Presented by:

This article appears in the E&P newsletter. Subscribe to the E&P newsletter here.

In recent years, operators have exponentially increased drilling efficiencies through multiple drilling optimization practices. These practices include enhanced tool designs extending usable life, higher energy output from drilling equipment and precise parameter optimization.

Arguably the most integral component to any drillstring is the PDC drill bit, but introducing these operational improvements creates new challenges for PDCs. As tools above the drill bit become more durable, powerful and efficient, the drill bit is required to withstand the additional energy output. These performance gains demand that fixed cutter PDC designs are optimized for a wide array of rock properties and interval lengths, as operators try to reduce days on well. This requires a precise understanding of how formation characteristics, drilling parameters and bottomhole assembly components are affecting the drill bit wear state, in turn leading to an improved design for the application.

One area that has lacked innovation in the drill bit sector has been a scientific and precise approach to dull drill bit analysis. Historically, the industry standard approach has been to eyeball the inner and outer portions of the drill bits cutting structure providing an often-haphazard analysis of the dull. This subjective form of PDC bit dull grading has encompassed most datasets used for analysis of drill bit performance for a given application. Taurex Drill Bits has helped solve this issue with its Automated Metrology Laboratory (AML) technology.

Taurex leadership recognized the lack of large-scale acquisition of dull bit data at the cusp of PDC innovation and embraced the opportunity to develop an automated approach to document PDC wear accurately. AML technology produces a digital dull report with precise wear measurements on every cutter to drive forensic analysis and scientific bit optimization strategies. Upon arrival to Taurex’s centralized repair facility, dull bits are loaded onto the AML rotary table in a specific orientation to aid alignment (see Figure 1 above). The fully automated scanning process then produces a digital dull by utilizing a metrology grade optical laser scanner, capturing point clouds that are converted to a 3D polygonal mesh model. The digital dull is automatically inspected measuring the exact diamond loss on every cutter, and a color map is added to show wear trends across the bit body and cutters. These data are then added to a composite dataset where engineers can reference the information to make informed decisions on product development.

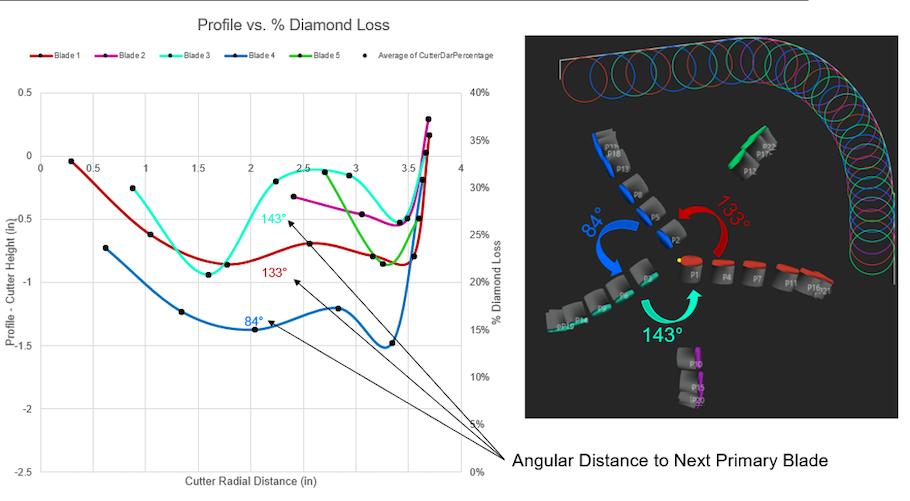

As drilling optimization advances, this methodical approach to drill bit wear has proven beneficial. Not only has AML allowed precision in drill bit dull analysis, but it has also allowed the company to create an extensive database of unambiguous dull grades, which can be tied to individual designs to analyze wear trends and improve design iterations (see Figure 2).

Case study

In one of many instances, Taurex partnered with a prominent operator in the Delaware Basin to reduce the number of bits it took to total depth (TD) their intermediate section by utilizing AML technology, identifying problem areas within the initial PDC design. Before implementing AML, this interval was taking two to three bits to reach TD with a 0% success rate of one bit to TD.

Based on AML results of the first design iteration, engineers were able to identify a consistent trend of diamond area removed in a particular area of the bits cutting structure. Multiple modifications were made to address this damage, lowering the overall work being done in that area. The result was a subsequent design iteration that averaged 21% more footage drilled and a 54% success rate of making it to TD in one bit, saving time and money on costly round trips for premature bit damage.

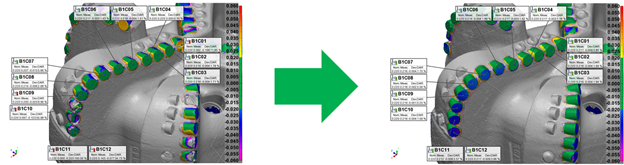

In the Midland Basin, an operator required a large diameter curve to be drilled, presenting unique challenges with more rigid tools and higher torque generation. The original bit being ran in the application was developing a consistent wear pattern identified by AML. It was determined that damage to cutters on the lower shoulder of the cutting structure led to a reduction in lateral cut efficiency causing reduced build rates and ROP. An improved cutter designed to withstand the diagnosed wear mode was implemented in the problem area. This led to a 42% increase in ROP and a 40% reduction in diamond loss in a direct offset comparison (see Figure 3).

The AML aided in identifying the weak point in the design, and it accurately gauged the amount of diamond retained with the upgraded cutters. This information was relayed to cutter suppliers to improve cutter design.

Taurex recently expanded AML technology to include automated high-resolution photography. This will enable the company to deploy machine learning methodology to digitize dull drill bits comprehensively.

About the authors: Taurex's Conner Richardson is a BOSS design engineer and Dustin Lyles is the vice president of technology.

Recommended Reading

SLB’s ChampionX Acquisition Key to Production Recovery Market

2024-04-19 - During a quarterly earnings call, SLB CEO Olivier Le Peuch highlighted the production recovery market as a key part of the company’s growth strategy.

PHX Minerals’ Borrowing Base Reaffirmed

2024-04-19 - PHX Minerals said the company’s credit facility was extended through Sept. 1, 2028.

BP Restructures, Reduces Executive Team to 10

2024-04-18 - BP said the organizational changes will reduce duplication and reporting line complexity.

Matador Resources Announces Quarterly Cash Dividend

2024-04-18 - Matador Resources’ dividend is payable on June 7 to shareholders of record by May 17.

EQT Declares Quarterly Dividend

2024-04-18 - EQT Corp.’s dividend is payable June 1 to shareholders of record by May 8.