Presented by:

This article appears in the E&P newsletter. Subscribe to the E&P newsletter here.

Methane is a very potent greenhouse gas responsible for global warming, accounting for about one-fifth of all man-made temperature increases so far. Because oil and gas facilities are among the leading causes of methane emissions, the EPA proposed regulations in November 2021 to reduce emissions from upstream and midstream oil and gas facilities by 70%. The proposed rules are far reaching, and the targeted emissions reduction has the equivalent climate effect of permanently removing about 25 million cars from America’s roads.

The EPA is focusing on methane “super emitters,” such as malfunctioning VRUs, open thief hatches, unlit flares, open bypass valves and blow-downs, and has proposed 10 kg/h (12 MCFD) methane as the detection limit for so called “advanced detection technologies.” These new technologies include airborne leak detection, continuous point sensors and continuous optical gas imaging (OGI) cameras.

Meeting impending methane regulations

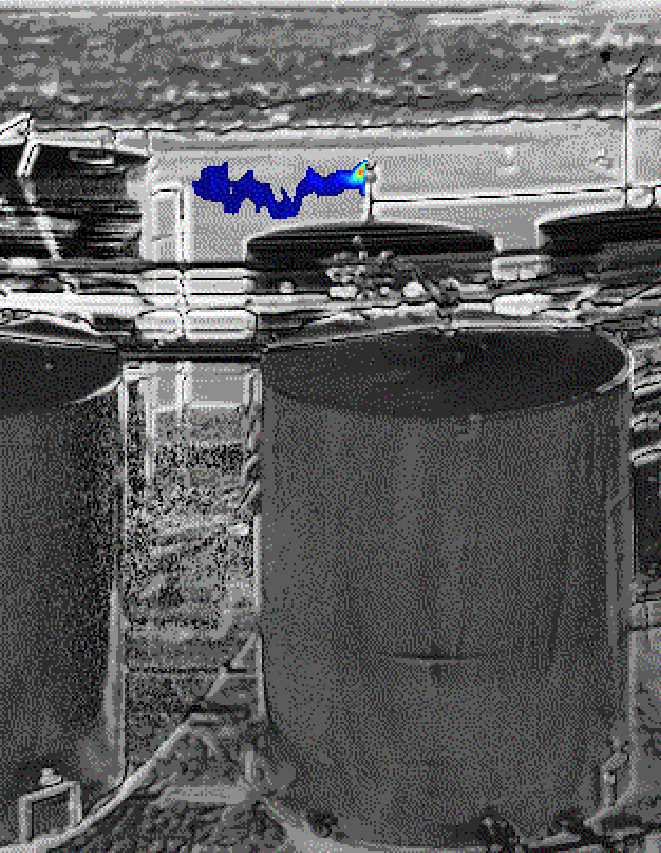

Airborne imaging can survey hundreds of miles per day to identify sources of emissions, while simultaneously collecting optical images. Aerial surveys are a promising solution as a large area can be screened for super emitters in a short time.

However, while airborne imaging is a key component in a broad approach to curbing emissions, the intermittency of significant emissions presents a major barrier. About 50% of detected emissions cannot be found on a second overflight, and a ground-based follow-up may not find a root cause of plane-detected emissions.

Due to the intermittency of emissions and because finding and repairing super emitters quickly is what contributes most to emissions reductions, continuous monitoring technologies are the ideal solution.

Continuous point sensors can detect emissions fast, but they face a number of operational challenges. Emissions from points higher up, such as tank thief hatches or pressure relief valves at separators, tend to be missed by point sensors as emissions blow over the installed height of point sensors and therefore are not detected.

The METEC test facility at Colorado State University conducted a five-month test of point sensors with hundreds of controlled gas releases in 2021 under the new ADED blind test protocol for continuous monitoring solutions. The report concluded that the configurations of point sensors tested missed about 50% of emissions because the plume never reached the sensor.

In contrast to point sensors, continuous OGI cameras tested in parallel with the same gas releases were able to detect all emissions larger than 3.7 kg/h and repeatedly as low as 0.25 kg/h. Continuous OGI cameras, like those available from Kuva Systems, address many of the challenges faced by both point sensors and aerial monitoring because the cameras offer continuous imagery of emission events sourced directly where emissions occur and do not rely on wind to bring emissions to the camera.

