Presented by:

Editor's note: This article appears in the new E&P newsletter. Subscribe to the E&P newsletter here.

The production of crude oil in the U.S. has more than doubled over the past decade, with virtually all this increase being driven by unconventional resource plays. Unlike in conventional plays where vertical wells are targeting reservoirs into which petroleum has migrated, unconventional plays are targeting the very source rocks themselves.

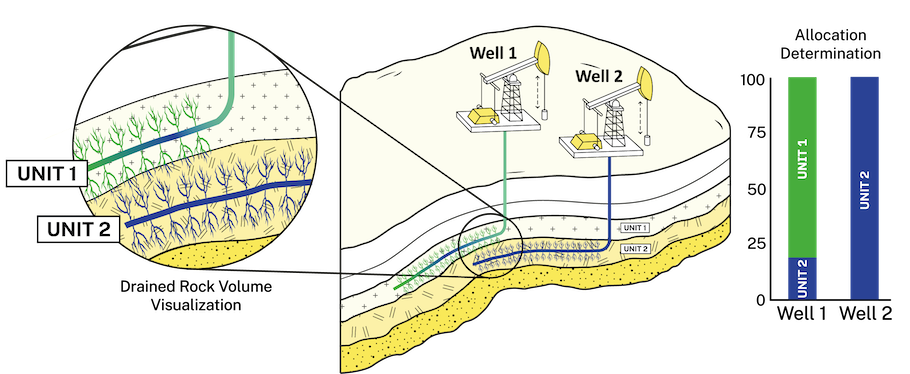

These shale plays often consist of stacked production units, many of which have the potential to produce significant volumes of oil and/or gas. To flow, however, these units need to be accessed via horizontal wells and hydraulically fractured. Depending upon well spacing design and frac height distribution, this process can result in potentially multiple unique production units being accessed and drained inefficiently. This can lead to several production and cost issues including variable well production rates, reduced well lifetimes, rapid decline rates, missed pay, and either too few or too many wells to ensure effective drainage.

Therefore, ensuring appropriate well spacing, in conjunction with frac height considerations, is crucial to ensuring effective, optimized production and ultimately reduction in capex. Applied Petroleum Technology (APT) has developed a workflow, APT Allomon, that is designed to directly assist operators with understanding their drainage networks in unconventional plays.

There are many techniques available that allow operators to infer the potential for commingled production across multiple source zones. Petroleum geochemistry, however, is the only way to directly measure interconnectivity.

Geochemical approaches require no operational interference, fluids can be collected directly from the wellhead, they tend to be significantly cheaper than other methods, and this approach can be deployed across as few or as many wells as needed as acreage positions are developed, providing a scalable solution.

Geochemical data are hugely underutilized in unconventional plays, yet offer the only direct insights into what is being produced. Production unit interconnectivity can and does change through time; therefore, continued monitoring of wells is essential to ensure effective production through time. This monitoring can be achieved through the periodic collection and geochemical analysis of production samples, all of which can be tied back to the initial geochemical baseline work.

Production allocation and monitoring

The term production allocation is used to describe methodologies for understanding interconnectivity and source-contributions at a single point in time. In contrast, production monitoring is the assessment of how a production fluid changes through time and what that might indicate.

Non-geochemical approaches to monitoring and allocation generally rely upon assessment of either a non-petroleum component, such as tracers or bacterial DNA. They also rely upon inferences from data, such as petrophysical logs, or are measured from optical methodologies in the production infrastructure via an in-situ monitor and are therefore indirect methods.

Geochemical approaches to both allocation and monitoring are direct measurements, which are widely considered as the most reliable and informative in unconventional plays.

However, most geochemical methods have suffered from two systematic problems:

- They are inflexible in methodology, assuming one size fits all; and

- They fail to account for the complexity inherent to these plays.

These failings largely stem from the fact that these methodologies are designed to meet the needs of conventional systems that, while complex themselves, do not pose the same unique allocation and monitoring challenges as unconventional plays.

