An acoustic sensor detected a hydrate plug in a submerged deepwater pipeline offshore Angola earlier this year.

While TSC Subsea’s Acoustic Resonance Technology (ART) is not new, the company developed an acoustic-sensing equipment package called ART vPush that could be propelled by a ROV specifically to detect the hydrate blockage in the Angolan pipeline. The job required partial pre-dredging of the pipeline, the actual ART vPush inspection, and follow-up high-resolution imaging of the ends of the hydrate plug carried out by TSC’s Acoustic Resonance Technology External Measurement Inspection System (ARTEMIS).

TSC uses ART to inspect or look inside walls of pipelines with “substantial coating on the exterior,” said Jonathan Bancroft, TSC Subsea global sales director.

An Italian operator had a submerged 8-inch 3LPP coated water injection line in 1,300 m water depth that was blocked by a hydrate somewhere in a 12-km stretch of pipeline. DOF Subsea Norway, a contractor for the Italian operator, sub-contracted with TSC Subsea to develop an acoustic method of locating the blockage.

“They wanted a fast and efficient way to locate it and size it accurately,” Bancroft said.

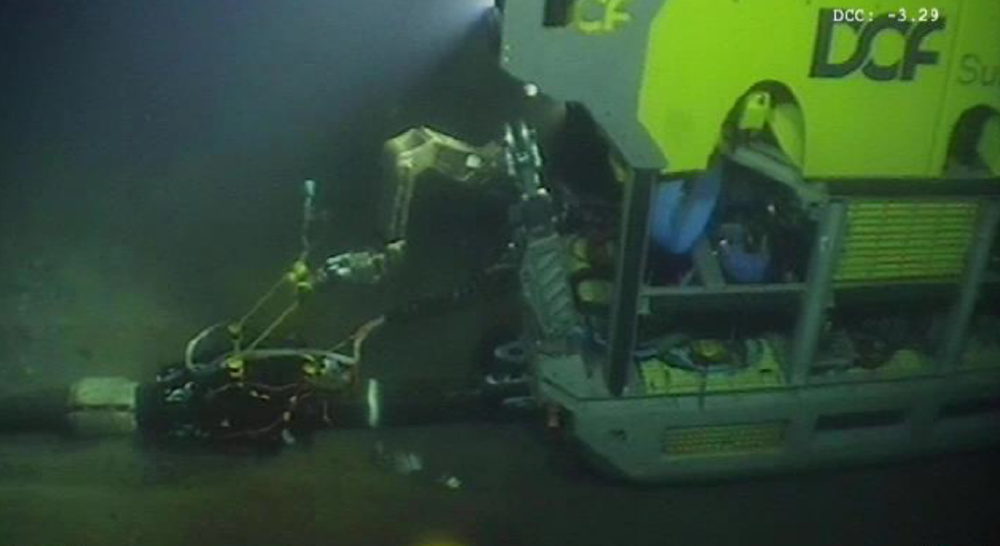

TSC developed the ART vPush means of deploying the technology via ROV, and its debut deployment was for the Angola pipeline.

“We developed a slide system to push it along the topside of the pipe by the ROV while looking from the top section into the pipe for any signs of the hydrate plug,” Bancroft said.

The resulting vPush is a moving platform that can rapidly assess pipeline contents acoustically over complete pipe runs. It collects data in real time that is sent to the surface via fiber-optic cable, and the data is processed to identify the presence of hydrates.

Rated to 3,000 m water depth, it can be deployed via ROV manipulator or fitted directly onto an ROV.

Preparing for the run

Before the Angolan pipeline could be inspected, it first had to be partially dredged so the vPush could slide along the top of the line.

“By only positioning sensors on the top section of the pipe, we could limit the amount of dredging,” he said.

Dredging was carried out in late 2021. Even though dredging operations had removed the obstructions between 10 and 2 on the clock face, by the time the ART vPush was deployed in January, some sediment had already settled on top of the line.

“We needed a low-pressure jetting system to jet away the loose debris as it was moving along the pipeline,” Bancroft said.

The ART vPush was deployed from a DOF Subsea ROV.

It carried out the 12-km inspection in one 33-hour run from an ROV operating at about half a knot speed, Bancroft said.

TSC Subsea’s ART works by emitting a sound signal toward a target, such as the pipeline wall, recording the returning sound signal after it resonates in the target, and identifying the resonant frequencies, which allows for direct measurement of the target’s thickness.

Once the ART vPush located the start of the hydrate plug, it carried on scanning until it reached the end of it.

“We were able to give an accurate size of the plug,” Bancroft said.

With the end points of the plug defined, it was necessary to fully dredge around those locations to allow ARTEMIS to carry out high-resolution imaging of the ends of the hydrate.

“The operator wanted a lot of high-resolution scans around the ends of the plug,” he added.

According to Bancroft, historically xray technology would have been used to locate a hydrate blockage.

Subsea “acoustic hydrate detection didn’t exist before this,” he said.

One of those reasons, said Rolf Sporkel, TSC Subsea business development manager, is that acoustic sensing generates a vast amount of data, and that data must be sent from subsea to the surface.

“This amount of data needs to fly in a very short time to maintain the speed of the movement of the vPush,” he said.

Fiber-optic transmission is necessary to have that quick rate of communication, he said.

And while the vPush kit was developed purely for the Angola job, Bancroft said, there has been a “huge amount of” interest in it, and some tenders are out.

Now that the ability to acoustically detect hydrates in deepwater via the vPush has been proven, TSC is looking into other use cases, such as detecting the buildup of hydrates and wax deposits before a plug forms, he said.

“We’ve proven to ourselves that the technology is capable of scanning through protective coating and detecting and sizing the hydrate,” he said. “Now we need to work backward and see if we can detect buildup before it turns into a plug. That’s the ultimate goal.”

Recommended Reading

Santos’ Pikka Phase 1 in Alaska to Deliver First Oil by 2026

2024-04-18 - Australia's Santos expects first oil to flow from the 80,000 bbl/d Pikka Phase 1 project in Alaska by 2026, diversifying Santos' portfolio and reducing geographic concentration risk.

Iraq to Seek Bids for Oil, Gas Contracts April 27

2024-04-18 - Iraq will auction 30 new oil and gas projects in two licensing rounds distributed across the country.

Vår Energi Hits Oil with Ringhorne North

2024-04-17 - Vår Energi’s North Sea discovery de-risks drilling prospects in the area and could be tied back to Balder area infrastructure.

Tethys Oil Releases March Production Results

2024-04-17 - Tethys Oil said the official selling price of its Oman Export Blend oil was $78.75/bbl.

Exxon Mobil Guyana Awards Two Contracts for its Whiptail Project

2024-04-16 - Exxon Mobil Guyana awarded Strohm and TechnipFMC with contracts for its Whiptail Project located offshore in Guyana’s Stabroek Block.