Presented by:

This article appears in the E&P newsletter. Subscribe to the E&P newsletter here.

The Norwegian Continental Shelf (NCS) contains some of the world’s largest oil and natural gas reserves. At the end of 2020, the Norwegian Ministry of Petroleum and Energy estimated that the NCS contains more than 8 billion standard cubic meters of oil equivalents (discovered and undiscovered) that have yet to be produced and sold.

Much of these remaining reserves, while technically recoverable, risk being classified as marginal by operators who are working with smaller capex and opex budgets than those of the past. While global lockdowns, driven by coronavirus, induced depressed commodity prices, which in turn contributed to tighter E&P budgets, ESG factors have emerged as increasingly critical drivers in the industry’s budgetary guidance and planning decisions. In the coming years, capital and carbon intensity discipline are likely to lead to fewer new large discoveries in the NCS. Subdued frontier exploration and capex-intensive greenfield development activity will ultimately make it more challenging for regional operators to replace their reserves. For this reason, many operators are shifting their focus to increasing recovery from existing well stocks, tapping into smaller near-field discoveries, and exploiting and extending the life of existing infrastructure.

Adapting to a dynamic industry

Industry-wide trends reveal an increase in well optimization opportunities through intervention and near-field, infrastructure-led exploration and development. Ultimately, what the offshore industry needs to remain competitive and thrive are high-value, low-carbon development opportunities that offer the best possible return on investment. But these opportunities do not simply materialize; they require engineering creativity, collaboration, careful planning—and a willingness to try new approaches—to become a reality.

Today, there is a new industry imperative to address climate change while meeting present and future energy demand, which is anticipated to rise with the growing global population, particularly in developing countries. This is a guiding light for the industry, which will continue to contribute a vital commodity to the total energy mix for years to come.

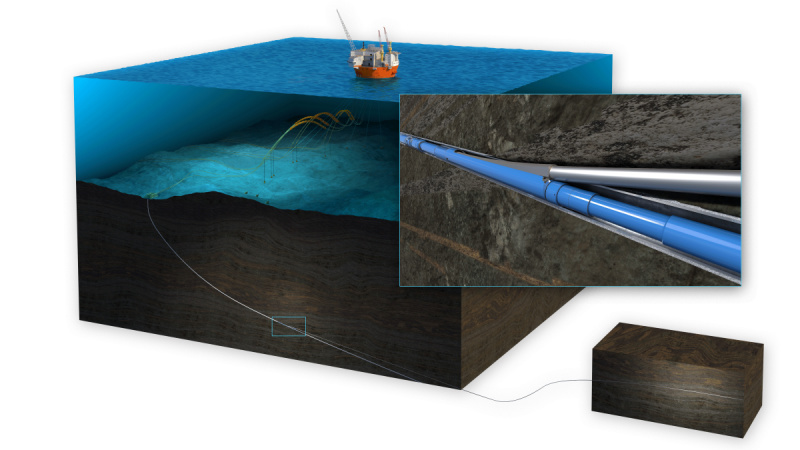

It is in context of this dynamic energy landscape that Vår Energi, one of the largest E&P companies on the NCS, decided to make a bold play for two of its wells in the Goliat Field in the Barents Sea. Vår Energi wanted to boost production by reaching new targets in its Snadd and Goliat West discoveries. However, the lack of available well slots in the current subsea infrastructure presented a challenge. Vår Energi considered the conventional approach to reach the new targets, but it was determined that the resources could not absorb the cost of additional subsea infrastructure. Moreover, the equipment lead times would have prevented Vår Energi from achieving first oil within its desired timeline.

Economically accessing new reserves in the Goliat Field

Vår Energi considered alternative concepts to unlock the potential volumes with reduced capex. Ultimately, retrofitting the monobore production wells into multilateral producers was determined to be the most efficient strategy for accessing the new reserves, improving the recovery from marginal infill wells, all the while maintaining the well’s existing production. Not only would this prove to be the most cost-effective option, it would, as an alternative to drilling two new wells and adding the required subsea infrastructure, also unlock a lower carbon-intensive pathway.

The decision to retrofit the wells with a sidetrack from the main wellbore was ambitious. While this type of operation has been executed before through dry trees on fixed installations offshore, it had never been attempted in a subsea well. It was at this point that Vår Energi and Schlumberger joined forces to execute on the vision for this project.

