Presented by:

Editor's note: This article appears in the new E&P newsletter. Subscribe to the E&P newsletter here.

Corrosion is considered to be the main cause of failure in the oil and gas production process. Due to the development of fields in deeper offshore wells with higher pressure, temperature and higher levels of hydrogen sulphide, CO2 and chloride, corrosion costs are increasing.

According to research from NACE International, the effects of corrosion can contribute between 3.5% and 5.2% of global GDP (i.e., between $285 billion and $439 billion annually on a global basis, calculated for 2020 GDP figures of $84.54 trillion U.S. dollars).

Until a decade ago, steel material for pipelines and pipe structures was the main option for the oil and gas industry. Strohm is developing and deploying thermoplastic composite pipe (TCP) to counter the inherent drawbacks of steel: corrosion, fatigue and weight.

TCP benefits

Strong, lightweight and corrosion resistant, TCP provides a wide variety of financial, operational and environmental benefits in subsea production and oilfield service applications.

“The value proposition that TCP has is threefold,” said Martin van Onna, Strohm's chief commercial officer. “One is completely doing away with corrosion, two is the reduction in total installation costs and the third, more recently added, is the reduction in carbon footprint. The cost and footprint elements are all around the ability to use small vessels to transport and install our pipes in a very cost-effective and fuel-efficient manner. This is not possible with steel pipes, because you have to mobilize a large pipelay barge and other vessels, which often have to come from other regions, before you can start installing your pipelines.”

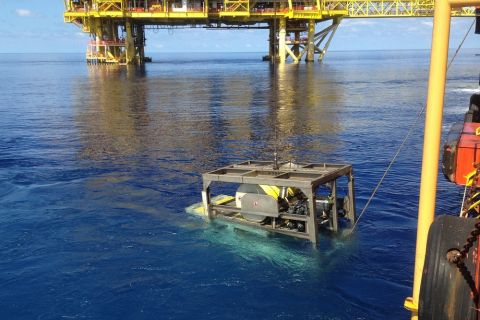

TCP features a solid pipe wall constructed from glass or carbon reinforcement fibers and thermoplastic polymeric materials. The melt-fusing manufacturing process results in a true composite structure, with the fibers fully embedded within the polymer matrix and ensuring the strongest interface possible between the different pipe layers. The fibers are linear in behavior and typically do not show plastic deformation or yielding. This creates a robust spoolable pipe, 80% lighter than metallic equivalents, and it is adapted to customer-specific requirements. For subsea applications, Strohm provides an on-target weight coating to ensure stability on the seabed.

There has been continued investment in TCP's growth and innovation from many global supermajors. TCP has been installed in every offshore oil and gas region globally with zero failures.

Applications for the energy industry

TCP is agnostic to fluids and gases as well as a viable and credible alternative for flowlines, risers and jumper spools to support hydrocarbon production, water injection, chemical and methanol injection, wellbore access, choke and kill, (de-)commissioning, and intervention activities.

Based on the application, the company selects the right thermoplastic compound for the liner, matrix, coating and fiber to ensure it has the best fit-for-purpose solution for static as well as dynamic applications in shallow-water and deepwater offshore and subsea environments.

For flowlines for water or methanol injection, for instance, the choice for the glass fiber in combination with polyethylene polymer provides the best solution for flexibility, stiffness and minimum bend radius. This reduces total installed cost in deepwater and shallow-water applications.

“Contrary to what most people think, the value proposition for TCP is strong in shallow water as well as in deep water," Van Onna said. "The fact that TCP can be installed using small vessels, and end-fittings installed offshore on small platforms, is a great advantage in brownfield, shallow-water applications.”

For deepwater, high-pressure dynamic risers, the combination of carbon fiber with the high-end PVDF polymer is designed to be the best field-proven solution in the context of installability, subsea stability and configuration.

The technology can help enhance production, particularly for brownfield developments that need old pipelines replaced to enable continued production from maturing fields in regions such as the North Sea and Gulf of Mexico. TCP flowlines for hydrocarbon production, water, gas lift and chemicals injection have also been installed in West Africa and Asia.

