Presented by:

Editor's note: This "Tech Trends" section appears in the new E&P newsletter. This weekly section highlights the latest upstream technologies and services for the oil and gas industry. The copy herein is compiled from press releases and product announcements from service companies and does not reflect the opinions of Hart Energy. Submit your company’s updates related to new technology products and services to Ariana Hurtado at ahurtado@hartenergy.com. Subscribe to the E&P newsletter here.

Companies partner for global integrated hydraulic intervention services

Helix Energy Solutions Inc. has joined Trendsetter Engineering Inc. in a global partnership to provide integrated hydraulic intervention services for subsea wells and flowlines. The partnership will integrate Trendsetter’s 15,000-psi subsea tree injection manifold and experienced personnel into Helix’s fleet of well intervention vessels and equipment used to perform well services globally. The well intervention vessels include the Q4000, Q5000, Q7000, Seawell, Well Enhancer and two chartered monohull vessels, the Siem Helix 1 and the Siem Helix 2.

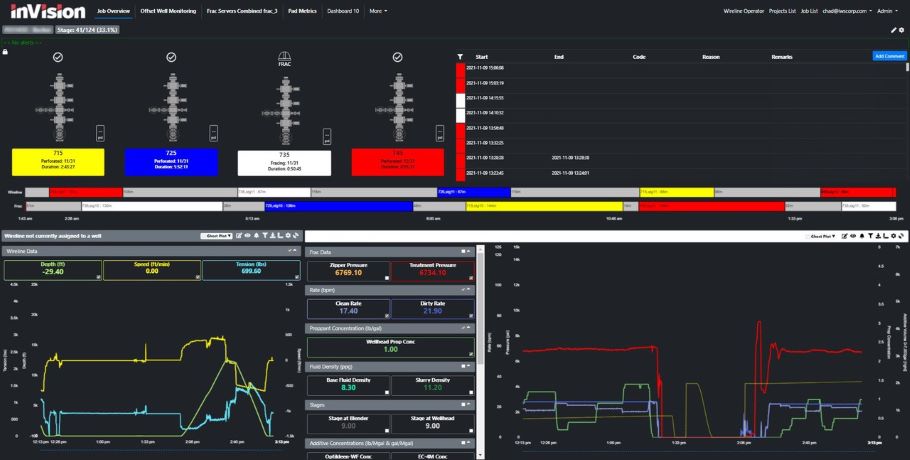

Digital completion technology provides incident-free safety

Intelligent Wellhead Systems Inc. has released its 10th-generation digital completion technology, inVision X. The upgrade to the inVision Technology Platform integrates engineered safety controls, automated digital standard operating procedure compliance and remote valve activation. Since the inVision I Technology Platform was released in 2018, the system has delivered more than 26,000 stages without a single wireline or pressure control incident. With its incident-free safety and reliability track record, the technology platform helps oil and gas operators improve completions performance. The company will continue its focus on developing a safer, more reliable and effective digital infrastructure for hydraulic fracturing and wireline operations.

Optimizing fluid performance and reducing costs

Rockwater Energy Solutions has released FluidWatch, a single-source provider to support operators seeking real-time frac optimization. Without a clear picture of each segment, operators run the risk of over-treating, overdosing chemistry and overpaying for a well. Creating the right produced water blend, flow rates and disinfection can influence a custom chemistry that reduces total operation inputs and creates opportunities for more automation and efficiency. Rockwater identifies and evaluates water data to match the right sources, whether produced, blended or fresh; employs comprehensive on-the-fly treatment and disinfection aligned with pre- and post-frac key performance indicators; leverages an established network of automated water logistics that can evaluate and adapt in real time; and develops, tests and manufactures chemical solutions to match water chemistry on a per-project basis.

Processing solution proven to reduce carbon emissions of drilling operations by 50%

TWMA’s TCC RotoMill wellsite processing solution allows drilling waste to be processed at the source, eliminating the requirement to ship drilling waste long distances for treatment. The solution significantly lowers carbon emissions, reduces well cost and improves safety performance. The company will highlight how its wellsite processing solution has been proven to reduce the carbon emissions of drilling operations by 50% at this year’s ADIPEC. The company is set to present a technical paper at a session hosted by the Society of Petroleum Engineers during the conference. The company is also releasing its real-time monitoring technology XLink, a hardware and software system upgrade that allows customers to monitor their drilling waste operations live from anywhere in the world. The system reduces personnel onboard, improves operational insights and automates wellsite processing systems to lower cost, improve safety and lower carbon emissions.

Recommended Reading

FERC Says 32 Bcf/d in US LNG Capacity Approved, Not Yet Built

2024-01-29 - The FERC—which has jurisdiction over the siting, construction and operation of LNG export facilities in the U.S.—reported that 18 projects worth 32 Bcf/d of export capacity have obtained approval but are yet to be built.

Watson: Implications of LNG Pause

2024-03-07 - Critical questions remain for LNG on the heels of the Biden administration's pause on LNG export permits to non-Free Trade Agreement countries.

Despite LNG Permitting Risks, Cheniere Expansions Continue

2024-02-28 - U.S.-based Cheniere Energy expects the U.S. market, which exported 86 million tonnes per annum (mtpa) of LNG in 2023, will be the first to surpass the 200 mtpa mark—even taking into account a recent pause on approvals related to new U.S. LNG projects.

Venture Global Seeks FERC Actions on LNG Projects with Sense of Urgency

2024-02-21 - Venture Global files requests with the Federal Energy Regulatory Commission for Calcasieu Pass 1 and 2 before a potential vacancy on the commission brings approvals to a standstill.

US Asks Venture Global LNG to Justify Filing of Confidential Documents

2024-03-13 - The FERC request comes days after Venture Global LNG customers had challenged the company's request for a one-year extension of its startup and urged the regulator to make Venture Global release the confidential commissioning documents.