(Source: Junrong, Shutterstock.com)

The 2019 Society of Petroleum Engineers (SPE) Annual Technical Conference and Exhibition (ATCE) will take place Sept. 30 to Oct. 2 in Calgary, Alberta, Canada.

“ATCE is SPE’s annual meeting of members and features groundbreaking papers and special technical events designed to accelerate the application of innovations in every technical discipline,” according to the conference website. “Attendees come from around the world to ATCE to keep up with the latest technologies, industry best practices and new product launches.”

The following is a sampling of some of the latest innovations that will be showcased at ATCE this year.

Editor’s note: The copy herein is contributed from service companies and does not reflect the opinions of Hart Energy.

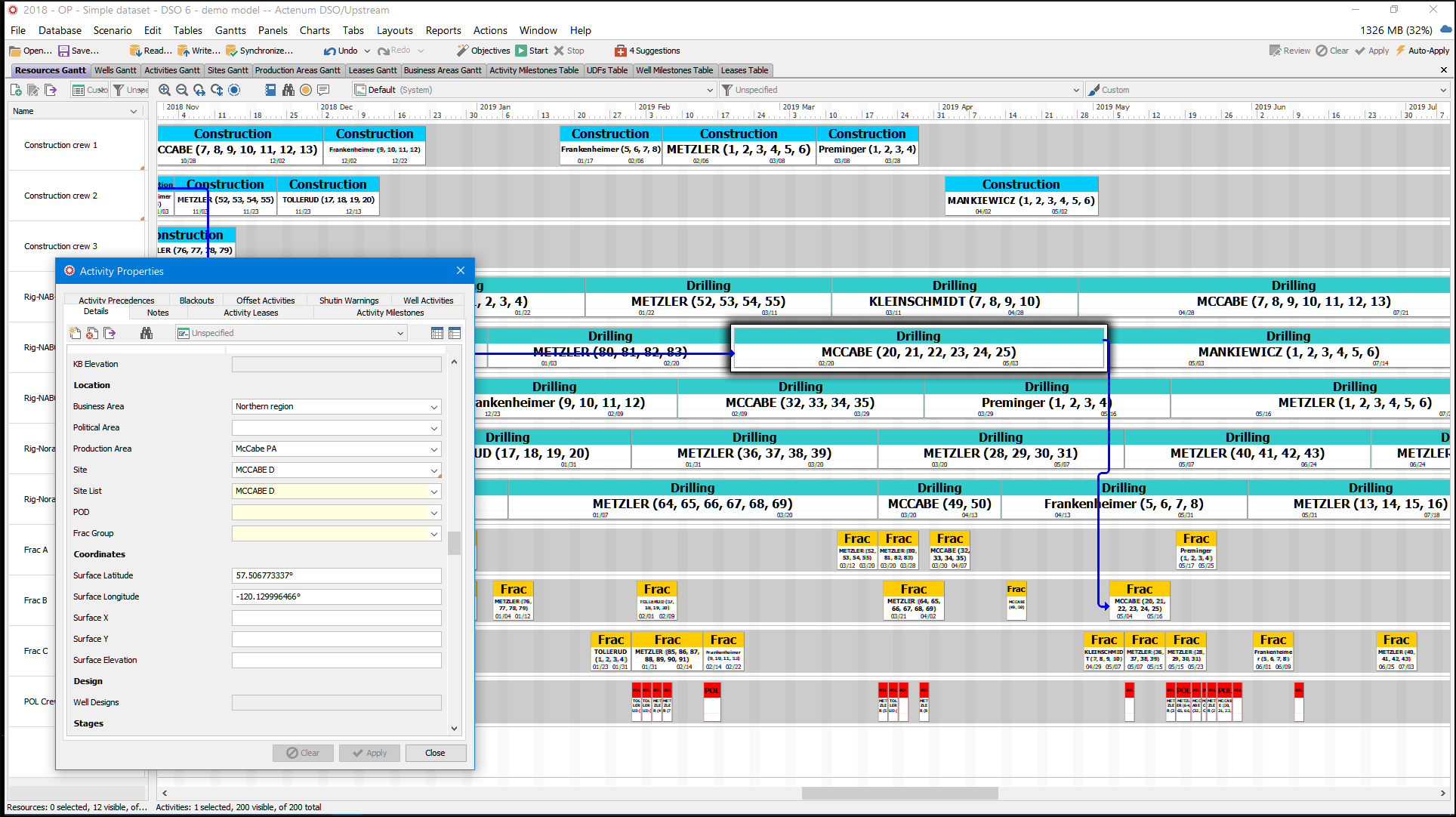

AI software builds and optimizes complex scheduling of well delivery resources

Actenum will be featuring its integrated well delivery scheduling and artificial intelligence (AI)-powered optimization software, Actenum Upstream, at ATCE. For operators, well delivery scheduling is a complex and critical process with substantial economic impact. Done well, it maximizes the efficient use of costly resources and yields substantial economic benefits. Done poorly, consequences can be severe—deferred production, cycle time delays and increased costs are but a few of the outcomes. Despite its importance—and surprisingly, in view of its complexity—well delivery scheduling is often done manually using unsophisticated software tools. Actenum Upstream uses AI to build and automatically optimize complex scheduling of well delivery resources, aligning schedules with business objectives. It overcomes the limitations of manual scheduling with capabilities that include comprehensive scheduling logic, a robust, well-based data model and teamwide schedule visualization. These tools enable operators to maximize project collaboration and efficiency, shorten cycle times, reduce risk and achieve predictable and reliable production. actenum.com

Wear-resistant plunger can withstand severe abrasive conditions

One of the challenges that rod lift systems have faced for several decades relates to plungers being dubbed the “sacrificial component” between the plunger and barrel. Plungers coated in spray metal and TUFFR have been reliable at combating this belief, but the industry needs a plunger that goes beyond current standards. Apergy’s new Harbison-Fischer UltraClad Plunger, designed with the company’s next-generation UltraClad coating, is a premium wear-resistant plunger. This extremely durable plunger can withstand severe abrasive conditions and maintain high pump efficiency for longer periods of time. The UltraClad has proven to be an improvement over conventional coatings, with UltraClad having a better wear resistance than TUFFR by a factor of 18 in laboratory abrasion tests. apergy.com

