Presented by:

Editor's note: This "Tech Trends" section appears in the new E&P newsletter. This weekly section highlights the latest upstream technologies and services for the oil and gas industry. The copy herein is compiled from press releases and product announcements from service companies and does not reflect the opinions of Hart Energy. Submit your company’s updates related to new technology products and services to Ariana Hurtado at ahurtado@hartenergy.com.

Subscribe to the E&P newsletter here.

Upgraded onshore turbine delivers more competitive power output

Siemens Gamesa has upgraded its onshore platform, increasing power output to 6.6 MW. The SG 6.6-155 and SG 6.6-170 turbines will offer a higher unitary power, in turn delivering a lower levelized cost of energy for customers. The increase will optimize performance in high, medium and low wind conditions for the 5.X platform. Both turbines offer greater annual energy production and optimized project capex. Both turbines combine a flexible power rating from 5.6 MW to 6.6 MW, with rotor diameters of 155 and 170 m. The first prototypes of the 5.X, the SG 6.6-150 in Alaiz, Spain, and the SG 6.6-170 in Hovsore, Denmark, are connected and in the testing phase.

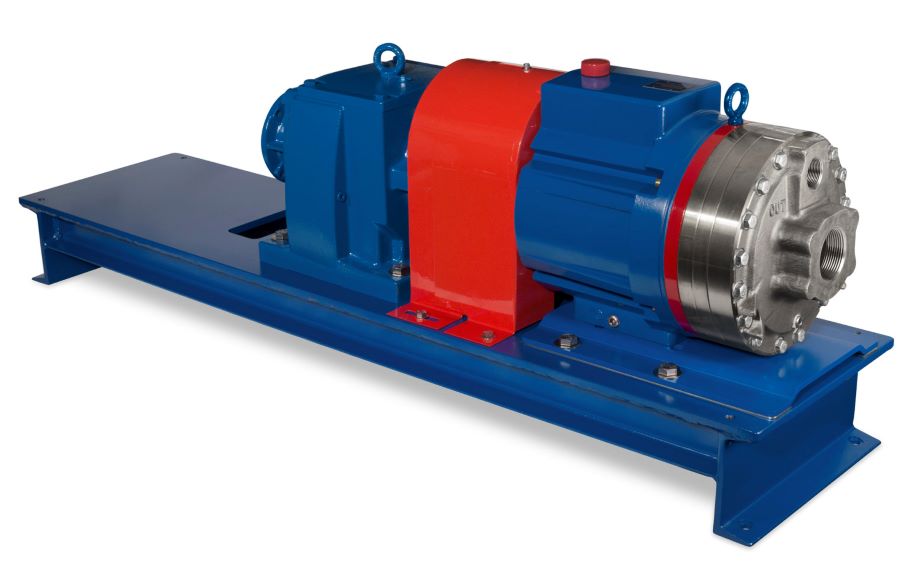

Metering pumps provide linear, virtually pulse-free flow

Wanner Engineering Inc. has released the Hydra-Cell Metering Solutions P700 Series metering pumps. The pumps feature a hydraulically balanced, multiple-diaphragm design to provide smooth, linear, virtually pulse-free flow without the need for expensive pulsation dampeners. Employing variable frequency drive electronic flow control adjustment, the pumps deliver precise, accurate flow throughout the turndown range at up to 1394 gph with discharge pressure ratings to 1,200 psi. The P700 features diaphragm position control that protects the pump and enables operation in case of a closed inlet. Since the process fluid is not used for lubrication, it can run dry indefinitely. A replenishment valve in every piston assembly ensures optimum actuating oil on every stroke for continuous accuracy. A variety of pressure valves, calibration cylinders, motors and controllers are available to accessorize the model to provide a complete metering pump system.

