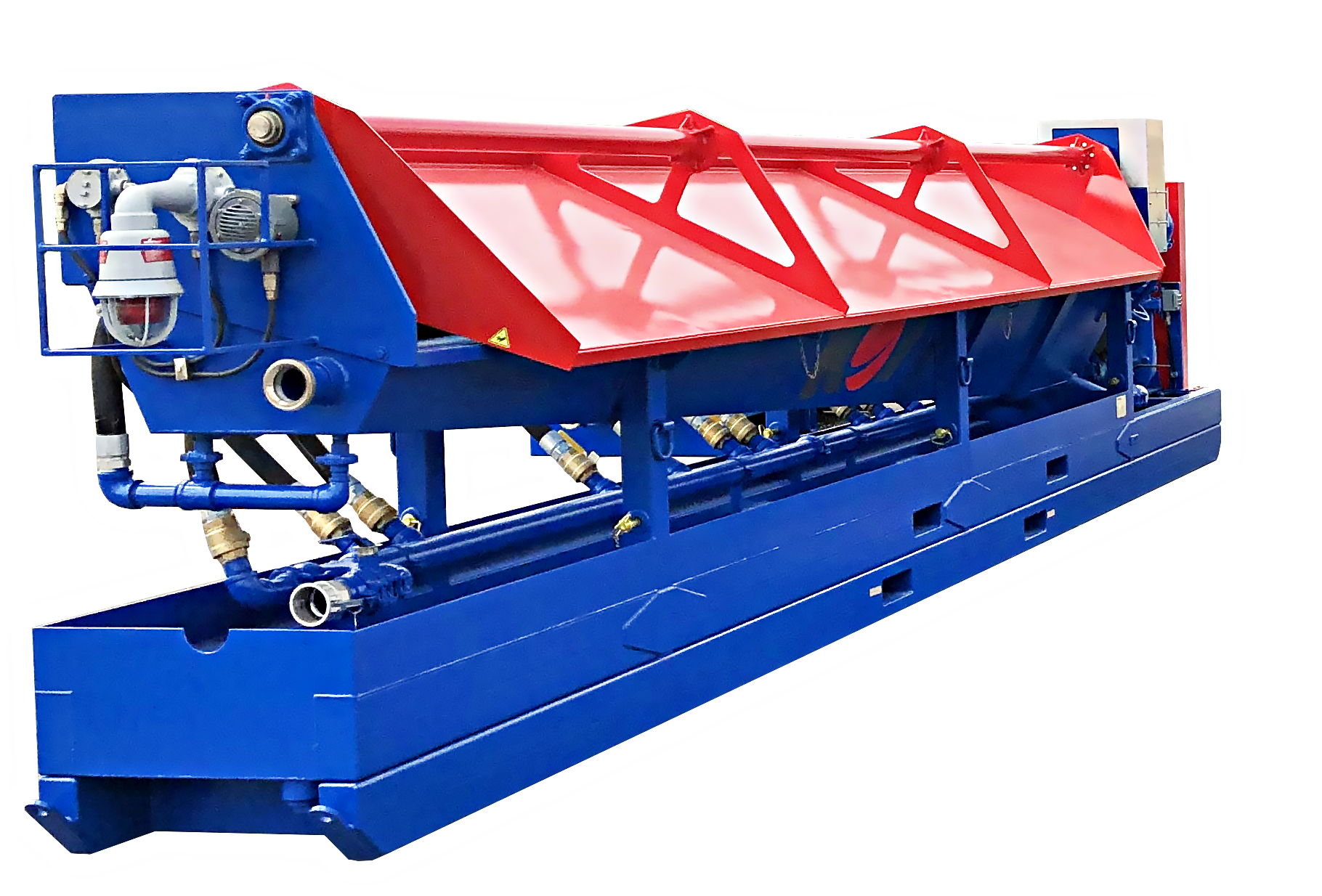

Fluid recovery system provides higher quality fluids

The BRANDT AFRS fluid recovery system from National Oilwell Varco (NOV) allows recovery of up to 95% of the fluid that is generally lost on cuttings, resulting in higher quality fluids due to little to no solids degradation, according to the company. The AFRS hopper is positioned beneath the shaker slides. After primary separation occurs at the rig shale shakers, the cuttings fall into the AFRS hopper and are pumped to a drying centrifuge using a patent-pending process, yielding oil on cuttings down to 6%. As this pump can move live seafood, it is ideal in being able to process cuttings from the shaker without detrimental cuttings degradation, thus significantly reducing the creation of low-gravity solids in the recovered fluid stream. nov.com