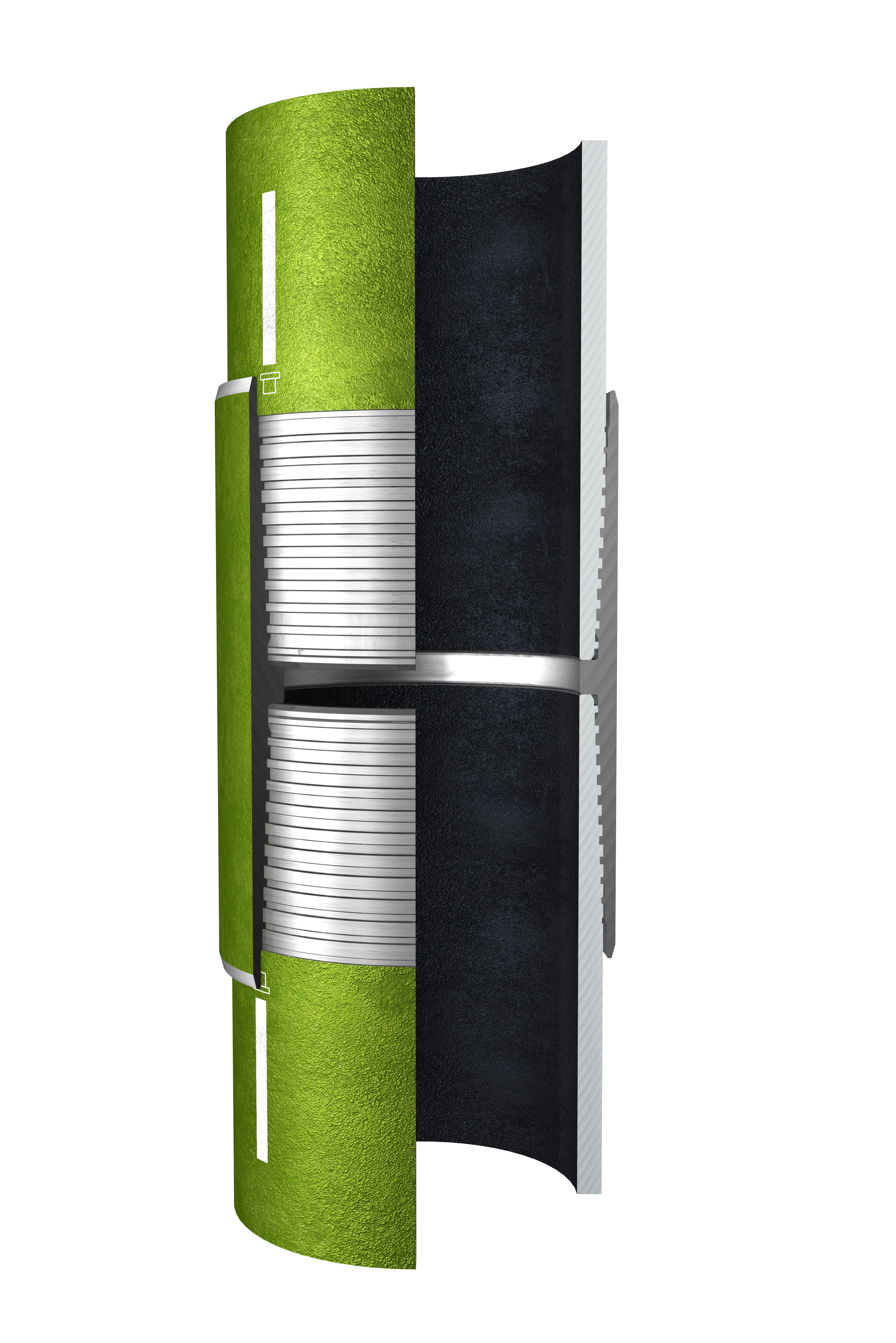

System provides a gravel and frac pack alternative

The GeoFORM conformable sand management system from Baker Hughes, a GE company (BHGE), offers an alternative to conventional sand control methods. The GeoFORM system uses a material that expands and conforms to complex well profiles, delivering a new level of sand control performance with fewer operational requirements. The GeoFORM system is run downhole like a sand screen, but it can be installed by a two-person crew and doesn’t require special pumping equipment or proppant, making it ideal for remote locations. When used in place of a gravel pack, the GeoFORM system can save one to three days of rig time per zone. The GeoFORM system’s shape memory polymer offers 3-D filtration without the complexities of pumping sand slurry. Once activated, the GeoFORM material fills the annulus, filtering sand particles and stabilizing the wellbore. Its microscopic pore structure captures a wide range of particle sizes while remaining highly porous to maximize hydrocarbon flow. bhge.com

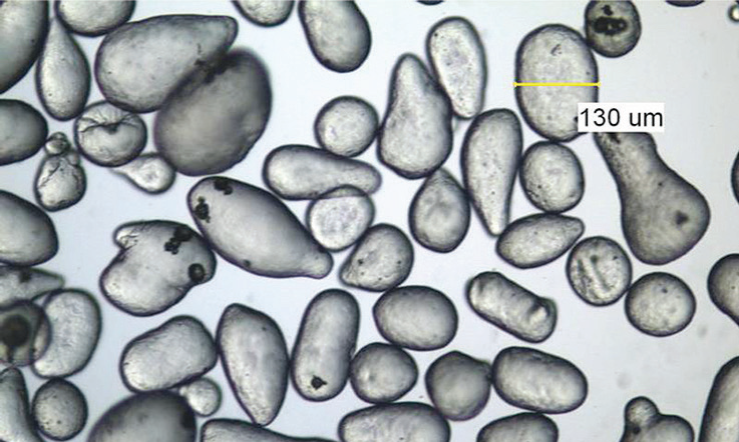

Ceramic microproppant maximizes propped contact with the reservoir

CARBO has released NANOMITE, a ceramic microproppant that is a fraction of the size of the smallest proppant commonly deployed to alleviate perforation entry issues, improve cluster fluid distribution and maximize contact with the reservoir. This results in improving stimulation efficiencies, reducing overall completion costs and improving production. NANOMITE is a cost effective, ideal solution for operators experiencing difficulty with proppant placement, elevated treatment pressure and early screenouts during treatment. Traditional proppant is too large to fit into a complex fracture network’s microfractures, and its transport characteristics limit how far it travels into the area. The smallest particles of NANOMITE C are more than five times smaller than the smallest particles in 100 mesh frac sand. This allows the particles to prop open even the narrowest secondary fractures and microfractures, resulting in an increase in overall production contribution from the reservoir matrix while lowering high surface treating pressures. carboceramics.com

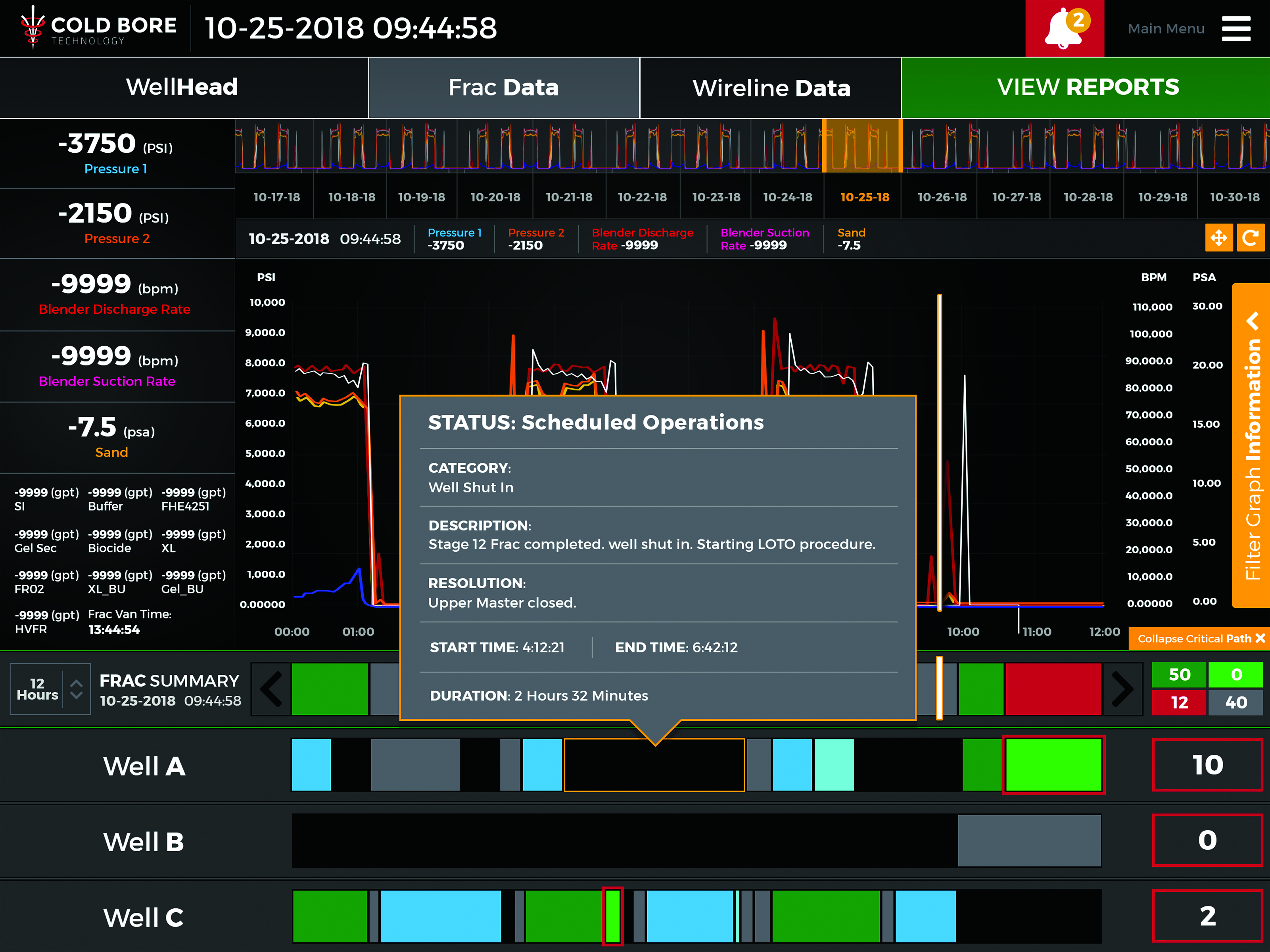

System enables real-time monitoring and analysis of multiwell pad operations

Cold Bore Technology’s SmartPAD is the first Industrial Internet of Things sensor-based, remote completions operating system that enables real-time monitoring, tracking and analysis of multiwell pad operations. It is helping operators improve their efficiency, enhance their onsite safety and reduce their overall number of frac days, resulting in costs savings of hundreds of thousands of dollars per pad. The system integrates service company data such as coil, wireline, frac, flowback and other digital data on location and couples it with sensor-driven operational data provided directly from the wellhead to generate a critical path time line. Valve positions are also displayed in real time, which is a significant safety feature. The comprehensive tracking of every minute detail of the operations provides new insight, and the instantaneous visibility of the operations has helped clients avoid serious incidents, damaged equipment and hazardous situations. coldboretechnology.com

Solution for gravel pack completions

DiverterPlus has recently developed the MicroVert+ and SolVert+ GP lines of degradable diverters specifically designed for use in wells completed with a gravel pack or other sand control completion methods. The particles exhibit a designed oblong geometry and elasticity that allows them to traverse the gravel pack and deposit on the formation face itself where they then encourage even distribution of injected fluids. The manufacturing process allows extreme control over particle size, so products are available for optimum performance in any size gravel pack. Density alteration and solvent resistant coatings allow for use in a variety of fluids, including the most aggressive asphaltene and paraffin treatments, while remaining suspended without the need for high velocity. The particles exhibit the hydrolysis behavior of DiverterPlus’ other lines of diverter, meaning that with time, temperature and the presence of water, the particles will chemically convert into a liquid form. diverterplus.com

A digital twin for every unconventional well

A new generation of physics-based models enables the attainment of a digital twin for every unconventional well. It is deployed in the cloud to monitor, process and history-match large volumes of data at “rest” (archived) and “in motion” (live data from sensors) in real time. It models the reservoir, wellbore and surface network as one entity and features artificial intelligence-boosted automated history match that refines its predictive capacity further with time. It enables production optimization throughout the connected wells’ life cycles with additional features, including production bottleneck identification, automated gas-lift optimization, virtual metering and virtual production logs. Unlike drilling and completion operations, which have recently experienced significant efficiency gains, production optimization has lagged due to the effort and time required to model production with physics-based models, hence reliance on empirical models for almost all wells. Paradigm k alleviates that with a fast and easy-to-use model specifically tailored for unconventional reservoirs. emerson.com

Technologies designed to lower costs

At this year’s ATCE, Expro will highlight CoilHose, a light well circulation system that minimizes the loss of hydrocarbon production and lowers the overall cost of intervention. The compact system is rapidly deployed, saving both time and cost over standard coiled tubing operations. It delivers a suite of wire deployed intervention options for cased-hole application, digital and standard well configuration tooling and heavy-duty fishing.

