Learn more about Hart Energy Conferences

Get our latest conference schedules, updates and insights straight to your inbox.

Artificial lift products and services can range from electric submersible and progressing cavity pumps and rod lift, gas-lift and surface pumping systems to power supply and control systems, monitoring and automation. The following is a sampling of the artificial lift equipment, accessories and services that enable operators to maximize the value of their wells while also lowering costs.

Editor’s note: The copy herein is contributed from service companies and does not reflect the opinions of Hart Energy. If you would like to be added to this article, submit a 150-200 words describing your latest artificial lift technology or service to Ariana Hurtado at ahurtado@hartenergy.com (the tool must have been developed, released or updated in the last year). Inclusion is at the discretion of the editors.

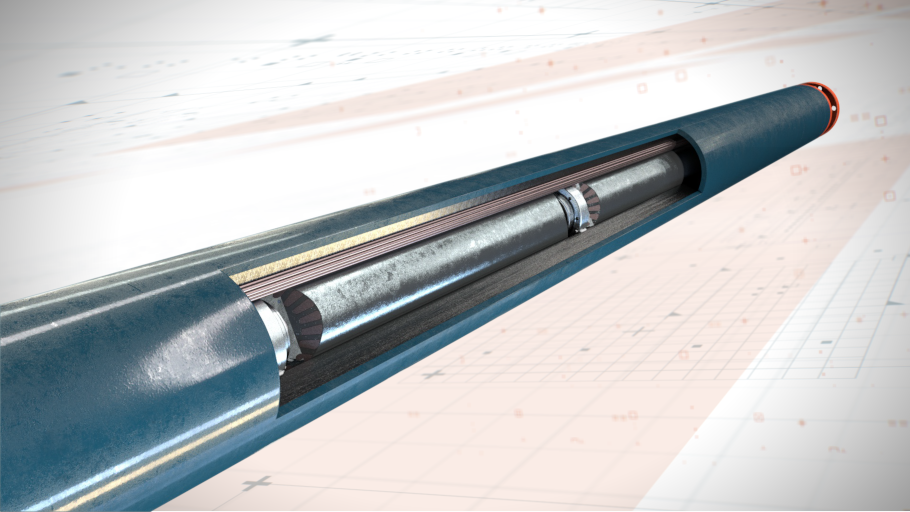

Rigless ESP system reduces risk and lowers the total cost of intervention operations

AccessESP has released a fourth-generation Wireless Retrievable ESP (electric submersible pump) deployment system to accommodate flow rates from 500 bbl/d to 10,000 bbl/d of oil by increasing the output of its permanent magnet motor to 1,200 hp. The flexibility to handle a wide range of production with live well intervention capabilities and fullbore access reduces risk, lowers the total cost of intervention operations and increases recovery. Unlike conventional ESP technologies, this rigless ESP system does not require the tubing to be pulled to resize a pump or to replace failed equipment. The redesigned AccessESP system includes an ultra-reliable cable with three times higher mechanical strength and a hydraulically compensated connection technology that eliminates field splicing to ensure the power delivery system lasts as long as the production tubing. The wider operating range also allows gas-lifted wells to be economically converted to higher drawdown ESP lifted wells. The upgraded system has been qualified by two major operators for deployment on new well completions and to retrofit gas-lifted wells that are watering out in mature fields with wells that cannot afford a multimillion dollar workover with a rig.