The company’s TCP jumpers are the only high-pressure pipe commercially available combining a smooth bore with high collapse resistance and flexibility. It outperforms rigid steel pipes and conventional unbonded flexible pipes by saving up to 50% on overall investment and procurement costs.

“TCP has completely removed the physiochemical parameters associated with the oxidation of steel in seawater, making it the definitive agnostic solution to CO2-induced corrosion and an industry game changer," Van Onna added.

TCP is also being used by Allseas to responsibly recover polymetallic nodules from the seabed at depths of 4,000 m to 6,500 m.

Sustainability is the future

With a growing list of operators announcing ambitions to reduce the carbon footprint of their operations and the products they sell, the oil and gas industry is taking unprecedented steps toward a lower carbon energy system.

Strohm has been investing in the development of TCP solutions aimed at the hydrogen and carbon, capture, utilization and storage (CCUS) markets. Unlike steel or unbonded flexible pipes, it does not corrode when exposed to CO2, and it does not become brittle with exposure to hydrogen. It is a more sustainable product and is proven to be durable for over 40 years.

The technology also has a low-carbon footprint, is easy to produce, maintain and recycle. Sustainability credentials versus steel pipes include 50% lower CO2 manufacturing footprint, 60% reduction in CO2 footprint compared on installation, and zero CO2 emissions once operating in-situ due to lack of maintenance requirements.

Conclusion

Carbon steel structures exposed to natural waters and corrosive environments generally corrode at an unacceptably high rate unless preventive actions are taken. An estimated one-sixth of all steel production worldwide is used to replace corroded metal, much of it at cooling water piping systems, and yet the rate of corrosion in pipelines is increasing and becoming more difficult to overcome.

Strohm’s materials are well positioned to maintain the oil and gas sector and support the energy transition industries. They can handle gases including hydrogen and CO2, which are both corrosive and present many challenges for steel. The firm’s deepwater risers also can be used to inject CO2 into subsea reservoirs, which can help companies in the CCUS space reduce their costs as CO2 doesn’t need to be purified for TCP usage.

“We are committed to supporting the industry towards achieving zero-net emissions," Van Onna concluded. "In the work done to date, we see that on an as-installed basis, TCP can lead to a significant footprint reduction of over 50%. The TCP product itself, especially when using glass fibers as reinforcement, leads to a significant reduction of the CO2 footprint when compared to steel.”

References:

- https://www.sciencedirect.com/science/article/pii/S1878535221001313

- https://membership.corrosion.com.au/wp-content/uploads/2021/07/Impacts-of-Corrosion-in-Australasia-3.6.pdf

- https://www.statista.com/statistics/268750/global-gross-domestic-product-gdp/

- https://www.researchgate.net/publication/342972987_Localized_Corrosion_and_Mitigation_Approach_of_Steel_Materials_Used_in_Oil_and_Gas_Pipelines_-An_overview

Recommended Reading

Forum Energy Signs MOU to Develop Electric ROV Thrusters

2024-03-13 - The electric thrusters for ROV systems will undergo extensive tests by Forum Energy Technologies and SAFEEN Survey & Subsea Services.

Sapura Acquires Exail Rovins’ Nano Inertial Navigation System

2024-02-01 - Exail Rovins’ Nano Inertial Navigation System is designed to enhance Sapura’s subsea installment capabilities.

2023-2025 Subsea Tieback Round-Up

2024-02-06 - Here's a look at subsea tieback projects across the globe. The first in a two-part series, this report highlights some of the subsea tiebacks scheduled to be online by 2025.

TGS Commences Multiclient 3D Seismic Project Offshore Malaysia

2024-04-03 - TGS said the Ramform Sovereign survey vessel was dispatched to the Penyu Basin in March.

Tech Trends: Autonomous Drone Aims to Disrupt Subsea Inspection

2024-01-30 - The partners in the project are working to usher in a new era of inspection efficiencies.