At the recent Society of Petroleum Engineers Tight Gas Completions conference in San Antonio, Texas, I heard a story that reinforces my conviction that all of the problems encountered by the oil and gas industry can ultimately be solved through the application of innovative outside- the-box thinking, good engineering, and perseverance.

No, this is not some kind of universal panacea that can be applied across a broad spectrum of the world’s wells – at least not yet. In fact, the solution has only been tested to date in the Eagle Ford shale play. But it so clearly illustrates the value of systematic technical approach that it is worth sharing.

Throughout history, many of the most useful, far-reaching discoveries were made by accident. The factor that turned surprise into success was the perseverance of the inventor to carefully go back to chronicle the details of the discovery, including everything that preceded it, no matter how insignificant; then attempt to recreate the event, all the time taking measurements so the discovery could be thoroughly characterized and its implications evaluated.

I hope I piqued your interest, because here (to quote the late radio personality Paul Harvey) is “the rest of the story.”

Good things come to those who wait

A South Texas operator was intent on stimulating some of his Eagle Ford wells. The approach recommended for those particular wells was to pump a low-viscosity fluid at a high rate interspersed with slugs of small-mesh proppant. Real-time microseismic fracture mapping techniques were used to track the propagation of the resulting fractures to ensure that maximum reservoir contact was achieved and that geohazards existing in a deeper horizon were avoided. The operator had run elemental capture spectroscopy logs to characterize the clays and maximize the amount of foreknowledge to achieve the best completion design.

Initial attempts to treat the formation had produced suboptimal results, and the stimulation service company partnered with the operator to see if a better solution could be found. At issue was increasing the estimated stimulated volume (ESV) of the treatment. However, in the midst of pumping one of the stages, a breakdown caused a delay that stretched to several hours. When the problem was resolved, the pumping schedule was resumed. To everyone’s surprise, the stage took more proppant than previous stages. This was confirmed by a dramatic increase in the number of microseismic events recorded. Looking back at previously-treated wells, there was a clear correlation between the number of microseismic events and production.

Production logs were acquired, cores were carefully evaluated, and by the time the next job was run, it was clear that the only difference between the previous stages and the new, high-ESV stage was the shut-down period. The next well was planned for 17 stages, so the first nine stages were pumped conventionally. During the treatment of stages 10, 12, 13, 14, and 17, however, the pumps were deliberately stopped for a “relax” period; then resumed.

The new technique was promptly named, “relax-a-frac.” But the engineers were not satisfied to chalk their discovery up to lucky coincidence. They replicated the procedure on additional wells and concluded that there is a direct correlation between ESV and microseismic events. Moreover, there seems to be a clear indication that using the relax-afrac technique increases the number of microseismic events, at least in the Eagle Ford shale. Accordingly, it would appear that the relax-a-frac technique increases ESV, whereas traditional changes in frac design, fluids, and pumping techniques had little effect.

More than one eyebrow was raised by conference attendees, but the evidence clearly suggests that the new technique has promise and should be attempted elsewhere, under carefully controlled conditions, of course.

Perhaps serendipity has struck only in South Texas, but perhaps the sun will shine on other shale plays. Hats off to the team that had the patience to investigate this phenomenon, the persistence to prove it works, and the guts to write a paper about it.

Recommended Reading

TGS, SLB to Conduct Engagement Phase 5 in GoM

2024-02-05 - TGS and SLB’s seventh program within the joint venture involves the acquisition of 157 Outer Continental Shelf blocks.

StimStixx, Hunting Titan Partner on Well Perforation, Acidizing

2024-02-07 - The strategic partnership between StimStixx Technologies and Hunting Titan will increase well treatments and reduce costs, the companies said.

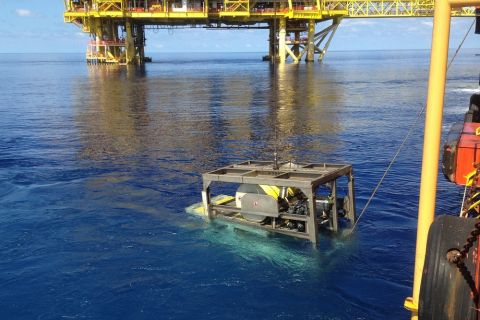

Forum Energy Signs MOU to Develop Electric ROV Thrusters

2024-03-13 - The electric thrusters for ROV systems will undergo extensive tests by Forum Energy Technologies and SAFEEN Survey & Subsea Services.

Axis Energy Deploys Fully Electric Well Service Rig

2024-03-13 - Axis Energy Services’ EPIC RIG has the ability to run on grid power for reduced emissions and increased fuel flexibility.

TotalEnergies Rolling Out Copilot for Microsoft 365

2024-02-27 - TotalEnergies’ rollout is part of the company’s digital transformation and is intended to help employees solve problems more efficiently.