For the project to be considered a success, each well needed to maintain production from its original bore while adding new production from one lateral. This option required multilateral technology with mechanical stability and hydraulic integrity. Furthermore, the completion needed to include a way to independently control contributions from each lateral to balance production and ultimate recovery.

At the onset of the project, initial concerns were around the risk of damage to and compromising production from the main wellbore. However, these risks were quite minimal as no preinstalled equipment was required to kick off the lateral. A wellbore stability assessment was conducted on both wells by the Schlumberger and Vår Energi teams before the job execution to determine if the wells were good candidates for multilateral retrofit installations and to ensure the ultimate success of the project.

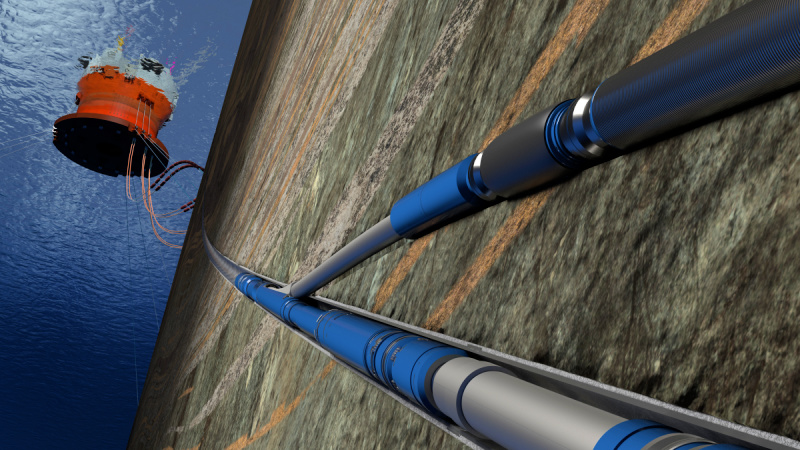

Reentry and lateral initiation

The wells were reentered using a standard marine drilling riser. Before a sidetrack was started, the upper completion was removed, the well was cleaned, and a multilateral anchor packer with a downhole isolation valve was installed. This temporarily isolated the original wellbore and provided an orienting and anchoring point for drilling the lateral and installing the junction. After the sidetrack was drilled and the wells were completed, the downhole isolation valve was opened hydraulically through the completion string. The lateral liner was run separately from the junction to make the liner design and installation simple and robust.

Multilateral junction and intelligent completion

The NCS is an area where requirements for multilateral junctions are well established. Junctions on most of the NCS projects need to provide mechanical integrity, sand exclusion, and pressure integrity. According to Technology Advancement of Multilaterals (TAML) classification, the junctions must be of level 5 to satisfy the criteria above. A RapidX* TAML 5 rated high-strength, hydraulic sealed-multilateral junction was the selected solution because it does not require any preinstalled hardware in the well. This technology is part of the recently introduced Schlumberger Transition Technologies* portfolio, which includes full-field development solutions aimed at reducing customer emissions while improving performance and value creation.

An intelligent completion was used for independent control of contributions from each leg at the junction. The ability to pressure test the junction allowed Vår Energi to confirm the installation was successful while the rig was in place, reducing uncertainty as a result.

To mitigate the risks for this subsea development, Schlumberger experts worked in constant collaboration with engineering teams from Vår Energi and its partners to optimize the final completion design and to elaborate comprehensive procedures and contingencies. Once the intelligent completion was installed, and production from existing branch was restored, the independent branch production initiated without any issues.

High-value, low carbon solution

Both sidetracks immediately added extra oil production and increased accessible reserves. Estimated total recovery from the wells is 7 to 8 million bbls. The campaign amounted to millions of dollars in savings and accelerated time to first oil by months when compared to the conventional approach. Another important success factor was reuse of existing infrastructure to avoid CO₂ emissions associated with drilling and completing new wells and the installation of additional infrastructure. This amounts to a 5,000 to 10,000 metric tons CO₂ equivalent emission avoidance. Following the success of Vår Energi’s multilateral retrofit installation, multiple NCS operators are evaluating or planning for similar installations, rather than drilling new wells, to reduce capital investment and lower their carbon footprint.