compression projects based on reciprocating compressors built to API11P or ISO13631 standards, as opposed to the more expensive and longer lead time centrifugal compressors or reciprocating compressors based on API618. arielcorp.com

Upstream technologies support MENA’s oil, gas needs

Baker Hughes has been present in the Middle East and North Africa (MENA) region for more than 80 years and has been leveraging ADIPEC as a key industry platform to showcase how its full-stream portfolio can support the region’s oil and gas needs. At ADIPEC, the company’s upstream technology showcase will feature its oilfield services, which include evaluation, drilling, completion, and production and optimization, as well as its equipment, specifically flexible pipes and Baker Hughes’ latest subsea equipment. The company also will be showcasing its latest artificial intelligence solutions, which deliver digital transformation technologies that will drive new levels of productivity for the oil and gas industry. bakerhughes.com

Run a more productive job site and improve safety culture

At ADIPEC, Caterpillar Oil and Gas will showcase the latest technological solutions from Cat Connect and different service options available for the industry. Cat Connect is an intelligent suite of hardware, software and services designed to help operators run a more profitable operation while boosting efficiency, improving safety and saving time and money. From simple asset tracking to full data and fleet management, Cat Connect offers options for every need and budget, and the technology works on both Cat and other manufacturers’ equipment. cat.com/oilandgas

New tool for rapid stuck-pipe recovery

Churchill Drilling Tools will showcase its HyPR HoleSaver tool, which enables safe and quick recovery from a stuck pipe by severing the drillstring. By pumping a “smart dart,” operators redirect the flow of mud creating a high-velocity stream of fluid to erode and sever the drillpipe. The smooth profile of the cut enables drilling teams to get back on track quickly through fishing or by opting to plug and sidetrack. A major Middle East operator used the HyPR tool, preplaced in the string as extra stuck pipe contingency, and successfully severed its drillsting after becoming differentially stuck. When jarring attempts failed, and having previously spent two days mobilizing explosives to manage an earlier stuck-pipe incident, the operator deployed the HyPR. Requiring no additional topside equipment or personnel, the tool severed the string in 60 minutes allowing the operator to recommence operations shortly after. circsub.com

Program facilitates efficient management of replacement inventory

Gardner Denver’s Parts on Demand (POD) service is a part of Experience 360, a comprehensive set of solutions built around pumps, parts, presence and people, and it is utilized in more than 100 customer sites in North America and the Middle East. The POD program facilitates efficient management of replacement parts inventory at regional locations, facilities or well sites. Gardner Denver will place physical inventory at the customer’s location in their warehouse or in a Gardner Denver container for onsite availability at any time. In addition, Gardner Denver’s Thunder Quintuplex frac pump combines 3,000 bhp with an 11-in. stroke to reduce running speed and extend consumable life. The new pump was designed for longevity with stainless steel construction, a new geometry to minimize stress and a design that is more conducive to efficient maintenance. gardnerdenver.com