Optimize plunger lift well margins

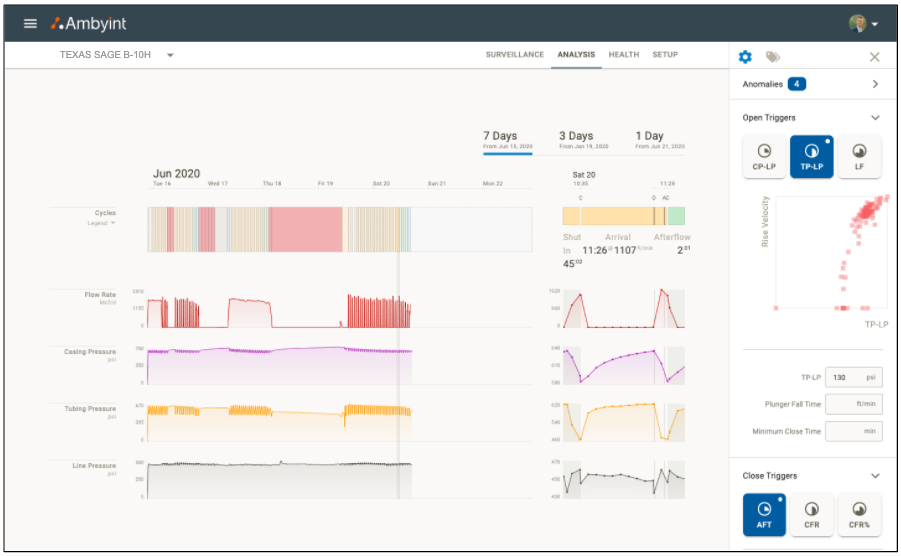

While plunger lift well systems are mechanically simple, they produce significant volumes of data causing engineers to perform hours of analysis looking for issues and determining courses of action. As a result, issues can slip through the cracks and become larger production problems. The prevalence of manual processes and legacy tools hampers often small operations teams from having full-field visibility, which is a situation further exacerbated by a reliance on outmoded physics models and optimization strategy heuristics dating back to the 1960s.

With more wells than people to manage them, it is unsurprising that 85% of all plunger lift wells are not optimized today. In an economic downturn where E&P companies require every bit of value from well production, leaving revenue in the ground and incurring unnecessary costs are bitter pills to swallow.

Ambyint InfinityPL is a data software product that utilizes advanced physics-based artificial intelligence combined with deep plunger lift expertise to optimize well production. Engineers no longer sift through data looking for anomalies or rely on heuristics to improve runtime settings. Instead, this software-as-a-service offering accurately and efficiently provides answers to critical production questions. E&P companies see up to 7% additional production at lower operating costs with InfinityPL.

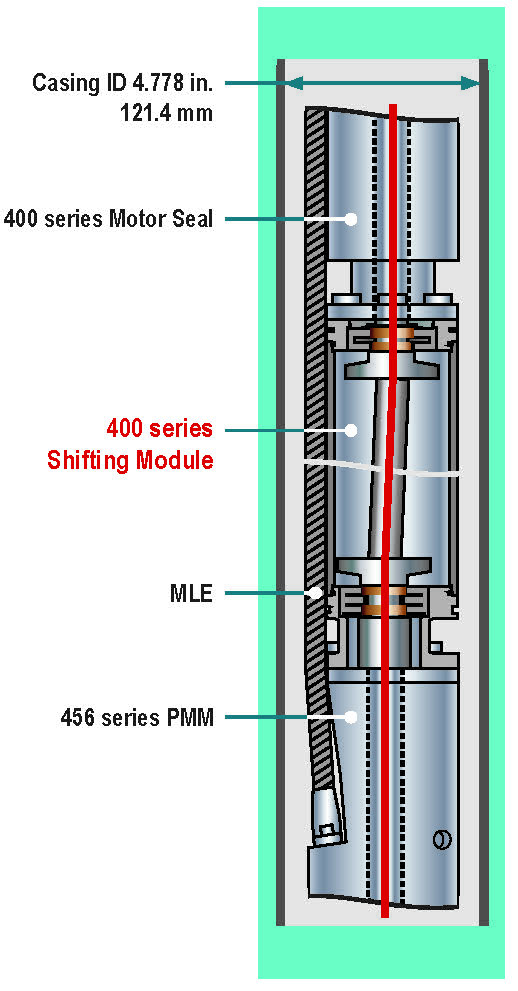

Expanding ESP design options in previously restrictive casing sizes

Many deep, prolific unconventional wells require high-horsepower, high-production electric submersible pumping (ESP) systems within 5.5 inch, 20-lb casing. Applications up to 400 hp are available using either 4.56-inch outer diameter (OD) tandem induction motors or single-section permanent magnet motors, but equipment clearance concerns arise.