Expro also will present its new intelligent intervention technology, an autonomous wireline system for the removal of waxes, scales and other solids. This technology saves the operator significant manpower and support costs as well as minimizes the environmental impact and community disturbance with the reduction of wireline trucks.

In addition, the company will showcase its production surveillance services, which are delivered through downhole monitoring and surface multiphase measurement, helping maximize production from operators’ reservoirs, wells and assets. exprogroup.com

Identifying and assessing early-onset damage

The productivity of wells completed in shale reservoirs can be substantially improved by Flex-Chem’s OptaSTIM technology. Insoluble material capable of severely blocking flow commonly forms due to undesirable interactions between shale reservoir formations and additives in many completion fluid systems. This damage, which forms early in the production life of the wells, is associated with highly variable completion outcomes and production restrictions. At ATCE, Flex- Chem Corp. will be highlighting its strong capabilities for identifying and assessing this early-onset damage as well as technologies and methods that address a range of formations and completion designs. Remedial treatments have shown marked success restoring flow conductivity in damaged zones and a proven record increasing well productivity. flex-chem.com

Reservoir-centric full-fluid systems

Flotek will be showcasing its reservoir-centric full-fluid systems, which are built upon its Complex nano-Fluid technologies and proven to enhance and improve hydrocarbon recovery. Additionally, Flotek will present its comprehensive analyses of the effectiveness of its reservoir- centric approach across a variety of applications in oil and gas reservoirs in basins across North America, including completions, remediation, frac hits and enhanced waterflooding. Flotek’s chemistries have been used in more than 10,000 wells across every major basin in the world and are designed to address every challenge in the life cycle of the reservoir and maximize recovery in both new and mature fields. The company’s fluid systems are tailored to the reservoir to increase effective permeability, reduce formation damage and lower gasoil ratio in volatile oil reservoirs. flotekind.com

Intelligent fracturing service helps deliver uniform fluid and proppant distribution

In unconventional reservoirs, E&P companies are continually adjusting stimulation parameters in an effort to achieve more fractures per wellbore and improve well performance. Stimulating each cluster uniformly and achieving these outcomes in a timely and cost-effective manner is the challenge. Halliburton’s Prodigi intelligent fracturing service incorporates data from thousands of stages along with real-time information to help deliver uniform fluid and proppant distribution. This data-rich approach, coupled with an advanced control system architecture, enables the Prodigi service to more uniformly deliver proppant and fluid. Numerous wells instrumented with fiber-optic sensors have shown the Prodigi intelligent fracturing service helps eliminate underperforming stages. Additional benefits can include lower treating pressure, faster stage pumping times and reduced screenouts. To date, the Prodigi service has improved stimulation effectiveness on more than 4,500 stages within 12 different basins for 35 E&P companies. halliburton.com

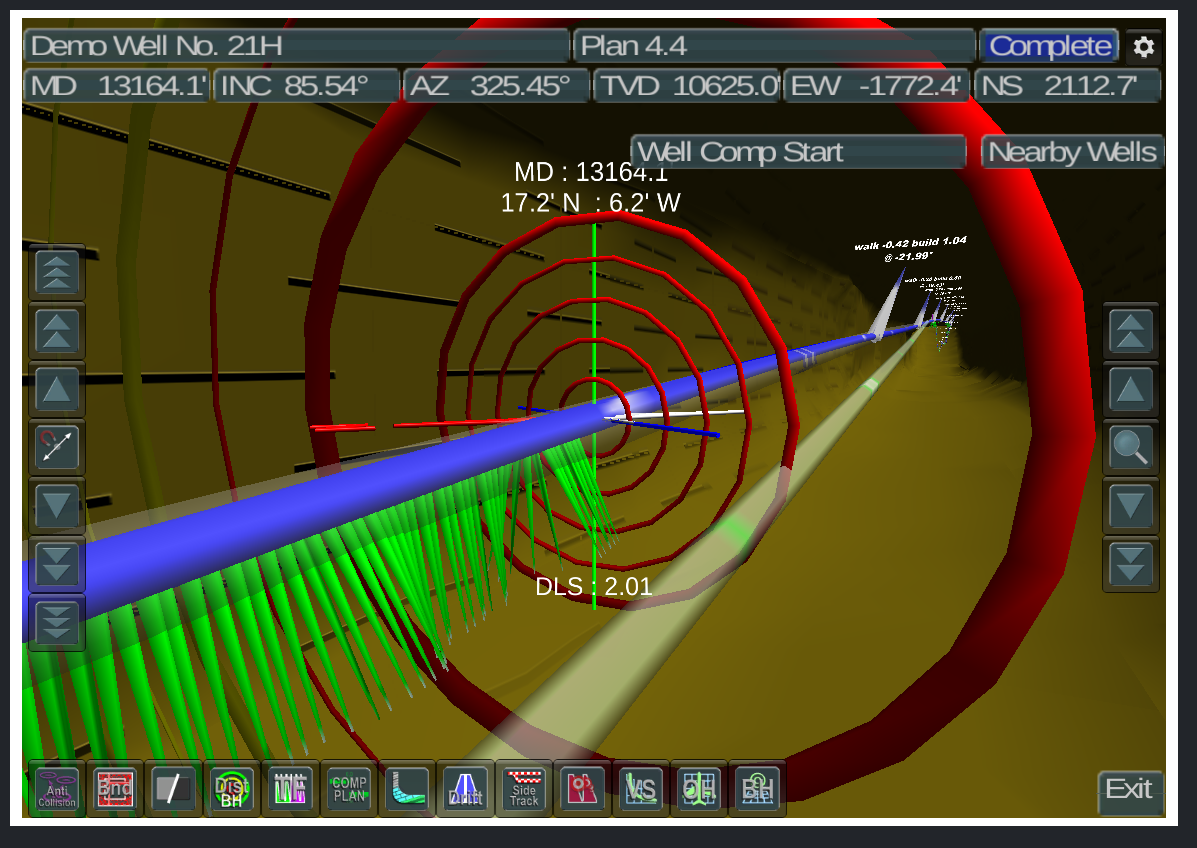

Directional drilling system automates decision-making and execution

Helmerich & Payne Technologies will be showcasing an automated directional drilling solution following a systematic, logical, phased approach to automating both directional drilling decision-making and the execution of slides. Attempting to follow a predefined path, even the best, most experienced drillers struggle to properly compensate for multiple variables including motor yield variations, target uncertainty, deflections, tortuosity risks and more. Slide execution has historically been more of an art form than a science; automating this process combines the two. The system processes a higher volume of data in a faster amount of time, allowing for continuous realtime improvement with additional analysis not possible by a human alone. Automating both the decision-making and the execution leads to reduced drilling costs, safer and more consistent operations, higher hydrocarbon production potential and improved wellbore quality. On the pathway to autonomous drilling, automated sliding is a crucial building block as part of a holistic approach fleetwide. hpinc.com

Technology reduces the production of formation water

Hexion’s AquaBond technology reduces the production of formation water while improving oil and gas production. It increases well profitability by reducing formation water management costs. Its chemistry is bonded to proppant and remains in place and effective for the life of the well. A recent case study in the San Andres Formation showed positive results utilizing just a 16.5% tail in of 20/40 mesh proppants using the technology. Formation water production was reduced by 15%, while oil production increased by 28% compared to offset wells. In the Granite Wash, wells utilizing AquaBond technology with 40/70 mesh proppants realized a reduction of formation water by more than 43% compared to offset wells. Additionally, the average cumulative barrel of oil equivalent was more than 40% higher. hexion.com

7.5-in. perforating gun fires up to three shots on a single plane

Hunting’s H-2 Perforating System has eliminated common surface handling inefficiencies and downhole challenges that the oil field is faced with while maintaining the highest performance standards. The H-2 is the shortest perforating gun in the oil field. At just 7.5 in. in length, the H-2 can fire up to three shots on a single plane and requires no wiring or detonating cord. H-2 is ideal for perforating with high cluster count per stage where rig height is limited. In a recent Delaware Basin field trial with a major operator, H-2 set a record for the number of multiple-shot perforating guns pumped down into a horizontal well on wireline. H-2 was utilized to successfully run 45 perforating guns, in conjunction with a plug, in a single run. hunting-intl.com

