With drilling costs and return on investment expectations both rising, drilling companies are continually searching for more speed and better process management. Two new tools close to hitting the market— a dual-diameter bit from NOV subsidiary ReedHycalog and a managed pressure drilling (MPD) system from Patterson-UTI—offer solutions.

Bit increases ROP rates

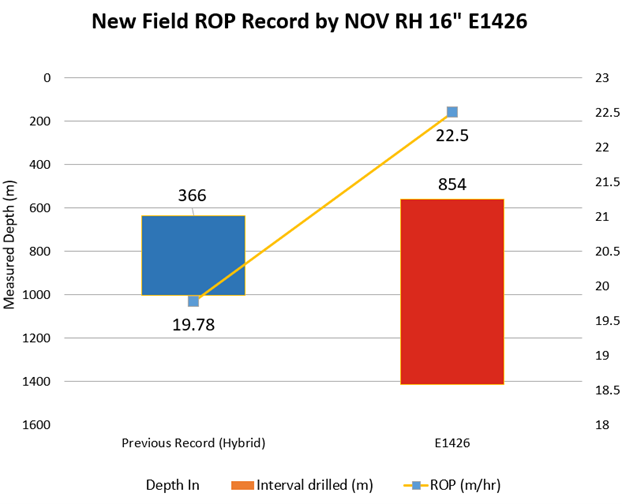

Recent years have seen ROP rates rise in oil and gas drilling, and NOV’s new bit is designed to extend the upper limit. Named Pegasus after the mythical flying horse, the bit aims to improve on existing dual-diameter designs by shortening the distance between the bit’s pilot and reamer sections to improve both stability and cuttings removal rates.

Once a bit penetrates the formation, the stress state around the bit and drilled well is significantly lowered, said Alex Benson, NOV’s product line director of drill bits.

“Conventional single diameter polycrystalline diamond compact (PDC) drill bits are not capable of taking advantage of this reduced effective rock strength,” he said.

Pegasus is a PDC bit, but its differs from the conventional model.

“The concentric, dual-diameter design lowers the effective rock strength encountered by the critical shoulder-to-gauge area of the bit’s cutting structure. The smaller pilot section of the bit design drills a pilot hole, which reduces the confinement and, thus, strength of the rock drilled by the larger reamer section,” he said. “The reamer section utilizes the bedded pilot bit for stabilization to offset the greater forces associated with larger-diameter drilling. The offset blade configuration of the bits also offers increased contact with the borehole and helps deliver a gun-barrel hole quality.”

While the dual diameter concept is not new, Benson noted that earlier versions in the marketplace had a 2-in. joiner between the pilot and the reamer. Pegasus reduces that interval, improving stability and steerability with the same number of cutters, he said.

Previous methods of improving stability relied on increasing blade counts from the standard six to seven or more. Adding contact points reduces vibrations that can damage the bit and other equipment, leading to downhole trips for repairs or replacements. But it also restricts the flow area for cuttings removal, which slows the instantaneous ROP. Lower blade counts penetrate faster for a higher instantaneous rate, but reduce the average ROP, which measures the time required from start to finish. The ROP drop was due to drilling halts required by downhole trips.

Pegasus can operate with any number of blades. Benson said.

“Its speed is similar to a six-bladed bit but with the stability of a seven-bladed bit,” without the seven-blade’s lower cuttings removal rate, he said.

The future of Pegasus

Pegasus is nearing release after almost a year of field trials. So far, it has been tested in onshore applications, including geothermal and oil and gas. Benson says it is designed for “inter-bedded formations or high-vibration environments where you want the bit to be stable drilling and you’re trying to reduce torque fluctuations in a heterogeneous formation.”

Tests have involved a six-bladed option “in what would otherwise be seven-bladed applications,” he said. “This has delivered higher ROP and stability over similar intervals.”