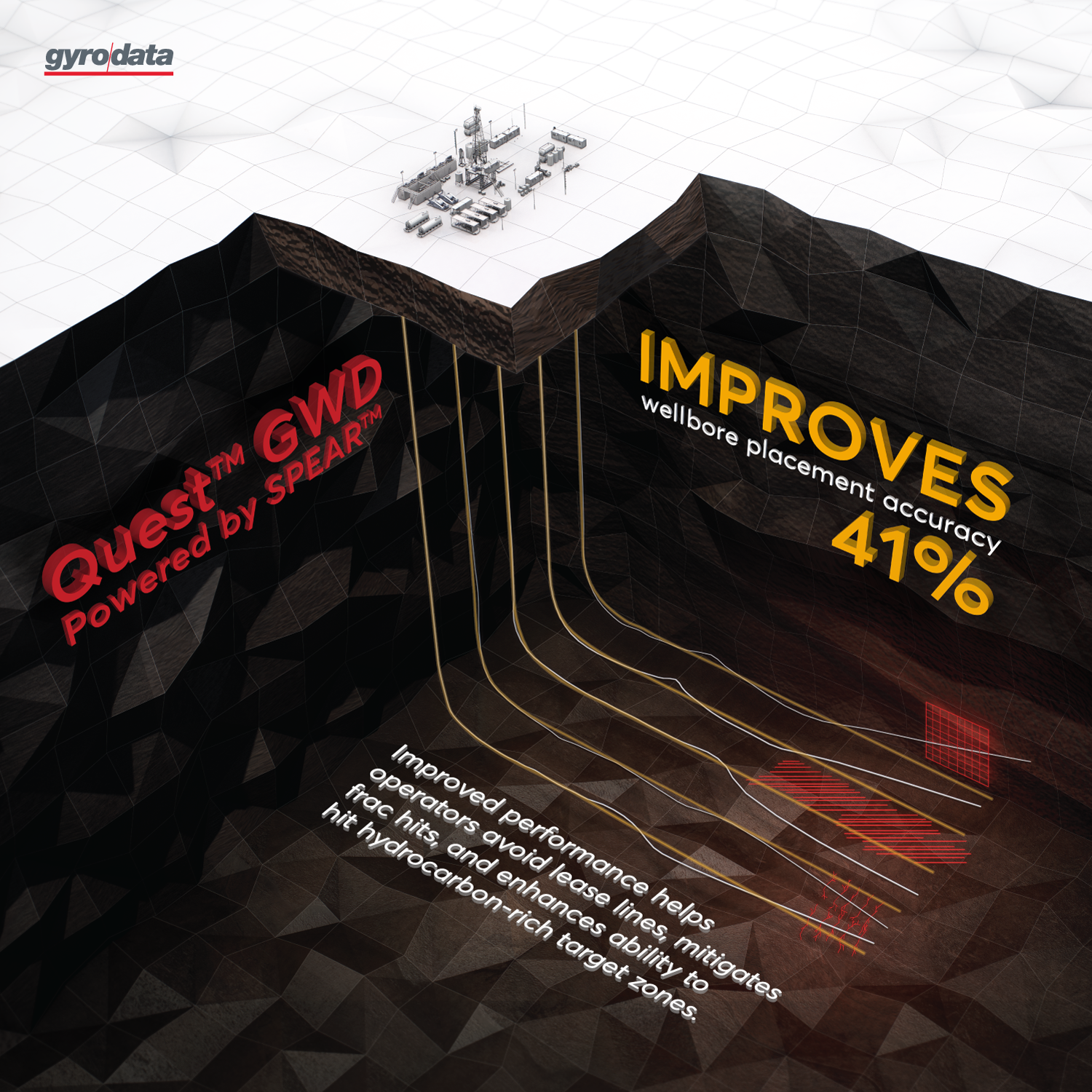

All-attitude, high-accuracy surveys in real time while drilling

Gyrodata will be showcasing its new gyro-while-drilling tool, Quest GWD, at ADIPEC 2019. The Quest GWD service provides all-attitude, high-accuracy surveys in real time while drilling. The system utilizes Gyrodata’s SPEAR solid-state gyro technology, which substantially reduces gyro surveying time and operational cost. Performance is improved for increased speed, precision, efficiency, accuracy and reliability. The improved accuracy of this technology results in a smaller ellipse of uncertainty, allowing wellbore trajectory to be precisely delivered. The improved accuracy helps operators avoid lease lines, mitigate frac hits, mitigate well-to-well production losses and enhanced ability to hit hydrocarbon-rich target zones. Additionally, Quest GWD’s high-performance Coriolis vibratory gyros assure precise wellbore guidance for collision avoidance. The tool also provides continuous inclination and toolface from the vertical while sliding as well as full surveys on demand. gyrodata.com