Boosting subsea oil recovery

Aker Solutions and FSubsea have agreed to create FASTSubsea to help operators increase oil recovery in a faster, simpler and more environmentally friendly way, a press release stated. Multiphase subsea pumping technology has the potential to increase oil recovery rates by more than 20%, but cost, space limitations and sometimes complex solutions mean multiphase pumps are installed in fewer than 30 of the world’s 1,500-plus offshore fields. New company FASTSubsea combines Aker Solutions’ high-performance multiphase hydraulic technology with FSubsea’s Hydromag technology to create the world’s first “topside-less” multiphase boosting system, according to the release. The pump module solution being developed by FASTSubsea can cut capex by half and enable subsea boosting at fields where there is no available topside space. Getting more out of existing wells reduces CO2-emissions per barrel. fsubsea.com, akersolutions.com

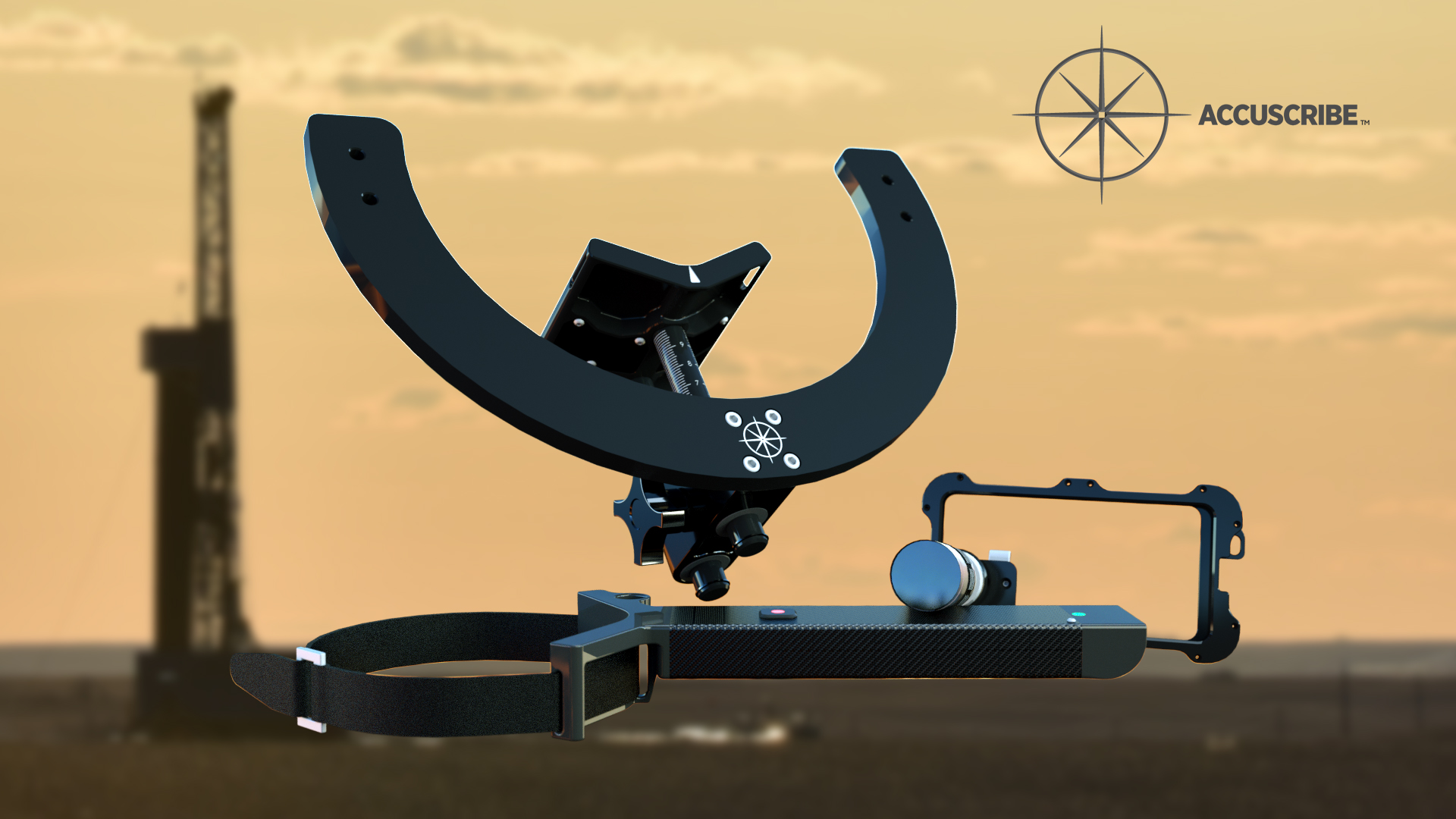

Error-proof method rapidly obtains drilling assembly offset

AccuScribe is an automated conventional drilling assembly offset (DAO) system. This hardware and software provides an error-proof method to rapidly obtain an accurate DAO, according to the company. In drilling for oil, the predictability of a drilling assembly is critical for reaching peak performance, and the accurate alignment of the DAO is a critical process in pre-run bottomhole assembly. A DAO is a process of transposing the high side of the MWD to the mud motor high side, such that the drilling wellbore can be directionally drilled with the drilling assembly according to a predetermined well path. Companies that choose to implement and standardize their operations with AccuScribe will see a return on their investment of up to 18 times the cost with minimal disruption to their current operations. Since its product launch in March 2018, AccuScribe has provided more than 600 offset measurements. The AccuScribe development team has gathered user feedback to enhance user experience. AccuScribe BLACK (version 3) launched in May and comes complete with the company’s new iOS application, ready to deploy in a matter of hours to the drilling rig. accuscribe.us

New oil and gas drone inspection technology

Recently released by Xtreme Cubes Corp. and AviSight Inc., the C3UBE is a sophisticated drone mobile command center. AviSight deploys the C3UBE for the inspection of oil, gas and power critical infrastructure. It allows simultaneous and multiple beyond-visual-line-of-sight (BVLOS) flight missions and provides real-time data transmission and artificial-intelligence-assisted fault detection in the most remote of locations. By enabling BVLOS flight of significant distance, for the first time drones are a real alternative to the unsafe and inefficient methods of inspection, which include helicopters and dangerous manual logistics. When critical infrastructure companies make this transition to unmanned data collection, they are able to cut costs, save lives and provide better service with less interruption to the final customer. xtremecubescorp.com, avisight.com

