Presented by:

This article appears in the E&P newsletter. Subscribe to the E&P newsletter here.

With more wells being brought online as the world slowly emerges from the sharp decline in well productivity in 2020, operators are looking for ways to boost efficiency and save time and money in the field. To do so means getting data and employees across each facet of a company organized and ready to perform at the highest capacity.

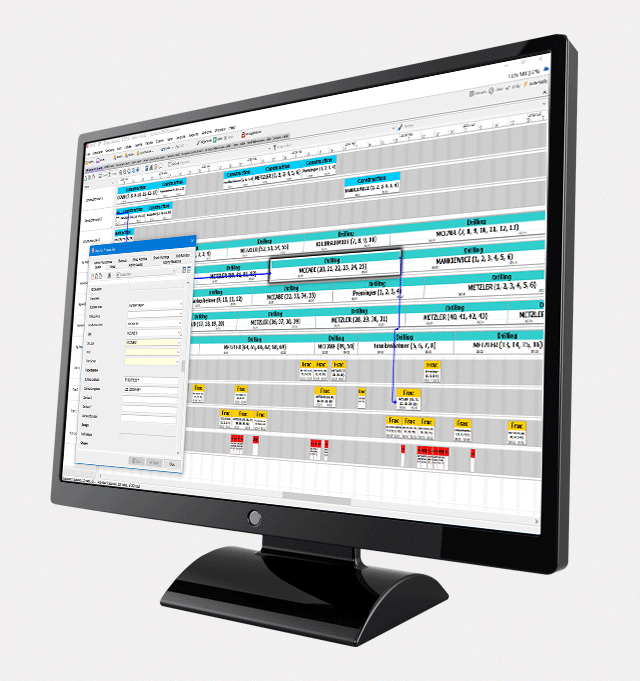

According to Owen Plowman, vice president of business development with Actenum, a crucial way for companies to enhance well delivery performance is by implementing advanced scheduling software to help connect the entire organization.

In the SPE Tech Talk, “Enhancing Well Delivery Performance through More Effective Scheduling,” on Jan. 11, Plowman discussed the advantages he has seen in organizations that switched to a connective scheduling system, including time- and cost-saving benefits.

Plowman cited key factors that degrade well performance, such as lack of effective leadership and lack of effective measurements, but the ones associated with and fixable with an advanced scheduling software include a poor integrated operating model, lack of access to data and lack of a reliable plan of attack.

Alternatively, identifying and setting key performance indicators (KPIs) is instrumental in enhancing well delivery performance. Clearly outlining the organization’s goals for an improvement initiative will “align the team around clear objectives” across all facets of the company, he said.

“You have to begin with the end in mind,” Plowman continued. “You have to decide what is important to measure appropriately to determine how successful your improvement initiative is. If you don’t have a performance initiative, then your company is all about drilling and getting hydrocarbons out of the ground, and what determines your success in that particular discipline?”

With an advanced scheduling system, companies can save time by effectively managing each employee’s time and reducing wasted potential, which in turn save sometimes millions of dollars. Overall, one of the biggest improvements Plowman stressed was better coordination and synchronization in the field.

“We had a customer where the scheduling was actually done in different technologies in the different groups. So drilling used something like Microsoft Project or Primavera, and completions used Excel, and the schedules weren’t synchronized,” Plowman explained as an example. “A completion crew would show up in the field to discover that the wells hadn’t even been drilled and there was no activity on the pad; the pad had been built, but they were in the wrong place at the wrong time. So there was money spent on fixing that, on redeploying the frac crew and so on.”

However, adjusting to new software can be a tumultuous undertaking if everyone at an organization is not on board with improving performance initiatives. Plowman warned that being open-minded to change can only help a company advance forward, and anything less than that mindset will be a detriment.

“In my opinion, and based on my 41 years of experience in the industry across a broad range of disciplines, not just oil and gas, the key thing is that people will make or break the initiative. Having the right people involved and having a small, enthusiastic team that really wants to make a difference and is willing to change, that is the most important thing to do,” he said. “All the software in the world will fail.It doesn’t matter how good it is; it will fail if people aren’t committed to change. Nothing will degrade performance and lead to problems more than having the wrong people involved.”

Overcoming hesitancy and embracing change

Currently, companies that use programs like Excel, one of Actenum’s biggest competitors, are missing out on the unification aspect that advanced scheduling softwares bring to the table. Leadership hesitant on changing to an innovative system might be holding back because translating a set of KPIs into a list of activities can seem daunting, Plowman said, but easing change into the organization will be easier for them to implement and help them achieve the desired results.

“You can start small and build your schedule out incrementally and adopt a new process for the entire performance improvement initiative, you can then start satisfying the requirements of the different disciplines,” he said. “Nobody’s saying start from here and then do some sort of big bang and three months later, everybody’s going to be in the brave new world with a highly sophisticated tool.”

Plowman continued, “It’s really important, I think, to start with a small group of enthusiastic people who want to make change and are interested in learning new approaches and new tools and bringing that to the organization and seeing the benefits of it, and then working with them on an incremental, evolutionary basis.”

Recommended Reading

Report: Crescent Midstream Exploring $1.3B Sale

2024-04-23 - Sources say another company is considering $1.3B acquisition for Crescent Midstream’s facilities and pipelines focused on Louisiana and the Gulf of Mexico.

For Sale? Trans Mountain Pipeline Tentatively on the Market

2024-04-22 - Politics and tariffs may delay ownership transfer of the Trans Mountain Pipeline, which the Canadian government spent CA$34 billion to build.

Energy Transfer Announces Cash Distribution on Series I Units

2024-04-22 - Energy Transfer’s distribution will be payable May 15 to Series I unitholders of record by May 1.

Balticconnector Gas Pipeline Back in Operation After Damage

2024-04-22 - The Balticconnector subsea gas link between Estonia and Finland was severely damaged in October, hurting energy security and raising alarm bells in the wider region.

Wayangankar: Golden Era for US Natural Gas Storage – Version 2.0

2024-04-19 - While the current resurgence in gas storage is reminiscent of the 2000s —an era that saw ~400 Bcf of storage capacity additions — the market drivers providing the tailwinds today are drastically different from that cycle.