Occidental Petroleum's Shauna Noonan used ChatGPT AI technology to spice up how well intervention operations are described to people new to the industry at a keynote luncheon at the SPE/ICoTA Well Intervention Conference and Exhibition in The Woodlands.. (Source: Shutterstock)

THE WOODLANDS, Texas — Technology is remaking how the oil and gas industry gets things done, from inspection techniques to well interventions. And perhaps tech could one day ghostwrite its own story in the annals of oil and gas innovation.

For Shauna Noonan, Occidental Petroleum’s Fellow and Senior Director for International and Gulf of Mexico Supply Chain, effectively telling the story of that technology in the industry—whether it’s robotic inspections or the impressive operations in a wellbore— is essential to attract fresh talent to the industry.

“It’s time to reframe the well intervention narrative,” Noonan said on March 21 during a keynote luncheon at the SPE/ICoTA (Intervention and Coiled Tubing Association) Well Intervention Conference and Exhibition in The Woodlands.

Technology is opening new possibilities all the time: 3D printers can make food, something that was once a sci-fi idea, she said. It’s now possible to replace some oilfield workers with robots. Even scripting the tale of new and fantastic technologies can be told with technology itself, via artificial intelligence (AI).

Training Spot, the robotic dog

Occidental has been trialing the use of Spot, a robot dog developed by Boston Dynamics, for visual inspections and emissions detection at onshore and offshore facilities.

“He’s sensor-ed up to see things we can’t see, and also to see things we can see,” Noonan said.

Emerson Toloza, a robotics specialist at Occidental, is one of Spot’s handlers. Like most dogs, Spot had to be trained.

“You first manually walk through the platform facility. You teach it what you want it to look for,” he said.

Now Spot’s capable of doing visual inspections and emissions detections, and it uses different types of sensors and recording equipment.

“Autonomous inspections, that’s our goal,” Toloza said.

So far, Spot’s field trial has been a success, he said.

Occidental is expanding its robotic dog pack. Noonan said the operator had purchased additional Spots from Boston Dynamics for direct air capture (DAC) facilities.

“One of those plants has over a 60-acre footprint. They're massive,” Noonan said. “In order to do proper and timely inspections, we've actually purchased a couple more” robots.

‘The unsung heroes of oil and gas’

Google doesn’t make well intervention sound like an interesting career.

Noonan said changing the narrative of technology in well intervention will help draw in the next generation of talent.

As an experiment, she checked for definitions of wireline intervention with two sources.

First, Google, which produced a definition that was accurate and boring. Google dutifully reported that intervention prolongs the life of producing wells.

Enter ChatGPT, an artificial intelligence (AI) interface that responds to text questions and generates natural language responses.

ChatGPT variously described wireline intervention as trying to thread a needle deep underground — but a needle that is on its side and twisting.

“It’s not just a matter of lowering the wire down the wellbore, it’s like trying to steer a ship through a minefield while blindfolded,” Noonan said. “The crew has to contend with curves, angles and deviations in the wellbore that can cause the wire to kink, buckle or even break.”

In the end, ChatGPT’s version suggested that wireline crews are “the unsung heroes of the oil and gas industry.”

In short, she said, “ChatGPT gets it.”

Part of what that new AI technology gets, she said, is how many different things can be done in wellbores.

“The interesting thing is even people in our own industry don’t realize how complex and advanced and how challenging of a job you have,” Noonan said. “That’s the story we need to get out there.”

And as that story spreads, she hopes the Google definition will evolve to: “Extending the life of producing wells with minimal environmental impact by using advanced technology to safely enter complex wellbores autonomously.”

And some of that advanced technology could be a variation on Spot.

“Why can’t we have a mini-Spot to go into our wellbores to deal with plugs?” she asked.

Recommended Reading

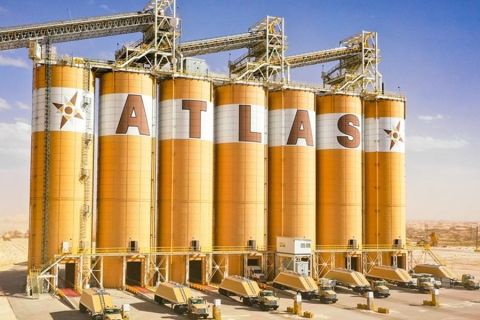

Fire Closes Atlas Energy’s Kermit, Texas Mining Facility

2024-04-15 - Atlas Energy Solutions said no injuries were reported and the closing of the mine would not affect services to the company’s Permian Basin customers.

Coalition Launches Decarbonization Program in Major US Cities, Counties

2024-04-11 - A national coalition will start decarbonization efforts in nine U.S. cities and counties following a federal award of $20 billion “green bank” grants.

Exclusive: Scepter CEO: Methane Emissions Detection Saves on Cost

2024-04-08 - Methane emissions detection saves on cost and "can pay for itself," Scepter CEO Phillip Father says in this Hart Energy exclusive interview.

Majority of Recent CO2 Emissions Linked to 57 Producers - Report

2024-04-03 - The world's top three CO2-emitting companies in the period were state-owned oil firm Saudi Aramco, Russia's state-owned energy giant Gazprom and state-owned producer Coal India, the report said.