Learn more about Hart Energy Conferences

Get our latest conference schedules, updates and insights straight to your inbox.

Presented by:

Editor's note: This "Tech Trends" section appears in the new E&P newsletter. This weekly section highlights the latest upstream technologies and services for the oil and gas industry. The copy herein is compiled from press releases and product announcements from service companies and does not reflect the opinions of Hart Energy. Submit your company’s updates related to new technology products and services to Ariana Hurtado at ahurtado@hartenergy.com. Subscribe to the E&P newsletter here.

Self-healing cement system minimizes risk of cement sheath failures

Superior Energy Services has released its RestoreCem self-healing cement, which has the capability to regain its zonal isolation properties and restore the cement sheath against induced cracks, microfractures or micro annuli, minimizing the risk of cement sheath failures that can lead to hydrocarbon percolation within the set cement or blowouts. It has improved mechanical properties over conventional cement, providing set cement downhole with the resilience, endurance and elasticity to withstand changes in stresses over the well production cycle. Recommended RestoreCem applications include unconventional wells with high-cyclic production activities that require specially designed cement, such as HP/HT deep oil and gas wells, thermal wells, gas injection wells and multi-fluid production wells. It is also ideal for critical cementing operations or where cementing best practices cannot be achieved, in addition to formation-fractured reservoirs, gas storage wells and plug-and-abandonment operations.

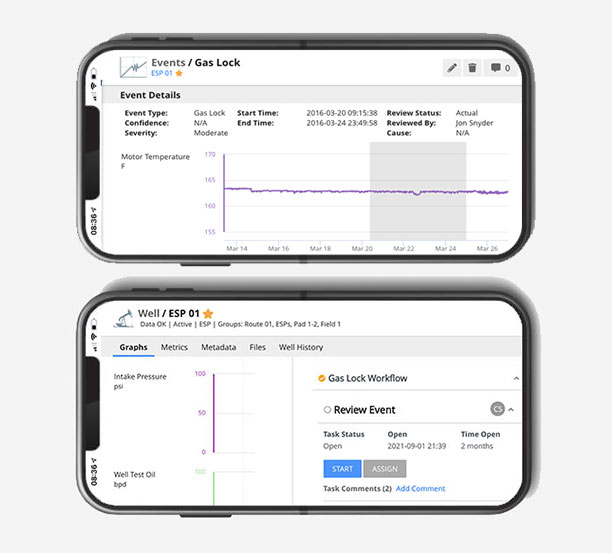

Access critical operating information and migrate evolving issues from virtually anywhere

OspreyData has released its OspreyData Vision platform on all mobile devices. The platform's full desktop capabilities are accessible on any smartphone or tablet, regardless of size or operating system. With this release, the company gives all its users a seat in the “Virtual Control Center.” Production engineers, artificial lift technicians and lease operators can access critical operating information and migrate evolving issues from virtually anywhere. Mobile offers key advantages that enhance the value of the product, reducing opex and increasing safety by delivering OspreyData’s machine-learning-generated alerts to production teams in the real time and enabling manage-by-exception practices that reduce windshield time and inefficient traveling. Teams can readily access all operating data within the Vision Unified Monitoring platform while leveraging the artificial-intelligence-assisted alerts to closely monitor performance from any device and location and be more connected to the field.

Autonomous sensor measures dynamic strain of offshore wind turbines

4Subsea has released an autonomous sensor that measures the dynamic strain of offshore wind turbines with high resolution and accuracy. The sensor will reduce cost of operations and maximize life of offshore wind turbines. Unlike other strain gage installations, the Smart Monitoring Sensor (SMS) Strain can be installed without special requirements such as the use of specialized technicians, equipment or a clean environment. The system has extremely low energy consumption, enabling continuous logging and data storage at 10-Hz sampling frequency for a full 12 months. The sensors can be cabled to motion sensors like the SMS Gateway or SMS Motion to provide fully synchronized strain and motion data. Furthermore, the sensors are made as true Internet-of-Things sensors where that, given access to power and the internet, they will automatically start sending data to the cloud where the data are processed, and insight from the data can be visualized to the customers.

