Presented by:

Editor's note: This article appears in the E&P newsletter. Subscribe here.

The Welltec Metal Expandable Packer (MEP) enabled the efficient drilling of a multilateral well within a highly permeable reservoir for an operator in a field in Scandinavia, significantly improving the overall net present value (NPV) of the well. The operator has extensive experience in drilling multilateral wells from platforms located in shallow waters (127 m) offshore Norway.

The initial development of the field occurred in 2003. As part of the ongoing redevelopment program, in 2019, the client opted to drill a multilateral well to maximize the reservoir contact and improve overall economics of the field.

The initial architecture of the multilateral well included a 9 5/8-inch cemented liner from which the 8½-inch main bore was drilled and then two 8½-inch horizontal laterals that would have been completed with 5 ½-inch standalone screens (SAS). Based on past experiences, the operator expected challenges with fluid losses to the main bore while milling the first and second windows of the two 8 ½-inch horizontal lateral sections.

These losses, if they occurred, would jeopardize the successful drilling of the lateral sections, which will in turn have significant effects on the future production (or injection) capacity of the well, thereby reducing the overall NPV of the project. To prevent losses while drilling the 8 ½-inch lateral sections, the seal around the 9 5/8 inches must provide annular isolation. Unfortunately, due to the many variables when cementing, this cannot always be guaranteed.

The operator deployed different technologies in the past to improve the seal around the 9 5/8-inch section with limited success. One of the technologies previously used were swell type packers, which were installed on the 5 ½-inch liner within the 8 ½-inch open-hole section. The swell type packer was positioned between the 9 5/8-inch casing and the SAS to prevent losses. Unfortunately, in this environment, the swell type packer require 25 days to reach its maximum expansion outer diameter (OD), introducing significant non-productive time (NPT) and an increase in the total cost of the project.

On prior projects where the operator elected to “wait on swell time”, losses were still encountered, and the lateral sections were not completed. Based on the experiences described, and a combination of other factors that would have challenged the proper placement of cement, for future projects the operator elected to install the 9 5/8-inch section without the use of cement that is cementless.

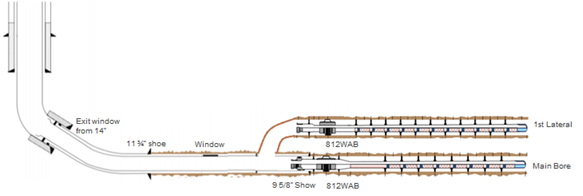

Welltec proposed to utilize the Welltec Annular Barrier (WAB) with the cementless 9 5/8-inch well architecture providing zonal isolation and the WAB installed on the top of the liner within the 8 ½-inch open hole to facilitate the milling of the 9 5/8-inch window and drilling the lateral sections without incurring losses to the 8 ½-inch holes section (Figure 1).

This positively impacts the cleaning of the wellbore as cutting will be easily transported to the surface.

Another challenge was the high permeability of the formation encouraging crossflow through the rock. Welltec addressed this challenge via the diversion of the mud through the formation by the WAB sealing against the borehole inner diameter, the solids forming a cake and a resistance to flow through the formation.

The MEP Welltec Annular Barrier (WAB) is a surface-controlled, metal hydraulic expandable packer mounted on a fullbore tubular (liner/tubing/casing). The all-metal design enables tubular rotation and circulation during deployment with minimal impact on equivalent circulating density during circulation. When the tubular has reached its shoe depth, the WAB is hydraulically expanded quickly under full surface control sealing off the tubular to open-hole or cased-hole annulus. The WAB is qualified to the highest industry packer standard ISO 14310 V3 & V0 with in-situ load (anchoring) providing best-in-class zonal isolation or well barrier annular sealing. Hydraulic expansion ensures conformance of the seal system to the open-hole wellbore or cased-hole applications.

An efficient deployment

After receiving the green light from the operator, Welltec designed and manufactured the 812WAB in a record time of eight weeks. The achievement of this feat was facilitated by a thorough gathering and understanding of the requirements of the operator, gathered using a detailed Statement of Requirement, the robust design of the MEP and fully automated manufacturing, assuring the delivery of the product.

The operator drilled the main bore, after which the WAB was installed on the 7-inch liner, which was positioned below the 9 5/8-inch shoe, above the SAS. The ability to rotate the WAB maximized getting the 7-inch by 5½-inch liner to reach the required depth. Once on depth, fluid was circulated to condition the open hole, the liner hanger was set using pressure cycles, after which the 812WAB was quickly set under full surface control.

The first window of the multilateral section was milled successfully without incurring approximately 25 days of NPT waiting on the swell packers to fully expand. Minimal fluid losses were experienced during the milling of the first window and the subsequent drilling of the first multilateral section, implying that the 812WAB installed in the main bore successfully sealed the annulus.

The second 812WAB was installed on a 5 ½-inch liner in the second multilateral section with the objective of preventing losses into the first multilateral section while milling the window prior to drilling the second multilateral section. Good circulation and returns were maintained during the drilling of the second multilateral section, again confirming that the combination of the 812WAB and the lost circulation material achieved the objective of minimizing the losses. The operator captured this as a significant achievement, which addressed some of the challenges experienced on previous wells.

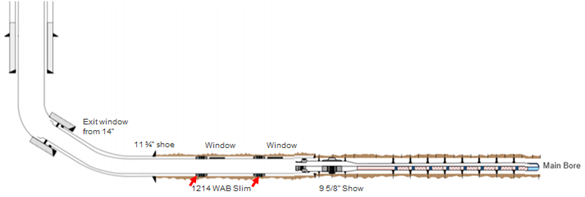

Based on the learnings from the initial deployment of the 812WAB, an alternative solution was proposed to install 1214WABs on the 9 5/8-inch liner (run through the 11 ¾-inch liner). The 1214WABs were positioned above the planned multilateral windows and expanded to seal within the 12 ¼-inch open hole (Figure 2).

An additional ISO 14310, V3 was performed to qualify the MEP and confirm that it will fit in the clearance between the 9 5/8-inch by 11 ¾-inch liners. The complete scope of work, including the manufacturing of products for deployment, was completed in record time to match the drilling schedule of the operator. The results were very positive, confirming that it was possible to drill two multilateral windows with a cementless 9 5/8-inch liner and minimal fluid losses.

Summary

The 812WAB and the 1214WAB tools enabled the deployment of a cementless liner to efficiently drill and complete a multilateral well with two different legs, significantly improving the overall NPV of the well by eliminating opex and NPT. This operation represents the first applications of the WAB technology to isolate losses during the construction of multilateral wells.

Recommended Reading

E&P Highlights: April 8, 2024

2024-04-08 - Here’s a roundup of the latest E&P headlines, including new contract awards and a product launch.

E&P Highlights: March 15, 2024

2024-03-15 - Here’s a roundup of the latest E&P headlines, including a new discovery and offshore contract awards.

Deepwater Roundup 2024: Offshore Australasia, Surrounding Areas

2024-04-09 - Projects in Australia and Asia are progressing in part two of Hart Energy's 2024 Deepwater Roundup. Deepwater projects in Vietnam and Australia look to yield high reserves, while a project offshore Malaysia looks to will be developed by an solar panel powered FPSO.

E&P Highlights: April 22, 2024

2024-04-22 - Here’s a roundup of the latest E&P headlines, including a standardization MoU and new contract awards.

E&P Highlights: March 11, 2024

2024-03-11 - Here’s a roundup of the latest E&P headlines, including a new bid round offshore Bangladesh and new contract awards.