Presented by:

Editor's note: This article appears in the new E&P newsletter. Subscribe to the E&P newsletter here.

Operators drilling deep wells in the Utica Formation conventionally favor oil-based drilling fluid (OBM) over water-based mud (WBM), which is considered a costly solution that can cause performance to suffer. Frequent changes in WBM properties require numerous checks compared with two mud checks per shift for OBM, increasing potential for error and adding operational time. However, higher-quality downhole images attainable in WBM have increased demand for WBM in deep wells.

Artex Energy Group LLC achieved recent success in the Utica Formation using an integrated solution with WBM, opening new opportunities for using the fluid type in areas where it was once considered too challenging and expensive.

While drilling two exploration wells measuring 20,000 ft MD and 13,000 ft lateral length, Artex Energy Group required a water-based drilling fluid system to produce downhole images, which would enable further analysis to understand viability for potential future projects. The company had an objective to stay 100% in the zone and wanted to ensure the most effective completion program and maximize exposure to the pay zone. To achieve these objectives, Schlumberger recommended using its HydraGlyde high-performance water-based drilling fluid system, RheoProfiler automated rheometer and DrillOps on-target well delivery tool with a drilling fluids advisor.

Integrated solution

The high-performance water-based drilling fluid system delivers oil mud–comparable ROP, exceptional hole cleaning and wellbore stability in high-angle-build and long-lateral sections without sacrificing drilling performance or increasing costs. It decreases risk of differential sticking and minimizes nonproductive time (NPT). The cost-effective chemistry reduces torque and drag as well as shale swelling and dispersion. The system provides a flexible drilling fluid solution and mitigates environmental impact.

By providing a high degree of lubricity, the system overcomes the typical drilling-related problems encountered in more mature shales, including wellbore instability, solids buildup and hole cleaning in the horizontal section. Drilling fluid systems are prone to experiencing elevated low gravity solid concentration in the mature, organic-rich Utica Shale. A dual M-I SWACO CD-500 XV centrifuge package was mobilized to the project and successfully managed the solids concentration within specification. With more than 300 successful projects worldwide, the system has helped operators prevent NPT and reduce operating costs.

The on-target well delivery tool monitors and captures operational data to support operators during drilling with real-time advice and coaching to improve decision-making and reduce risk. Intelligent advisory systems guide crews to stay within operating windows and safety thresholds. Predictive analytics continuously identify drilling dysfunctions, alerting personnel before predefined limits are due to be exceeded to reduce NPT. This enables operators to more easily resolve potential conflicts and administer corrective action. All actions are automatically documented within the digital well file to streamline reporting and drive continuous improvement.

The automated rheometer automatically checks density and rheology and the drilling fluids advisor sends this information, providing real-time visualization of drilling operations. The operator can run density and rheology checks as often as needed to better understand changes. This provides an advantage in WBM, where properties change faster than in OBM. The technology can complete 34 checks compared with nine manual checks in the same amount of time. By viewing continuous changes via the dashboard, operators can see values and properties more easily, save time and avoid human error. The more frequent checks will also aid in more accurate data for future projects in the same area.

From planning to execution, the collaboration of the drilling engineers and Artex Energy Group contributed to the overall success of the project. Implementing the integrated solution enabled Artex Energy Group to achieve project objectives and established the benefits of using WBM in deeper wells.

Drilling deep wells in the Utica

Using the fully integrated solution, Artex Energy Group drilled both wells under budget and stayed 100% in the zone without sacrificing performance in the lateral sections. The automated rheometer and on-target well delivery solution visualized fluid and drilling measurements for real-time WBM performance tracking. The automated rheometer enabled drilling fluid engineers to increase data collection by 100% while exporting fluid properties in real time to the engineers on location. The seamless transition of fluid properties from the automated rheometer to the on-target well delivery solution enabled the drilling engineers to improve hydraulics modeling and drilling optimization recommendations for Artex Energy Group.

Artex Energy Group tripped out the drilling assembly on both wells and ran production casing to the bottom without issue. Days drilled matched offset well data even while the operator controlled drilling to stay in the zone. The drilling fluid cost per foot decreased by 39% compared with the offset group. The total cost of the second well decreased by 28%. Using a very low concentration of Schlumberger's HydraSpeed ROP-enhancing primary lubricant throughout the well enabled surface torque to match performance of an oil-based mud system. The flexibility of the high-performance water-based drilling fluid system proved beneficial for changing fluid characteristics while drilling.

