With remote monitoring and communication capabilities, cement jobs can be monitored in real time anywhere with the use of a smartphone or tablet PC. (Source: Nine Energy Service)

The oil and gas industry is more competitive today than ever before. Organizations are aware that every decision made has a direct impact on well productivity and the bottom line. To remain competitive, today’s oil and gas organizations have to be vigilantly proactive in remaining up to date with the best practices within the industry. The scope of this practice extends from staying on top of the latest in technological advancements to ensuring the right maintenance techniques are being used for pump equipment.

Selecting cement

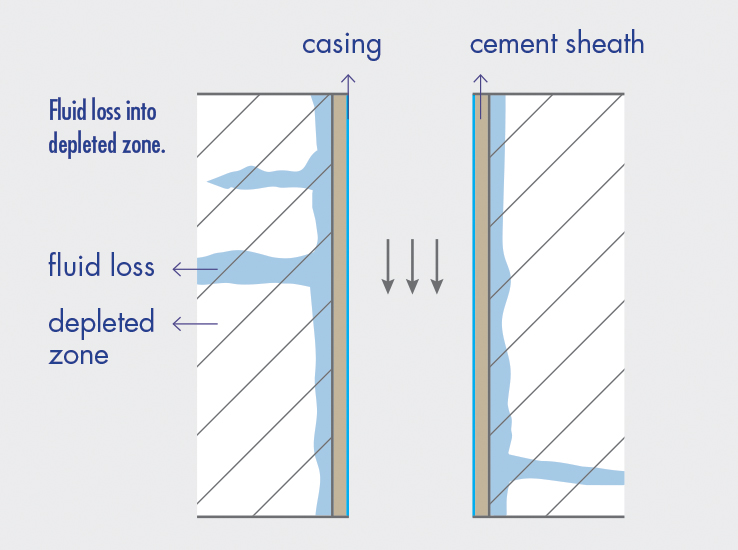

For starters, the quality of cement used has a significant impact on the performance of today’s horizontal wells. In the Permian Basin, the majority of existing Texas wells have demonstrated annular pressure and the need to get through depleted zones to drill. These low-pressure zones present a variety of challenges, including the potential for severe fluid loss, which has an impact on cement and can result in insufficient zonal isolation. Selecting the right cement for these tasks becomes vital, as the wrong cement can inhibit bottom-line impact by limiting the well’s production, creating the need for costly remediation. With these challenges and risks in mind, picking the right cement and strategy is more crucial than ever.

Leveraging lightweight or ultralightweight types of cement is a common tactic that is used to reduce hydrostatic pressure and consequently minimize fluid loss. Two approaches are generally used for these lightweight types of cement.

One strategy involves adding hollow glass microspheres to the cement mix. This creates a predictable slurry mixture because the glass microspheres are precisely manufactured with every batch, making variations very unlikely. These types of cement also have a fast compressive strength development, a high-set cement strength and can retain their strength at high temperatures.

While cement may have the needed properties at surface levels, downhole conditions can be quite different and cause shattering and a loss of buoyancy, ultimately leading to unsuccessful cementing. The slurry design should account for the crush strength and minimize the separation of low-density microspheres to prevent free water and loss of zonal isolation downhole to overcome this challenge.

Another approach to slurry design is injecting nitrogen gas. This offers good fluid loss control, high-tensile strength and ductility, efficient mud-displacement and hole-cleaning properties as well as creating better strength overall.

Cement setting time is also very important. The sooner the slurry sets, the quicker the operator can drill. Two options, in particular, can help speed up the process. Accelerators can speed it up, getting it down to as few as 12 hours while a preblended, quick-setting cement can set in as few as 6 hours. Utilizing either of these options for cementing jobs can improve an operation’s bottom line.

Planning a job to completion

The planning and execution of a cement job cannot be undervalued. By selecting the right partner with the necessary expertise, resources and reliability helps ensure that every aspect of a cement job is optimized. As that partner, the service team can recommend the optimal solution for each individual case. Additionally, the team can assist with designing, testing and executing specialized slurries utilizing low- and high-density ingredients at an R&D laboratory to achieve the required balance between well economics and cement quality.

Building upon the above qualities, the service team should be easily accessible and provide local testing facilities. Having a partner with experience in the location also can be helpful, as this provides another level of expertise.

Using modern equipment

Technology in the oil and gas industry has evolved substantially over the last several years, and the modern equipment and technology available today can deliver better and more predictable results. Investing in this equipment can increase efficiencies, reduce risks and save time.

Remote monitoring is one modern piece of equipment that can be helpful for cementing jobs. A smartphone or tablet can enable the maintaining of real-time monitoring and communication from anywhere while a job takes place. This provides multiple benefits, including removing the time and costs of driving to a well site and HSE risks. It also allows the user to manage multiple jobs in multiple locations. Additionally, remote monitoring allows cementing crews to stay connected with experts back at the base for support if necessary.

Putting best practices to the test

One operator in the Delaware Basin put modern best practices in cementing to the test. The operator wanted faster set times for cement, which would enable drilling of the intermediate shoe at the eight-hour regulated time or earlier, reducing the downtime while waiting on cement.

The operator had been using a conventional Class H slurry at 15.6 lb/gal, which resulted in reaching 500 psi in 10 to 13 hours. This led to a two- to three-hour wait period. At a spread rate of $3,200/hr, this grew to be a big expense that ultimately hurt the organization’s bottom line.

Leveraging Nine Energy Service, the operator tried a new approach. Nine utilized its Rapid Set One line of cement, which reached 500 psi in less than 8 hours by using a combination of cement materials and additives.

The first slurry tested and run by Nine was at a density of 15.6 lb/gal, which consistently reached 500 psi in less than 6 hours after dynamic conditioning time equaled the placement time on the job (about 2 hours).

After continuing to develop its Rapid Set One cement, Nine created formulations with densities between 13.5 and 14.2 lb/gal for formations requiring a lighter weight tail slurry while still remaining under 8 hours to reach 500 psi. The operator reached 500 psi up to 3 hours sooner than it had previously achieved, reducing wait time to the minimum regulatory requirements. This saved the operator approximately $8,000 in nonproductive time (NPT) per well.

As operators seek to refine and optimize their processes to improve their profits, it is clear that each aspect of their operation should be examined to determine how digitalization, new technologies and new best practices can shape what happens on site. Cementing improvement and modernizations are an important area to consider, as cementing optimizations can produce cost savings and reduce NPT, improving overall revenue per well.

Recommended Reading

Hess Corp. Boosts Bakken Output, Drilling Ahead of Chevron Merger

2024-01-31 - Hess Corp. increased its drilling activity and output from the Bakken play of North Dakota during the fourth quarter, the E&P reported in its latest earnings.

Petrie Partners: A Small Wonder

2024-02-01 - Petrie Partners may not be the biggest or flashiest investment bank on the block, but after over two decades, its executives have been around the block more than most.

CEO: Coterra ‘Deeply Curious’ on M&A Amid E&P Consolidation Wave

2024-02-26 - Coterra Energy has yet to get in on the large-scale M&A wave sweeping across the Lower 48—but CEO Tom Jorden said Coterra is keeping an eye on acquisition opportunities.

CEO: Magnolia Hunting Giddings Bolt-ons that ‘Pack a Punch’ in ‘24

2024-02-16 - Magnolia Oil & Gas plans to boost production volumes in the single digits this year, with the majority of the growth coming from the Giddings Field.

E&P Earnings Season Proves Up Stronger Efficiencies, Profits

2024-04-04 - The 2024 outlook for E&Ps largely surprises to the upside with conservative budgets and steady volumes.