Presented by:

Editor's note: This article appears in the E&P newsletter. Subscribe to the E&P newsletter here.

The oil and gas industry is on the precipice of an upcycle, with all indications pointing toward a demand-led recovery toward the end of 2022. This will require new wells to be drilled and brought online, but climate change concerns and an increased focus on capital discipline are driving a change in how the industry drills its wells. Today, operators are looking for opportunities to improve their drilling performance, predictability and consistency to achieve greater efficiency and sustainability benefits, and autonomous directional drilling (ADD) solutions can help the industry achieve these objectives.

For several years, Schlumberger has been working toward the goal of a fully autonomous drilling system. The company’s autonomous vision is built upon four pillars that include intelligent planning, intelligent execution, surface automation and downhole automation. While each pillar is key to the ultimate vision of realizing a fully autonomous drilling system, downhole automation is essential because it drives steering adjustments as conditions are encountered, representing a significant step change for the industry to steer autonomously through any section of the wellbore.

Today, downhole automation is enhancing the driller’s control of traditional rotary steerable systems (RSSs) and newer at-bit steerable systems (ABSSs), which bring the cutting structure and the steering system closer together. Without downhole automation, control of the RSS and ABSS relies on decisions made at the surface, resulting in a decision loop from surface to downhole that can add up to 20 minutes to an operation. A long control latency can create several adverse impacts on the directional drilling process, including generating downlinks on surface decisions. This requires adjusting drilling parameters, sending the RSS on an uncorrected path and deviating from the drilling plan, which can create severe tortuosity that can reduce the life of the well. Further to this, increased time on hole also contributes to increased CO2 emissions.

Technology driving downhole automation

To achieve downhole automation, an advanced and intelligent closed-loop control tool called the autonomous downhole control system (ADCS) acquires, interprets, and acts upon data to drill better wells, faster. This system performs immediate corrections, ensuring drilling trajectory accuracy, and removes data-to-surface delays to improve decision latency, resulting in greater overall directional drilling efficiency. The tool measures the exact strength of the earth’s gravitational and magnetic fields 100 times per second and corrects steering parameters each second. The ADCS includes four applications: auto-vertical, auto-tangent, auto-curve, and auto-inclination. Auto-curve, which is the latest advancement, has shown advantages of the ADCS even in the curve parts of wells. The application bundles all the steps of manual mode into a single downhole autonomous process that begins with the directional driller downlinking the dogleg severity (DLS) and toolface (TF) as required on the well plan. The ABSS or RSS receives the command downhole and alone automatically adjusts its steering force and TF to match the demanded DLS and TF.

Replacing a long surface loop time with an immediate downhole response reduces the number of downlinks needed to drill curves, and the directional drilling focus can be directed fully onto drilling efficiency, enabling better ROP. Smaller, more frequent downhole adjustments enable smoother trajectories with more consistency and repeatability.

Operators in the United States and the Middle East have used the ADCS to improve directional drilling, reduce downlinks, overcome control-loop time, and increase ROP.

Drilling curves in the Northeast Basin

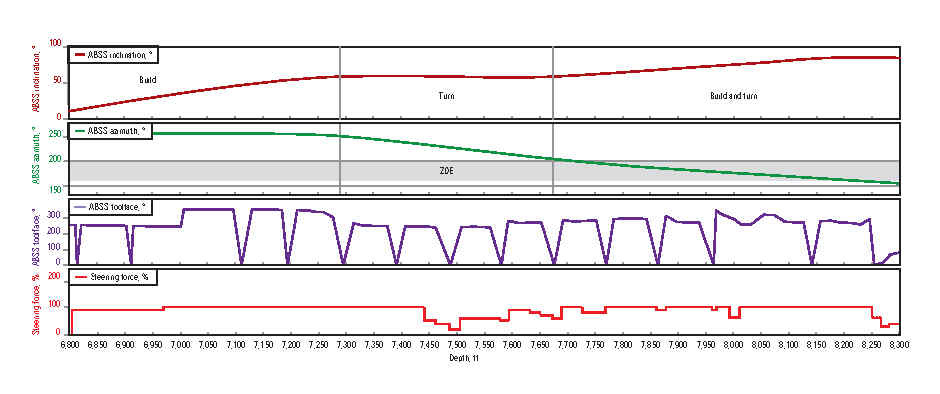

An operator in the U.S. Northeast Basin needed to drill a curve section with high-DLS severity with the compounding challenge of orienting the wells in the zone of exclusion (ZOE), a narrow north-south window with azimuths between 160° to 200° southerly and 240° to 20° northerly. The ZOE could further destabilize azimuthal headings already stressed by the formation’s inherent shock and vibration characteristics. To avoid drilling RSSs in manual mode and making multiple interventions and downlinks from the directional driller at the surface, the operator deployed NeoSteer CL* curve and lateral at-bit steerable system with ADCS to build curve and lateral sections. The capabilities bundled all the steps of manual mode sequence into a single downhole autonomous control beginning with the directional driller downlinking the DLS and TF as required in the well plan. The curve and lateral at-bit steerable system received the command downhole and automatically adjusted steering force and TF to match the demanded DLS and TF. Sensors close to the bit enabled continuous tracking of inclination and azimuth. The autonomous downhole control system used ROP data to enable the ABSS to compute its resulting DLS and TF. The tool adjusted steering parameters every second to ensure it met the designated trajectory and functioned without the need for surface control, which meant fewer downlinks and less time lost to the cycle. Frequent and small downhole adjustments minimized tortuosity compared with infrequent and violent surface control.

