During the past decade, digital transformation emerged as a driver of revolutionary business practices in the energy industry, empowering organizations with unparalleled opportunities. Upstream companies are catching up on the digitalization uptake, integrating technologies in their field operations, including the Industrial Internet of Things (IIoT), cloud computing and artificial intelligence. According to a recent study by Rystad Energy, the upstream industry can save up to $100 billion through automation and digitalization initiatives in the 2020s.

Despite the huge potential, Deloitte’s digital maturity index shows that the oil and gas industry is lagging behind all the other sectors in the digitalization race. EY estimated that only 10% to 20% of the industry is digitalized.

“We’re still at a critical stage because even though many companies have gained the vision to pursue digital transformation, they don’t know where to start and can get frustrated,” said Stuart Harris, group president of Emerson’s newly formed digital transformation business line, speaking at the recent Emerson Global Users Exchange event in Nashville, Tenn. “We define digital transformation as smart, connected technologies used to solve problems, usually involving changes in business practices. Digital transformation must be guided by specific problems, but it won’t work unless people are engaged and appropriate technologies are adopted.”

Harris noted that the challenge most companies face when conducting digital pilots is trying to scale those pilots. “Those who start with technology first tend to get frustrated because a return on investment [ROI] can be difficult to achieve [with that approach],” he said. “That’s why it’s important to have a focus, know the metrics of success and measure your performance against those.”

Taking a step further

Recognizing the need for a dedicated organization focused on digital transformation technologies and programs, Emerson recently announced its new Digital Transformation business line. The new department will bring together critical resources to help manufacturers develop and implement pragmatic digital transformation strategies that deliver top-quartile performance, according to a press release. The $650-plus million business combines existing expertise in consulting, project execution, smart sensor technologies, data management and analytics, which are all a part of Emerson’s Plantweb digital ecosystem. The organization will help customers establish a clear vision for digital transformation and gradually execute and realize measurable results at each step of their journey.

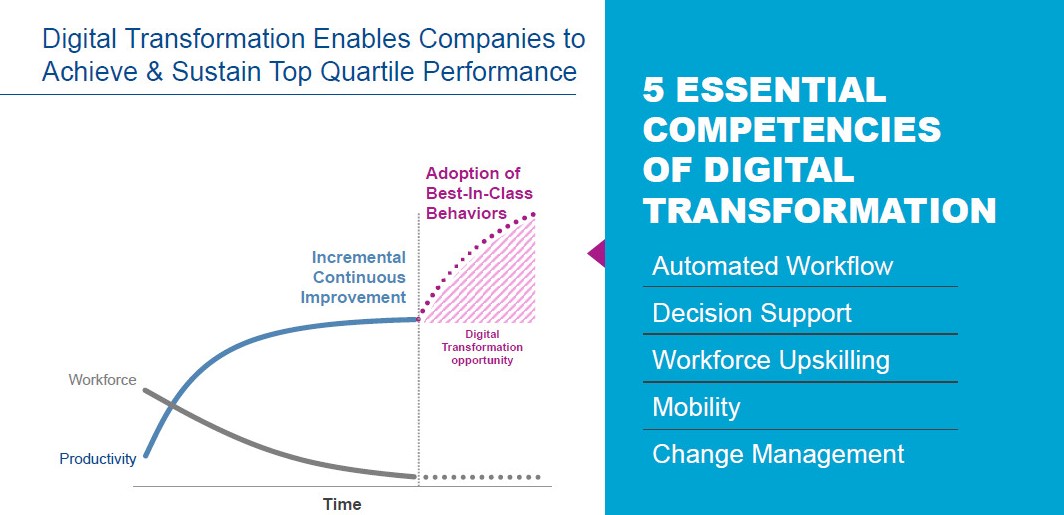

Speaking at a press conference during the Emerson Global Users Exchange event, Harris identified automated workflow, decision support, workforce upskilling, mobility and change management as the five competencies of digital transformation that companies need to unlock the potential of employees and sustain top-quartile performance (Figure 1). He also pointed out that the three critical success factors of digital transformation are technology decisions driven by business outcomes, scalable approach guided by vision instead of doing it all at once and technology investments that also are seen as investments in people.

Harris pointed out that while some companies are executing pilot programs and seeing early benefits, everyone needs to connect their businesses and digital transformation strategies with practical applications. “Strategy and business cases are what come first with digital transformation—not the technology. Once ROI is captured for a solution, it can be scaled across the whole enterprise,” he said.

On a broader scale, once digital transformation initiatives define the goals and identify challenges and opportunities, companies must develop proofs of concept and pilot projects that can demonstrate some of that much-needed ROI. This encourages further commitment and investment as well as helps participants to scale up their solutions to many more applications that can achieve similar advantages and benefits.

“Many digital transformation pilots can get started for $50,000 to $100,000 in one or a few processes, prove themselves and then scale up to many processes and save millions or tens of millions of dollars,” Harris said. “We’ve learned that digital transformation is urgent because it can help users achieve top-quartile performance, add two weeks of uptime, cut maintenance incidents in half or reduce safety incidents by 30%.”

Empowering the workforce

Energy companies face a number of challenges on their path to digital transformation, many of which are attributed to the aging workforce. Moreover, several studies reveal that since the industry is viewed as environmentally unfriendly and technologically backward by the future workforce, companies are in danger of losing fresh digital talent to other sectors.

