Recent field trials in the Adriatic Sea gas fields offshore Italy demonstrated the advantages of a new multidetector-array pulsed neutron formation gas measurement tool. Weatherford’s Raptor cased-hole reservoir evaluation system is designed specifically for greater sensitivity to formation fluids and to provide calibratable curves for use in formation gas analysis. These attributes are particularly valuable in either mature or developmental surveillance programs aimed at maximizing production.

In this application the tool provided behind-the-casing views of the reservoir hydrocarbons and quantified the volume of gas in the porosity while being run in complex, single- and dual-string completions.

Technology overview

Unlike typical dual-detector instruments, the new generation of multidetector pulsed neutron technology uses a detector array of much larger dimensions. This allows the sampling of a larger volume of the neutron-gamma transport field and yields a greater volume of investigation and greater sensitivity to the formation fluids. The tool response is characterized not only for the attributes of the reservoir mineralogy and fluids but also for the exact wellbore geometry and borehole fluid conditions.

Every well logged by the tool goes through this computerized characterization in a Weatherford modeling factory that contains more than 400 computer processors. Based at the Fort Worth, Texas, R&D facility, the modeling is automated to handle the roughly 5,000 data files associated with the process for a single logging characterization in about 8 hours. Most of the time the characterization is completed before the well is logged, but if unsuspected conditions are encountered in the wellbore, new characterization can be completed in less than a day.

The logging procedures in the field follow standard practices except for the instrument calibration, which includes calibrating both the absolute value of the measured curves and the oil and gas sensitivity of the Raptor readings. This calibration means that every time the tool leaves the base, the customer can be assured that it reads the same as it did yesterday or last year and that it reads the same as any other Raptor tool.

The process of getting the final oil and gas saturation answers uses new algorithms for the high-sensitivity response characterization and for shale petrophysics. The analysis workflows are designed to strengthen the mathematical and petrophysical handling of the shale effects on the saturation answers.

Field trial details

The main challenge encountered along the Adriatic coast was finding producible hydrocarbons (gas) in old wells in mature reservoirs. The field for this trial was characterized by thin-bedded Pliocene sand-shale sequences showing good areal continuity. While looking for bypassed production targets, the producer faced issues such as distinguishing between gas sands at original saturation (production targets), flushed saturation (wetted sands being produced by another well) or pressure-depleted sands (sands in hydraulic isolation that are being produced by another well and that reduce pressure as a result). As detailed in a paper presented at last year’s Offshore Mediterranean Conference and Exhibition in Ravenna, Italy, this logging initiative reports the first application of the Raptor array pulsed neutron tool and the associated interpretation technology in single- and dual-string completions offshore Italy.

The logging campaign involved data acquisition from two candidate wells. Well A1 required a dual-string completion with 7-in. production casing and dual 2.375-in. production tubing strings. In the logged interval, the annulus was brine-filled, and the tubing was water-filled. The tool was logged in the long string. Well A2 involved a single-string completion with 7-in. production casing and 3.5-in. production tubing. In the logged interval the annulus was brine-filled and the tubing was water-filled.

The detector array is configured with four spectroscopic lanthanum bromide gamma ray detectors. It also has a fast neutron detector distributed axially along the tool body coupled with high-count-rate electronics. This array generated two new principal measurements for use in formation evaluation: a fast neutron normalized burst ratio and a capture ratio, both constructed as a ratio of the count rates of the nearest and farthest detectors. These measurements were made using a generator burst timing mode—called N-Vision—that is different from both the sigma and carbon/oxygen (C/O) burst modes. Conventional sigma and C/O measurements also were made in which the four detectors of the array each produce a sigma and C/O curve. These four signals are mixed according to the requirements of the logging objectives. The N-Vision mode also yields a simultaneous sigma measurement.

