Presented by:

Editor's note: This article appears in the E&P newsletter. Subscribe to the E&P newsletter here.

The industry’s first high-density (1.145 SG) equipment preservation and hydrate prevention fluid was recently deployed successfully to four subsea trees by a major independent operator in the Gulf of Mexico. Developed by Houston-based Universal Subsea Inc. (USI), the environmentally friendly fluid was injected into the access bore of four subsea wells in the first field application of this novel product.

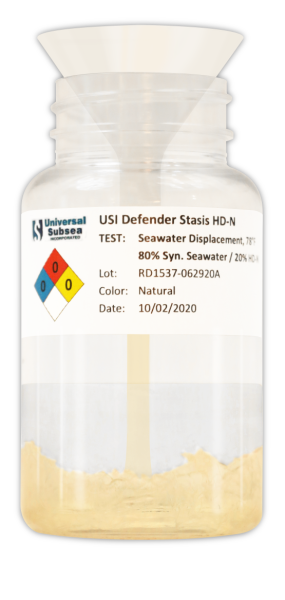

USI’s Defender Stasis HD preservation fluid was successfully injected in its first deployment subsea in August 2020 on a relatively shallow well in 1,500 ft. of water using a top fill method. The fluid performed identically to lab testing to effectively displace the seawater from the access bore of the subsea tree above the swab valve. This first use subsea verified the remarkable capability of Stasis HD to sweep seawater from the subsea equipment bore under deepsea conditions just by pouring the high-density fluid into the top of the tree. After a second successful deployment three weeks later, the operator selected the Stasis HD fluid for a deepwater intervention on two high-pressure subsea wells in 4,500 ft. of water. The successful use on these two additional wells for a prominent project completed the field trials of the fluid in preparation for commercial release.

The Defender Stasis HD fluid was formulated to stop degradation and preserve sealing integrity of subsea tree mandrels, tree access bores, tubing head spools and similar subsea equipment while preventing costly methane hydrate blockages in the access bore of trees where gas may accumulate. The fluid has unique properties to protect subsea equipment from corrosion, calcareous deposits and marine fouling while preventing methane hydrates.

“Early in the development of our Defender subsea isolation cap, we recognized the need for an improved lightweight preservation fluid for subsea wellhead caps,” reports Sean Thomas, P.E., USI president and founder. “We discovered that the water-based wellhead preservation fluids contained toxic hydrocarbon solvents and were much less effective than we had believed. These water-based fluids are toxic to personnel and marine life, and posed risk of damage to some elastomers and plastics. These drawbacks led us to develop our lightweight Defender Stasis LT preservation fluid. We also saw the need for a high-density preservation fluid for subsea tree and tubing head applications, but we knew this product would be much more exotic, and it would be difficult to find a formulation that would meet environmental regulations for direct release to sea. We could see a significant benefit to the industry for this product, and we recognized that the high-density fluid could play a key role in preventing hydrates in subsea well access bores.”

The Defender Stasis HD fluid is formulated with an exclusive, high-density, biodegradable synthetic ester which is engineered to be similar to natural vegetable oils. The fluid is environmentally nontoxic, biodegradable, non-bioaccumulating, non-sheen forming and non-hydrate forming. The revolutionary fluid is classified as a subsea equipment preservation fluid in compliance with U.S. EPA NPDES GMG290000 and is approved for direct release to sea from subsea oil and gas facilities. This unique fluid will even biodegrade at the ocean floor in pitch darkness at near freezing temperatures. The fluid meets the strictest regulatory requirements for offshore oil-producing nations worldwide.

“Most offshore operators are familiar with the high costs associated with gas hydrate blockages in the access bore of subsea trees,” stated John Fitzgerald, Director of Sales and Marketing, USI. “Many subsea trees will slowly bubble natural gas past the annulus access valve, crown plugs or swab valves. The methane gas mixes with seawater and freezes to form gas hydrate plugs in the well access bore. The resulting blockage impedes well intervention, requiring hydrate remediation units with methanol injection to depressurize and melt the hydrates. This process can require up to 24 hours or more of vessel time, costing $150,000 to $800,000 depending on the vessel type.”

“For a vertical tree, the hydrate blockage can extend from the internal tree cap all the way down into the swab valves,” Fitzgerald added. “There have been some field reports that the hydrates can damage the sealing performance of the swab valves, which would have major consequences for well containment and continued subsea well operation. Multiple incidents have also occurred where the internal tree cap has been frozen in place by hydrates, resulting in significant vessel downtime and high costs to remove the cap.”

The biodegradable ester used in the Stasis HD fluid is very different than water-based fluids and water-glycols normally used for subsea tree caps. When injected into the subsea tree access bore, the fluid creates a non-aqueous environment so that methane gas will bubble through the preservation fluid without forming hydrates.