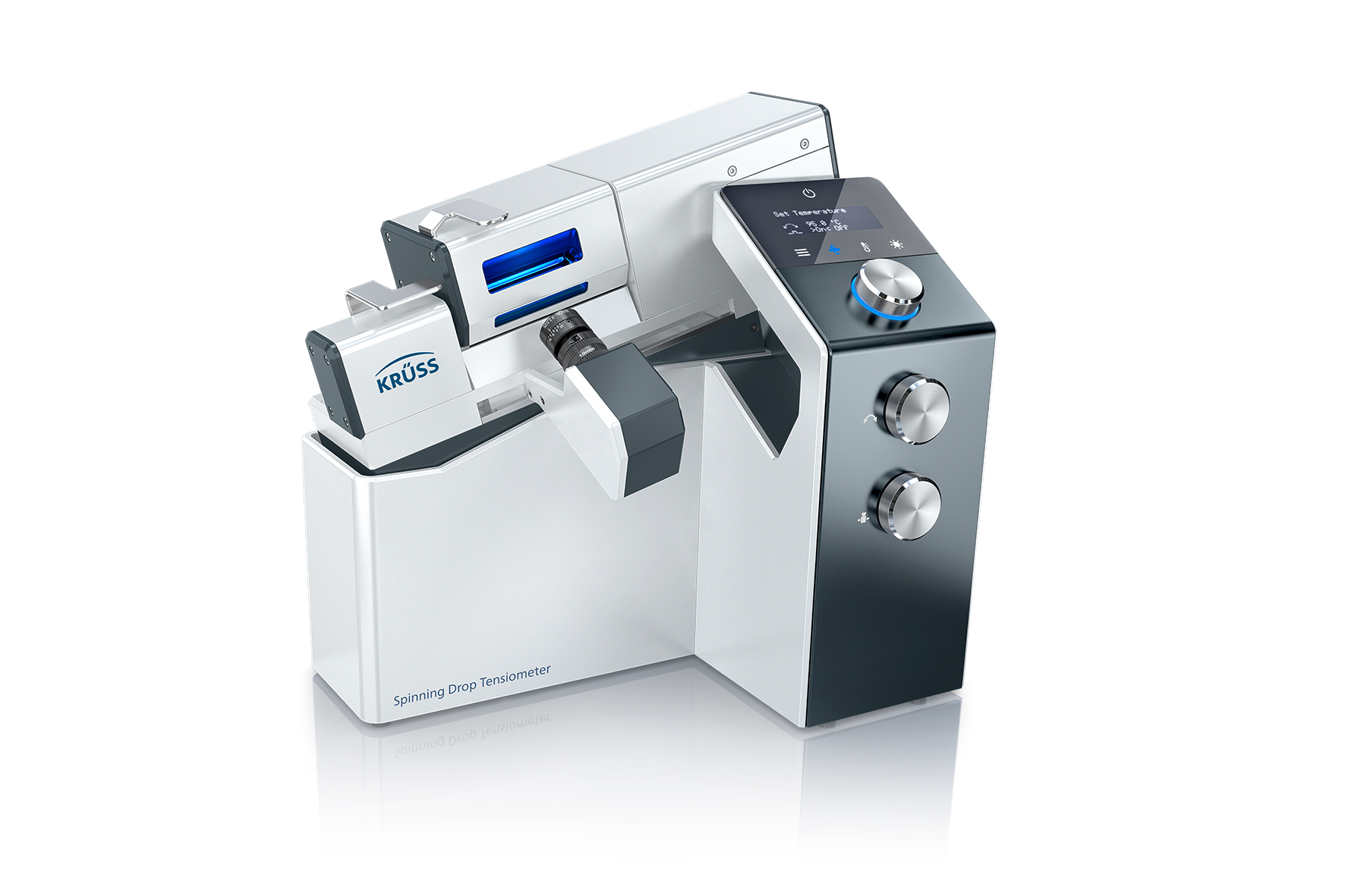

Tool analyzes interfacial behaviors of mini and microemulsions

KRUSS Scientific’s Spinning Drop Tensiometer (SDT) instrument is the ideal solution for the quality control and development of emulsions and surfactants, as it easily analyzes the interfacial behaviors of mini and microemulsions. It is commonly used in the petroleum industry where it is essential to measure extremely low interfacial tensions, such as in EOR processes. Unlike older instrumentation, the SDT has significantly reduced the laborious sample preparation experience through newly patented accessories. And paired with the ADVANCE software, the instrument can be automatically controlled and utilizes prepared and easily adaptable templates. kruss-scientific.com

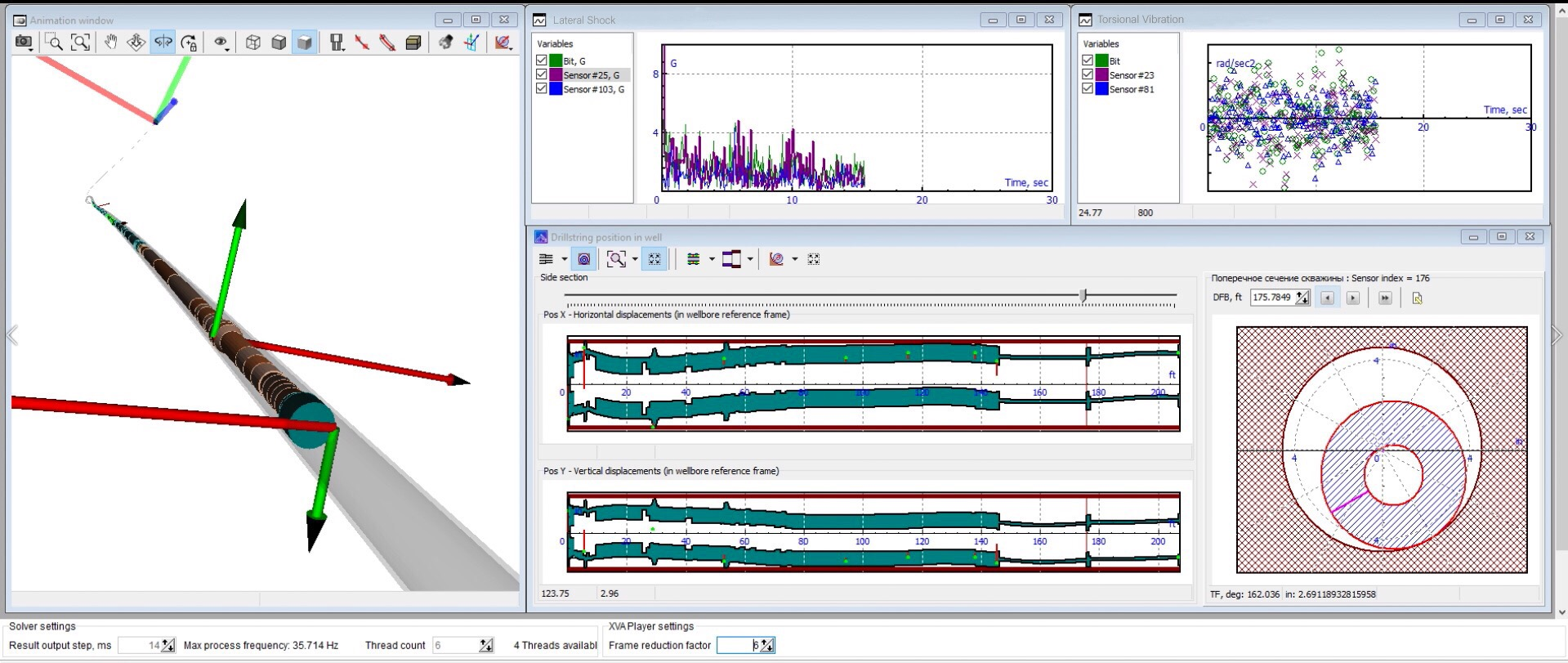

Digital well engineering platform

RiMo is a digital engineering platform that consumes critical data and leverages artificial intelligence (AI) and machine learning driven-data visualization to develop unique solutions to service companies and operators alike. MindMesh has successfully unlocked and combined physics and mathematical modeling to deep machine learning principles to create digital twins that quickly can enable companies to run more efficiently, safer and economical. The company’s drillstring dynamics functionality allows drilling engineers to leverage analysis for static, directional tendencies, critical speed and, most importantly, time-domain analysis. The RiMo well engineering platform can use be used for the design of soft and stiff string and hydraulics. Mind- Mesh’s workflow process has enabled companies that are in any stage of building their team. mindmeshtech.com

Fluid with a high degree of emulsion stability overcomes drilling problems

Conventional water-based drilling fluids have simple formulations and at first glance appear to keep drilling fluid costs low. However, when using a closed-loop system, the costs of water supply and hauling excess fluid significantly increases fluid management costs. The standard method to manage fluid volume cannot be applied while drilling through salt because it causes extreme washout of the formation due to reduced salinity levels. Significant water flow or lost circulation events also require various density changes. M-I SWACO, a Schlumberger company, developed the FluxDril direct emulsion fluid to meet the requirements for drilling a gauge wellbore and handle high amounts of drilled solids while maintaining ROP. This fluid provides a high degree of emulsion stability and overcomes the typical drilling-related problems encountered: salt formations, water flows, sour gas and mud losses in depleted formations. The FluxDril fluid also has the ability to recover a significant portion of the emulsified base oil, which reduces the associated drilling fluid cost. slb.com/fluxdril