The new Eccentric Shifting Module (ESM) by Borets expands ESP design options in previously restrictive casing sizes. Installed in the ESP string between the seal and motor, the ESM axially offsets the seal and pump assembly while preserving a robust shaft mechanical linkage with the motor. This centerline axial offset in the equipment connected above the motor provides greater clearance for the motor lead extension (MLE) cable while reducing overall string running OD.

The typical MLE installed with a conventional ESP string using 4.56-inch motors normally yields an overall running OD that exceeds the drift inside diameter of 5.5-inch, 20-lb casing. A consequence of this reduced annular clearance is that ESP applications requiring 4.56-inch series equipment may not be achievable in this casing size or come with a high risk for being stuck during installation or pull. The ESM eliminates the clearance risks and enables the full range of ESP systems with 4.56-inch motors for this application.

ESP motor provides 208 hp per motor to produce deep, horizontal unconventional wells

The ChampionX Artificial Lift AFFIRMED PowerFit electric submersible pumping (ESP) motor is specifically designed to fit unconventional wells completed with 5½-inch, 20-lb and 23-lb casing. Operators are drilling smaller-diameter wells to improve wellbore stability and save costs during the drilling and completion phase, but these wells present significant challenges for traditional ESP systems. Motors designed to deliver the horsepower required to meet IP targets from unconventional wells require modifications to fit in small-diameter wells, which can negatively impact reliability, and smaller-sized ESPs struggle to deliver enough horsepower.

The optimized electromagnetic design of the AFFIRMED PowerFit motor provides the necessary horsepower (208 hp per motor) to effectively produce deep, horizontal unconventional wells with an outside diameter that fits in 5½-inch, 20-lb and 23-lb wells with no modifications to the equipment. The motor also leaves room for capillary tubing for chemical injection or for tech wires from discharge sensors.

Unlike smaller-diameter permanent magnet motors, the new AFFIRMED PowerFit motor requires no changes to standard HSE protocols or installation and retrieval operating procedures; uses existing surface control systems, which saves additional capital costs; and requires no extra HSE measures to mitigate risks due to back spinning when the system shuts down.

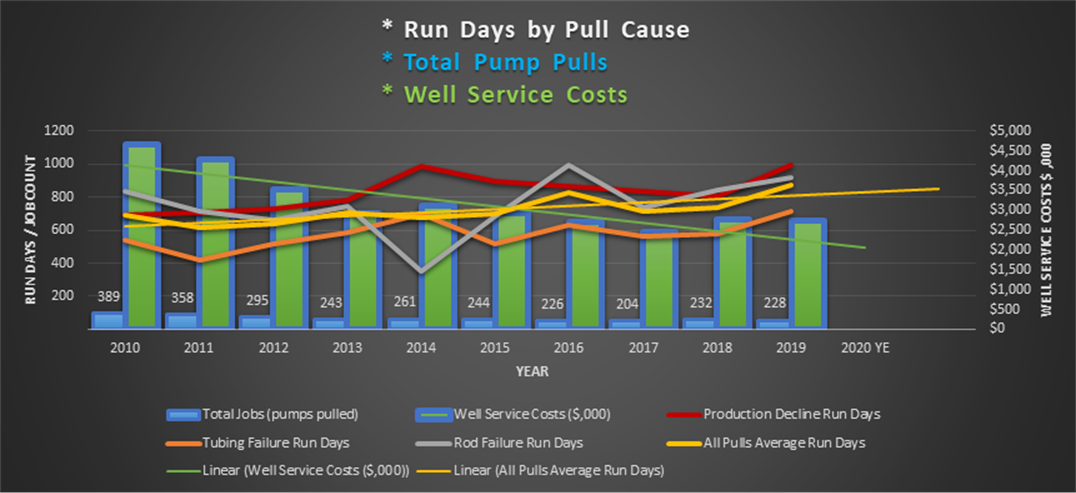

Pump tracking analytics focused on pump performance, not pump failure

The data from today’s horizontal wells tell a different story when compared historically to the vertical wells in the same formations. Extended rod pump runlife is achieved when experienced subject matter experts utilize rod pump inspection data to collaborate with producers looking to maximize production at the lowest lifting costs possible. While all pull causes are logged, the data should most importantly provide performance trends related to the primary identified, unplanned, pull causes: tubing failure, rod failure or production decline (pump failure).