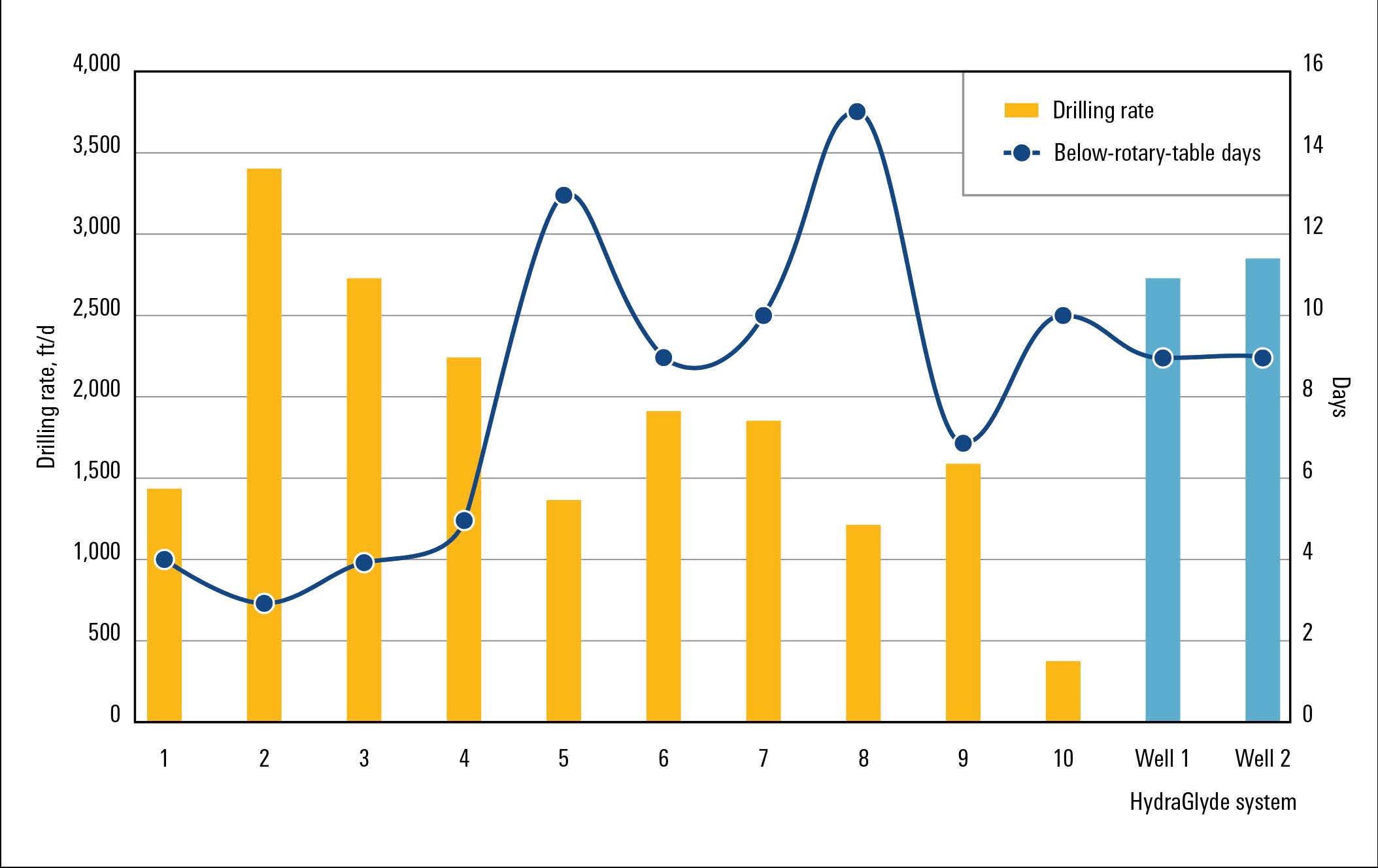

Compared with 10 offset wells in the same area, the wells drilled using the water-based drilling fluid system matched the average days drilled while exceeding the daily footage. The HydraGlyde wells still outperformed most offset wells on the average drilling rates even while control drilling in the lateral sections (Figure 1).