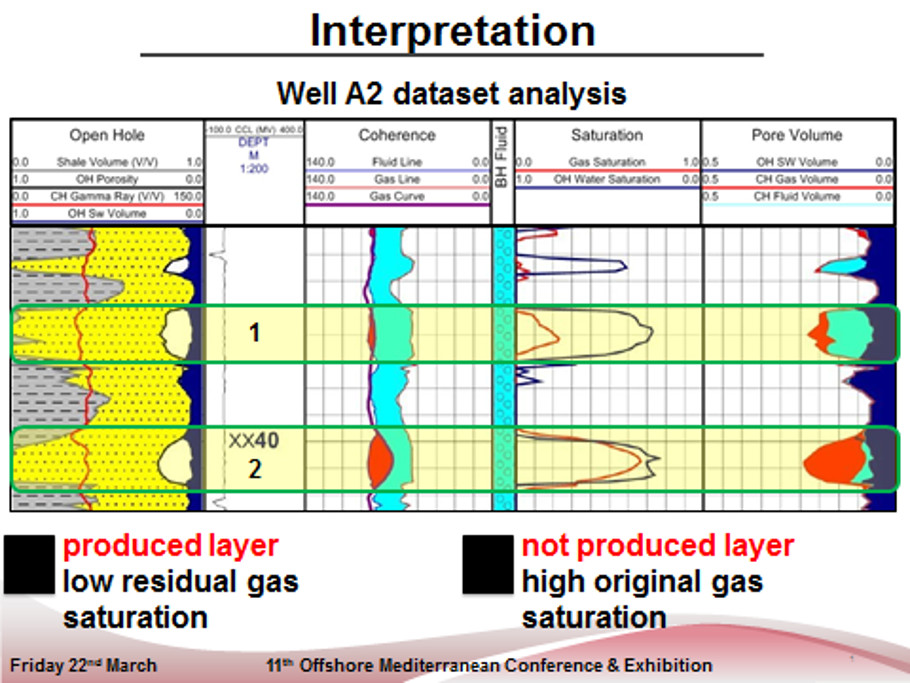

A typical section of the answer product is shown in Figure 2. The track of interest is the saturation track, which shows the quantified remaining gas saturation from the Raptor tool (red curve) and the original openhole gas saturation (in blue). The remaining gas saturation is the primary indicator of the remaining producible gas content of the sands. Two sands are highlighted in the figure. In the first sand the saturation curves show clearly that the remaining gas saturation is about 30% of the original. This sand has been produced by another well and flushed with formation water. In the second sand, however, the saturations are essentially equal, indicating producible gas remaining in this sand. Identification of production targets such as these is the object of the logging activities.

The tool provided a coherent and clear evaluation of production targets while logging in very complex borehole environments involving both single- and dual-string completions. The high sensitivity of the detector array plays a large part in this result, and the innovations in the petrophysical aspects of the analysis workflows pay big dividends. The high-accuracy response characterization adds assurance that the tool response is correct for the operator’s reservoir and wellbore. The calibration of the tools provides confidence that the tool’s sensitivity to oil and gas is the same at each use. And the mathematical shale handling helps the petrophysical analyst to know that the shale effect is taken into account correctly. The results are reliable oil and gas saturations.

Showcasing an emerging reservoir evaluation technology, this field trial represents just the beginning of what is possible. This technology can be applied virtually anywhere an operator wants to locate hydrocarbons behind casing—in production development, field rejuvenation and complex EOR recovery programs.

Recommended Reading

E&P Highlights: April 8, 2024

2024-04-08 - Here’s a roundup of the latest E&P headlines, including new contract awards and a product launch.

Tech Trends: Halliburton’s Carbon Capturing Cement Solution

2024-02-20 - Halliburton’s new CorrosaLock cement solution provides chemical resistance to CO2 and minimizes the impact of cyclic loading on the cement barrier.

Halliburton’s Low-key M&A Strategy Remains Unchanged

2024-04-23 - Halliburton CEO Jeff Miller says expected organic growth generates more shareholder value than following consolidation trends, such as chief rival SLB’s plans to buy ChampionX.

Deepwater Roundup 2024: Americas

2024-04-23 - The final part of Hart Energy E&P’s Deepwater Roundup focuses on projects coming online in the Americas from 2023 until the end of the decade.

Oceaneering Won $200MM in Manufactured Products Contracts in Q4 2023

2024-02-05 - The revenues from Oceaneering International’s manufactured products contracts range in value from less than $10 million to greater than $100 million.