Enterprise-level analytics platform collects, analyzes and acts on data

The major focus area for Honeywell at ADIPEC 2019 will be the advancement of digitalization across the Middle East’s oil and gas industry. At the show, the company will debut a new enterprise-level analytics platform for the first time in the region. Honeywell Forge for Industrial is a new category of software that improves the way companies collect, analyze and act on data from their operations. It converts massive quantities of data from processes, assets and people into actionable insights and enables top-to-bottom visibility into how operations are performing from a single screen. This new enterprise performance management software leverages predictive analytics to help identify maintenance issues before they happen, enables workers to be more productive and safe, and reduces costs while increasing productivity. honeywell.com

Tool allows compromised area to be clad, sealed with minimal ID loss

Mohawk Energy develops, manufactures and installs expandable tubular technologies that are designed to solve the most critical downhole challenges. Casing, tubing or completion equipment in the wellbore may fail or deteriorate over the life of the well. This may occur due to multiple reasons including corrosion, leaking tubular connections or failed sliding sleeves. Mohawk Energy’s ReLine MNS product allows the compromised area to be clad and sealed with minimal inner diameter (ID) loss, while providing high burst and collapse rating. The ReLine MNS is designed for deployment on jointed pipe. The patch can cover an area ranging from 30 ft to more than 7,000 ft in length. The ReLine MNS also can be deployed through various ID restrictions in the wellbore such as nipples, frac sleeves or mixed strings of heavyweight casing. mohawkenergy.com

Bit designed for drilling challenges of the Middle East and North Africa

National Oilwell Varco (NOV) will be highlighting its Falcon regional bit line at ADIPEC 2019. The new Falcon bit is based on the proven Tektonic platform but incorporates a number of new features designed to address the drilling challenges of the Middle East and North African markets. ION application-specific multidimensional cutter geometries, which are fine-tuned to overcome critical failure modes, are tougher and more resistant to abrasion while in difficult downhole environments. Deepleach technology helps ION cutters maintain thermal stability, and as the cutters are designed for fracturing and shearing, they are more effective in brittle formations such as carbonates and clastic rock. The Falcon bit also incorporates depth-of-cut control components that maximize surface contact area to improve cutter engagement, which provides a significant reduction in torque fluctuations. Finally, improved HydroShear nozzles increase hydraulic shear close to the formation surface and cutter interface, overcoming typical issues with cuttings evacuations and heat accumulation on PDC cutters. nov.com

Demulsifiers more than 60% biodegradable in seawater

With the growing environmental regulations surrounding the oil and gas industry, companies are faced with the challenge of employing sustainable and environmentally acceptable materials in oil and gas applications. Demulsifiers are an essential component of upstream production chemicals that are necessary to separate oil from water once crude oil is produced from a well. High-performance and environmentally compliant materials for this application are still scarce. Nouryon has released a range of demulsifiers that provide oil producers with a more sustainable option to separate crude oil from natural gas and water. The Witbreak NEO range is more than 60% biodegradable in seawater based on OECD 306 and holds no substitution warnings per CEFAS classification. nouryon.com

New gas pressure regulator valve reduces weight and costs

Oxford Flow designs and manufactures pressure control equipment using technology originally developed at Oxford University. Oxford Flow’s pressure reducing valves can significantly reduce costs for the oil and gas, water and process industries. The company’s new IM gas pressure regulator valve is designed to increase reliability and reduce costs for operators. The valve offers superior pressure control compared to conventional technologies, and its compact construction considerably reduces weight and therefore the need for expensive lifting equipment. The design also removes the valve components most prone to failure, almost entirely eliminating the need for maintenance. Oxford Flow’s most recent advance is a valve designed specifically to handle oil and gas fluids. This control valve has no valve stem, which removes the most prone leak path and reduces the risk of fugitive emissions. oxford-flow.com