Succeeding with MPD onshore

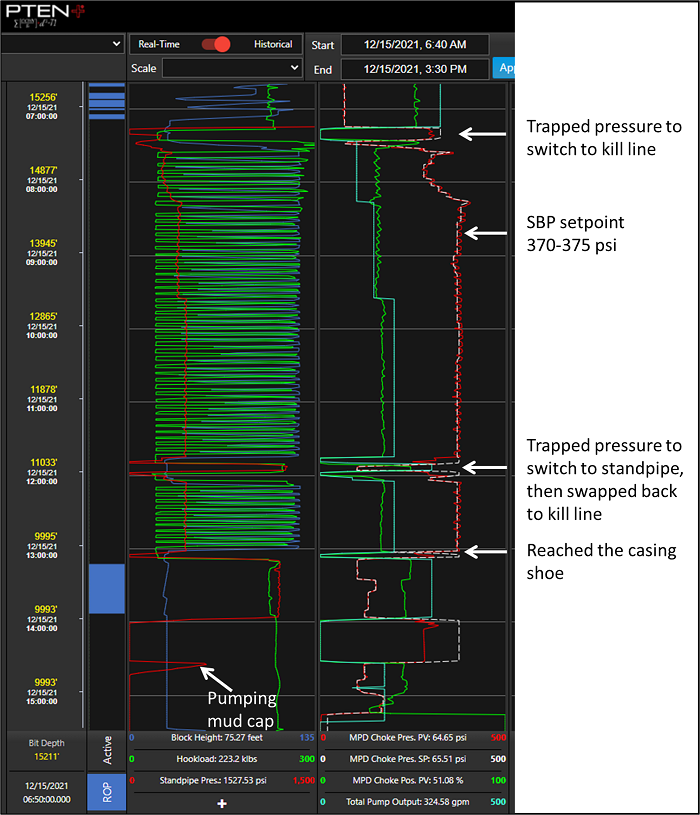

MPD has been an important tool for drillers for many years, said Adam Keith, MPD product champion for Patterson-UTI.

He describes MPD as “an adaptive drilling technique that allows for more exact management of the annular pressure profile of the wellbore. We’re applying pressure back to the well in order to control what’s happening downhole.”

The Society of Petroleum Engineers’ website observes that “MPD … reduces several drilling problems that cost time and money, and increases safety of drilling operations.”

As powerful as MPD is, the significant costs and manpower requirements of a full MPD deployment have meant it was usually only economical in high-producing environments, Keith said. Oversimplified onshore MPD versions that gained some traction around 2014 “often led to compromises in both technical capability and operational safety,” Keith said.

In 2020, Patterson-UTI devised a way to use advancing technology to improve performance and reduce required manpower, allowing it to perform better and at a lower cost than previous systems. These updates would make it as powerful on land as it had been offshore, he noted.