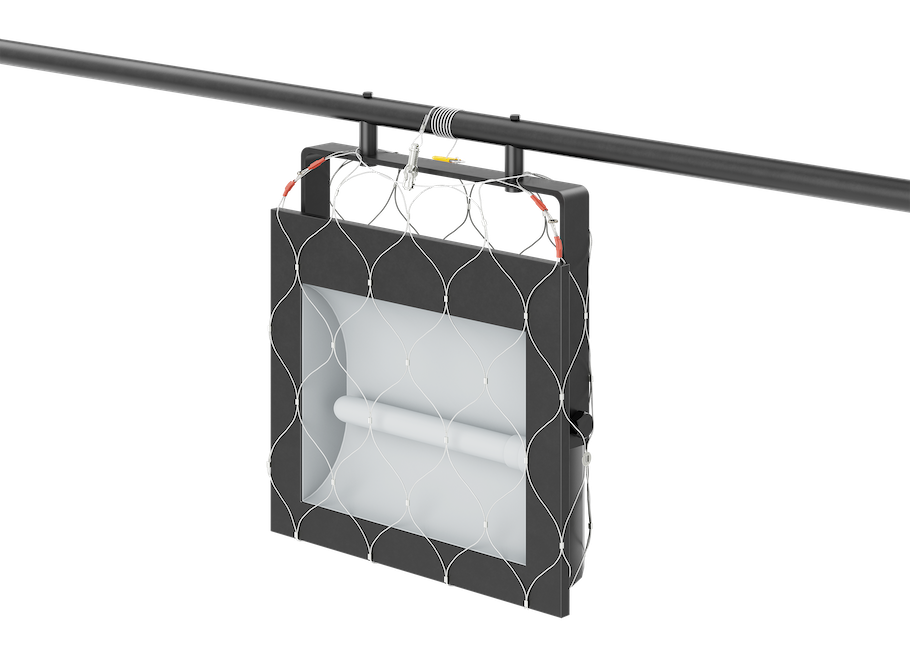

Nets add enhanced layer of security, reduce human risk

Dropsafe has released a new upgraded version of its steel wire mesh Net, adding an enhanced layer of security and traceability to an essential piece of safety equipment. The new range of Nets enable operators to further reduce the risk of human error. Safety securing is a vital aspect of dropped object prevention programs on industrial facilities globally. At these sites, fixtures such as lights and cameras may loosen due to corrosion or impacts, then fall and strike personnel or equipment. In one recent incident highlighted by IMCA earlier this year, a 6-kg floodlight dropped 4.5 m due to corrosion. The deterioration had been hidden by paintwork, and no secondary retention solution was in place. Drops prevention Nets enclose and tether objects at height to a secure attachment point, mitigating these drops risks and the threats they pose to personnel, equipment, finances and reputation.

Confined space controls and air quality management

Bravo Target Safety, a provider of industrial and oilfield emergency response and safety services, has announced a partnership with Evolved Industrial Solutions, a developer of technology focused within the management of confined space work activities with the integration of automated mechanical ventilation. Evolved E-Zephyr Technology integrates ventilation controls with confined space management to effectively reduce risk, limit exposure hours, enhance monitoring controls, create installation efficiency and accelerate emergency response times. Together, the companies are providing a safer environment for workers operating in confined spaces. This combination ensures two fundamental benefits: elevated safety for confined space workers and cost efficiencies for clients.

Recommended Reading

Petrie Partners: A Small Wonder

2024-02-01 - Petrie Partners may not be the biggest or flashiest investment bank on the block, but after over two decades, its executives have been around the block more than most.

CEO: Coterra ‘Deeply Curious’ on M&A Amid E&P Consolidation Wave

2024-02-26 - Coterra Energy has yet to get in on the large-scale M&A wave sweeping across the Lower 48—but CEO Tom Jorden said Coterra is keeping an eye on acquisition opportunities.

CEO: Magnolia Hunting Giddings Bolt-ons that ‘Pack a Punch’ in ‘24

2024-02-16 - Magnolia Oil & Gas plans to boost production volumes in the single digits this year, with the majority of the growth coming from the Giddings Field.

Endeavor Integration Brings Capital Efficiency, Durability to Diamondback

2024-02-22 - The combined Diamondback-Endeavor deal is expected to realize $3 billion in synergies and have 12 years of sub-$40/bbl breakeven inventory.

Exxon, Chevron Tapping Permian for Output Growth in ‘24

2024-02-02 - Exxon Mobil and Chevron plan to tap West Texas and New Mexico for oil and gas production growth in 2024, the U.S. majors reported in their latest earnings.