Mixer treats natural gas for the LNG industry

ProSep’s Annular Injection Mixer (AIM) has demonstrated its high efficiency in treating natural gas for the LNG industry, providing an optimized method to increase the LNG’s heating value and removing BTEX contaminants. The high-efficiency AIM design comprises an inlet convergent cone, injection spool and divergent cone, which allows for a liquid hydrocarbon stream to be blended (quenching) into natural gas, achieving 100% vaporization. The AIM mechanical design delivers enhanced fluid dispersion using the momentum transfer between the gas stream and the injected stream creating high mass-transfer properties, while the annular injection ring generates a homogeneous downstream process fluid. prosep.com

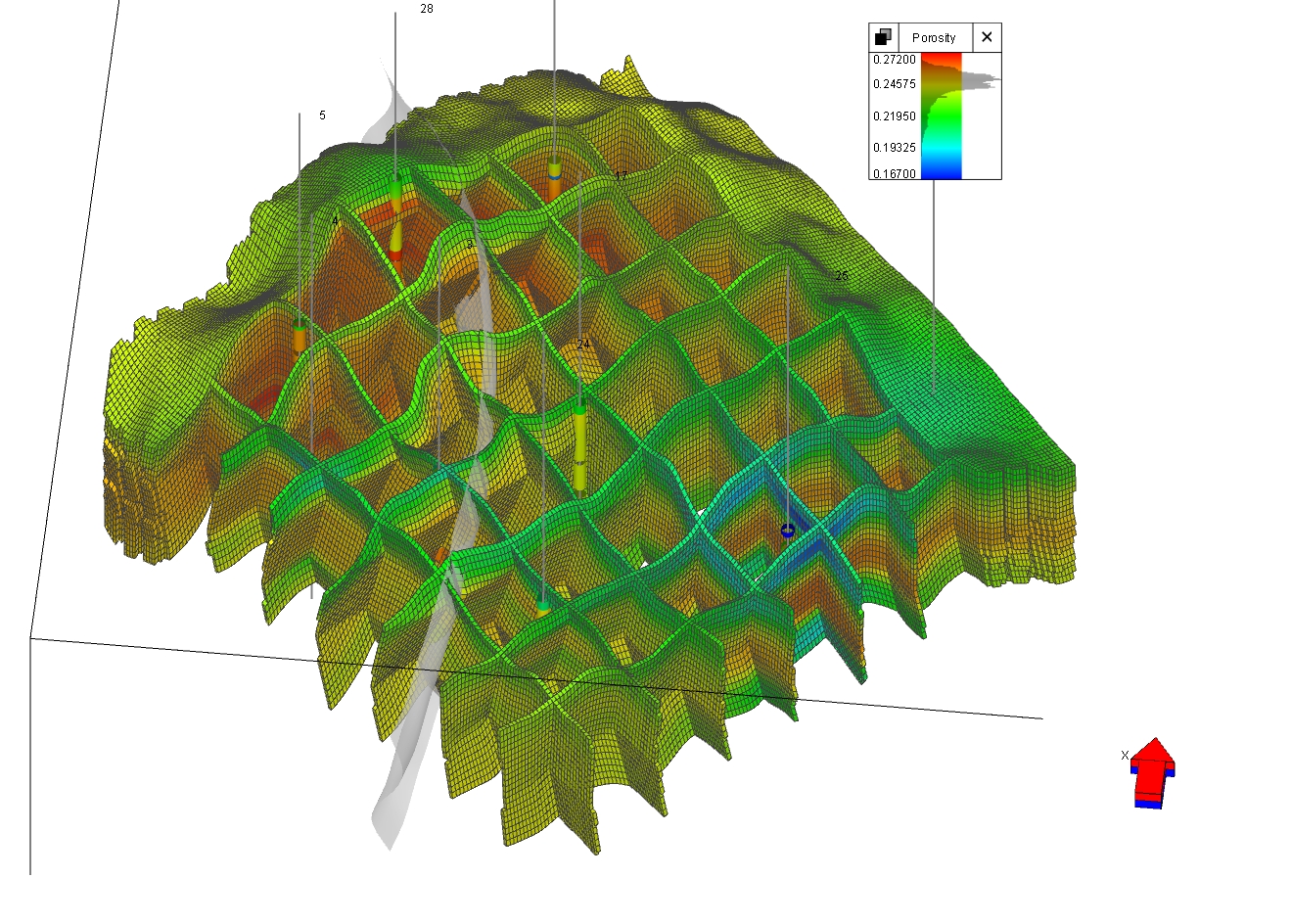

Reservoir management program creates value for assets

At ADIPEC, Rock Flow Dynamics will present its tNavigator comprehensive reservoir management program. tNavigator is a single program covering seismic interpretation, well correlation, geological modeling, fluid characterization, well modeling, reservoir simulation and surface network design. The program creates value for conventional and unconventional assets. This means users deal with only one interface and only one point of data entry. This avoids extra work and makes learning easier. In addition, workflows can be put under the control of tNavigator’s optimization and uncertainty engine. These workflows can improve understanding of the interactions between the individual elements of the workflow. For example, the impact of uncertainty in seismic velocity modeling on water handling capacity can be quickly and easily determined in a single workflow in the same program using robust physics. Answers to this question on water handling capacity can help avoid the need for expensive retrofitting of surface facilities. rfdyn.com

Tubing products designed to enhance productivity

Sandvik is a developer and producer of advanced stainless steels, special alloys, titanium and other high-performance materials. At ADIPEC 2019, Sandvik will showcase an extended range of tube products for upstream and downstream markets, including high-corrosion-resistant products such as hydraulic and instrumentation, heat exchanger, and oil country tubular goods tubing, control lines and umbilicals. Sandvik also will showcase its productivity-enhancing transportable onsite or container-based coiled tubing production unit. The onsite unit allows installation of equipment at the