Historical and predictive data analytics validates pump performance (or lack thereof) related to specific pump style, type, specific components and/or metallurgy. More costly workovers due to rod or tubing failure may also be avoided by implementing operational changes identified by trends in recorded pump component details. Utilizing DistributionNOW’s Global Pump Tracking & Service (GPTS), the company's rod pump experts use pump tracking data trends, practical experience and specific well information to advise its customers on maximizing pump performance while mitigating unplanned workovers.

Tool provides real-time analysis and results

In today’s oil field, every penny spent on lifting costs must carry its weight. Debt burdens and plunging commodity prices are putting the squeeze on producers in every area, including lift. But doing the analysis required to determine which is the best lift system can require more time than many engineers have these days. Too often companies simply do what they’ve always done and hope that works.

An analytic tool from Extract Production Services makes this easy, as it can help determine whether electric submersible pump (ESP), rod pump or gas lift is the most economical method—and, if gas lift or ESP is the choice, it can help design the most efficient system to save even more money.

Extract Production Services' Nodal Analysis software combines NODAL analysis with design software, allowing the complex analytical calculations to inform the design software. This allows users to compare multiple lift option scenarios on one screen. Plus, as well parameters change, the design may need to be tweaked along the way. No other software makes it so easy to test multiple design options. Extract’s Nodal Analysis software can show producers how to reduce lifting costs while preserving or, oftentimes, increasing production.

Being a web-based tool, it also allows multiple users to collaborate remotely to receive input from all parties, reaching a production consensus efficiently and quickly.

Wellbore tortuosity logging technology

Large changes in trajectory in a wellbore’s path over a short distance create problems with running casing as well as production equipment failure. Solutions in the current market rely on using the calculated dogleg of the wellbore to provide information on well tortuosity. These solutions have experienced varying degrees of success over the past several decades. The information received, however, lacks the precision and granularity necessary to explain the difficulties running and operating equipment in the well.

Gyrodata has released MicroGuide, a wellbore tortuosity logging technology that generates numerical and graphical representations based on 1-ft resolution analysis,to address this challenge. As the data are processed, MicroGuide estimates a reference path for the wellbore and determines displacements from that reference path. The result is rendered in 3D, enabling visualization of wellbore trajectory and allowing the operator to make informed decisions on where to place artificial lift and other production equipment. Electric submersible pumps, for example, might be wrongfully placed in tortuous areas not identified by MWD surveys, causing production losses and equipment damage. By revealing these areas of hidden tortuosity, MicroGuide helps operators achieve optimized equipment placement, reducing costs and potentially improving production.

Mature wells get a boost through efficient intermittent lift

To reduce compression costs and optimize production rates in mature wells, Mako Lift has released a new pilot valve system for intermittent lift applications that also removed the need for complicated surface controls and constant operator oversight. In a recent Permian Basin application, the system increased production rates by more than 40% while reducing compression rates by 50% as compared to the preceding continuous lift design. Most importantly to customer partners of Mako, the system was built for reliability, incorporating over a year of complex design optimization and durability testing.

Stabilizer bars increase overall pump efficiency

RFG Petro Systems’ grade DS stabilizer bars (normalized and tempered) are made in the U.S. with a 1-inch diameter bar and 1.50-inch pin shoulder, and they come with either a 3/4-inch or 7/8-inch pin with rolled threads. These dimensions allow one bar to be used in both 2⅜-inch and 2⅞-inch tubing. Available in lengths of 30-inch (one guide) or 48-inch (three guides), the RFG Stabilizer Bars help centralize the pump plunger on the down stroke and reduce premature wear on pump parts, thereby increasing overall pump efficiency. The MP Polymer guides, suitable for lined or unlined tubing, have the highest temperature rating and longest wear life.

