(Source: Marc Morrison/marcmorrison.com)

[Editor's note: This article originally appeared in the November issue of E&P Plus. Subscribe to the digital publication here.]

It is common for offshore oil and gas facility control systems to operate reliably for many years without major intervention. This is not surprising since reliability and availability are fundamental requirements in control system design. This high level of reliability is a desirable characteristic of these systems in the offshore environment since they support the oil and gas production processes and the essential self-supporting utilities and services of the asset.

However, a very robust control system that provides years of reliable service can bring about an associated lack of attention to the control system infrastructure that can lead to a hidden issue: unrecognized obsolescence. In this case, when an obsolete component finally does fail, it can be challenging to find replacement parts or repair services. It also can be difficult to find technicians with experience in older hardware or software platforms to service these systems. This may present a significant risk to production and unexpected interruptions in essential utilities and services.

While some organizations implement obsolescence management programs with proactive strategies for mitigating obsolescence, many others do not and only discover the magnitude of these risks when an issue, such as a failed component, arises. In some cases, the risks associated with these obsolete systems, along with facility life extensions and forecasted production levels over that time, can lead some operators to consider a complete control system overhaul to a modern, fully supported control system.

There are significant challenges with upgrading the control system of an actively operating offshore oil and gas production facility. Some of the common challenges are

- Lack of accurate and complete detailed documentation of the existing infrastructure;

- Maintaining essential utilities and services during installation and commissioning (e.g., power, water, emergency response systems, hull bilge, ballast controls and fire protection services);

- Minimizing production downtime associated with cutover and commissioning activities; and

- Design constraints due to limits on existing space, power, etc.

The Approach

Understanding the complete scope of obsolescence and the resultant upgrade is a critical first step. Discovery activities are performed, which include a combination of reviewing existing system documentation and site surveys for verification and to close any information gaps. With these data, upgrade concepts are developed to address each area of obsolescence.

Some manufacturers offer hardware conversion systems to facilitate easier migration from some of their older hardware platforms to modern ones. These conversion systems keep all existing I/O wiring terminations intact, eliminating the need for time-consuming wiring verifications. However, there can be challenges with these conversion systems. Existing panels and cabinets may not have enough space to accommodate the increased space requirements of the conversion system hardware, making it necessary to develop alternative solutions. Hardware conversion systems are not available for all hardware platforms. In this case, I/O wiring terminations must be reestablished to the new hardware.

This might also be a good time to consider incorporating advanced technologies and features that may be advantageous to production efficiency. If the facility has significant remaining life expectancy and possible expansions, implementing newer object-based elements in the control system can provide a solid platform for simplified system maintenance and future expansion.

Detailed planning is required to ensure that the cutover and commissioning activities are completed as efficiently as possible to minimize the downtime associated with the upgrade. Individual work plans are developed for each panel or cabinet where work is required, and cutover tasks are divided into two categories: those that can be completed prior to a production shutdown and those that must be completed once production has been safely stopped.

All hardware components are staged and configured, and hardware tests are performed to verify appropriate functionality. The process control and safety system programming is installed on the staged hardware and a full software verification is completed to ensure compliance with all governing documentation.

