Presented by:

This article appears in the E&P newsletter. Subscribe to the E&P newsletter here.

As the oil and gas industry continues to gain momentum implementing various ESG strategies to aid in the protection of people and the environment, there is a need for solutions that can better prevent or minimize fugitive methane (CH4) leaks over the life of a well.

According to the Environmental Protection Agency (EPA), “[n]atural gas and petroleum systems are the second largest source of CH4 emissions in the United States” (Overview of Greenhouse Gases | US EPA). Second to CO₂, which accounts for about 80% of U.S. greenhouse-gas (GHG) emissions, methane accounts for around 10% of U.S. GHG emissions (Overview of Greenhouse Gases | US EPA). In terms of Global Warming Potential (GWP) over a 100-year period, methane is about 25 times more potent than CO₂ as it absorbs radiation more efficiently within a shorter atmospheric lifetime than CO₂ (Overview of Greenhouse Gases | US EPA). With respect to the oil and gas industry, an extensive study led by the Environmental Defense Fund (EDF) from 2012 to 2018 revealed that the oil and gas industry emitted 60% more methane than the EPA originally estimated at the time (Major studies reveal 60% more methane emissions | Environmental Defense Fund (edf.org)). These figures suggest opportunities for the oil and gas industry to seek and apply solutions that better prevent or minimize methane emissions. One such area where these solutions can be applied is during a well’s construction, particularly within the cementing phase.

The main objectives in cementing oil and gas wells are to secure the casing to the surrounding rock formation and to provide good zonal isolation in the wellbore. The cement sheath creates a hydraulic seal that prevents the formation fluid and gases, such as methane, from migrating into adjacent aquifers and/or up to the surface. The cementing operation itself involves mixing a slurry of cement with cement additives and water, pumping the cement slurry through the inside of the casing, and displacing the slurry into the annulus. Due to the wide range of temperatures, pressures, and formation conditions present in a well, cement additives are often used to modify cement slurry properties to meet individual well conditions and improve the overall integrity and sustainability of the wellbore. Cementing additive technologies for the purpose of enabling the prevention or minimization of fugitive methane emissions are reasonably well-known within the industry. The challenge, however, is to take an integrated approach to deploying these technologies collectively, consistently, and reliably. In many cases, the investment decision in deploying these technologies is economical as the well intervention cost is typically significant.

To minimize fugitive methane (CH4) leaks and reduce remedial expenditures over the life of a well, it is critical to take an integrated approach that enables the industry to build more sustainable wells by delivering preventative solutions. For instance, the integrated program may consist of a set of specialty chemical solutions, such as mix-on-the fly spacer, fluid loss and gas migration control agents, temperature triggered anti-settling agent, and expansion agents.

