Rock core imaging technology virtually removes resolution limitations

The ImaCore 3017, a new 3-D magnetic resonance imaging (MRI) technology, has been released by MR Solutions. MR Solutions, in partnership with Green Imaging Technologies, have combined technologies to bring complete high-resolution rock core imaging to the oil and gas sector, a press release stated. Traditionally, rock core analysis is an exercise in providing measured data, but equipment limitations can result in final analysis that involves using theories to understand what is happening at the pore level. The ImaCore 3017 will virtually remove these resolution limitations by allowing users to bolster the theoretical with actual images of all the fluid present in the rock core sample and thus the pore network. MR Solution’s cryogen-free MRI technology is highly versatile as the magnet field can be adjusted from 0.1T to 3.0T, depending on image requirements. Sample sizes can range from 1-in. to 4-in. diameters, and ample space is provided for pressure and flow cells, allowing users to make measurements at reservoir conditions and to perform high-resolution flow studies. MR Solutions’ technology, including the latest 3-D imaging pulse sequences, is combined with Green Imaging’s software products to provide an easy-to-use interface. This provides workflow management and easy calibration and system monitoring. mrsolutions.com

Service improves maintenance strategies, operational effectiveness

The new diagnostic reliability service from Rockwell Automation helps manufacturers and industrial producers drive a streamlined maintenance strategy on mission-critical integrated equipment lines, a press release stated. The system deploys a layer of technology across plant devices and equipment to monitor and perform analysis as well as create a continuous improvement approach to reliability maintenance, reducing operational risk. As part of the service, a Rockwell Automation domain service expert closely tracks equipment performance to advise on reliability improvements to the production facility. The system automatically collects identity and health data from all networked devices on the production control network. The data are then modeled with asset management information to trigger events and send alerts to necessary personnel for proactive maintenance. With the service, Rockwell Automation asset reliability professionals assist users in applying the intelligence on their critical equipment to inform data-driven maintenance decisions and increase productivity. rockwellautomation.com

Subsurface workflows enhanced with more automation, tighter product integration

Paradigm has released its Paradigm 15.5 comprehensive solution suite aimed at extending its high-definition subsurface workflows and enhancing user productivity, a press release stated. According to the company, Paradigm 15.5 reinforces and enhances the performance gains established in the Paradigm 15 solution released in 2015 and helps users resolve stratigraphic details and recover the subsurface features that control hydrocarbon accumulation and recovery. Paradigm 15.5 is designed to improve the seismic interpretation process and experience with new and enhanced features such as memory-efficient multivolume, multihorizon and multisurvey flattening; multivolume attribute extraction and blending with geometric attributes in 3-D Canvas; quality-control attributes generated on the fly when propagating horizons; and horizon-fault contacts calculated and editable on the fly. Additionally, the Paradigm Quantitative Interpretation solution for recovering rock properties from seismic and well data has been updated with a wedge modeling application that analyzes the effect of bed thickness on seismic amplitudes and provides the option to easily test “what if” scenarios. pdgm.com

