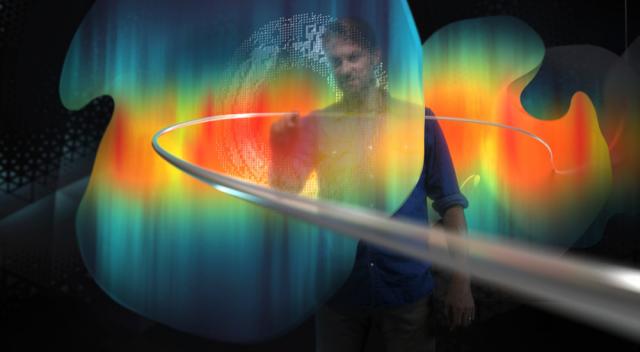

During a recent SPE Tech Talk webinar, Mauro Viandante, geosteering and reservoir mapping domain champion at Schlumberger, shared how the reservoir geosteering technology was able to help a client stay on the right track by creating the right path for their well. (Source: Schlumberger Ltd.)

Presented by:

This article appears in the E&P newsletter. Subscribe to the E&P newsletter here.

The steep prices of well upkeep can be intimidating for operators, especially when they don’t have a clear understanding of what is happening in the well. Geosteering and reservoir mapping technology is a helpful resource operators use, but with more complex wells, it’s necessary to invest in more complex technology.

In the SPE Tech Talk webinar “3D Reservoir Mapping-While-Drilling Service” on March 17, Mauro Viandante, geosteering and reservoir mapping domain champion at Schlumberger, explained the advantages of 3D mapping-while-drilling technologies over 2D technologies.

“We are adding a new dimension to the geosteering world,” Viandante said. “So we can now see in 3D and practical steering and make decisions that are now there are more advice, so we can really see the true geology of the field.”

While traditional 2D devices can map the distance between well boundaries, the 3D devices can measure both the distance and volume within the well’s depth. Schlumberger’s server mapping GeoSphere 360 device gives users better visuals using the “3D visualization and multidisciplinary integration.”

“We can optimize the completion, the design of the well, because we can map contents and see how they're approaching our well, but also extend the life of the field because now we can drill more accurate wells and fewer wells, but more accurate,” Viandante said. “So we can optimize the production of the field and, extend as a consequence, the life of the field.”

Since 3D mapping-while-drilling technology has better visuals than previously developed 2D technology, operators are able to spot obstructions and difficulties in the well and allow them to fix them. In addition, it makes it easier for operators to plan the trajectory of the well’s path to best avoid complications.

“We plan our trajectory accordingly to the best model along the structural axis to anti decline,” Viandante said. “But when drilling at one point, the oil exceeds the target unexpected, and it can hinder your burden section due to, for example, a sudden change. In this case, it will be better if we are able to see the structural deep changes, still respect to it and keep the well into the target.”

3D geosteering can help operators lower field costs because the tool allows them to plan the well path trajectory with better visualization, decreasing the chances of running into errors and forcing them to start at the beginning, saving both time and money.

In one example, Viandante shared how the reservoir geosteering technology was able to help a client stay on the right track by creating the right path for their well.

“This is a complex sand reservoir with strong lateral connectivity,” he said. “They drilled this well, but now they wanted to plan [to] go either to the right or to the left when we set track. So what we did, we used the 3D reservoir mapping while drilling service to map the distribution later, and then optimize the placement of this track in the area on this side where we have more sand.

“And this is what was what happened, help our client. So in this case, we optimize the development of the field because if we went to the wrong direction, we encountered more shale, and then as a consequence, we had to set track one more time.”