PLA resins produced in various grades, optimized for a range of applications

While polylactide (PLA) polymers, a bio-based and degradable thermoplastic, have been used for more than a decade as a diverter to enhance fracture stimulation, it has only been in the last few years that materials science and best practices have begun to reduce the guesswork in diverter application. It is now possible to achieve predictable oil and gas production enhancements in well after well using degradable PLA diverters. NatureWorks PLA resins sold under the brand name Ingeo are produced in various grades optimized for a wide range of consumer and industrial applications. Using the toolbox of lactide monomers available, NatureWorks fine-tunes the rate of degradation of PLA grades to provide the desired downhole performance over the 49 C to 149 C (120 F to 300 F) temperature range. At ATCE, NatureWorks will be featuring its latest solution, DH1000, which is for lower temperature wells, as well as showcasing additional shape, size and grade solutions for utmost well stimulation. natureworksllc.com

Stimulation and completion fluids designed to enhance performance

Newpark Fluids Systems will introduce its expanded portfolio of stimulation and completion fluids at ATCE. In addition to drilling fluids, Newpark will now enhance operation performance, safety and efficiencies with new completion and stimulation fluids. Tim Armand, president, North America, at Newpark Fluids Systems, said, “Our goal is to allow oil and gas companies to conquer the most challenging environments with faster, safer and cleaner results.” Newpark also will feature its hydraulics modeling software that provides customers with a simulated analysis of a given fluid product and tests how well it performs within a particular environment, saving time and resources. newpark.com

AI for oil and gas

In an environment of prolonged volatility and price compression, unconventional operators are focused on optimizing field development economics. OAG Analytics is a software suite that enables collaborative, data-driven optimization for some of the most expensive decisions in the upstream life cycle, including well spacing, sequencing and landing zone. Addressing the criticality of data quality, OAG Data Manager ensures the right data are ready for analysis by breaking down data silos and providing quality control for a cross-discipline master database. Out of the box, OAG provides artificial intelligence (AI) applications to predict missing rock properties, optimize a section, perform predictive maintenance and frac hit feature engineering. In addition, data scientists and subject matter experts are able to create and share applications specific to a program with in-house developed algorithms. OAG can optimize well spacing, quantify geo parameter impact on production and integrate to Spotfire. oaganalytics.com

Ball-activated steam valve enhances SAGD completions

Installing steam valves along the tubing string in steamassisted gravity drainage (SAGD) completions improves steam distribution along the lateral for uniform reservoir coverage. The Packers Plus Inferno Ball-Activated Steam Valve builds on this enhancement by eliminating the need to use coiled tubing (CT) to open the valves, saving time and cost during completion operations. The Inferno Ball-Activated Steam Valve is installed in the closed position and the sleeves are initially shifted using degradable actuation balls. By using actuation balls, the well does not have to be killed—which unnecessarily cools the reservoir—to activate the valves. Following sleeve activation, the ball is then pumped out into the liner where it degrades. The ball-activated steam valves can be closed and reopened multiple times using a shifting tool. Packers Plus collaborated with an operator to deploy the Inferno Ball Activated Steam Valve in Alberta’s oil sands, and after three consecutive successful field trial runs, the operator has installed the valves in seven additional wells. packersplus.com

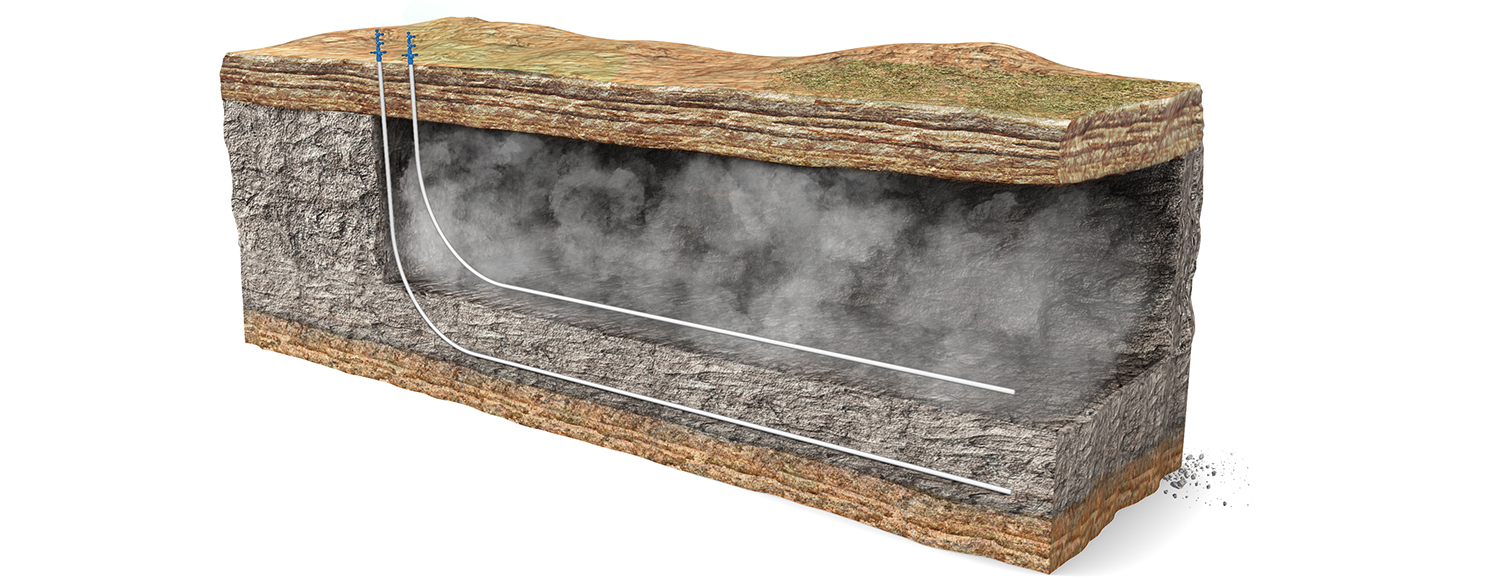

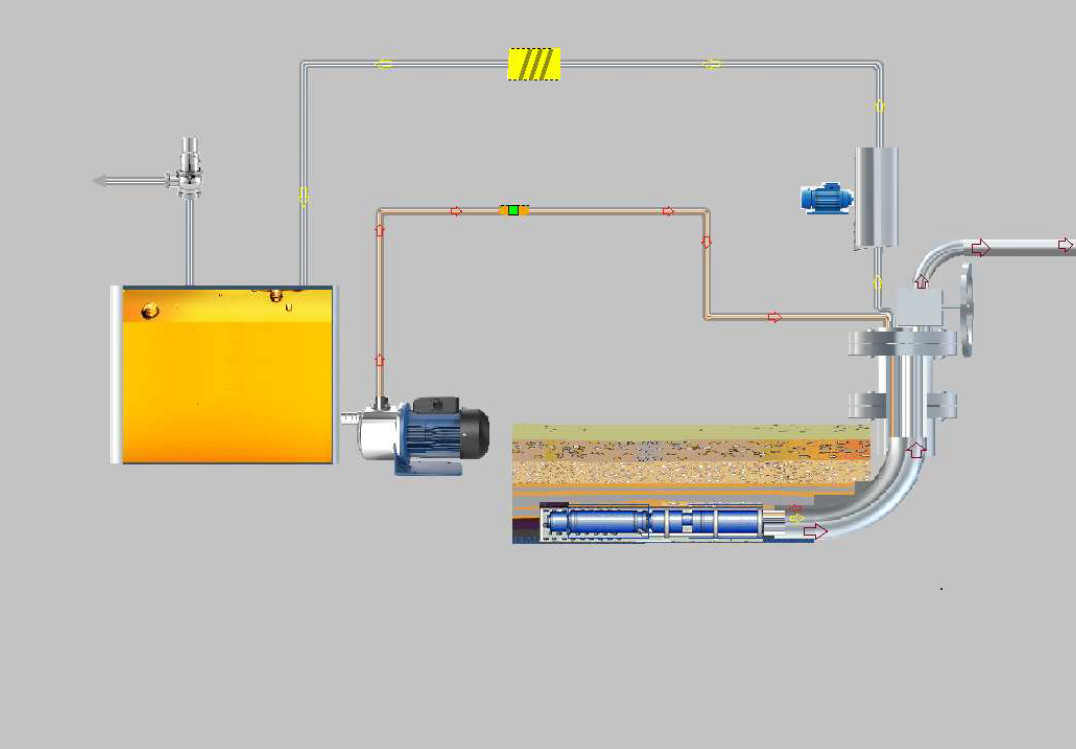

Pump system improves production in vertical, deviated and horizontal oil wells

PMC Pumps Canada Inc. has developed a hydraulically actuated positive displacement pump system to improve production in vertical, deviated and horizontal oil wells. The system can pump at least four times as much liquid as same-sized rod pumps if running at the same strokes per minute. Unlike rod pumps, the PMC pump system can produce liquids at constant flow with little wellbore pressure fluctuation. The PMC pumps do not need rodstring, so they eliminate rod wear-out and reduce sand production. This pump can be used in high-temperature environments with large production steam-assisted gravity drainage wells in Alberta, Canada. Compared with electric submersible pumps, its slow speed and elimination of downhole electric motor increase mechanical reliability and energy efficiency, resulting in longer run time. In addition, such a pump will not have gas lock damage. This pump system will be running and demonstrated during ATCE in a simulated pump test facility in Calgary with pump flow of 600 bbl/d to 4,000 bbl/d, operating at pressures up to 10 MPag and temperatures up to 220 C (428 F). pmcpump.com