“Whether injected into equipment subsea or tested in the lab, Stasis HD immediately sinks to the bottom of equipment bores and immersed cavities filled with seawater or other fluids, displacing those fluids from the bottom upwards, completing a full sweep and replacement of the fluids with the high-density fluid,” explained Thomas. “Stasis HD will displace and sweep water, seawater, alcohols, glycols, water-based control fluids, crude oil, most refined petroleum oils and diluted completion brines (SG < 1.14). The fluid has truly unique properties to protect equipment installed subsea.”

The Defender Stasis HD fluid can be injected into a closed chamber such as a subsea tree cap (with venting at the top), in open water with a dispensing hose or by simply holding an ROV hot stab over the bore of the subsea tree mandrel. In all cases, the fluid immediately falls to the bottom of the access bore, equipment bore or container, displacing any fluids in the bore (SG < 1.14), and progressively completing a uniform sweep with the high-density fluid.

The Stasis HD fluid works equally well when there are multiple cavities or annuli at the bottom of the equipment bore, such as horizontal tree tubing hangers, subsea tubing head spools and vertical tree swab valves. The fluid is rated as a dielectric fluid at full concentration, so it is ideal to protect electrical couplers for tubing head spools during subsea well construction and temporary abandonments. The Stasis HD fluid is also an excellent choice for subsea manifolds, PLETs/PLEMs and related subsea equipment that are deployed dry, flooded, and then wet parked prior to connection and commissioning. The fluid will effectively dewater the bores of the wet parked equipment to create a non-aqueous environment prior to installing a protective cap to the hub or mandrel.

The Defender Stasis HD preservation fluid is an important addition to USI’s line of Defender Stasis preservation fluids and Defender subsea isolation caps. The lightweight Defender Stasis LT and ST preservation fluids are formulated from natural and modified vegetables oils and environmentally friendly additives to provide superior protection for subsea wellhead and tree mandrels in addition to storage and shipping applications. In the subsea environment, the lightweight Stasis LT and ST fluids (SG < 0.93) are buoyant and will displace seawater downwards when injected into a subsea well protector cap.

The patented Defender isolation cap is the first lightweight subsea well protector cap that completely isolates the subsea well mandrel from the marine environment. The Defender isolation cap used with Defender Stasis preservation fluids provides a total of four barriers to the cathodic protection system to completely halt all corrosion, marine growth and calcareous deposits, ensuring that there is no degradation of critical sealing and locking profiles to provide gas-tight sealing integrity over the life of the subsea well. This preventive measure for the subsea well interface virtually eliminates the need for scrubbing activities and acid wash jobs that can cause further damage to sealing surfaces, and are incapable of restoring gas sealing performance once it has been lost.

After decommissioning, most subsea wells will have residual hydrocarbons, and there is increasing attention from regulators to the risk of methane releases from plugged and abandoned subsea wells. It is well known in the industry that cement plugs and annular casing cement will develop microcracks over time and become decreasingly effective as a gas-tight barrier. In deep water, and sometimes in shallower water, the subsea wellhead will be left in place on the seabed, which provides a means for the operator to return to the subsea well to check pressure integrity of the plugs and perform repairs if necessary.

Several companies have introduced subsea well methane detection systems which alert the operator to the methane leak so that the plugs can be repaired or reset. However, the subsea well mandrel must be in serviceable condition when the operator returns to the subsea well for the intervention five or ten years later. With current industry practices the subsea well mandrel will be severely deteriorated after a long abandonment, and in may not be possible to get a successful BOP test even after extensive and costly scrubbing of the sealing surface. For these applications, the Defender Stasis preservation fluids and Defender subsea isolation cap can play a critical role to maintain subsea well reliability into the permanent abandonment phase in the mission to minimize methane releases from subsea oilfields to reduce carbon footprint and help mitigate climate change.

Recommended Reading

Baker Hughes Marks Hydrogen Milestones

2024-01-29 - The energy technology company is involved with several hydrogen projects as it works to accelerate the hydrogen economy.

Shell Taps Bloom Energy’s SOEC Technology for Clean Hydrogen Projects

2024-03-07 - Shell and Bloom Energy’s partnership will investigate decarbonization solutions with the goal of developing large-scale, solid oxide electrolyzer systems for use at Shell’s assets.

Plug Power Finalizes Contract with US Auto Manufacturer

2024-02-21 - Plug Power says it will supply hydrogen infrastructure and fuel cell solutions as part of the agreement.

Going Green? Kraft Seeks $170MM from DOE for ‘Delicious Decarbonization’

2024-03-25 - Kraft Heinz, a $43 billion food company, is seeking to reduce its annual emissions by 99% through a Department of Energy grant.

Mitsubishi, Chevron Overcome Hydrogen, Storage Project Woes

2024-03-21 - ACES Delta developers say the project remains on track for 2025 startup, despite previous supply chain obstacles.