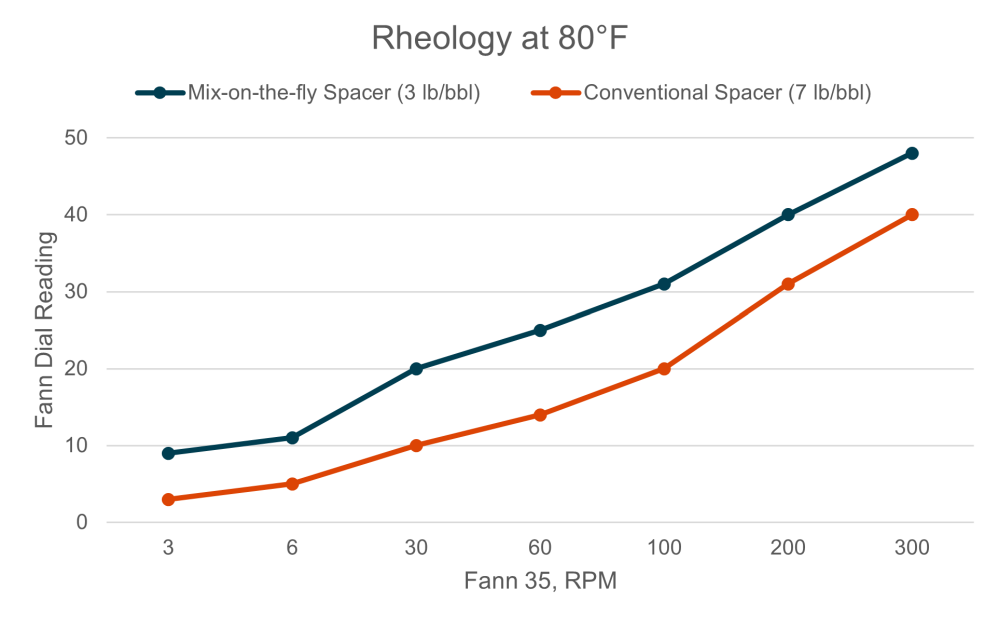

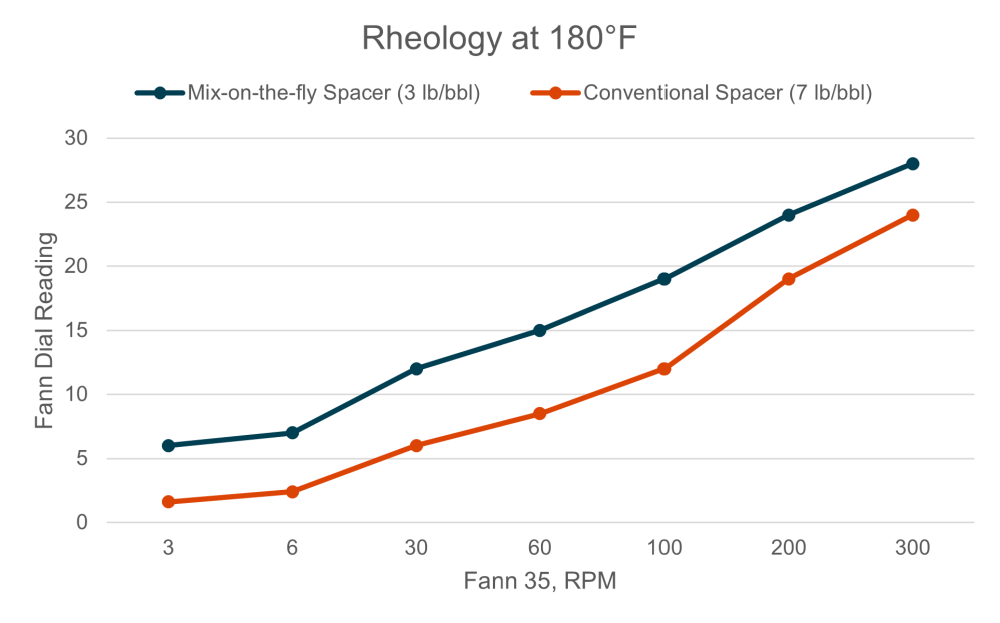

- Mix-on-the-fly Spacer: A spacer is a viscous aqueous fluid that is typically used to displace drilling fluids prior to a primary cementing operation. A well-engineered spacer is critical to the success of proper cement placement and achieving good zonal isolation. A mix-on-the-fly spacer reduces surface equipment footprint and enables real time rheology adjustment. It can be used in combination with chemical washes and other additives to further aid mud removal and improve cement bonding to the formation and casings, thereby eliminating the pathway for gas migration.

- Fluid Loss and Gas Migration Control Agents: During a cementing operation, the aqueous phase of a cement slurry can leak into the formation due to pressure differentials when the slurry is pumped against a permeable formation. The loss of fluid can result in rapid increase in slurry viscosity during placement or negatively accelerate cement setting. As such, fluid loss agents are always applied to the cement slurry to ensure proper placement and zonal coverage per job design. Gas migration control is typically achieved through both good fluid loss control and short transition time to set.

