Learn more about Hart Energy Conferences

Get our latest conference schedules, updates and insights straight to your inbox.

Since the construction of the first deepwater field—Cognac at 311 m (1,022 ft) depth—there has been an inevitable and increasing shift toward oil and gas production in deepwater fields. Indeed, the Bureau of Ocean Energy Management reported that more than 80% of developments in the Gulf of Mexico are in deep water; this is partly driven by the fact that many of the most easily accessible hydrocarbon reserves have been recovered.

Deepwater fields present many challenges for design, construction and operation, and many of these challenges translate into difficulties for ongoing inspection and monitoring of pipelines. Also, for deepwater discoveries that are too small to be economically developed as standalone projects, operators often might prefer to instead tie back the wells to existing production facilities. This, in turn, increases the number of flowlines, which are typically difficult to inspect, while usually being exposed to the most challenging pipeline operating conditions at the same time.

Design, inspection challenges

Historically, many deepwater developments have pushed the boundaries of the technology capabilities in the oil and gas industry at the time of their design. For example, deepwater pipelines are subject to a much higher external pressure than their shallow-water siblings. Pipelines are constructed from thicker and heavier material to withstand this increased external pressure. This places additional stresses on the line during the construction and installation stage, and can potentially lead to the development of unexpected or even entirely new failure mechanisms.

Due (in part) to the temperatures and pressures the transported product experiences at several thousand feet of sea depth, deepwater pipelines often will require chemical controls, heating and insulation to ensure the pipeline product continues to flow. In situations where these measures fail, deposits can form on the pipe bore. Initially, this leads to increased operational costs (as more power is required to push the fluid along the pipe) but ultimately this can lead to a partial or complete blockage of the line, which has both cost and safety implications.

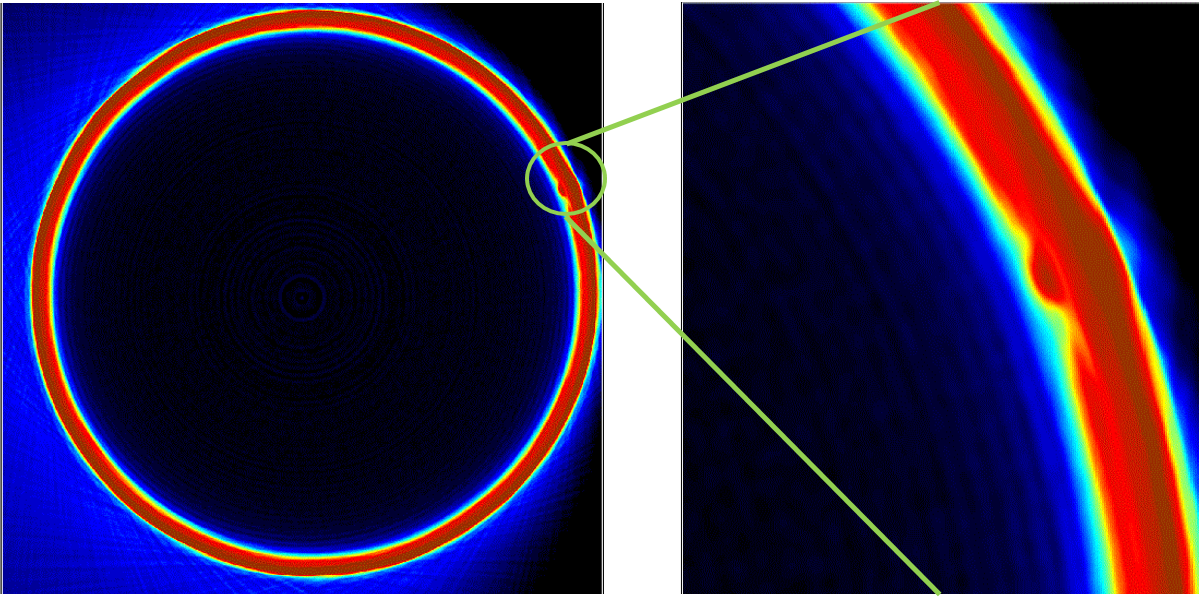

It is not possible to internally inspect a pipeline with a partial or complete blockage, at least without significant cleaning of the pipe. Unfortunately, the insulation or heating systems can limit the effectiveness of many conventional external inspection techniques. For operators with these systems, Tracerco’s Discovery system is available. Discovery is a subsea computed tomography (CT) scanner designed for external scanning of pipelines. The CT scanner is unaffected by the material it is scanning through and is easily capable of scanning through several inches of pipeline steel. Discovery enables an operator to see the condition of both the pipe wall and the bore, meaning that in a single scan, the system can provide relevant information for both ongoing integrity and flow assurance.

Reducing the inspection information gap

A continuous problem that operators face, particularly those with deepwater assets, is the amount of useful inspection data available to them. In many systems conventional inspection techniques might not be practical or even possible. In such cases, operators may be forced to limit themselves to performing localized inspections at potential hot spots; further inspections may be required depending on the information found at these hot spots. For all operators this can be a costly process, but this is particularly true for inspections in deepwater systems.