customer’s facilities for final stage production, while the container unit provides a temporary installation with equipment built within a fully mobile container. These provide Middle East customers a solution for decoiling, straightening and line marking to any lengths in remote areas. In addition, generator operation and air conditioning make it ideal for use in desert environments. sandvik.com

AI-based application enables operators to predict and preempt costly ESP failures

Due to the nature of electric submersible pumps (ESPs) being buried at the bottom of the borehole, monitoring their performance is a significant challenge. Existing monitoring and control technologies on the market look retrospectively at sensor data and are primarily used for troubleshooting and forensic analysis. Additionally, most traditional control systems can only make use of current sensor values and do not consider historical data, which are critical to developing performance trends for predictive maintenance. Siemens developed and field-tested AI4ESP, an autonomous well surveillance tool for remotely monitoring ESP performance that uses artificial intelligence (AI) to predict failures days before they occur. Incorporating self-learning models, AI4ESP uses operating data (real-time and historical) from a variety of sensors as “fuel” to build an increasingly robust ESP behavior profile for anomaly detection and predictive maintenance. siemens.com

Digital gas-lift system enables more production with less intervention

At ADIPEC 2019, Silverwell will be exhibiting its Digital Intelligent Artificial Lift (DIAL) gas-lift production optimization system. DIAL overcomes the production constraining limitations of existing gas-lift technology, enabling on-demand adjustment of gas-lift injection rate and depth from the surface without intervention. Typical achievable production uplifts are in the order of 10% to 20%, although this can be even greater in dual-string applications that Silverwell is piloting with a client in the United Arab Emirates. In addition to enabling more production with less intervention, DIAL provides a continuous stream of in-well pressure and temperature data. More data significantly reduce uncertainty in gas-lift well design and when making production and reservoir management decisions. In addition to showcasing DIAL, Silverwell will be unveiling a new demonstration unit to illustrate the production enabling benefits of DIAL in both single and dual-string completions. silverwellenergy.com