New simulator training for next generation electric vehicles

Forum Subsea Technologies has released the latest version of its VMAX simulator to integrate with its next-generation of electric ROVs (eROV), a press release stated. The XLe Spirit was the first vehicle to be launched from the new range last year, and Forum has now added the eROV to its choice of vehicles within the simulator. The new lightweight and ergonomically designed eROV Hand Controller console also can be interfaced to VMAX to allow pilots to be trained in the use of the new console. The VMAX software is a 3-D ROV simulation system that is predominantly used for the training and evaluation of ROV pilots. It also can be utilized by subsea engineering teams for modeling and verification of procedures involving intervention tasks for subsea equipment. The system provides a variety of ROV scenarios designed to test pilots’ skills, such as tether management, manipulator control and tooling operation within realistic operational conditions. The XLe Spirit is the smallest in the new range but is powerful enough to perform subsea maintenance and repair work with the use of its optional electric or hydraulic five-function manipulator arm. f-e-t.com

New clamp meters allow users to measure current in tight spaces

Emerson is expanding its Greenlee test and measurement offering with four new meters and probes: the CMF Series (CMF-110 and CMF-118 flexible clamp meters) and the FC Series (FC-110 and FC-118 flexible clamp current probes), according to a recent product announcement. The flexible coils allow professionals to measure current in hard-to-reach cables and large conductors that hard-jaw clamp meters cannot clamp around. Available in either 10-in. or 18-in. flexible coil offerings, Greenlee’s CMF Series flexible clamp meter is a standalone meter that accurately measures true root mean square alternating current (AC), AC voltage, resistance, frequency and inrush current, and has a bright LCD screen to display measurements clearly. The CMF Series features a flexible coil that professionals can easily thread around large conductors. Capable of reading measurements up to 3,000 amps, the CMF Series has a convenient auto or manual range selection and a unique data hold function that captures measurement for reading after the professional removes the meter from the conductor or enclosure. In addition, Greenlee’s FC Series flexible clamp current probe offerings are compatible with most meters that measure AC millivolts using universal banana leads. Also available in 10-in. or 18-in. coil options, the FC Series add measurement capability of up to 3,000 amps to existing meters. A manual range selection feature for AC current enhances performance by allowing the professional to select measurement ranges up to 30 amps, 300 amps or 3,000 amps. emerson.com