A mini separator system simplifies sampling

Solids can impact a number of areas with regard to flow assurance and production chemistry, including stabilizing emulsions and limiting the ability to inject water due to the increased blocking of pores. They also can impact the amount of oil in overboard water and erode pipework and valves. Sampling is vital for learning what solids are being produced and in what quantities. At ATCE, Proserv will discuss its capabilities for addressing the production of solids and will highlight solutions including its subsea solid filtration sampling and handheld solid sampling filtration units. Proserv’s sampling team also will be emphasizing its topside filtration trolleys, which enable safe and consistent sampling at the wellhead and flowlines, upstream of first stage separation for water chemistry, sand and solid loading, and hydrocarbon composition, all simultaneously. The trolleys minimize production deferment and exposure to toxic gases. proserv.com

Technology allows users to forecast wells, create type curves and value properties

Q Engineering will be showcasing its TypecurveStudio application and its latest release, BasinStudio, at ATCE. Q Engineering addresses processing limitations to unconventional reservoir engineering workflows by harnessing the power of Amazon Web Services. By unlocking cloud computing, Q Engineering has created fast and reliable forecasts of production data. This allows engineers and analysts to forecast wells, create type curves and value properties most efficiently. In an industry that faces Big Data limitations, Q Engineering strives to address these issues to allow users to forecast entire basins at a time to gain the most competitive operator intelligence in any area of interest. This technology allows users to make the most informed decisions in a particular play in the least amount of time. q.engineering