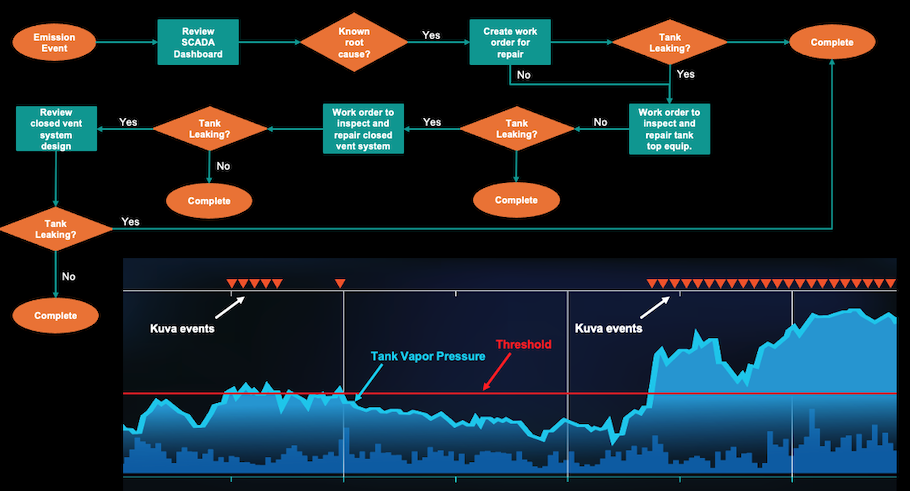

Continuous OGI cameras are typically mounted on a tower or pole and placed near the center of a site and can be rotated 360 degrees, with multiple fields of view for full-site coverage. Images with colorized gas plumes allow pinpointing of emissions to a specific piece of equipment or a specific component. Visual review of an image of emissions allows users to differentiate between permitted methane slip from compressors and abnormal emissions without the need to access a site or for follow-on inspections. Correlating time-stamped images of emissions with process SCADA data from sites has proven to be highly effective at determining the cause of process-related emissions.

Continuous OGI cameras also can be used to validate repairs, replacing the need for an expensive manual OGI inspection. Moreover, because they operate continuously, installed continuous OGI cameras and the associated cloud solutions are ideal for generating the required documentation to demonstrate ongoing compliance to regulators.

A key aspect of any advanced monitoring technology is to avoid false positive alarms. False positive alarms create inefficiencies, expenses and lost time for operators unnecessarily responding to false alerts. The Kuva camera participated in the above-mentioned blind testing at METEC and was found to produce zero false positive alerts during the entire five-month test period.

Case study 1

A Delaware Basin operator installed its first Kuva camera on a pristine tank battery site with PLC, draft range tank vapor sensors, a VRU, VFDs and a barrage of point sensors, with hopes of finding no emissions. Within hours of the camera being operational, it presented images of the Enardo valve flowing quite a bit of gas, with no indication from the point sensors. This caused the operator to take a deeper look into their facility design and process control strategy. Ultimately, the company was able to learn from the application and replicate those improvements at other similar sites.

Case study 2

While monitoring the production tank battery, a Permian Basin operator using a Kuva camera noticed that gas was flowing along the bottom part of their tanks. In curiosity they panned the camera to see where the gas was originating and noticed it was flowing from their produced water tanks. Not being a point of concern, they dug into to why this might be happening and learned that their separator dump cycles were too close together. By simply extending the retention time, they were able to mitigate the majority of those emissions.

ESG strategies of the oil and gas industry

Many publicly listed oil and gas companies have positioned themselves as ESG leaders in the industry based on methane reduction efforts that go beyond current requirements. Proposed EPA regulations dramatically increase the baseline for methane reduction so that ESG policies that tout “beyond compliance” actions will need to be revised.

Innovation will be crucial in meeting the challenge of climate change. With recent innovations in methane detection, the oil and gas industry has the tools and technologies to get the emissions reduction job done in a cost-scalable manner. Continuous OGI cameras are a clear path forward for the industry to demonstrate ESG leadership and regain its credibility as a responsibly sourced form of energy.

About the authors: Stefan Bokaemper is Kuva Systems' CEO, and Robert Ward is the vice president of business development.

Recommended Reading

Kimmeridge Fast Forwards on SilverBow with Takeover Bid

2024-03-13 - Investment firm Kimmeridge Energy Management, which first asked for additional SilverBow Resources board seats, has followed up with a buyout offer. A deal would make a nearly 1 Bcfe/d Eagle Ford pureplay.

Laredo Oil Subsidiary, Erehwon Enter Into Drilling Agreement with Texakoma

2024-03-14 - The agreement with Lustre Oil and Erehwon Oil & Gas would allow Texakoma to participate in the development of 7,375 net acres of mineral rights in Valley County, Montana.

Hess Corp. Boosts Bakken Output, Drilling Ahead of Chevron Merger

2024-01-31 - Hess Corp. increased its drilling activity and output from the Bakken play of North Dakota during the fourth quarter, the E&P reported in its latest earnings.

The OGInterview: Petrie Partners a Big Deal Among Investment Banks

2024-02-01 - In this OGInterview, Hart Energy's Chris Mathews sat down with Petrie Partners—perhaps not the biggest or flashiest investment bank around, but after over two decades, the firm has been around the block more than most.

Petrie Partners: A Small Wonder

2024-02-01 - Petrie Partners may not be the biggest or flashiest investment bank on the block, but after over two decades, its executives have been around the block more than most.