Presented by:

Editor's note: This article appears in the special OTC edition of the E&P newsletter. Subscribe here.

Industrial digitalization is a megatrend that is changing production operations in the oil and gas industry.

One key branch in industrial digitalization is process automation and control, in which a number of sensors are used to measure the state of the process, and collected data are transferred to data analytics software. The data are then analyzed and optimal control parameters are sent to process automation systems. The digitalized process automation requires that the sensors and other automation systems are connected through a network. The performance and productivity of the plant can be improved by controlling the processes optimally. Optimizing the operations is key for efficient resource use and essential for low-carbon emissions.

Process automation requires an accurate measurement of the process state. In the oil and gas industry, the real-time monitoring of the process has been a great challenge due to the continuously changing process conditions. For example, the surface of the measurement sensor is typically contaminated by wax deposits and other materials, which conventional sensors cannot measure through accurately.

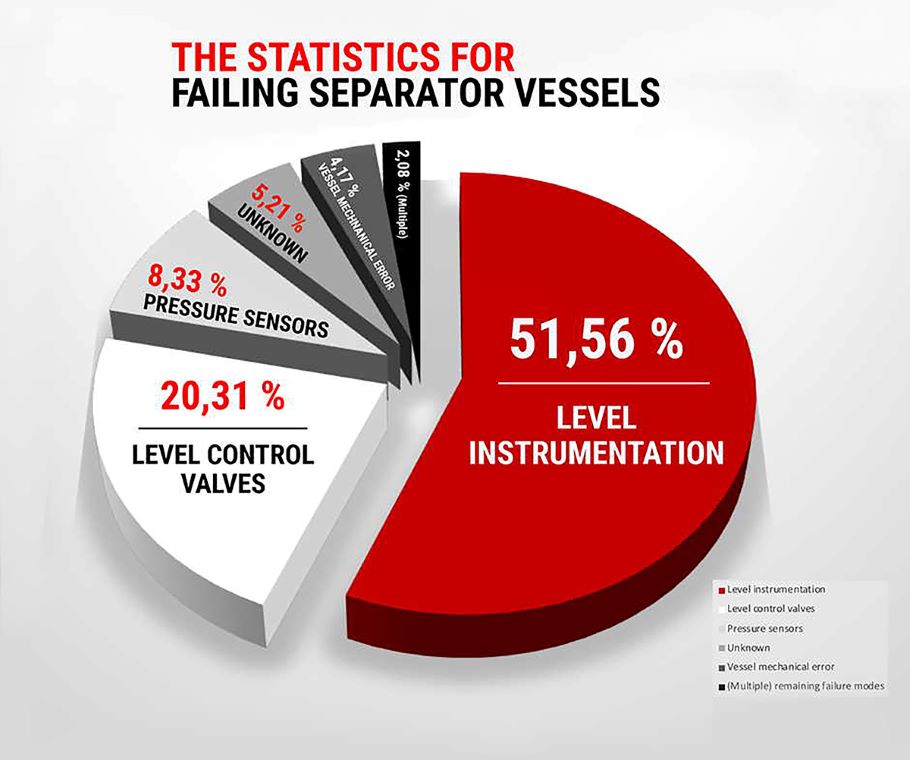

More than 51% of separator failures are due to faulty level instrumentation, as discussed in a 2016 SPE article. About 80% of global production is from mature assets, where they have challenging operating conditions, which makes frequent reliable data so critical.

Process monitoring sensors

ROCSOLE's process monitoring sensors provide access to reliable instrumentation with frequent data (typically 10 datapoints per second), and it is designed to work even in the toughest operating conditions. The sensors provide insights from critical processes like the separators and settling tanks. These data are required for the operators to be able to optimize their production by rightly handling watercuts, oil-in-water/water-in-oil emulsion layers, bitumen and rag layers, solid buildup and other process upsets. Further data analytics can be provided as a data-as-a-service model, which results in multimillion-dollar operational savings and revenue improvements with a payback time that, in some cases, can be a matter of days.

The measurement principle of the ROCSOLE sensors is based on electrical tomography. Completely safe low-voltage signals are used to scan the subject area of measurement. The measurement rates are high enough, enabling real-time monitoring of the process. The sensors can tolerate high temperatures and pressures. ROCSOLE has industrialized the tomography technology, widely used in the health-tech sector. With the company's efforts, it made the technology compact, robust, fast-acting and with a high resolution suitable for the type of operations encountered in the oil and gas industry.

Carbon neutrality

The accurate measurement and data insights of the process conditions make it possible to reduce risks and optimize performance leading to a more efficient energy and resource utilization with high uptime and less need for field services and maintenance. This ultimately supports the industry in the energy transition to carbon neutrality.

With ROCSOLE's connected Internet of Things devices, the company can assist operators remotely, which has shown to be very useful in pandemic times with all the travel and site visit restrictions. The company has done remote startups helping operators on their digitalization journey. As personnel does not need to be present on site, this contributes to a reduced carbon footprint in the range of 2 to 4 metric tonnes CO2 per installation.

Digitalization offers great new possibilities to process automation, bringing the industry to a new era, both in terms of operational efficiency and low-carbon emission efforts. The development of deep learning algorithms enables the utilization of huge amounts of data (Big Data).

ROCSOLE's special approach to this is to utilize its own reliable data, which can be from several sources (e.g., several separators in the production train or several sensor points in one process vessel). The real-time data and databases can be used to predict the behavior of the process, and every part of the process can be controlled individually, reaching an overall high performance and uptime.

Recommended Reading

Green Swan Seeks US Financing for Global Decarbonization Projects

2024-02-21 - Green Swan, an investment platform seeking to provide capital to countries signed on to the Paris Agreement, is courting U.S. investors to fund decarbonization projects in countries including Iran and Venezuela, its executives told Hart Energy.

Air Products Sees $15B Hydrogen, Energy Transition Project Backlog

2024-02-07 - Pennsylvania-headquartered Air Products has eight hydrogen projects underway and is targeting an IRR of more than 10%.

Petrie Partners: A Small Wonder

2024-02-01 - Petrie Partners may not be the biggest or flashiest investment bank on the block, but after over two decades, its executives have been around the block more than most.

Sunoco’s $7B Acquisition of NuStar Evades Further FTC Scrutiny

2024-04-09 - The waiting period under the Hart-Scott-Rodino Antitrust Improvements Act for Sunoco’s pending acquisition of NuStar Energy has expired, bringing the deal one step closer to completion.

SM Energy Adds Brookman to Board, Promotes Lebeck to Executive VP

2024-02-23 - Barton R. Brookman previously served as President and CEO of PDC Energy and James B. Lebeck served as senior vice president and general counsel since January 2023.