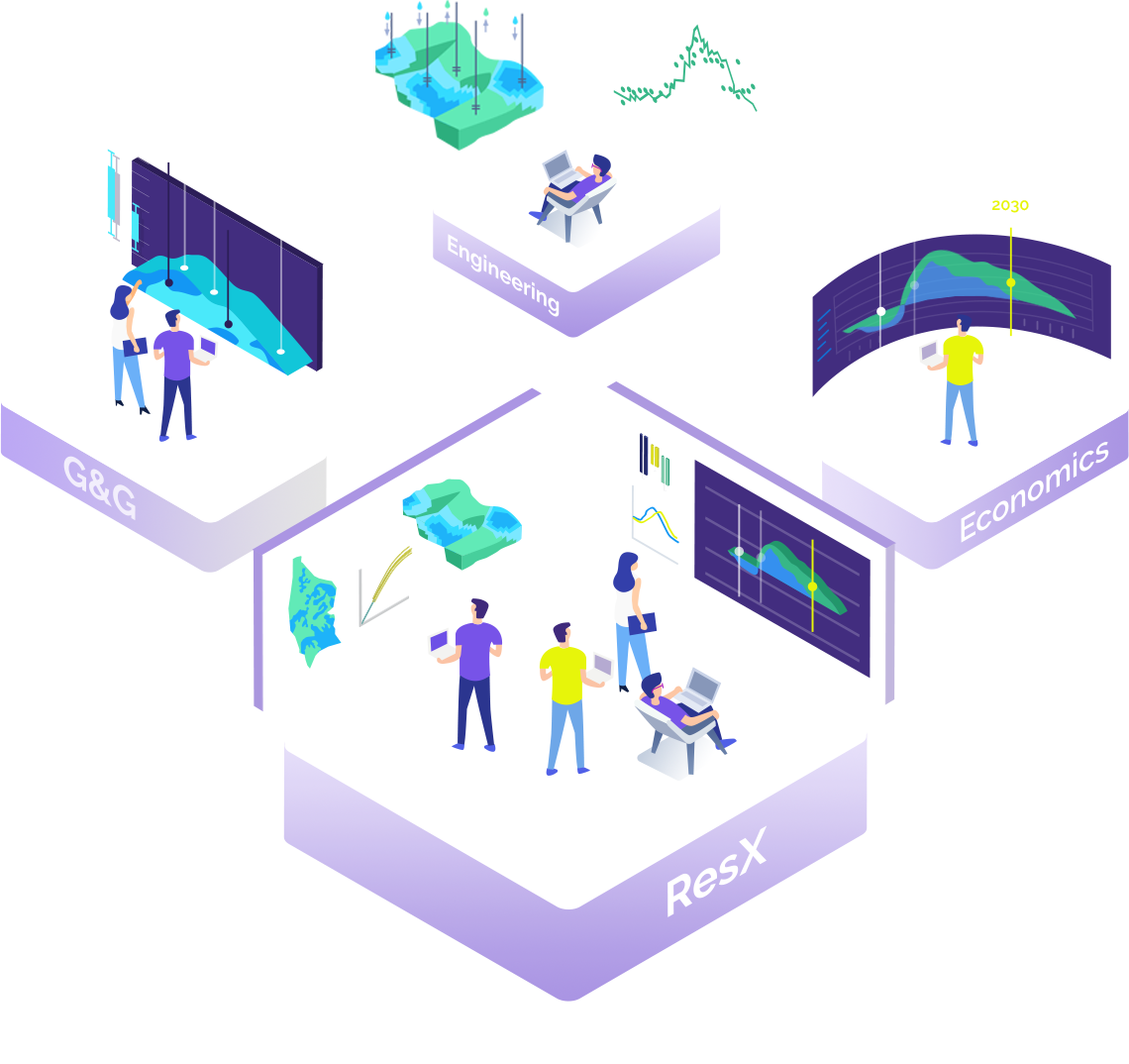

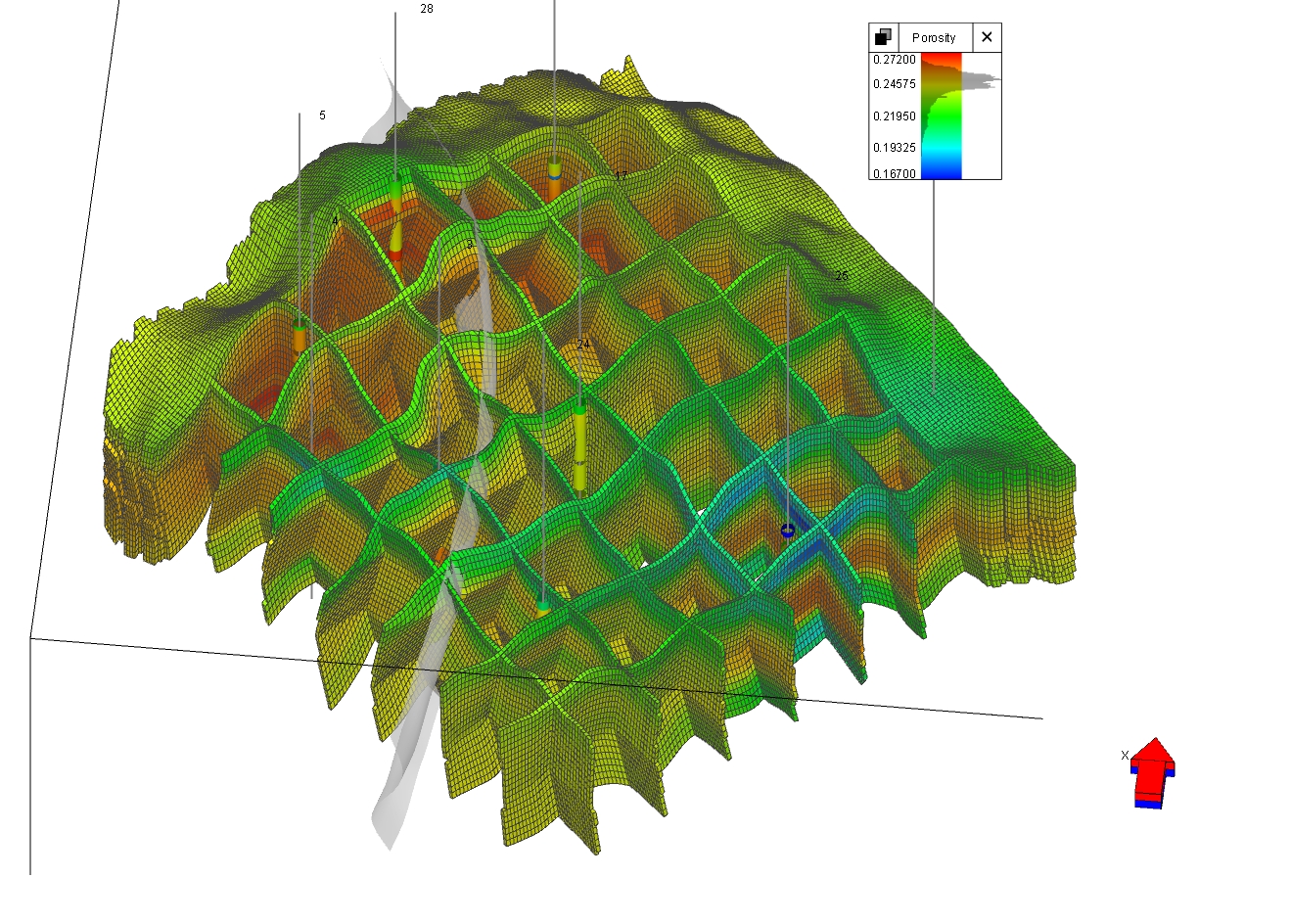

Evaluate subsurface uncertainty

Resoptima removes the traditional limitations of reservoir modeling by unlocking the power of data to evaluate subsurface uncertainty. The company’s vision is that there is not just one view of the subsurface. The company’s technology is based on a methodology that enables geoscientists and engineers to continually create and recreate geological and reservoir models by testing uncertainties and assimilating them to collected data. Resoptima’s ensemble-based solution orchestrates static and dynamic modeling processes, bringing in all data to let users create, evaluate and reevaluate the reservoir in all the complexity a user sees. Powered by Resoptima technology, subsurface uncertainty is transformed by data and physics into actionable insights and measurable value. resoptima.com

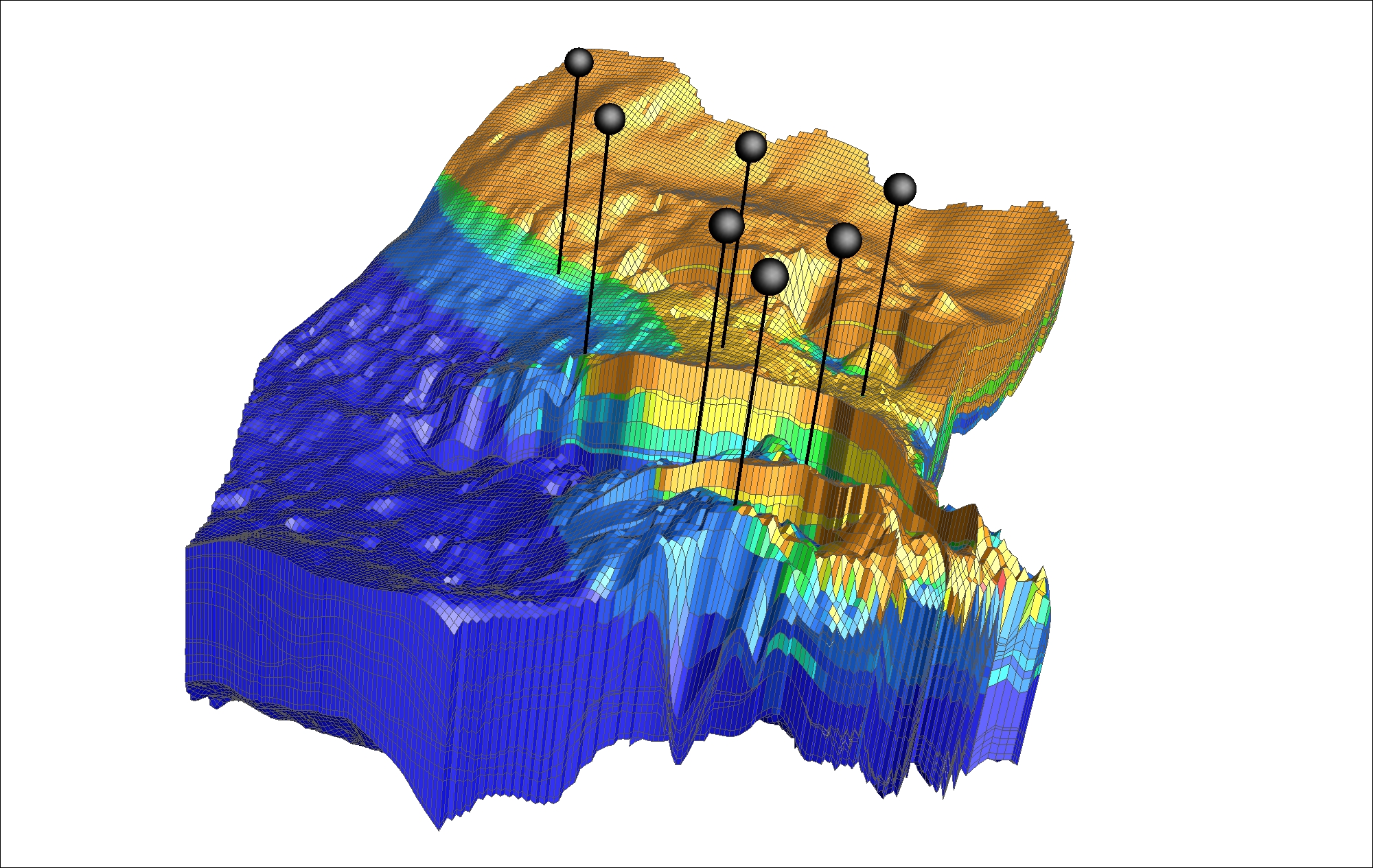

Tool for integrated static and dynamic modeling from reservoir to surface networks

Rock Flow Dynamics’ comprehensive reservoir management solution, tNavigator, is a single program covering seismic interpretation, well correlation, geological modeling, fluid characterization, well modeling, reservoir simulation and surface network design. The program creates value for both conventional and unconventional assets. This means users deal with only one interface and only one point of data entry. This avoids extra work and makes learning easier. In addition, workflows can be put under the control of tNavigator’s optimization and uncertainty engine. These workflows can improve understanding of the interactions between the individual elements of the workflow. As an example, the impact of uncertainty in seismic velocity modeling on water handling capacity can be determined easily in a single workflow in the same program using robust physics quickly. Answers to this question on water handling capacity can help to avoid the need for expensive retrofitting of surface facilities. rfdyn.com

Accelerate workflows with a cloud-based technology platform

RS Energy Group (RSEG) provides a high-speed, scalable and adaptive software platform called RS Prism. This technology enables faster data processing and can run analytical queries on billions of rows of data in milliseconds rather than hours or days, uncovering patterns and hidden insights for rapid analysis and decision-making. The comprehensive and accurate assessment of RSEG clients’ most critical strategies—involving operational optimization, evaluating potential acquisition targets, competitor surveillance, benchmarking and other key capital allocation decisions—can be performed in seconds. All RSEG solutions reside in this single platform. RSEG’s solutions combine public operational, financial and geological data with 20 years of RSEG’s intellectual property (IP), advanced analytics and applied data science/machine learning models. The merging of this technology and RSEG’s analytics/IP allows RSEG clients to streamline their daily workflows across asset teams, strategy and planning, investor relations, executive management and others. rseg.com

Improving flowability of crude oil below its wax appearance temperature

At ATCE, Sasol will be presenting its non-ionic surfactants (SPE-195894 paper), which can be included in paraffin treatment formulations for rheology modification of crude oils. The latter helps to control flow assurance issues caused by paraffin wax, a widespread phenomenon costing the petroleum industry billions of dollars yearly. Unlike traditional paraffin inhibitors, which are more effective against low molecular weight waxes, Sasol’s surfactants target the high molecular weight paraffin chains that can negatively impact pour point, gel strength and wax appearance temperature. The effectiveness of Sasol’s new chemistry in reducing the deposition of high carbon chain paraffin is an important advantage and represents a significant contribution toward cost-effectively managing a significant industry problem. sasol.com

Rise of the robots: enhancing operational efficiency while reducing risk and costs

Robots, science fiction’s go-to, no longer represent the frontiers of automation. The future is now, as Saudi Aramco harnesses robotics as a foundational element of the company’s digitalization strategy, able to capture and process data and make asset management more efficient in extreme conditions. Developed by Aramco’s Research & Development Center, the Shallow Water Inspection and Monitoring Robot, or SWIM-R, is equipped with sensors to conduct visual underwater pipeline inspections, clean marine life growth with a water jet and take ultrasonic thickness readings and cathodic protection voltage measurements in up to 10-m (33-ft) depth. The compact robot easily circumvents physical hazards that can limit a diver’s access; it also can navigate currents and crawl along the seabed. The only robot of its kind, SWIM-R has 10 patents and has been licensed for global commercialization. saudiaramco.com

Get answers about reservoir model behavior in just a few mouse clicks

In a world as technically intricate as the oil and gas industry—when billions of dollars of revenue are on the line—reservoir engineers must be confident that they have predicted the behavior of complex systems with reasonable accuracy. Experts in the field of reservoir behavior analysis are frequently asked to compare reservoir simulation datasets of a single oil field, interpret those data and determine whether the projections are reasonable or make recommendations

on a plan of recovery. The results are complex and diverse, making it difficult to compare and validate results with reasonable accuracy. Tecplot RS is a reservoir simulation visualization and analysis tool for oil and gas reservoir modeling that is able to load data from many different sources. The program supports all major reservoir simulators and has streamlined “Smart View” processes to get reservoir engineers their answers in just a few mouse clicks. tecplot.com