Seal-less pumps have no seals or packing to leak, wear or replace

Wanner Engineering Inc. has released its new Hydra-Cell T200 Series medium-pressure pumps. They feature a seal-less design that avoids the maintenance problems of mechanical or dynamic seals and packing that can leak and wear, a press release stated. With flow rates up to 95 gpm (359 l/min; 3,258 bbl/d) and a maximum pressure rating of 3,500 psi, Hydra-Cell T200 models are ideal for a variety of high-capacity applications including saltwater disposal, saltwater injection, bulk transfer and hydraulic lift in oil fields as well as steam generation, reverse osmosis in water and wastewater treatment, mine dewatering, boiler feed, and high-pressure cleaning. The seal-less design means that Hydra-Cell T200 pumps do not have a leak path and therefore eliminate hazardous volatile organic compound emissions and the cleanup and disposal costs of packed-pump leakage. This also eliminates the need for external lubrication and maintenance as well as plunger wear problems associated with packing. Hydra-Cell T200 Series pumps can run dry without damage, will operate with a closed or blocked suction line and can pump hot abrasive fluids effectively. The Hydra-Cell T200 Series pumps employ hydraulically balanced, multiple diaphragms that enable the pump to handle high pressures with low stress and process

abrasive particulates up to 800 μ in size. hydra-cell.com

Garment designed to save lives offshore

Iron Ocean worked with the Oil & Gas Innovation Centre and Heriot-Watt University to develop the Centurion 3, a three-layer upper body garment that produces heat when immersed in cold water and is designed to be worn under the traditional offshore survival suit, a press release stated. A prototype of the garment, which could save the lives of offshore workers in the event of an accident at sea, was unveiled Jan. 17. The three layers are tear-resistant, fire-retardant and compression fit, making the Centurion 3 less bulky and restrictive compared to traditional suits, and gives the wearer increased mobility and protection. Current garments worn under the survival suit do not provide active heating. Consequently, immersion into the cold waters of the North Sea, for instance, causes the body temperature of the wearer to very rapidly decrease with an estimated life expectancy of 10 to 12 minutes. By comparison, the newly developed material incorporated into Centurion 3 immediately activates when in contact with water and produces a heat output above the average body temperature for more than 20 minutes. Therefore, the self-heating material allows the wearer to retain body heat during a critical period, preventing the fatal effects of cold water immersion. ironocean.co.uk, ogic.co.uk

Multiservice vessel serves deepwater stimulation, intervention needs

Oceaneering International Inc. has taken delivery of the advanced subsea construction support vessel Ocean Evolution, according to a press release. The vessel has completed sea trials and received all necessary ABS and U.S. Coast Guard certifications and is in Port Fourchon, La., completing final outfitting and preparing for project work scheduled to begin in June. The Ocean Evolution is the most advanced, U.S.-flagged, Jones Act-compliant, multiservice vessel on the market. Its capabilities are headlined by its 250-mt active heave compensated (AHC) crane, two work class ROVs with AHC launch systems, survey systems and subsea tooling all built for work in up to 4,000-m (13,123-ft) water depths. The vessel serves the deepwater stimulation and intervention needs of its customers with its well stimulation and well intervention design, ABS Well Stimulation and Well Intervention ready notation and under deck capacity to store special products. oceaneering.com

Please submit your company’s updates related to new technology products and services to Ariana Hurtado at ahurtado@hartenergy.com.

Recommended Reading

For Sale? Trans Mountain Pipeline Tentatively on the Market

2024-04-22 - Politics and tariffs may delay ownership transfer of the Trans Mountain Pipeline, which the Canadian government spent CA$34 billion to build.

Energy Transfer Announces Cash Distribution on Series I Units

2024-04-22 - Energy Transfer’s distribution will be payable May 15 to Series I unitholders of record by May 1.

Balticconnector Gas Pipeline Back in Operation After Damage

2024-04-22 - The Balticconnector subsea gas link between Estonia and Finland was severely damaged in October, hurting energy security and raising alarm bells in the wider region.

Wayangankar: Golden Era for US Natural Gas Storage – Version 2.0

2024-04-19 - While the current resurgence in gas storage is reminiscent of the 2000s —an era that saw ~400 Bcf of storage capacity additions — the market drivers providing the tailwinds today are drastically different from that cycle.

Ozark Gas Transmission’s Pipeline Supply Access Project in Service

2024-04-18 - Black Bear Transmission’s subsidiary Ozark Gas Transmission placed its supply access project in service on April 8, providing increased gas supply reliability for Ozark shippers.