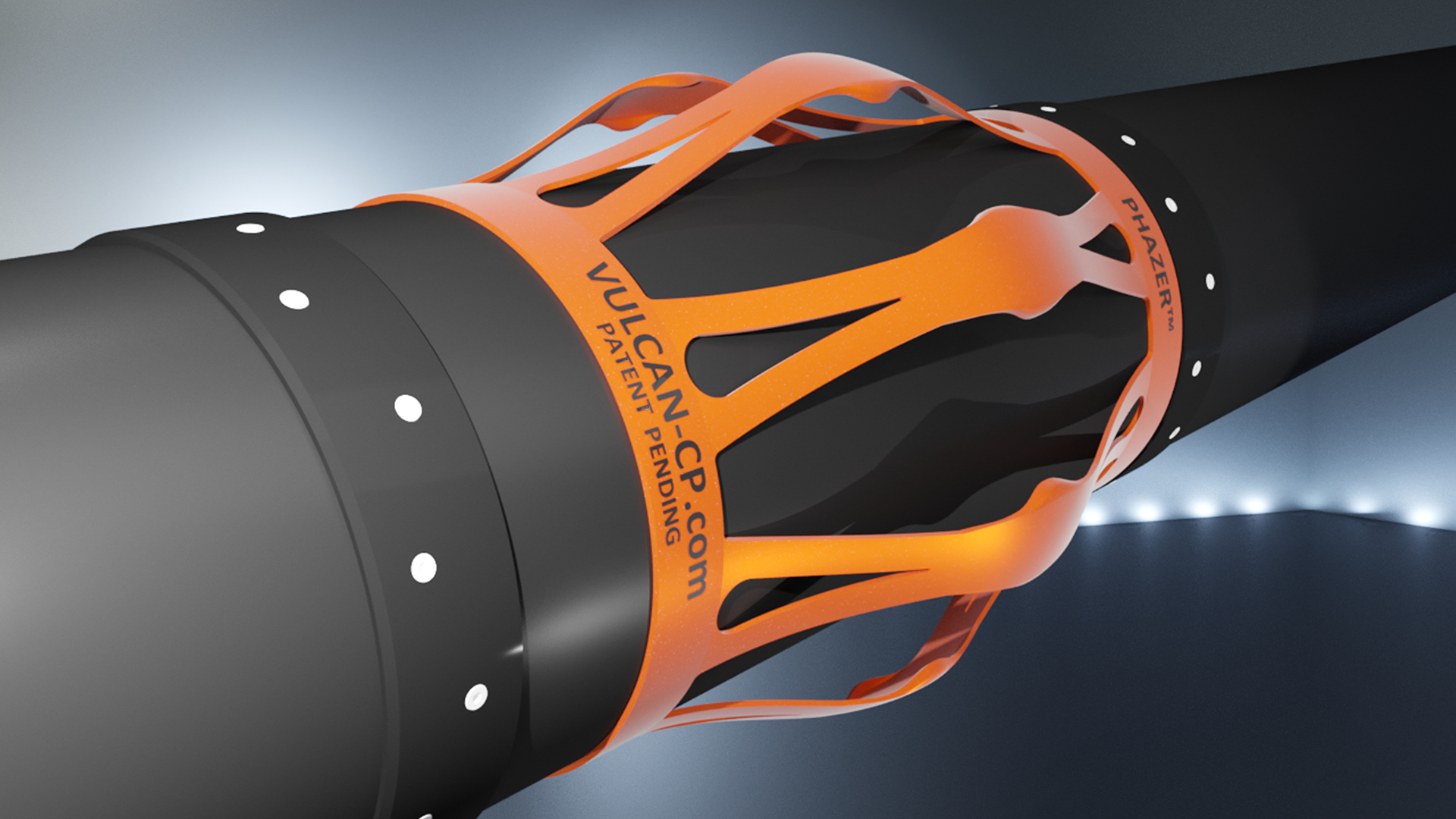

Next generation of centralization

Some companies face the challenge of centralization in an under-reamed open hole. To date, it has proven very difficult to run casing and liners through tight cased-hole restrictions with oversized large diameter centralizers. This is due to the high accumulative drag forces that provide effective centralization in the larger under-reamed openhole sections. After more than two years of R&D, Vulcan has engineered a slip-on centralizer called PHAZER: FLEX. Its new blade design maintains low run into hole drag forces when passing through the cased-hole restrictions. Upon entering the under-reamed openhole sections, superior standoff also is achieved, in turn providing ideal conditions for zonal isolation. This design offers a 100% performance improvement over the existing centralizer products available in the market and, in most cases, replaces expensive centralizer sub alternatives. vulcan-cp.com