Beyond specifying problems, goals and technologies, digital transformation is impossible without the deep and continuous engagement of people, especially those on the plant floor, Harris explained.

“Executive support is essential and information technology [IT] has to be involved, but it’s most important for the operations folks to be engaged because they have the domain knowledge about where it’s best to apply digital transformation,” he said. “Every functional group can contribute and take on new roles. They can serve as bridges connecting lines of stakeholders or develop internal academies to train colleagues on how to use new analytics tools.”

Emerson provides technical resources and curriculum development to more than 350 educational institutions to help students develop the skills that employers need. Recently Emerson collaborated with San Jacinto College to help design, equip and provide training tools for the college’s Center for Petrochemical, Energy and Technology, which is designed to empower students of all levels with the skills and training needed to support careers in the evolving petrochemical and refining industries.

Digitizing upstream

For the upstream industry, the advantages of IIoT applications lie in creating value through an integrated deployment strategy, which can potentially increase production, reduce downtime, limit emissions and improve safety.

During an upstream panel discussion at the Emerson Global Users Exchange event, executives of major oil companies reported that legacy assets, workforce attrition, political climate and cybersecurity are the main challenges that slow down IIoT and digitalization. However, they agreed that a well-planned and careful approach can solve the majority of the issues and help companies in delivering value through digitalization.

“We had 300 wells, which we couldn’t monitor remotely, so whenever there was a drop in production, we had to send someone out in a helicopter,” said Todd Anslinger, control systems engineer of the IIoT Center of Excellence at Chevron. He said it took 37 helicopter trips and two weeks to check those wells, and identify and resolve the issues.

“Since we added Emerson transmitters and Digi gateways that transfer 4 to 20 milliamp signals to the cloud via LTE cellular wireless networking, we can monitor when they go below a certain output pressure, for example, and determine if they really need a visit or not. We estimate to save about $25,000 per event,” Anslinger said.

One of the main advantages of the IIoT and digitalization in general is that users can collect more signals and data as well as get them much more often. “With our wireless devices, we can check process or equipment status every hour. For instance, when we inject CO2 and water into wells, we can see the downhole pressure more frequently and make better decisions,” Anslinger said.

Occidental Petroleum implemented the Internet of Things (IoT) last year and began by proving its viability and value, researching available IoT platforms, determining device connections and validating how to create software containers and analytics, according to Jim Sage, IT principal for emerging technology at Occidental.

“We learned that it’s important to determine the IoT-readiness of the larger organization, so over the last year and a half, we got ready with a cloud computing that we could plug our IoT solution into. Now, we can connect edge computing devices to help control shutdown devices,” Sage said.

According to Tim White, asset management director at Valaris (formerly Ensco Rowan), “When events happen offshore, managers onshore want to know what’s happening. However, it can be risky to have calls coming in every hour, so we’ve been trying to correlate our data to better inform our rig managers, so they don’t have to call as much.”

White added that Valaris will use its increased data volume and speed to improve maintenance as well as optimize operations. “One of our big goals is condition-based maintenance, and we know the IIoT will help accomplish it as well as reduce staff and deploy ‘tiger teams’ that can manage multiple rigs,” he said.

Gary Baxter, former production operations director at EQT Corp., said the natural gas producer recently implemented IBM Maximo asset management software to help its supervisors and managers by showing production data on their PCs and smart phones. “This solution got us involved with IIoT, but we soon found that we needed 78 database revisions. We couldn’t do all of them, so we had to revise and implement Emerson’s ROC800 remote operations controller, which let us do more analytics,” he said.

Returns on digital investments

New technologies typically involve heavy capital investments and extended supply chains.

Since new innovations also face scarce funding and hesitation from higher management, executives at the upstream panel discussion said IIoT and associated new technologies must demonstrate their value quickly to gain acceptance.

“We look to see financial benefits within one year because if it’s two or three years, then it won’t get funded because everyone assumes the technology is going to change anyway,” Anslinger said. “Behavior changes with familiarity and training, so it’s crucial to show people what the IIoT can do for them, what dollars and cents they can gain and that it’s cost-effective to implement.”

In addition to returns, IIoT must also show it can ease user workloads, White said. He explained that it’s important to demonstrate the benefits of IIoT to senior management and convince them that new technologies can automate tasks and ease the workload of employees.

Adding to that, Sage explained that any effort to get potential users accustomed to the IIoT can be helpful because disruptive changes have been coming so fast. “Most changes in process control and automation have been incremental, but what’s happening now is a reallocation of people to learn the new skills needed as we transition from previous methods to those based on the IIoT. And once we connect to our edge devices, the benefits of their data will start to come in,” he said.

Recommended Reading

CERAWeek: Large Language Models Fuel Industry-wide Productivity

2024-03-21 - AI experts promote the generative advantage of using AI to handle busywork while people focus on innovations.

Cyber-informed Engineering Can Fortify OT Security

2024-03-12 - Ransomware is still a top threat in cybersecurity even as hacktivist attacks trend up, and the oil and gas sector must address both to maintain operational security.

Exclusive: Halliburton’s Frac Automation Roadmap

2024-03-06 - In this Hart Energy Exclusive, Halliburton’s William Ruhle describes the challenges and future of automating frac jobs.

Oil States’ ACTIVEHub for Digitized Assets

2024-03-14 - Oil States Energy Services’ new ACTIVEHub system and ACTIVELatch help operators remotely monitor and automate frac locations for a more efficient and safer wellsite.