Techniques such as the fast scanning approach, which has been developed by Tracerco, provide rapid defect identification during CT scanning, allowing operators of deepwater systems to obtain the maximum amount of valuable data from a single inspection campaign.

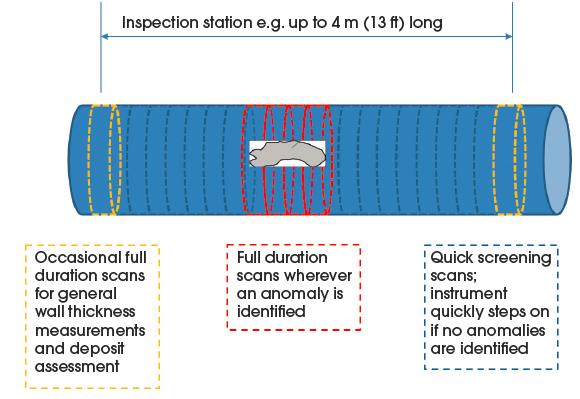

By deploying the fast scanning approach, Tracerco has determined that certain key characteristics indicating the presence of a defect can be identified in pipe scans before completion of a full CT scan. Although these characteristics do not include sufficient information to enable the dimensions of the anomaly to be determined to within Discovery’s stated tolerances, the fact that the anomaly can be identified at this early stage means a full sizing scan can be performed only when it is of most benefit (Figure 1).

The area to be scanned by Discovery is split into separate sections and a suitable interval for full duration scans is determined. These full duration scans will be performed irrespective of presence (or lack of presence) of any anomalies or defects and enable general wall thickness measurements and deposit assessments to be performed (Figure 2).

For the remainder of the section, fast scanning is performed. Provided that no anomaly characteristics are identified, the Discovery scan can then finish at the end of the fast scan time. However, if an anomaly is identified, the Discovery scan is extended to a full duration scan to enable accurate sizing of the anomaly.

Case study

A pipeline life extension was required on a pipeline that was considered to be difficult to inspect by conventional pipeline methods. The operator was aware of several potential failure mechanisms (such as preferential weld corrosion) and had, by the use of corrosion and risk assessments performed before the inspection campaign, identified areas that were considered to be at the highest risk of failure.

A large amount of pipeline required inspection, but the operator was working within a restricted timescale due to various operational issues.

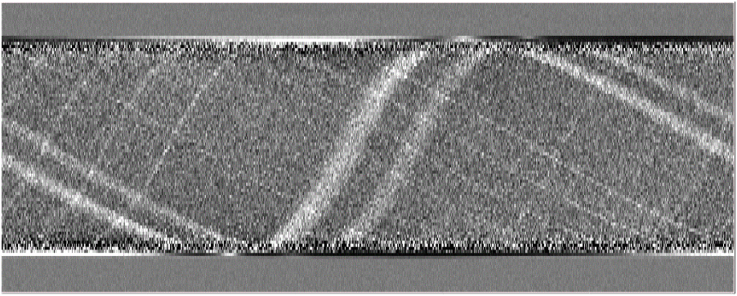

Discovery was identified as the most suitable method for inspecting the pipeline, but the predicted overall inspection campaign time (including full Discovery scans) was unsuitable. It was determined that the fast scanning method could be used and would enable time savings of up to 79% on the overall Discovery inspection time; this had the added benefit of saving the operator approximately 35% on the total project cost. Consequently, the operator deployed Discovery and, using the fast scanning technique, confirmed that corrosion had occurred (Figure 3).

Following the conclusion of the Discovery scanning campaign, the operator was able to perform remediation measures that enabled the pipeline system to continue operation.

With the increasing move toward oil and gas extraction in deepwater fields and the additional engineering complexities associated with installation and inspection at these depths, inspection techniques need to be developed and improved to enable their safe ongoing operation. Newer inspection techniques, such as Discovery, are available to operators with challenging deepwater assets.

Recommended Reading

ConocoPhillips EVP of Strategy, Sustainability, Technology Macklon to Retire

2024-02-16 - Dominic Macklon, who began his career with Conoco in 1991, is set to retire ConocoPhillips May 1.

Buffett: ‘No Interest’ in Occidental Takeover, Praises 'Hallelujah!' Shale

2024-02-27 - Berkshire Hathaway’s Warren Buffett added that the U.S. electric power situation is “ominous.”

The One Where EOG’s Stock Tanked

2024-02-23 - A rare earnings miss pushed the wildcatter’s stock down as much as 6%, while larger and smaller peers’ share prices were mostly unchanged. One analyst asked if EOG is like Narcissus.

Bobby Tudor on Capital Access and Oil, Gas Participation in the Energy Transition

2024-04-05 - Bobby Tudor, the founder and CEO of Artemis Energy Partners, says while public companies are generating cash, private equity firms in the upstream business are facing more difficulties raising new funds, in this Hart Energy Exclusive interview.

Cheniere Energy Declares Quarterly Cash Dividend, Distribution

2024-01-26 - Cheniere’s quarterly cash dividend is payable on Feb. 23 to shareholders of record by Feb. 6.