First single-trip openhole cementing and sidetrack system

Weatherford has announced the market launch of its AlphaST single-trip openhole cementing sidetrack system, a market-first capability to initiate sidetrack operations without the need of a cement plug. Designed to increase operator flexibility, eliminate multiple trips and avoid costly cementing operations, AlphaST is the world’s only single-trip openhole cementing and sidetrack system. The system enables operators to never again need to sidetrack from a cement plug and avoid the cost and time of setting a cement plug, waiting on cement and time drilling. The bottom line is opex savings equal to days of rig time. weatherford.com

Services help put well back on production safely and quickly

During ADIPEC 2019, Wild Well will be displaying its Unconventional Intervention services of Freeze, Hot Tap and Valve Drilling to highlight the challenges clients face to gain access to inoperable valves, usually as part of the plug and abandonment process. The goal of the Unconventional Intervention service line is to provide clients with safe well access by determining if trapped pressure exists in the wellhead. Valve Drilling services can help return a well to production by fully opening a stuck lower master valve. Most projects focus on the vertical wellhead or completion tree components aligned with the wellbore. Valve Drilling can also work in a horizontal position for side-entry applications on valves and other wellhead components. In addition, Wild Well provides Cryogenic Freeze services, which are used to place a temporary ice plug barrier in tubulars to maintain pressure control while allowing remedial repairs to be made to surface equipment. Using cost-effective engineered services like Freeze, Hot Tap and Valve Drilling, Wild Well’s clients save time and money by putting the well back on production safely and quickly. wildwell.com

Robotic catalyst removal technology increases uptime

Launched commercially in May, Worley’s CAROL (Catalyst Removal Amphirol) is the world’s first commercially available robotic catalyst removal technology. CAROL minimizes the time spent by workers unloading catalyst in confined refinery and petrochemical vessels and increases uptime, thereby reducing the unloading duration. Human safety is improved by a factor of 10. Efficiency is improved by at least 20%. Until now, catalyst unloading has typically been performed by catalyst contractors that enter the vessel with a breathing apparatus. Contractors spend about 10,000 hours unloading catalyst every year in a nitrogen atmosphere that does not support life. By inventing a robot that can remove this catalyst and eliminate the need for human entry into an inert atmosphere, CAROL has the potential to save many lives. The robot also provides an alternative to waterflooding and the associated disposal of the potentially contaminated water. worleyparsons.com

Recommended Reading

Midstream Operators See Strong NGL Performance in Q4

2024-02-20 - Export demand drives a record fourth quarter as companies including Enterprise Products Partners, MPLX and Williams look to expand in the NGL market.

Enbridge Sells Off NGL Pipeline, Assets to Pembina for $2.9B

2024-04-01 - With its deal to buy Enbridge’s NGL assets closed, Canada's Pembina Pipeline raised EBITDA guidance for 2024.

Pembina Pipeline Enters Ethane-Supply Agreement, Slow Walks LNG Project

2024-02-26 - Canadian midstream company Pembina Pipeline also said it would hold off on new LNG terminal decision in a fourth quarter earnings call.

Williams Beats 2023 Expectations, Touts Natgas Infrastructure Additions

2024-02-14 - Williams to continue developing natural gas infrastructure in 2024 with growth capex expected to top $1.45 billion.

Report: Crescent Midstream Exploring $1.3B Sale

2024-04-23 - Sources say another company is considering $1.3B acquisition for Crescent Midstream’s facilities and pipelines focused on Louisiana and the Gulf of Mexico.