Extreme torque solution for longer laterals

West Canadian operators are focused on gaining efficiencies in their operations, as lateral wells are getting longer and directional drilling is becoming more challenging. Tenaris offers its new threaded and coupled Tenaris-Hydril Wedge XP 2.0 connection to cover these encounters. As part of the TenarisHydril Wedge series, the Wedge XP 2.0 provides exceptional over-torque performance achieved by the robustness of the Wedge thread design and a pin-to-pin backup mechanism. In unconventional operations, this new generation of semi-premium connections has demonstrated its ability to reduce running times, decrease connection rejects rates and decrease the risk of pipe stuck in a hole, while optimizing performance. This case will demonstrate real field experience of how the Tenaris-Hydril Wedge XP 2.0 connection delivered under very demanding well conditions. When combined with the company’s direct mill-to-well solution, Rig Direct services, customers receive streamlined logistics, further enhancing supply chain management, technical and field services. tenaris.com

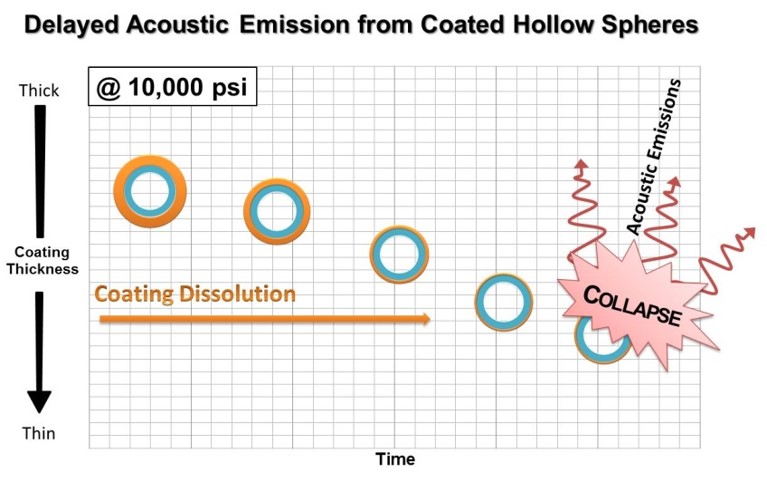

Mapping proppant reduces risks associated with completion and production

Terves’ VisionFrax is a proppant mimicking pumpable acoustic emitter with time-controlled signal generation. Once in situ and exposed to specific downhole conditions, this lightweight proppant exerts an audible signal in response to time, fracture closing or critical stresses. VisionFrax acoustic emission pops providing a signal for sensitive downhole acoustic sensors, enabling mapping of stimulated fracture and proppant placement after the pumping operation. This signal is capable of being received through hydraulic pathways and ultimately allows the completions organization to accurately map the penetration and location of this proppant throughout their frac cavity. VisionFrax is tailored to match pumped proppant and well conditions for a controlled signaling window after well stimulation. VisonFrax is a commercially available product that is made in the U.S. and is being field tested by several customers. tervesinc.com

Offerings for produced water transfer, de-sanding, treatment and recycling

Shale operations are dealing with higher water management costs and more environmental and operational risks than ever before, both of which are becoming an increasingly larger part of operators’ costs. Sourcing freshwater and increasing volumes of sand flowback and produced water, which are often trucked out and disposed of, are the primary cause. Addressing these challenges in an environmentally responsible way frequently requires adding more services and personnel at each site. TETRA Technologies’ water management solution delivers differentiating offerings for produced water transfer, de-sanding and on-the-fly water treatment and recycling. By integrating and automating the company’s offerings, efficiency is maximized through job planning and crew optimization, helping reduce manpower for a typical fully integrated completion operation by more than 30%. The step change in efficiency is delivered through fully automated technology that provides greater transparency and quality control throughout the transfer, flowback and recycling of produced water—all while simultaneously improving environmental considerations. tetratec.com/water

Machine learning technology for well curve prediction

Analytics Ready LAS (ARLAS) uses machine learning algorithms to fill in gaps in log curves and calculate the curve response of missing log runs. With as little as one curve, ARLAS can predict an entire quad-combo suite allowing users to see data where they didn’t exist before. Machine learning technology benefits significantly with access to large amounts of sample or training data, and TGS has the largest commercial library in the world from which to learn. Machine learning models improve and data outputs achieve higher accuracies with each iteration. ARLAS accuracy is well above 90% due to more than 75 different machine learning models calibrated for each basin with TGS’ vast data library. For example, TGS has more than 316,000 LAS immediately available in the Permian Basin alone, seven times more than other providers. This results in high-quality predicted quad-combo suites across the entire basin. tgs.com

Diverter technology reduces the total number of bridge plugs within a wellbore

SlicFrac is Thru Tubing Solutions’ diverter technology that allows operators to reduce the total number of bridge plugs within a wellbore while maintaining the advantages of closer stage spacing and adding additional clusters. The risk of a preset plug can be drastically reduced, along with pump downtime, completion cost and resources associated for the corresponding wireline runs and subsequent mill-out work. Applying SlicFrac diversion technology between bridge plugs allows the operator to achieve maximum cluster efficiency while stimulating the entire stage, without leaving orphan clusters behind. This ensures a more consistent stimulation volume pumped into each perforation cluster, ultimately providing a more balanced treatment and reducing the probability of a runaway frac, which could potentially damage offset wells. thrutubing.com

Organic oil recovery

The Titan Process alters production declines and releases and recovers trapped oil by uniquely creating micro-oil droplets that can move through the tight reservoir rock spaces and be recovered. The process is low cost, requires no capital expense and is biodegradable. The company’s breakthrough technology (creating micro-oil droplets) is based on a nutrient formula custom- made for each oil field, and this formula activates the biology of the reservoir. The Titan Process has been applied to 48 oil fields on four continents with 340 well applications. Four peer-reviewed SPE papers confirmed more than 200% production increases from 24 commercial well pilots. The Titan Process addresses production declines, trapped oil, increases recovery factor and decreases H2S. titanoilrecovery.com

Downhole automation increases efficiency

An increasing number of wells in U.S. Permian fields are being drilled using the Tomax AST tool. The tool provides automation through a simple, downhole algorithm that balances the depth of cut versus the rate of change in reactive torque. The nominal results are 40% faster ROP and almost double footage. Reaction time is the key to explain this huge improvement. The AST stabilizes the cut within 20 ms. That is very fast compared to the minutes it takes to tune the drilling parameters upon alerts from the MWD system or other warnings. The prevention of system excitation through the fast reaction time almost eliminates peak loads and thus overheating of the PDC cutting edges. The cutting edges have an obvious effect on both speed and footage. An additional benefit is reduced vibration and risk of damages to other tools in the downhole suite. tomax.no

Technology provides efficiency of up to 96%

WAGO’s new Pro 2 Power Supply Series is the new industry communication and parameterization standard. With six power supply units ranging from 120 W to 960 W, the Pro 2 Series provides an efficiency of up to 96%. These new power supplies permit easy fieldbus connection via modular type communication modules and incorporate an interface that can be tailored to any application. With combined exceptional highpower density with excellent efficiency, the Pro 2 Series has performance-enhancing Top-Boost, which delivers 600% extra output current and a PowerBoost that provides an additional 150% output current for 5 seconds. The high power density of the WAGO Power Supply Pro 2 allows significant space savings in the control cabinet. The digital twin concept saves time and money from the very beginning—from planning to installation to operation—over the course of many years. wago.com/us

Microproppant provides uplift and a reduced decline rate in shale

Zeeopheres Ceramics LLC’s Deeprop 1000 is a strong, perfectly spherical microproppant made in the U.S. that is used to support dilated secondary fractures created in shale during the hydraulic fracturing process. The material is designed to provide long-term conductivity in fractures that are 10 times smaller than 100 mesh can penetrate. It has no closure pressure or temperature limits. The economic benefits of utilizing this small proppant in both oil and gas wells have been demonstrated utilizing production data from several different rock systems including the Barnett, Woodford, Utica and Permian Basin shales. Several additional operational benefits including reduced pumping pressures and far-field diversion to prevent frac hits have been reported by the E&P companies that have used Deeprop 1000.

Recommended Reading

BP Restructures, Reduces Executive Team to 10

2024-04-18 - BP said the organizational changes will reduce duplication and reporting line complexity.

Matador Resources Announces Quarterly Cash Dividend

2024-04-18 - Matador Resources’ dividend is payable on June 7 to shareholders of record by May 17.

EQT Declares Quarterly Dividend

2024-04-18 - EQT Corp.’s dividend is payable June 1 to shareholders of record by May 8.

Daniel Berenbaum Joins Bloom Energy as CFO

2024-04-17 - Berenbaum succeeds CFO Greg Cameron, who is staying with Bloom until mid-May to facilitate the transition.

Equinor Releases Overview of Share Buyback Program

2024-04-17 - Equinor said the maximum shares to be repurchased is 16.8 million, of which up to 7.4 million shares can be acquired until May 15 and up to 9.4 million shares until Jan. 15, 2025 — the program’s end date.