The RFG Stabilizer Bars are also ideal for centralizing sinker bars in deviated wells as the 1.5-inch pin shoulder matches the 1.5-inch outer diameter of the sinker bars and a 3/4-inch slimhole coupling, thereby eliminating a step that can cause fluid turbulence. A major E&P company in the Permian started using RFG Stabilizer Bars in several deviated wells and experienced very favorable results, including reduced friction and longer run times.

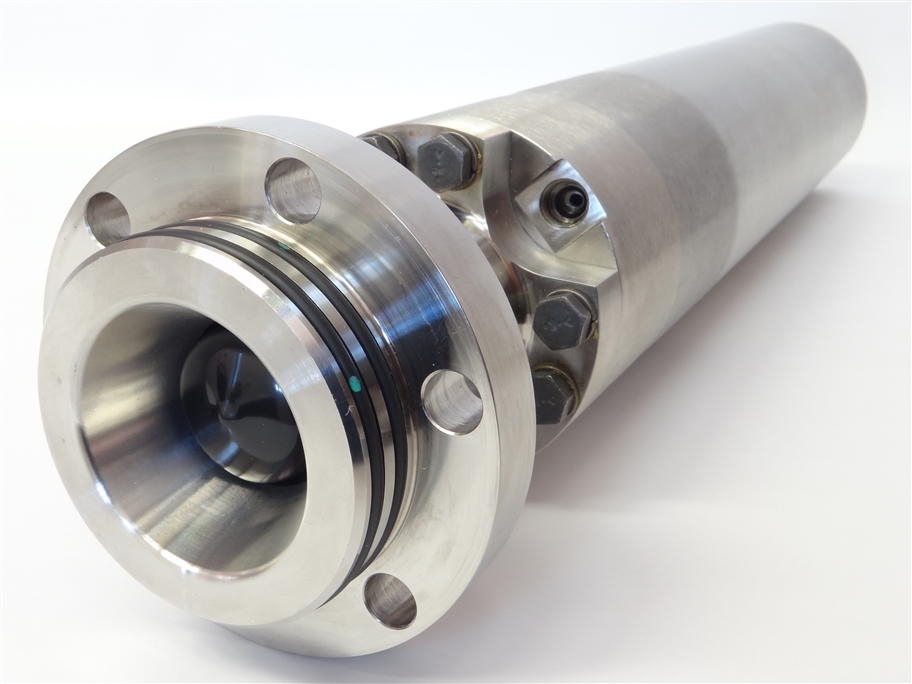

Monitor well performance, even when motor connection is submerged in water

Sercel-GRC’s Spy Pro is an electronic submersible pump (ESP) gauge with a waterproof, metal-to-metal sealed design. The technology enables users to monitor well performance, even when the motor connection is submerged in water. The ESP gauge is connected to the surface choke, gauge surface readout and ESP motor controller.

Together, Sercel-GRC’s Spy Pro ESP systems represent a unique mechanical concept, with new electronic features and channels of customizable fit-for-purpose data that extend the monitoring capabilities of a typical ESP sensor to serve a full cycle of monitoring applications needs required during the completion of a new ESP well. The electrical health of the ESP can be accurately measured and determined and motor winding temperature can be read with resistance temperature detectors and thermocouple options.

The system includes a welded sealed mechanical design to reduce the risk of contamination and a shorter and lighter design to improve deployment in dogleg and rigless applications. The technology reduces well interventions and associated liabilities and costs, and it maximizes pump performance, runlife and oil production while protecting personnel, the pump and reservoir.

Technology that controls artificial lift devices also used to reuse produced water

The Smart Pumper controls various artificial lift devices, which include progressing cavity pumps, rod pumps, tower pumps, electric submersible pumps, permanent magnet motors and hydraulic drive heads. The water produced in those wells have to be either disposed of or made reusable. The Smart Pumper has been supporting companies looking at ideas to reuse the produced water. The latest design function provides automation for a proven water recycling technology that involves converting produced water to drinking water as well as desalination of water for agriculture purposes. This involves converting waste energy to purify water and recycle waste. The entire thermal distillation process takes place inside a heat exchanger, which drastically reduces capex and opex.