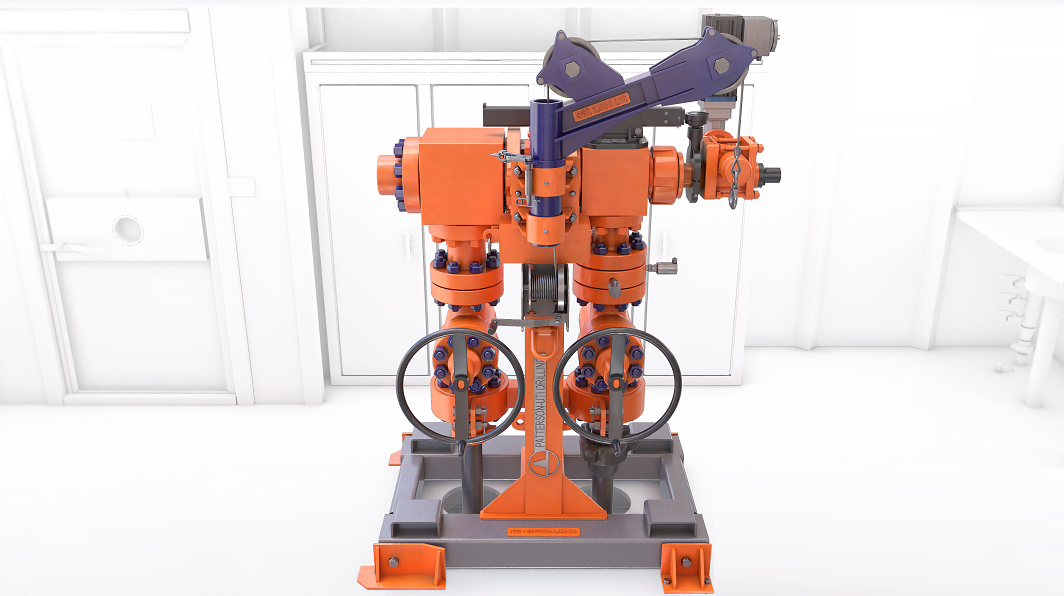

Most MPD systems are completely standalone, limiting their potential benefits. Patterson-UTI created greater efficiency by integrating fit-for-purpose MPD equipment into its Tier 1 Super Spec AC land rigs.

“We integrated not only the hardware to the rig, but also the controls,” Keith said.

To further streamline the operation, the company installed an electrically actuated choke manifold on the rig floor, among other hardware updates.

“Because our system is on the rig floor, the rig can pad-drill without having to rig anything down and up between wells, saving a lot of time” on a rig that costs thousands of dollars per day, Keith said. It also improves safety by cutting back on the need to rig up, he added.

Integrating the controls with this proprietary system streamlines data connections. Rather than the driller operating the MPD system with a separate control panel, or human-machine interface (HMI), Keith said, “we’ve integrated it into the existing drilling HMI.” This has made it user-friendly for the driller and has eliminated the need for outside personnel to operate the system.

That integration also allows the rig’s own automation system to read and respond to the MPD status, Keith said. For example, for a separate MPD system to know and respond to the mud pumps’ stroke rates, that information must be separately collected by the MPD system. Patterson-UTI’s version, known as the CORTEX Regulator, “knows the RPM of the VFD (variable frequency drive) of the mud pumps,” he said.

By comparing that to the pumps’ set point as created by the driller, the CORTEX Regulator system can make proactive choke adjustments for greater pressure control, and automate the pumps for MPD connections.

“That has made a big difference in the performance of the MPD system,” Keith said.

NOV’s Pegasus rollout is coming soon, and Patterson-UTI began field operations with CORTEX in late 2022. While both could be considered incremental rather than revolutionary, they are important steps forward.

Recommended Reading

Benchmark Buys Revolution Resources’ Anadarko Assets in $145MM Deal

2024-02-20 - Benchmark Energy II is acquiring Revolution Resources just over four years after Revolution bought out Jones Energy Inc.’s Midcontinent portfolio.

Continental Resources Makes $1B in M&A Moves—But Where?

2024-02-26 - Continental Resources added acreage in Oklahoma’s Anadarko Basin, but precisely where else it bought and sold is a little more complicated.

Marketed: DRII 642 Well Package in Louisiana, Oklahoma, Texas, Wyoming

2024-04-02 - DRII LLC retained EnergyNet for the sale of a 642 well package across various counties and parishes in Louisiana, Oklahoma, Texas and Wyoming.

Marketed: Anadarko Minerals Woodford Shale Opportunity

2024-02-26 - Anadarko Minerals has retained EnergyNet for the sale of a Woodford Shale opportunity in Blaine County, Oklahoma.

EIA: E&P Dealmaking Activity Soars to $234 Billion in ‘23

2024-03-19 - Oil and gas E&Ps spent a collective $234 billion on corporate M&A and asset acquisitions in 2023, the most in more than a decade, the U.S. Energy Information Administration reported.