System helps avoid production interruptions

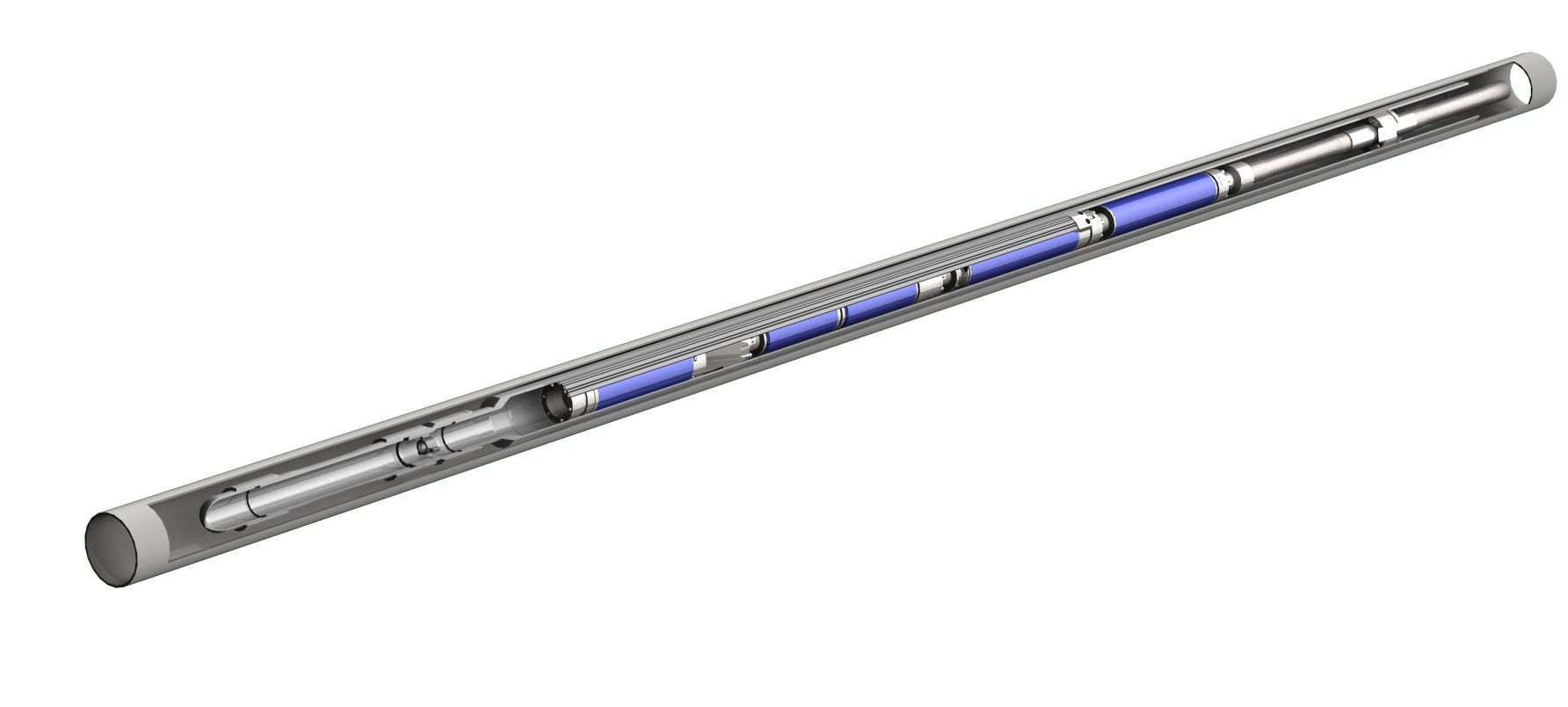

Baker Hughes has released its CENesis PHASE multiphase encapsulated production system, which helps operators avoid production interruptions in unconventional wells. Designed to separate natural gas from the oil stream before it can enter an electric submersible pumping (ESP) system, the system mitigates production downtime and potential ESP performance issues, which can ultimately improve reserve recovery, a product announcement stated. During the production phase in unconventional plays, higher levels of natural gas are usually released from the payzone as reservoir pressure depletes. This gas typically enters the horizontal wellbore and accumulates in the high-side of the lateral, creating large gas slugs that, as they move up the wellbore, cause low-flow or no-flow conditions in an ESP. The CENesis PHASE system mitigates this problem by surrounding the entire ESP system in a shroud, allowing

lighter natural gas to continue flowing up the wellbore while heavier production fl uid fl ows into the shroud and is produced through the ESP system. The shroud also provides a supply of production fl uid so the ESP can continue to operate during gas slug events when natural gas completely displaces fl uid in the wellbore. Mitigating this gas interference in the pumping system stabilizes production and reduces downtime associated with pump cycling and gas locking conditions. bakerhughes.com

