To improve oil recovery, several techniques have been applied to improve the water conformance of injection wells. While standalone passive flow control devices combined with sliding sleeves have been successful to improve the conformance in the wells, they may fail to provide the required performance in the reservoirs with complex/dynamic properties including propagating/dilating fractures or faults and may also require costly and complex intervention.

Compared to active inflow control devices (ICVs), which can change the inflow area and ultimately control the well in a proactive and/or reactive manner, passive devices, such as outflow control devices (OCDs) a.k.a. ICDs, are less expensive and create completion with a fixed configuration influencing the well’s outflow. However, the effectiveness could be limited if the well completion with the OCD is not properly designed. It can be even less effective if there are dynamic changes in reservoir properties. Although autonomous devices have been used in production wells, there have been no applications of autonomous devices in injection wells.

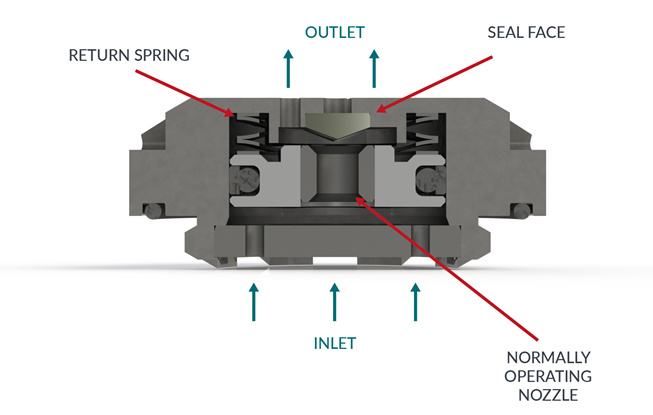

Global production optimization specialist, Tendeka, has developed a new autonomous outflow control device (AOCD), FloFuse (Figure 1), to selectively choke the injection of fluid into the growing dilated/propagated thief zones such as fractures, faults and high perm streaks crossing the well. Therefore, this technology mitigates disproportional injection of fluid into the thief zone which could potentially create a short-circuit to production wells.(1)

The company recently performed a comprehensive study with a major Middle East operator to change the existing dual completion to a single completion incorporating AOCDs and determine the optimum completion design for delivering the targeted rate for the well while considering the huge uncertainty around the faults and features properties.

Autonomous outflow control device

FloFuse is a bi-stable active flow control device with two operating scenarios. First, it initially operates as a normal passive OCD, and second, if the injected flowrate through the valve exceeds a designed limit, then the device will automatically shut off. As a spring-loaded, open injection outflow valve, the device functions when a prescribed tripping flow rate is exceeded, to significantly limit the flow area to those zones. This provides the advantage of controlling the faults and fractures in case they were highly conductive as compared to other sections of the well. In addition, once these zones are closed, the device enables the fluid to be distributed to other sections of the well, thereby, improving the overall injection conformance.

Like other OCDs, this device should be installed in several zones in the injection well. If the injection of a minimum flowrate is required to the fused zone, the technology could be installed along with bypass OCD devices. When the valve shuts, the bypass OCD will still deliver the minimum flowrate desired to that zone. Importantly, this technology removes the need and cost of running a PLT and the complex well interventions required to open/close the integrated sliding sleeves in traditional completions, thereby achieving optimized well performance autonomously.(2)

The valve is fully reversible and will re-set if the rate becomes sufficiently distributed again. The target normal operating rates and degree of outflow control and trigger rates can be varied by changing the size and number of nozzles.

Optimizing well performance

Drilled in 2012, Well-A in a limestone reservoir in the Middle East had been injecting water into the reservoir for several years. The main challenges of the reservoir are heterogeneity, production/injection conformance and waterfront advance tracking due accessibility to the horizontal wells. A PLT in 2014 plus the production profiles from nearby producers confirmed significant water conformance control issues for the operator as water had passed through several thief zones indicating existence of major faults and ant-tracks, however with huge uncertainty around its properties, including conductivity, length, etc.

After timely surveillance, integrated technical evaluation and analysis of various possible solutions, the AOCD was selected as it could:

- Autonomously restrict the injection of fluid into dilating fractures

- Mitigate the disproportional injection of fluid into the thief zones without the need for any intervention.

A comprehensive workflow and an assessment of the performance of various completion settings sensitivities was carried out to determine the optimum AOCD design.

The final completion was installed in the well through a workover in 2020 and consisted of nine 4½” AOCD joints, five joints of bypass high pressure ICDS and five swellable packers for compartmentalization and zonal isolation. The well was divided into six compartments based on fractures/an-track depths.

A new set of PLTs were recorded in March 2021 to confirm the function of the valves. Based on the comparison between old and new PLTs, it was determined that the injection rate into the zones with faults and ant-tracks has been reduced by 42% while an increase of 20-25% in water injection has been achieved in the other zones with no suspected faults and very low injectivity.

As the valve autonomously reacts to changes in reservoir conditions, the results of the case study in the Middle East clearly demonstrate how Tendeka’s FloFuse valve could manage uncertainties in reservoir properties while delivering optimized well performance. As a result of this, the overall sweep efficiency in the well has been improved significantly. Moreover, water injection contribution along the horizontal section of the hole was enhanced.

As these valves could be used to function as mechanical diverters, an acid stimulation operation is planned in the wells in the near future to help improve the injectivity of zones with low permeability and remove any skin accumulated over years of injection. This would improve the water injection conformance of the zones further.

References

- M. Ismail et al. A Game Changer for Injection Wells Outflow Control Devices to Efficiently Control the Injection Fluid Conformance. Paper Presented at ADIPEC 2019 conference. 11-14 November 2019. Paper SPE-197612-MS

- M. Moradi. Autonomously Controlling the Conformance of Injection-Well Fluids. Journal of Petroleum Technology 73 (06): 38-40. Published on 1st June 2021. Paper SPE-0621-0038-JPT

Recommended Reading

Enbridge Closes First Utility Transaction with Dominion for $6.6B

2024-03-07 - Enbridge’s purchase of The East Ohio Gas Co. from Dominion is part of $14 billion in M&A the companies announced in September.

SCF Acquires Flowchem, Val-Tex and Sealweld

2024-03-04 - Flowchem, Val-Tex and Sealweld were formerly part of Entegris Inc.

Pembina Cleared to Buy Enbridge's Pipeline, NGL JV Interests for $2.2B

2024-03-19 - Pembina Pipeline received a no-action letter from the Canadian Competition Bureau, meaning that the government will not challenge the company’s acquisition of Enbridge’s interest in a joint venture with the Alliance Pipeline and Aux Sable NGL fractionation facilities.

Global Partners Buys Four Liquid Energy Terminals from Gulf Oil

2024-04-10 - Global Partners initially set out to buy five terminals from Gulf Oil but the purchase of a terminal in Portland was abandoned after antitrust concerns were raised by the FTC and the Maine attorney general.

DXP Enterprises Buys Water Service Company Kappe Associates

2024-02-06 - DXP Enterprise’s purchase of Kappe, a water and wastewater company, adds scale to DXP’s national water management profile.