Compared with nearby offsets drilled in manual mode, downlinks to the NeoSteer CL ABSS were reduced 21%. The auto-curve engaged for a 10°, three-part build, proceeding all the way to horizontal landing. The curve began with a 2D build to 7,250-ft MD, followed by a 2D turn to 7,750 ft, and then a final 3D build and turn. Auto-tangent engaged and drilled to the landing point at 8,250 ft. ROP also increased 34%.

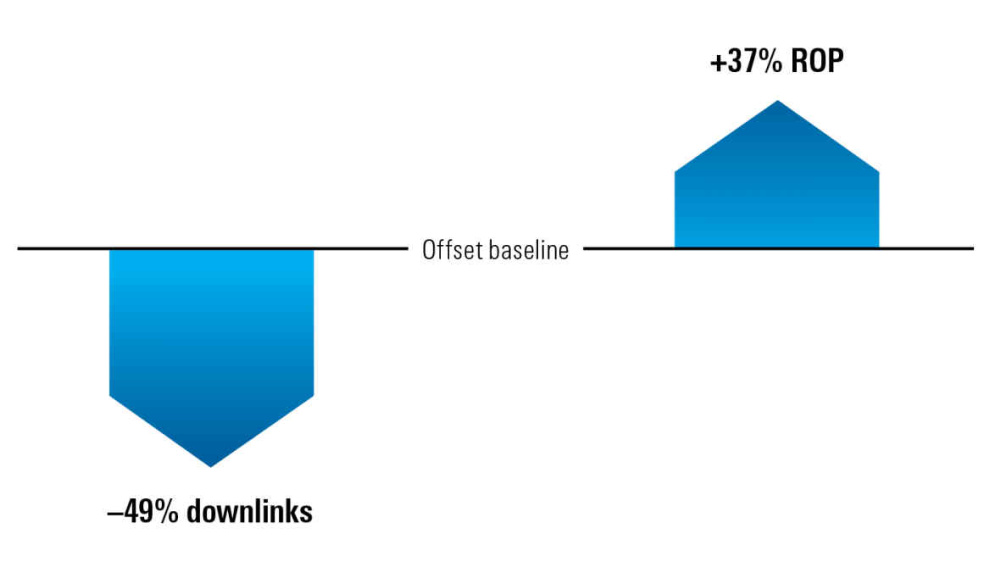

Reducing downlinks and increasing ROP in the Middle East

An operator in the Middle East wanted to avoid multiple interventions and downlinks while drilling curves using RSSs. The operator deployed a BHA with ADCS with an auto-curve component, which bundles all steps of manual mode into a single downhole autonomous control process beginning with the directional driller downlinking the DLS and TF as required on the well plan. The auto-curve capability enabled a PowerDrive Orbit G2* RSS to drill a curve in each of four wells in their respective 8 ½-in sections. Results observed across the land wells were compared with nearby offsets and curves drilled in manual mode. Downlinks to the RSS were reduced on average over 49% in each of the four wells as compared with offsets using manual mode. ROP increased an average of 37% while drilling the curves with auto-curve.

Improving performance and reducing environmental impact

With more than 26,000 ft of curves drilled in auto-curve autonomous mode, the ADCS has enabled operators across the globe to autonomously control RSS and ABSS, reduce downlinks needed to drill curves, and increase overall drilling speed. By reducing control latency, the solution enables precision to stay on plan and achieve more predictable, consistent directional results and better well economics. Compared with operating in manual mode, the ADCS builds the curve more consistently with less deviation from the plan and less tortuosity while also drilling faster to minimize drilling emissions.

Looking toward the future, as ADD solutions mature and work more closely together, they will be increasingly compatible with advanced remote operations capabilities. This will eliminate the need for engineers to travel to wellsites, reducing emissions from associated travel, housing on the rig and HSE risks—without inhibiting performance. These improvements will further help operators achieve even greater efficiency and sustainability benefits.

Recommended Reading

US Interior Department Releases Offshore Wind Lease Schedule

2024-04-24 - The U.S. Interior Department’s schedule includes up to a dozen lease sales through 2028 for offshore wind, compared to three for oil and gas lease sales through 2029.

Utah’s Ute Tribe Demands FTC Allow XCL-Altamont Deal

2024-04-24 - More than 90% of the Utah Ute tribe’s income is from energy development on its 4.5-million-acre reservation and the tribe says XCL Resources’ bid to buy Altamont Energy shouldn’t be blocked.

Mexico Presidential Hopeful Sheinbaum Emphasizes Energy Sovereignty

2024-04-24 - Claudia Sheinbaum, vying to becoming Mexico’s next president this summer, says she isn’t in favor of an absolute privatization of the energy sector but she isn’t against private investments either.

Venture Global Gets FERC Nod to Process Gas for LNG

2024-04-23 - Venture Global’s massive export terminal will change natural gas flows across the Gulf of Mexico but its Plaquemines LNG export terminal may still be years away from delivering LNG to long-term customers.

US EPA Expected to Drop Hydrogen from Power Plant Rule, Sources Say

2024-04-22 - The move reflects skepticism within the U.S. government that the technology will develop quickly enough to become a significant tool to decarbonize the electricity industry.