Upgrading Process Control

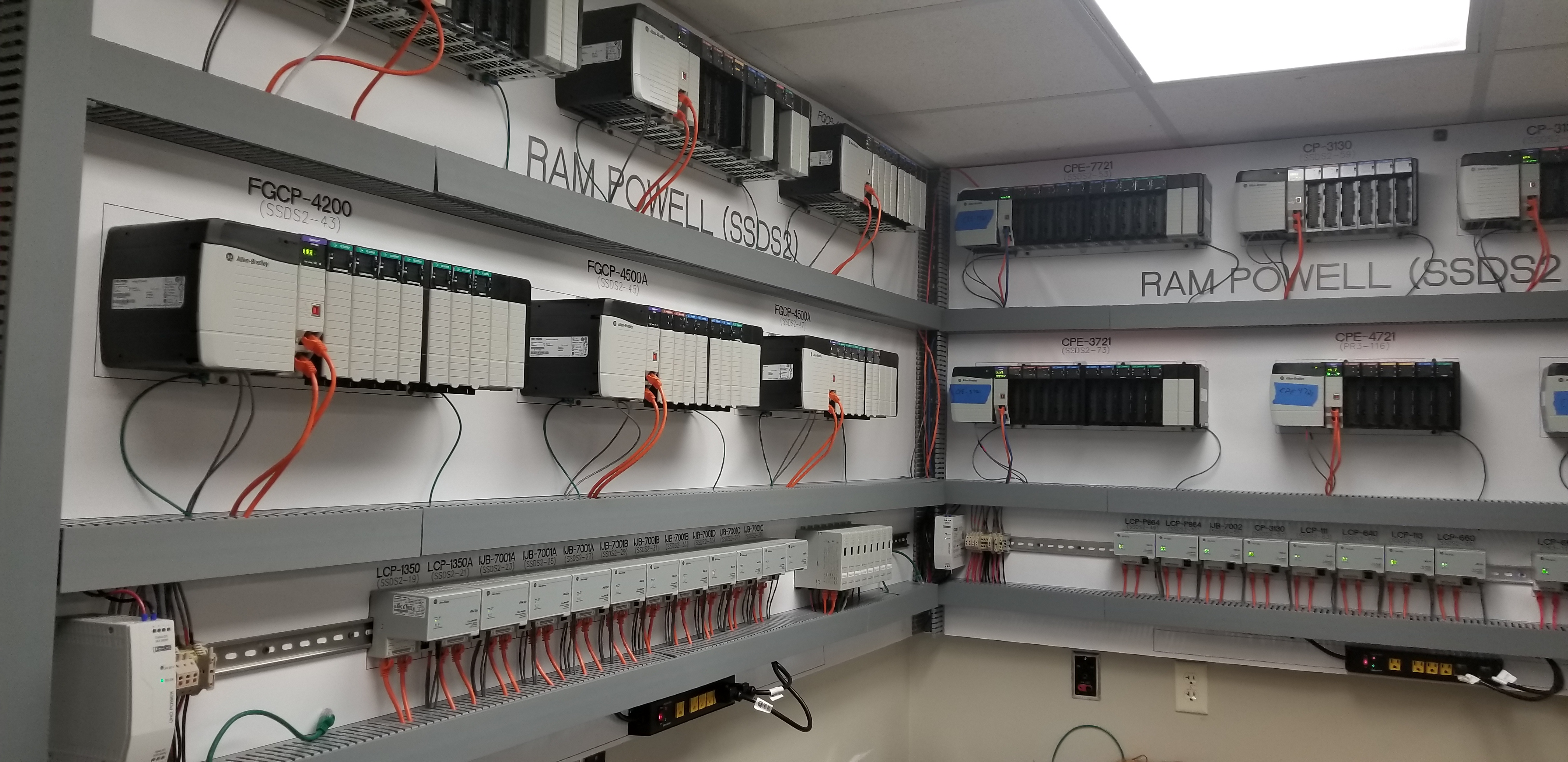

W-Industries recently had the opportunity to execute an upgrade of the process control and safety systems on the Ram Powell tension-leg platform in the Gulf of Mexico. The facility had been recently purchased from Shell by Talos Energy and included an obsolete Allen Bradley PLC-5 based process control and safety system. The control system obsolescence issues were identified by Talos Energy prior to the acquisition of the asset, and the company made plans to proceed with the execution of an upgrade shortly after taking ownership.