Water quality sensors used include TDS, TSS, PH, iron, bacteria and hydrocarbon. This would also halt the water output if any of the water being monitored is outside of predefined parameters, and it would send an alert to the user to troubleshoot before resuming water recycling. The end users are working with FEMA to provide drinking water during natural disasters. The project offers 24-hour monitoring and security. The project that involves converting the waste energy to purify water and recycle the waste components was partly funded by the National Science Foundation Phase Small Business Innovative Research.

Extended warranty protects equipment in the oil field

Innovation in the oil field takes many forms, particularly in automation. SPOC Automation’s DriveShield is an extended warranty that even covers damage from lightning strikes. Heat, dust and cold take a toll on equipment. And a billion-volt bolt of lightning? Well, nothing survives that kind of power. DriveShield was designed to help protect a customer’s equipment. The warranty comes in three-year, six-year and 10-year versions. Each one includes protection against voltage anomalies and lightning. DriveShield includes 24/7 tech support, one to two-day expedited parts shipping and onsite field service. The 10-year version also includes an annual inspection beginning in the sixth year and 24/7 monitoring of the health of the drive.

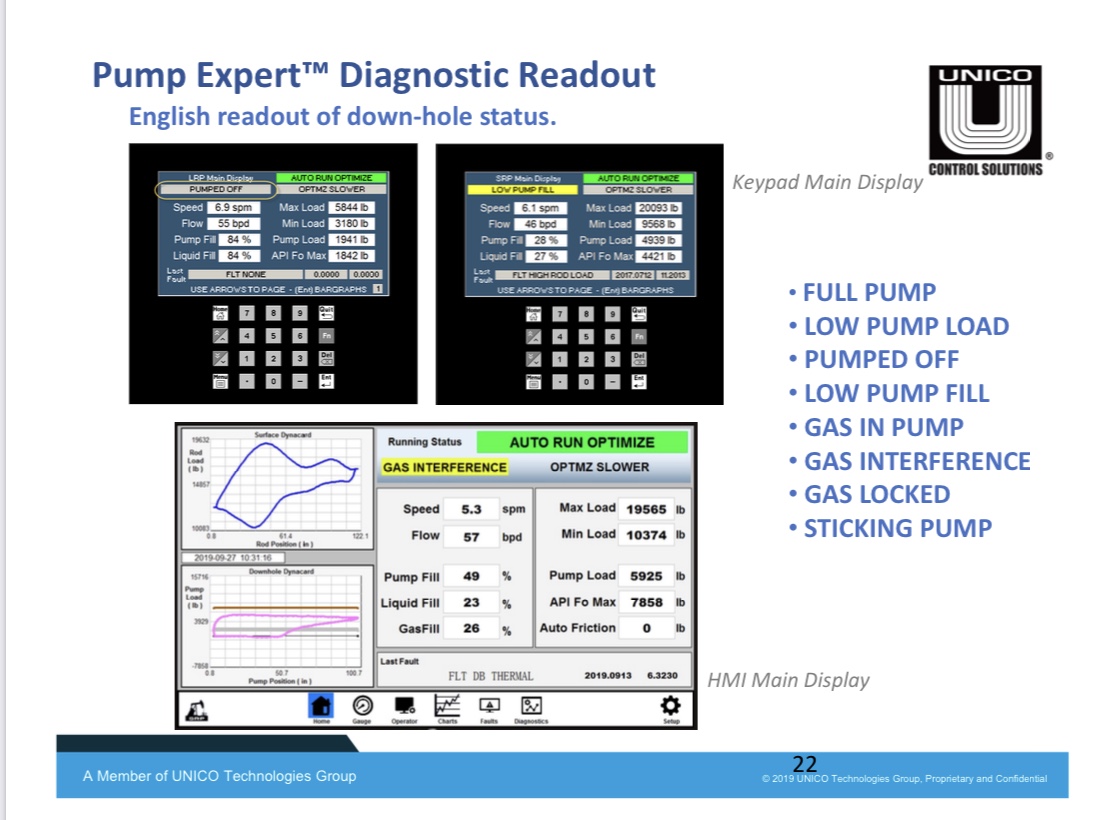

New algorithm provides diagnostics readouts

Local to the SRP drive, Unico LLC’s Pump Expert algorithm will automatically process well information and identify problems, assess overall health of the pumping system and generate simple English language messaging on the pump drive human machine interface (HMI). This technology can also be used for upstream applications, such as normal operation, full pump, low pump load, pumped off, low pump fill, gas interference, gas locked and sticking pump.

New subsurface compressor system boosted production by 62%

Upwing Energy has developed a high-speed Subsurface Compressor System (SCS) with advanced magnetic technologies that maximizes gas and condensate production, recoverable reserves and liquid unloading at the same time. These benefits can be realized in any type of formation and wellbore geometry in both the onshore and offshore environments.

Upwing recently completed its first unconventional field trial of the SCS in a shale gas well in Indiana, which resulted in a 62% increase in gas production and a 50% increase in liquid production over the well’s steady-state performance with a rod pump prior to the SCS installation.

Liquid loading can dramatically reduce production and lead to premature well abandonment. The SCS lowers bottomhole well pressure and increases gas velocity by creating a suction effect at the compressor inlet at the bottom of the wellbore. The drawdown in the wellbore induces more gas flow from the formation to the wellbore. The SCS also generates higher gas velocities in the horizontal and vertical sections of the well, carrying more liquids out of the wellbore. Decreasing backpressure from liquid loading results in increased gas production, which in turn accelerates liquid unloading and prevents vapor condensation when exiting the compressor.

