Offshore operators are squeezed between investors looking for a greater return: dividends and ESG compliance on the one hand, and the pressure to get more oil to the quickly-recovering consumer marketplace. That’s a lot of boxes to check, so to meet those demands Baker Hughes Co. is aggregating data in real time to inform drilling while Schlumberger Ltd. is offering a technology that finds the middle ground between transient and drillstem tests.

Aggregating Real-time Data to Inform Drilling

Drilling a new well, even in an established area, involves collecting, sorting and analyzing increasingly massive amounts of data from several sectors. Decisions are not made based on hunches or what happened in other wells, although historical database information does come into play. Nor are decisions delayed while waiting on data collected on freestanding sensors to be downloaded and analyzed a week or two later.

Just a few years ago downhole data was less reliable, says Svein Hovland, reservoir technical services digital lead for Baker Hughes. Today’s armies of better-calibrated sensors informing better-educated artificial intelligence (AI) and machine learning systems is changing that perception. The challenge now is in finding ways to leverage the data to quickly make decisions that boost production, short-term and long-term while reducing well construction cost in the process.

“There’s so much data you have to be smart about what you do,” he said, “because it’s too much for a human being to interpret without digital solutions.”

Clients are also demanding more speed, which is where AI and machine learning come to the forefront.

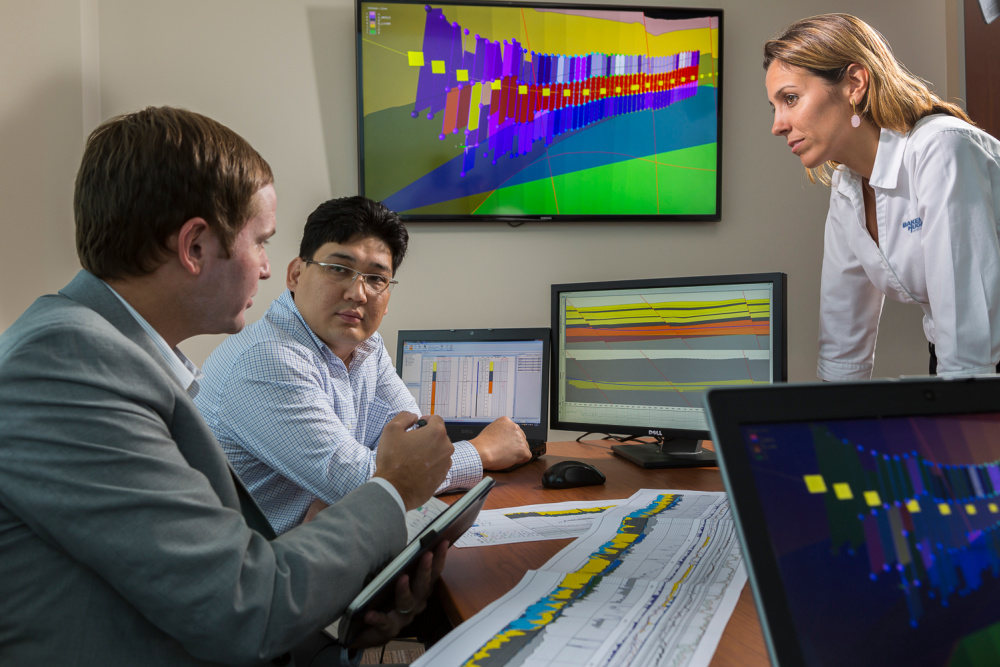

One goal of the new technology is to eliminate the hunches and the issue of two geoscientists arriving at different decisions based on the same data. “It’s not as subjective as it has been,” he said. Even so, “subject matter expert guidance” (SMEs) is still key; even AI and machine learning need humans to accurately make many decisions.

Aggregating this kind of data for those SMEs is part of Hovland’s responsibility. One of the ways Baker Hughes wants to apply this technology is in fully automating reservoir navigation. That is “basically where we have a rotary steerable system that optimizes the well trajectory and position within the reservoir, based on real-time data,” he said.

Maximizing reservoir contact is one of the top goals for reservoir navigation. AI can leverage extensive data, including drilling dynamics, multiphysics data, offset well data and more in real time instead of waiting for humans to work through it. As such, Hovland believes, “as we drill deeper and more complex reservoirs we may be able to leverage AI to optimally place the wellbore.”

Making major decisions based on information received from sensors embedded in the heat and corrosion of a drilling rig might seem risky, but using AI and machine learning might mitigate those risks with the use of digital twins.

“If you run machine learning in combination with a digital twin, for example, then you could also have a software sensor,” Hovland said. “As you compare your readings over time, with a digital twin that predicts what the sensor should read, you can use the AI to also detect potential sensor failures.”

Case Study

In the Edvard Grieg Field in the North Sea, optimal positioning of horizontal production wells requires a well trajectory close to the reservoir roof while maintaining a safe stand-off. Because of the formation’s complex characteristics, real-time mapping is instrumental in successful well placement, requiring accurately aggregated data from several tools and services, according to Hovland.