Front-end engineering began with the analysis of all available information and a resulting survey of the facility to close all information gaps. Armed with this information, W-Industries developed two different upgrade concepts. The first concept was an upgrade “in-kind” option, which included upgrading to modern hardware and supported software and provided only the functionality included in the existing system. The second concept incorporated additional functionality and enhancements, such as redundancy in communications, software and hardware redundancy, additional controls via a central control room, onsite historian, and programming enhancements that take advantage of available features in the modern control system platform. When presented with these two options, Talos Energy considered the expected longevity of the asset and chose to take advantage of the upgrade opportunity to implement the additional functionality and enhancements, which should increase uptime and provide a more robust system to accommodate future expansion.

During detailed design, numerous challenges were encountered. An original equipment manufacturer conversion system was used to migrate from the obsolete Allen Bradley 1771 series I/O to the modern 1756 ControlLogix platform. This system provides a significant benefit by allowing field wiring terminations to remain in place on existing swing arms, eliminating the risk of wiring errors and reducing cutover time. However, the larger space requirements of the conversion kits made modifications necessary to accommodate them in existing cabinets due to space limitations.

The existing control system also included several Allen Bradley 1791 series Block I/O modules throughout the facility. This type of I/O has no swing arm, which made it necessary to reestablish all I/O field wiring. The distributed nature of these modules and number of panels in which they were located presented a challenge in minimizing cutover time. To combat this, W-Industries designed centralized panels housing the new 1756 I/O. These panels were pre-installed with cabling installed between these panels and each panel with Block I/O. This reduced the cutover work scope to the removal of the wiring between 1791 I/O and the field terminal blocks in each panel and terminating the preinstalled wiring to the new centralized panels. This eliminated the need to physically remove old modules, install new modules and reestablish power and communications in each panel during the cutover.

Device level ring networks were designed for all I/O communications as a replacement of the existing data highway networks. Device level ring offers a huge performance improvement over Data Highway and also provides media redundancy.

Ethernet communications networks were designed in accordance with the ANSI/ISA 62443 standard, following all network segmentation and separation rules. As an enhancement to the existing system, the HMI system infrastructure was designed with redundancy to protect against hardware failures. The design features triple redundant hardware in which the load is distributed across all physical host machines under normal conditions, with each physical host capable of assuming 100% of the load if required.

Full hardware and software testing and verification was completed onshore prior to shipment. All hardware was staged and the complete system mockup was used to facilitate testing. This provided a high level of confidence that the system would perform as expected when installed on the facility.

In the end, the new facility control system was cutover and commissioned in conjunction with other work scope that required a production shut-in during a 14-day turnaround. This compressed time frame was made possible using design elements that allow work to be done prior to the facility shut-in, minimization of activity required during cutover, and detailed planning and work instructions for use by the installation personnel to streamline their activities.

In 14 days, the Ram Powell facility was upgraded from an obsolete process safety and control system that exposed Talos Energy to significant downtime risks to a control system with modern technologies and features that provide advanced diagnostic information aimed at increasing facility production uptime and will also make facility additions or expansions much easier in the future.

Recommended Reading

From Restructuring to Reinvention, Weatherford Upbeat on Upcycle

2024-02-11 - Weatherford CEO Girish Saligram charts course for growth as the company looks to enter the third year of what appears to be a long upcycle.

TechnipFMC Eyes $30B in Subsea Orders by 2025

2024-02-23 - TechnipFMC is capitalizing on an industry shift in spending to offshore projects from land projects.

NOV's AI, Edge Offerings Find Traction—Despite Crowded Field

2024-02-02 - NOV’s CEO Clay Williams is bullish on the company’s digital future, highlighting value-driven adoption of tech by customers.

Patterson-UTI Braces for Activity ‘Pause’ After E&P Consolidations

2024-02-19 - Patterson-UTI saw net income rebound from 2022 and CEO Andy Hendricks says the company is well positioned following a wave of E&P consolidations that may slow activity.

ProPetro Reports Material Weakness in Financial Reporting Controls

2024-03-14 - ProPetro identified a material weakness in internal controls over financial reporting, the oilfield services firm said in a filing.