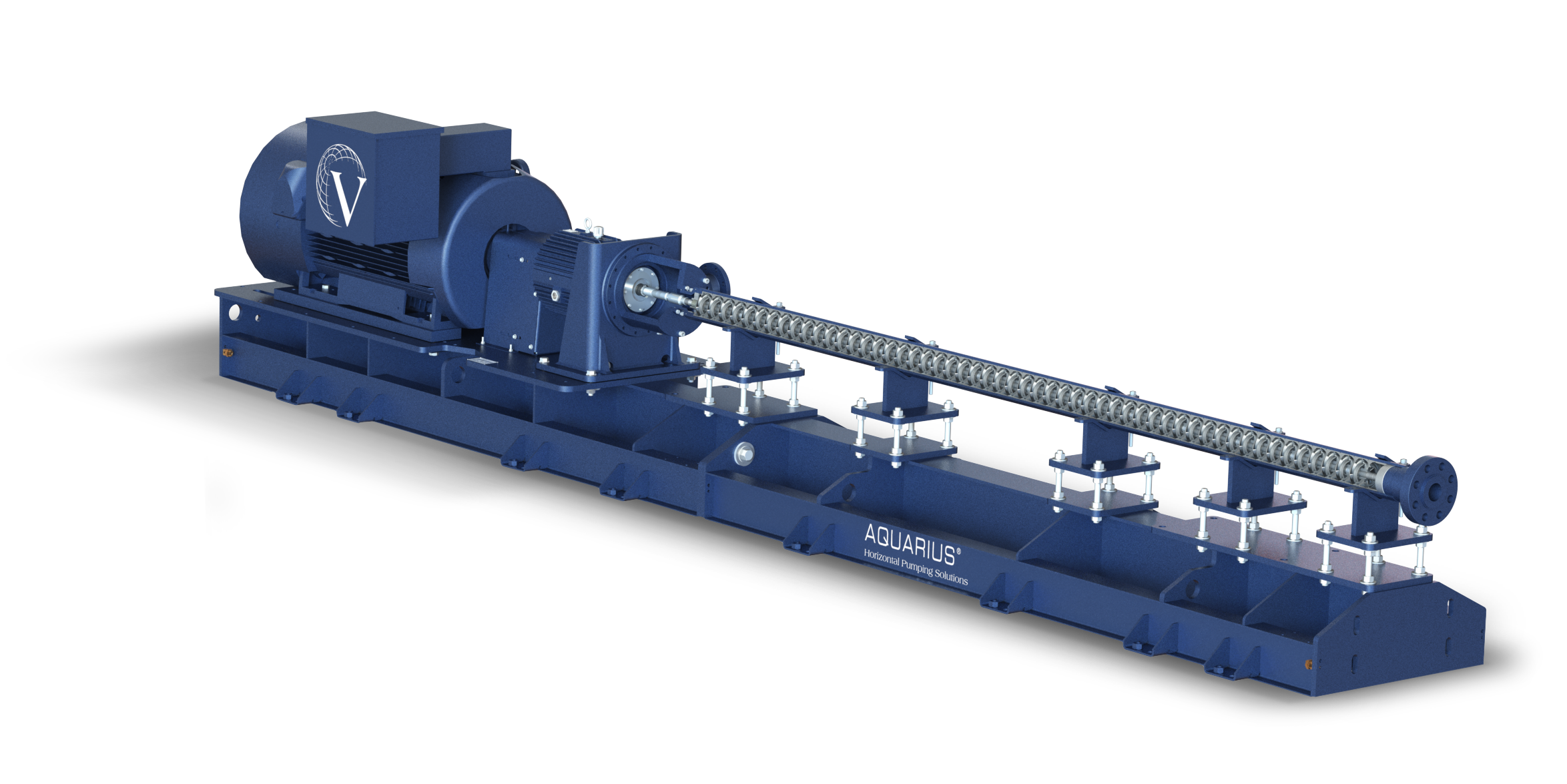

Horizontal pumps provide flexible surface solutions for jet lift

Jet pumps provide a unique artificial lift solution to overcome some of operators’ most pressing production challenges: restrictive casing sizes, deviated wellbores, abrasive solids, high gas-oil ratios and corrosive fluids. When coupled with durable, low-maintenance pumping equipment at the surface, producers can maximize their cost-saving potential and overall well performance.

Ideally suited for supplying power fluid to jet pumps, Valiant’s portfolio of Aquarius Horizontal Pumping Solutions provides comprehensive injection pressures and flow rates to support dynamic production requirements. When one jet pumping application called for a surface pump to inject 3,800 bbl/d of fluid at 3,500 psi, Valiant designed a system consisting of a VE5500, 160-stage pump, Ni-resist stages for excellent corrosion-handling, reinforced high-pressure pump connections for safety assurance, a 500-hp motor, and pressure and vibration transmitters for real-time performance monitoring. An environmentally friendly alternative to traditional split-case and triplex pump systems, Aquarius Horizontal Pumping Solutions are constructed in surface or trailer-mounted configurations and all components are field replaceable, thus providing operators the flexibility to resize equipment with less downtime and reduce their cost of ownership over the life of the well.

View the 2019 Artificial Lift Technology Showcase.

Recommended Reading

Exxon Ups Mammoth Offshore Guyana Production by Another 100,000 bbl/d

2024-04-15 - Exxon Mobil, which took a final investment decision on its Whiptail development on April 12, now estimates its six offshore Guyana projects will average gross production of 1.3 MMbbl/d by 2027.

NAPE: Chevron’s Chris Powers Talks Traditional Oil, Gas Role in CCUS

2024-02-12 - Policy, innovation and partnership are among the areas needed to help grow the emerging CCUS sector, a Chevron executive said.

CNOOC Sets Increased 2024-2026 Production Targets

2024-01-25 - CNOOC Ltd. plans on $17.5B capex in 2024, with 63% of that dedicated to project development.

Sangomar FPSO Arrives Offshore Senegal

2024-02-13 - Woodside’s Sangomar Field on track to start production in mid-2024.

CNOOC Finds Light Crude at Kaiping South Field

2024-03-07 - The deepwater Kaiping South Field in the South China Sea holds at least 100 MMtons of oil equivalent.