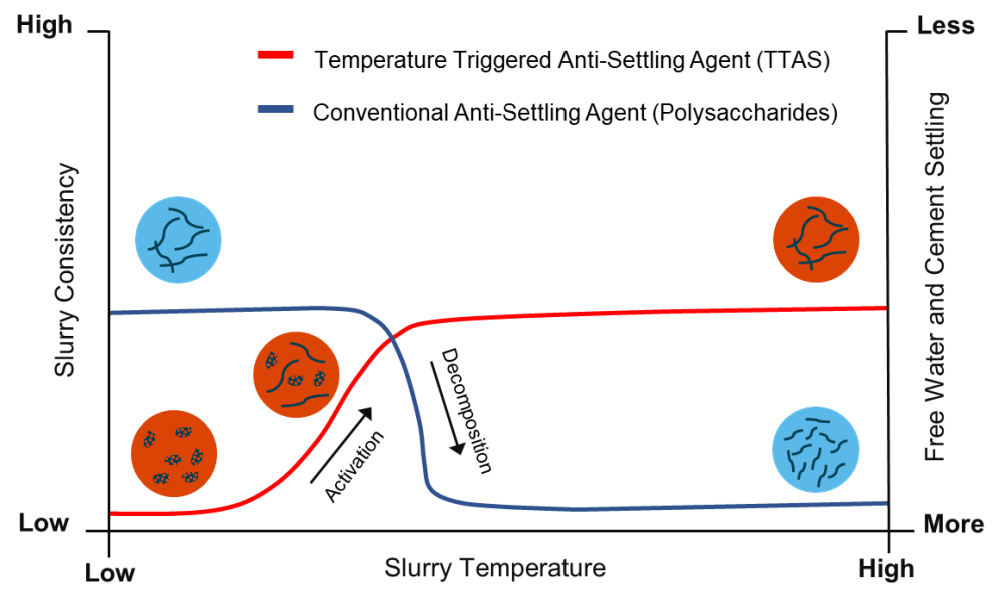

- Temperature Triggered Anti-Settling Agent (TTAS): Anti-settling agents are often applied to improve cement slurry stability by preventing solids settling and mitigating the formation of free fluid in cement slurries that are over-dispersed or in high density slurries where weighing agents such as hematite are used. Conventional anti-settling additives, such as clays and polysaccharides, start to lose effectiveness above 260 F. Consequently, higher dosages of conventional anti-settling additives are often applied to compensate for high temperature thermal thinning effects, which inadvertently increase slurry placement difficulty with minimal improvement to slurry stability. By contrast, a TTAS has minimal impact on slurry rheology before the temperature trigger sets in around 200 F, thereby reducing slurry mixing and pumping difficulty on surface. It also maintains stability at higher downhole temperature conditions up to 350°F or higher to ensure cement sheath integrity across longer and hotter hole sections. A more consistent cement set helps eliminate any weak points for gas migration.

- Expansion Agents: Effective bonding between cement and formation and between cement and casings is required to achieve good zonal isolation. Inherent chemical shrinkage as cement sets can decrease bulk volume of cement and cause undesirable zonal communication. Expansion agents enable cement to expand after the cement sets and effectively prevent debonding between the cement and the formation and between the cement and casings. Expansion agents are designed to counter bulk cement shrinkage, which is the cornerstone of cementing technology for mitigating methane leakage.

While we know the collective application of these technologies enables the construction of more sustainable wells, ChampionX’s future work involving these integrated technologies is to better understand its contribution to mitigating methane leaks on a more quantifiable level through continued partnerships with its customers applying these chemistries. ChampionX also continues to support ESG initiatives thru the development and utilization of an internal platform to understand its manufacturing and logistics carbon footprint from the chemical solutions it delivers to its customers. As an industry, we must take a proactive and holistic approach to curbing methane leaks in collaboration with all parties involved in the life cycle of a well. Through these partnerships and shared ESG initiatives, we can truly start to realize the impact on reducing or eliminating methane emissions.

Recommended Reading

From Restructuring to Reinvention, Weatherford Upbeat on Upcycle

2024-02-11 - Weatherford CEO Girish Saligram charts course for growth as the company looks to enter the third year of what appears to be a long upcycle.

TechnipFMC Eyes $30B in Subsea Orders by 2025

2024-02-23 - TechnipFMC is capitalizing on an industry shift in spending to offshore projects from land projects.

NOV's AI, Edge Offerings Find Traction—Despite Crowded Field

2024-02-02 - NOV’s CEO Clay Williams is bullish on the company’s digital future, highlighting value-driven adoption of tech by customers.

Patterson-UTI Braces for Activity ‘Pause’ After E&P Consolidations

2024-02-19 - Patterson-UTI saw net income rebound from 2022 and CEO Andy Hendricks says the company is well positioned following a wave of E&P consolidations that may slow activity.

ProPetro Reports Material Weakness in Financial Reporting Controls

2024-03-14 - ProPetro identified a material weakness in internal controls over financial reporting, the oilfield services firm said in a filing.