e-frac pump improves efficiency and provides ESG advantages

SPM Oil & Gas Inc. has released its SPM Quintuplex Extended Max (QEM) 5000 E-Frac Pump, reducing environmental impact and yielding positive cost savings in the Haynesville, Permian, Eagle Ford and Marcellus basins. The SPM QEM 5000 is designed for electric or gas turbines and 5,000-hp capacity in a single unit, rated for service at 100% of its 308,000-lb rod load capacity 24/7, even in extreme conditions. Half of the units in operation are powered by turbine-driven units, while the remaining 50% are powered by an e-frac motor. In addition to eliminating diesel use on site, the product reduces the total number of pumps required at a site, which enables operators to significantly lower fuel spend, emissions and consumables costs. Beyond contributing to reduced emissions, the pump also enables operators and oilfield service companies to leverage simul-frac operations to achieve even greater efficiencies; the doubling of pumps required by simul-frac is at odds with ESG goals.

Companies partner to offer energy technology and policy eCourse

EPIcenter has partnered with Smart Energy Education to offer access to the Introduction to Energy Technology and Policy (ETP) eCourse. Smart Energy Education is partnering with Dr. Webber of the University of Texas Austin Cockrell School of Engineering and Disco Learning Media, a subsidiary of Upstryve Inc., to underwrite scholarships for San Antonio, Texas, residents who enroll in the ETP eCourse. This course will be taught virtually by Dr. Michael E. Webber and his team of senior researchers from The University of Texas at Austin. Postsecondary students, rising managers or mid-level executives who want to deepen and broaden their knowledge in the energy industry, oil and gas specialists or professionals in other sectors such as finance, consulting and human resources who want to break into the energy sector are encouraged to take the course. The goal of the initiative is to demonstrate how improving energy and water literacy can foster community engagement and inspire collaborations among communities to solve the world’s greatest challenges of the future.

High-tech vehicles locate natural gas leaks and lower emissions

Consumers Energy, a subsidiary of CMS Energy, has deployed two Ford Eagle SUVs equipped with sensitive mobile natural gas leak detection systems from Picarro Inc. The rolling laboratories can gather and instantly analyze methane, wind, atmospheric and GPS data to find natural gas leaks and calculate their risks. The vehicles will help the energy provider prioritize leaks in natural gas pipes faster and more accurately and improve response to storms and natural disasters. The rolling labs are outfitted with Picarro technology, a combination of hardware, software and data analytics that is 1,000 times more sensitive than the process currently used to survey Consumer Energy’s nearly 28,000-mile distribution network. The vehicles will collect and analyze methane data as they roll down the road. They can patrol geographic areas quickly, scanning for potential trouble spots and providing real-time information to identify leaks and target areas for further investigation.

Recommended Reading

Oil States’ ACTIVEHub for Digitized Assets

2024-03-14 - Oil States Energy Services’ new ACTIVEHub system and ACTIVELatch help operators remotely monitor and automate frac locations for a more efficient and safer wellsite.

AI Advancing Underwater, Reducing Human Risk

2024-03-25 - Experts at CERAWeek by S&P Global detail the changes AI has made in the subsea robotics space while reducing the amount of human effort and safety hazards offshore.

Exclusive: Meet the Data Van, the Heart of Completion Operations

2024-01-23 - In this Hart Energy Live Exclusive, NexTier’s Ben Dickinson describes how the data van centralizes completions controls and data and reduces on-site personnel requirements as the industry moves ever closer to remote fracs.

PGS Wins 3D Contract Offshore South Atlantic Margin

2024-04-08 - PGS said a Ramform Titan-class vessel is scheduled to commence mobilization in June.

TGS Commences Multiclient 3D Seismic Project Offshore Malaysia

2024-04-03 - TGS said the Ramform Sovereign survey vessel was dispatched to the Penyu Basin in March.