Smartphone designed for rugged market

Cat Phones has released the Cat S50c rugged smartphone, connected exclusively on the Verizon network, according to a product announcement. The device has been rigorously tested and designed for challenging environments. The Cat S50c comes from Caterpillar Inc., and its robust design meets U.S. military standards and is IP67 certified, providing protection against drops, water, dust, extreme temperatures, humidity, thermal shocks, vibration and salt mist. The phone is fully impervious to dust, waterproof in 1 m (3.3 ft) of water for up to 30 minutes and is drop-proof up to 1.2 m (3.9 ft). It also features a scratch- and shatter-resistant Gorilla glass screen that won’t crack under pressure. The 4.7-in. high-definition display is fully operational while wearing gloves up to 4 mm thick, with wet hands, and even in the rain or snow. Additionally, it features an 8-MP camera. The Cat S50c is also “Push to Talk” ready with a dedicated key to allow users to communicate instantly with one person or an entire workforce. The smartphone features a 1.2-GHz quad-core processor, 1GB of RAM, 8 GB of flash and is expandable by Micro SD up to 64 GB. catphones.com

Software makes driver-based compliance the new regulatory standard

A better way for oil and gas companies to technologically manage their complex regulatory requirements is available from ACS Engineering through its Continuous Compliance Monitoring System (CCMS) software, according to the company. Eliminating the inefficient, awkward but widely used task-based approach, the CCMS is regulation/driver-based and unique in design, delivery and maintenance. For all the regulatory complexities, the system’s operation is simple; now companies do not have to painstakingly figure out how to comply with applicable regulations. With the CCMS, companies only receive relevant regulations, which are auto-applied to compliance manuals and tasks. As a compliance-centric bonus, using only site-specific applicability rules (not more or less) loaded into the system saves time and increases economic efficiency, the company said. This system deals exclusively with permits, regulations, plans and manuals, for example, that drive the compliance tasks. After the system is populated with a company’s applicable regulations, it continually expands its knowledge base with each new operation. By automatically tracking and continuously updating the drivers, the system stays current 24/7 without the traditional manual rigors. acsengineering.com

Self-retracting lifeline designed for harsh environments

Honeywell’s Miller DuraSeal self-retracting lifeline (SRL) is designed to provide greater reliability and safety in the harshest environments, including onshore and offshore oil and gas, a press release stated. The DuraSeal SRL features patent-pending sealed technology that prevents contaminants from entering the mechanism, earning the design an IP69K certification, and it ensures that the SRL’s brake system, power spring and bearings are never exposed to debris, water or chemicals. The braking system is designed to withstand multiple falls. The unit installs and transports easier, and quick, low-cost lifeline replacements in the field are possible. Engineered to be up to 30% lighter in weight than competitive sealed SRLs, the DuraSeal reduces user fatigue and increases productivity, according to the company. With a weight capacity of 420 lb (180 kg), the DuraSeal provides protection for a wide range of workers who often carry heavy tools. The DuraSeal requires no annual recertification. millerfallprotection.com

Recommended Reading

Report: Freeport LNG Hits Sixth Day of Dwindling Gas Consumption

2024-04-17 - With Freeport LNG operating at a fraction of its full capacity, natural gas futures have fallen following a short rally the week before.

Permian NatGas Hits 15-month Low as Negative Prices Linger

2024-04-16 - Prices at the Waha Hub in West Texas closed at negative $2.99/MMBtu on April 15, its lowest since December 2022.

BP Starts Oil Production at New Offshore Platform in Azerbaijan

2024-04-16 - Azeri Central East offshore platform is the seventh oil platform installed in the Azeri-Chirag-Gunashli field in the Caspian Sea.

US Could Release More SPR Oil to Keep Gas Prices Low, Senior White House Adviser Says

2024-04-16 - White House senior adviser John Podesta stopped short of saying there would be a release from the Strategic Petroleum Reserve any time soon at an industry conference on April 16.

Core Scientific to Expand its Texas Bitcoin Mining Center

2024-04-16 - Core Scientific said its Denton, Texas, data center currently operates 125 megawatts of bitcoin mining with total contracted power of approximately 300 MW.