Learn more about Hart Energy Conferences

Get our latest conference schedules, updates and insights straight to your inbox.

As oil and gas companies face increasing pressures to become more efficient, U.S. shale operators are becoming smarter and faster—and it’s more important than ever.

The demand for energy continues outstripping supply despite a rising rig count. According to industry analyst Enverus Foundations, the number of rigs running in the U.S. in the second quarter rose 9% compared to the first quarter, and the rig count is 54% higher year-over-year.

Challenging the status quo of long-held assumptions or approaches in the field is necessary to uncover new methods that can lead to greater productivity to maximize capital and human resources. Continuing to do an activity the same way it has always been done can cause companies to lose efficiency gains that could make a difference in their profits.

The understanding and use of proppant is a prime example. Operators rely on large quantities of water, chemicals and sand to extract oil and gas, allowing those assets to flow to the surface. Sand and fluid are essential to open and keep fractures open in a well and stimulate the well to produce. Proppant materials are sorted for size and sphericity to ensure they serve as an efficient conduit for hydrocarbon production from the reservoir to the wellbore.

The oil and gas industry has long assumed that sand and fluid flow uniformly together through casing. Surface tests conducted by GEODynamics and six shale operators in the U.S. unequivocally proved otherwise. This revelation is important because inconsistent proppant placement impacts well productivity and frac operations and increases risk of screen-out.

The surface tests revealed important insights. First, larger grains of proppant are far more likely to slip past early clusters than smaller grains, which tend to be distributed evenly among clusters. Second, perforating designs can result in more evenly distributed proppant among clusters and further flatten the distribution. Indeed, the irregular flow of proppant in the casing is just as important as formation variability or stress shadowing. Third, larger-sized 40/70 mesh sand is more likely to slip past earlier clusters than 100 mesh sand.

A second round of tests with the U.S. shale operators followed, which showed that a change in the fracture design which focused on a more even slurry distribution from cluster to cluster further reduced the differences among clusters although larger grains still slipped past early clusters.

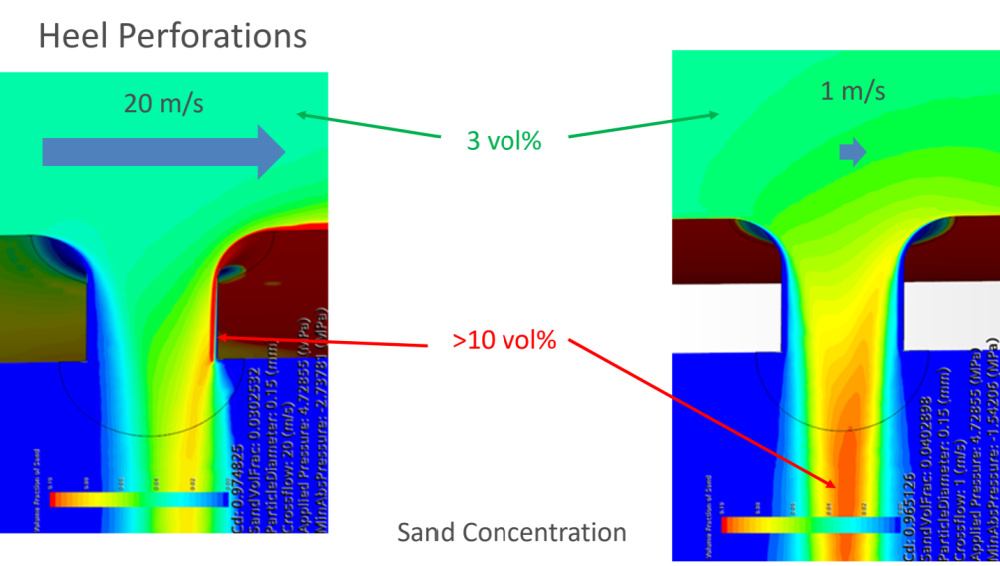

Fine sand is distributed uniformly throughout the length of a perforated completion while coarser sand tends to slip past the heel perforations and concentrate on the bottom toward the toe of the completion. As these are broad statements, the main point is that gravity and physics work. Fluid velocity (which varies), fluid properties, proppant size and perforation orientation all matter.

While not all perforation holes are created equal, it is now possible to predict how proppant will flow. This gives oil and gas companies insight into when and where to invest to maximize their returns.

As a result of the previously mentioned surface tests conducted with U.S. shale operators, StageCoach was developed to accurately predict how proppant and fluid will flow through casing. The surface testing also provided insight on hole placement: outflow can be optimized by placing perforations in the middle rather than the top of the pipe.

By accurately modeling proppant transport, distribution and erosion across clusters, operators are empowered to be more deliberate when selecting hole size and/or charge type, enabling them to achieve the assumed distribution without cost variances. Computational fluid dynamics modeling of proppant slurry movement powers predictive insights, which optimizes job parameters to ensure a more uniform proppant distribution from cluster to cluster.

Beyond the applicable learnings and predictive insights this software modeling can deliver, it’s poignant to note how the creation and application of digital technologies has helped oil and gas companies carve out competitive advantages that impact production and the bottom line.

Digitizing surface test information to predict where sand will go in a stage debunked historical assumptions about proppant flow that could negatively impact companies’ well productivity. This enables crews to work smarter and more efficiently. It also enables crews to make the proposed frac design on paper a reality in the field. Better fracs lead to better stimulation, which results in better performing wells and optimized completions.

Maximizing production is key to all stakeholders in the production chain as completing a well is very expensive. The ability to predict how proppant will flow allows oil and gas companies to create more accurate frac designs that result in more productive wells. The efficiencies gained through this process can positively impact profits.

About the Authors: Phil Snider is consulting completions adviser at GEODynamics. Steve Baumgartner serves as GEODynamics’ senior engineering technical adviser.

Recommended Reading

Exxon Mobil Guyana Awards Two Contracts for its Whiptail Project

2024-04-16 - Exxon Mobil Guyana awarded Strohm and TechnipFMC with contracts for its Whiptail Project located offshore in Guyana’s Stabroek Block.

Deepwater Roundup 2024: Offshore Europe, Middle East

2024-04-16 - Part three of Hart Energy’s 2024 Deepwater Roundup takes a look at Europe and the Middle East. Aphrodite, Cyprus’ first offshore project looks to come online in 2027 and Phase 2 of TPAO-operated Sakarya Field looks to come onstream the following year.

E&P Highlights: April 15, 2024

2024-04-15 - Here’s a roundup of the latest E&P headlines, including an ultra-deepwater discovery and new contract awards.

Trio Petroleum to Increase Monterey County Oil Production

2024-04-15 - Trio Petroleum’s HH-1 well in McCool Ranch and the HV-3A well in the Presidents Field collectively produce about 75 bbl/d.

Trillion Energy Begins SASB Revitalization Project

2024-04-15 - Trillion Energy reported 49 m of new gas pay will be perforated in four wells.