Furthermore, the prevalent usage of oil-based drilling fluid means that cuttings, and sometimes core , are not viable for geochemical assessment in these systems, thereby increasing complexity. There is also the more general challenge that operators rarely have in-house geochemical specialists. Therefore, service companies need to offer solutions applicable and accessible across a range of disciplines and not merely provide data.

The APT Allomon (allocation and monitoring) workflow is designed to provide direct solutions to the challenges presented in unconventional plays. This workflow is designed to be agile and ensure the specific methodologies and deliverables meet the unique requirements of individual operators.

Developing and deploying the workflow

The APT Allomon workflow was developed by APTs geochemists as part of a multiyear collaborative effort to design a robust and flexible product for unconventional operators. Therefore, it was developed with a series of questions in mind:

- What are the problems that shale play operators need answers to?

- What are the main failings of current methodologies to these problems?

- How can we ensure built-in flexibility in approach, method and deliverables?

The APT Allomon workflow was developed from the ground up, involving a thorough and complete review of existing literature and methods, theoretical testing and development of the full suite of methodologies and statistical approaches, and beta deployment on synthetic mixes and operator datasets.

This approach resulted in the development of the APT Allomon workflow, newly released in the summer of 2021, which includes a deconvolution software package for defining source contributions from the full range of production phases and laboratory analytical tools. The agile nature of APT Allomon allows it to be deployed in both unconventional and conventional systems, and to gas or oil production.

In unconventional plays, APT Allomon is designed to provide solutions based upon an operator’s objectives, the scale of the project and the phases (gas or fluid) available. Where only a single well needs to be assessed, the analytical program would be elevated and the workflow combined with operator data to assess likely drained rock volume, mixing potential and, if assessed through time, potential causes of any fluid variations.

Inclusion of additional wells would allow further refinement of drained rock volume and interconnectivity, while also addressing questions of compartmentalization and effective drainage design. Where appropriate, and depending upon sample numbers, compartmentalization and the availability of viable and definitive end-member samples, quantitative allocation will also be a deliverable. However, every project is unique and the goal of APT Allomon is not to aim for one specific deliverable, but to maximize the value of the data and provide tangible optimization solutions.

Case study

Development of the APT Allomon workflow, and the associated deliverables, included a pilot case study from the Midland Basin. This study included cuttings and core, drilled with water-based mud, as well as produced oil samples, and it primarily focused upon understanding drainage in the Lower Spraberry, Dean, Wolfcamp A and Wolfcamp B formations.

In this study, APT was able to identify both in-situ and migrated fluids and determine whether the oils were produced from a single or multiple zones and therefore the extent of drained rock volume. The number of unique fluid compartments and the range of signatures across the assessed stratigraphy could also be defined from the core extract signatures.

From this alone, the workflow allowed APT to comprehensively define drainage across the wells being assessed, propose any optimization and inform for any future development in this acreage. The fluids were also successfully allocated with the source contributions closely matching with the findings from the rest of the project workflow.

APT Allomon has also been deployed for a number of conventional case studies in the North Sea where end-member definition and allocation has had considerable success.

Future development and applications

Although developed as an upstream workflow, the deconvolution software built into APT Allomon also has potential to be deployed in midstream operations where allocation is of utmost importance. The workflow itself will also continue to be developed through testing of additional analytical and phase inputs as well as additional deliverables through further operator feedback.

Recommended Reading

BP Restructures, Reduces Executive Team to 10

2024-04-18 - BP said the organizational changes will reduce duplication and reporting line complexity.

Matador Resources Announces Quarterly Cash Dividend

2024-04-18 - Matador Resources’ dividend is payable on June 7 to shareholders of record by May 17.

EQT Declares Quarterly Dividend

2024-04-18 - EQT Corp.’s dividend is payable June 1 to shareholders of record by May 8.

Daniel Berenbaum Joins Bloom Energy as CFO

2024-04-17 - Berenbaum succeeds CFO Greg Cameron, who is staying with Bloom until mid-May to facilitate the transition.

Equinor Releases Overview of Share Buyback Program

2024-04-17 - Equinor said the maximum shares to be repurchased is 16.8 million, of which up to 7.4 million shares can be acquired until May 15 and up to 9.4 million shares until Jan. 15, 2025 — the program’s end date.