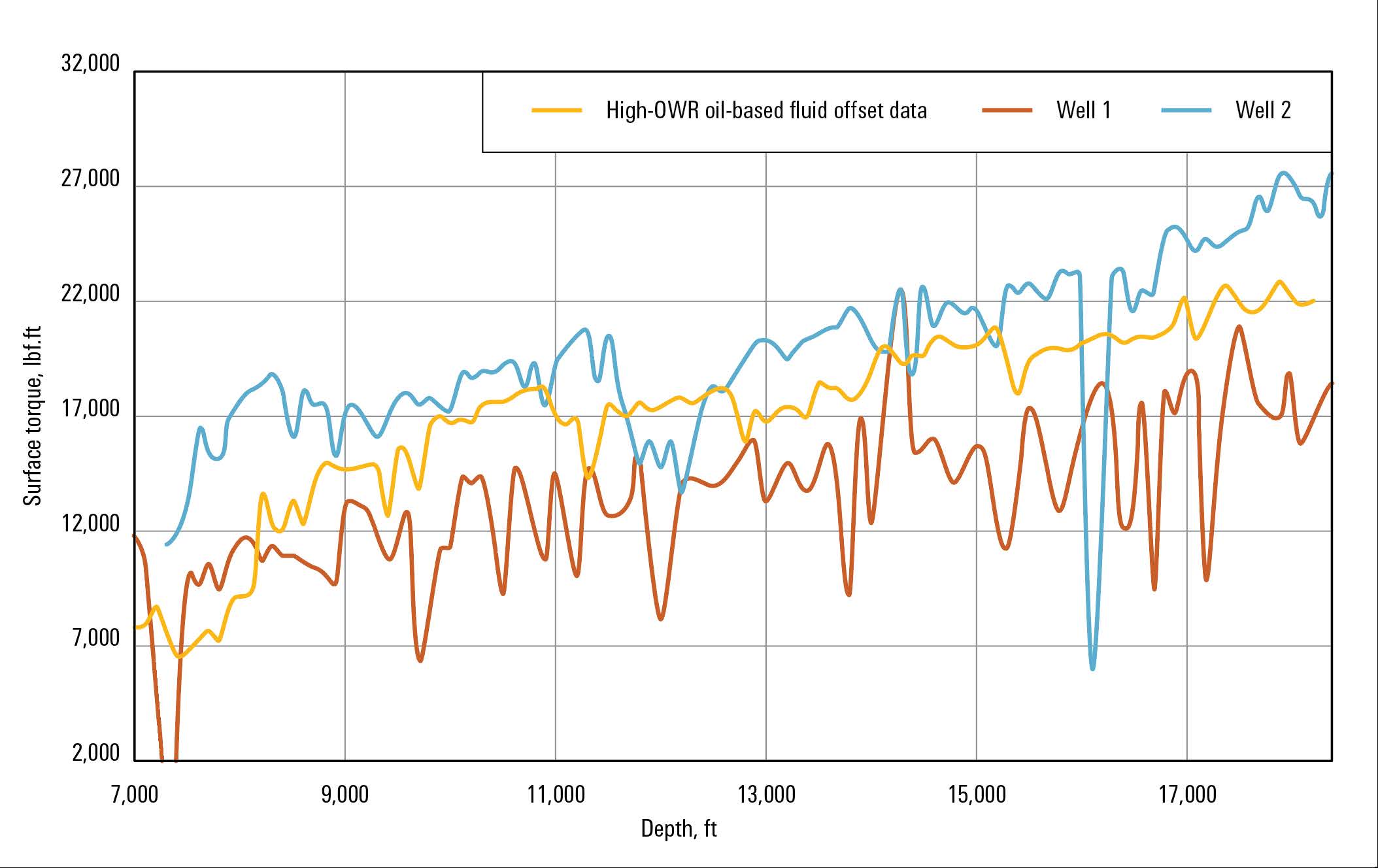

An offset well with a high oil/water ratio fluid was compared with the surface torque of the high-performance water-based drilling fluid system wells in the same area. HydraSpeed lubricant was added halfway through the first well at 1% volume. The second well maintained a HydraSpeed lubricant concentration of about 1% to 2% by volume (Figure 2).

Conclusion

The success Artex Energy Group achieved in the Utica Formation demonstrates the viability of using the high-performance water-based drilling fluid system in deep wells. The solution enabled verification of the landing and lateral path within a 12-ft interval. The two 13,000-ft laterals drilled using the fluid system achieved similar performance compared with OBM. A consistent footage drilled on both wells in the lateral allowed to stay on target for days on well. The fluid properties remained in specification, eliminated wellbore stability issues as well as completing the casing run to bottom smoothly.

Constant monitoring and real-time visualization of WBM properties using an integrated solution enables operators to make informed drilling decisions to increase drilling efficiency and reduce NPT, ensuring the most effective completion program and maximizing exposure to the pay zone. The ability to see real-time fluid properties more frequently allowed HydraGlyde to be run as efficiently as possible. The success of this project will further open the door for drilling with high-performance water-based systems in challenging areas of the world.

Recommended Reading

Kimmeridge Fast Forwards on SilverBow with Takeover Bid

2024-03-13 - Investment firm Kimmeridge Energy Management, which first asked for additional SilverBow Resources board seats, has followed up with a buyout offer. A deal would make a nearly 1 Bcfe/d Eagle Ford pureplay.

Laredo Oil Subsidiary, Erehwon Enter Into Drilling Agreement with Texakoma

2024-03-14 - The agreement with Lustre Oil and Erehwon Oil & Gas would allow Texakoma to participate in the development of 7,375 net acres of mineral rights in Valley County, Montana.

NOV's AI, Edge Offerings Find Traction—Despite Crowded Field

2024-02-02 - NOV’s CEO Clay Williams is bullish on the company’s digital future, highlighting value-driven adoption of tech by customers.

From Restructuring to Reinvention, Weatherford Upbeat on Upcycle

2024-02-11 - Weatherford CEO Girish Saligram charts course for growth as the company looks to enter the third year of what appears to be a long upcycle.

Hess Corp. Boosts Bakken Output, Drilling Ahead of Chevron Merger

2024-01-31 - Hess Corp. increased its drilling activity and output from the Bakken play of North Dakota during the fourth quarter, the E&P reported in its latest earnings.