The operator drilled three pilot wells, 10 oil producers and four injection wells during the field’s first production drilling campaign. On all the production wells and one of the pilots, Baker Hughes used their reservation navigation service (RNS), including technologies such as VisiTrak extra deep azimuthal resistivity and “StarTrak high-resolution advanced logging-while-drilling” imaging system to collect and aggregate the needed data.

Wired drill pipe was deployed to deliver high data density and quality, in real time, giving the operations team detailed data immediately, thereby facilitating detailed analysis of StarTrak image data.

Over a total of 16,683 m drilled, the system collected and integrated data from multiple disciplines, while RNS ensured improved situational awareness for the producer’s operations team. Optimized well placement and reservoir mapping led to optimal production from the field, according to Baker Hughes.

Advance in Reservoir Testing

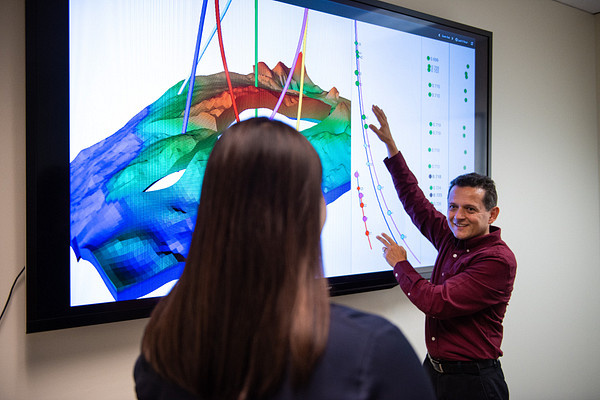

Ashers Partouche, the product champion for Ora, explains that Schlumberger’s Ora intelligent wireline formation testing platform combines the best of the two most common forms of reservoir characterization. Wireline transient testing is fast, but investigates a relatively small portion of the reservoir. The other option, drillstem testing (DST), provides a deep measurement—but can delay the well’s completion by several weeks.

“There was nothing in between,” said Partouche. “You either had to go with very incomplete data to assess the reservoir, or you had to go with very intensive testing.”

Ora, with its deep transient testing (DTT), is bridging the gap with the high granularity of a wireline test, combined with multiple zone testing and a larger radius of investigation from the wellbore up to several 100 meters, which previously came only from DST. Sometimes a DST may be required because the two tests overlap, but each technique provides data unique from the other.

The goal for the Ora platform, which enables DTT on wireline, is to provide more complete reservoir data than traditional wireline transient testing in a relatively short amount of time. Overarching all this are ESG features: No methane is released in the process, no heavy equipment is shipped to and from the platform, and the test requires 50% less energy than previous technologies, according to the service company.

Ora provides such information as hydrocarbons in place and well deliverability and can inform the reservoir booking.

In one recent case, “We were able to confirm minimum hydrocarbon in place and reservoir deliverability just six weeks after the start of the well” without releasing any flaring-related greenhouse gases, Partouche said. The availability of these more immediate answers from Ora helps operators accelerate their field development, Partouche added.

Ora DTT on wireline can also assess connectivity between reservoir layers. Partouche spoke of one offshore well with multiple producing zones requiring assessment where they assessed both reservoir size and vertical connectivity by characterizing reservoir fluid in real time.

The speed, accuracy, efficiency and ESG benefits revolve around wireline tools that withstand temperatures up to 392 F and pressures to 35,000 psi, higher than available before.

The company estimates that, because the procedure eliminates flaring, it saves 5,700 metric tons of carbon per zone tested, 96% less than a DST procedure would release.

While there is some artificial intelligence involved, Partouche said Ora’s main data-side benefit is its immediacy—real-time data availability for preemptive decisions.

Recommended Reading

E&P Highlights: April 15, 2024

2024-04-15 - Here’s a roundup of the latest E&P headlines, including an ultra-deepwater discovery and new contract awards.

Rystad: More Deepwater Wells to be Drilled in 2024

2024-02-29 - Upstream majors dive into deeper and frontier waters while exploration budgets for 2024 remain flat.

Diamondback May Go Nuclear to Power Permian Basin Ops

2024-04-08 - Oklo Inc., a California fission power plant developer, on April 8 said it signed a letter of intent to collaborate with Diamondback Energy on implementation of nuclear energy for drilling operations in the Permian Basin.

To Dawson: EOG, SM Energy, More Aim to Push Midland Heat Map North

2024-02-22 - SM Energy joined Birch Operations, EOG Resources and Callon Petroleum in applying the newest D&C intel to areas north of Midland and Martin counties.

CNX, Appalachia Peers Defer Completions as NatGas Prices Languish

2024-04-25 - Henry Hub blues: CNX Resources and other Appalachia producers are slashing production and deferring well completions as natural gas spot prices hover near record lows.