Editor’s note: this is an abridged version of SPE-200177-MS, which was presented at the SPE Conference at Oman Petroleum & Energy Show, 21-23 March 2022, Muscat, Oman.

The change in the injectivity of an injection well could result from several phenomena that alter initial reservoir properties, especially near-wellbore conditions. Above all, the development of thermal fractures and/or dilating natural fractures’ apertures pose significant impacts on injection well performance and subsequently, conformance of the injected fluid.

To increase water/polymer flooding performance and eventually, field oil recovery, several techniques have been applied to improve fluid conformance of injection wells. Several operators have used conventional passive nozzle-type outflow control devices (OCDs) or inflow control devices (ICDs), while others have used more flexible, complex interval control valve completion options (References 1-3).

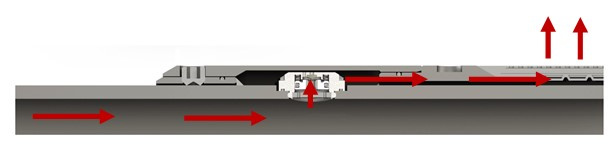

Tendeka developed FloFuse, an autonomous OCD (AOCD) that freely chokes the injection fluid into the propagating fractures crossing the well to maintain a balanced/prescribed injection distribution. Figure 1 shows the AOCD installed along with the lower completion string in horizontal/vertical injection wells.

To find the optimum completion design and demonstrate its added value, Tendeka and Petroleum Expert Ltd. performed an extensive dynamic reservoir simulation study. This evaluated the impact of pressure, temperature and flow variations of injection fluids near the wellbore on the performance of injection wells completed with various completions. To understand the initiation and propagation of fractures, the dynamic reservoir matrix conditions were coupled with a finite element solution of fracture mechanics and the injection well model to simulate the impact of the thermal fractures.

Simulation study

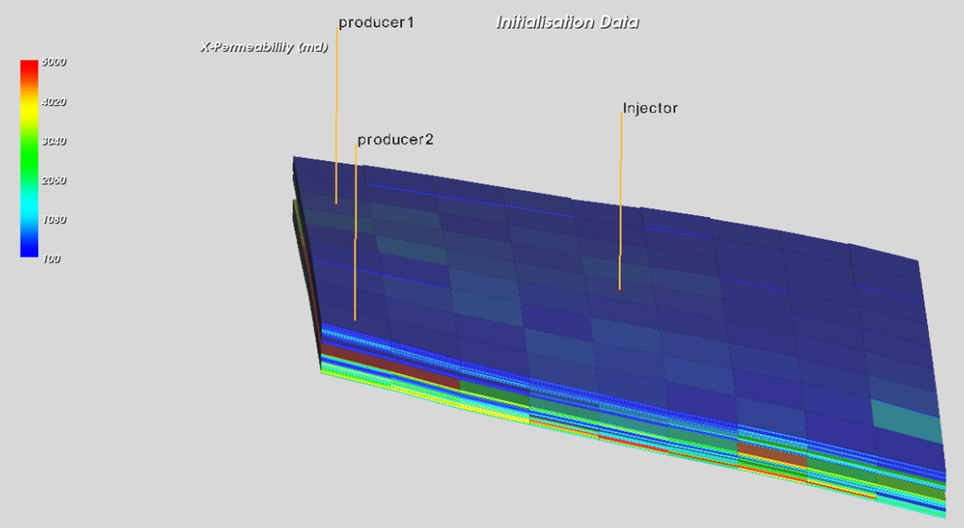

The sector reservoir model (Figure 2) included one vertical injector and two vertical producers and was located at 27,000 ft. The wells intersect four reservoir layers, with layers one and two in the upper part and layers three and four in the lower part. An aquifer is down-dip of the injector well.

The initial reservoir pressure and temperature were 20,200 psi and 200 F. The gas-oil ratio (GOR) of oil is 531 with a gravity of 29 degrees API and downhole viscosity of 4.5 centipoise (cP). In terms of geomechanics properties, there is an initial stress distribution across the reservoir with the top two layers more likely to develop the fracture first and hence, become thief layers. The production wells are assumed to be completed with ICDs with the aim of retarding the inflow from the lower two layers toward the well.

The initial design recommendation was to divide the well into four completion zones along with all four layers with packers installed at the border of layers to isolate the zones (Figure 3). Due to the high injection rate, 4.5 mm AOCD valves were selected for this well along with 3 mm OCDs.

The completion design for the conventional passive OCDs, interval control valves and open hole completions was optimized to ensure a fair evaluation once compared with the performance of the AOCD. Like other OCDs, this device should be installed in several zones in the injection well.

Completion comparison

While normal OCDs are effective solutions in reservoirs with static properties, they fail in reservoirs with complex/dynamic properties including those growing fractures.

The simulation study showed that after reaching a designated flow rate, the AOCD minimizes the impacts of thief zones on the injected fluid conformance by reacting to dynamic changes in reservoir properties, specifically the growth of fractures. This allows operators to produce more volume of oil with less volume of water injection. Subsequently, this reduces injection cost and improves the reliability of injection well systems. It essentially eliminates most of the deficiencies of OCDs as well as the requirements of running production logging tool.

Due to the uncertainty of heterogeneous reservoirs and the potential for dynamic changes in properties of the reservoir, the simulation study showed the fluid front could be managed much more efficiently with a less imposed pressure drop compared to OCDs to achieve the desired sweep and maximize ultimate recovery.

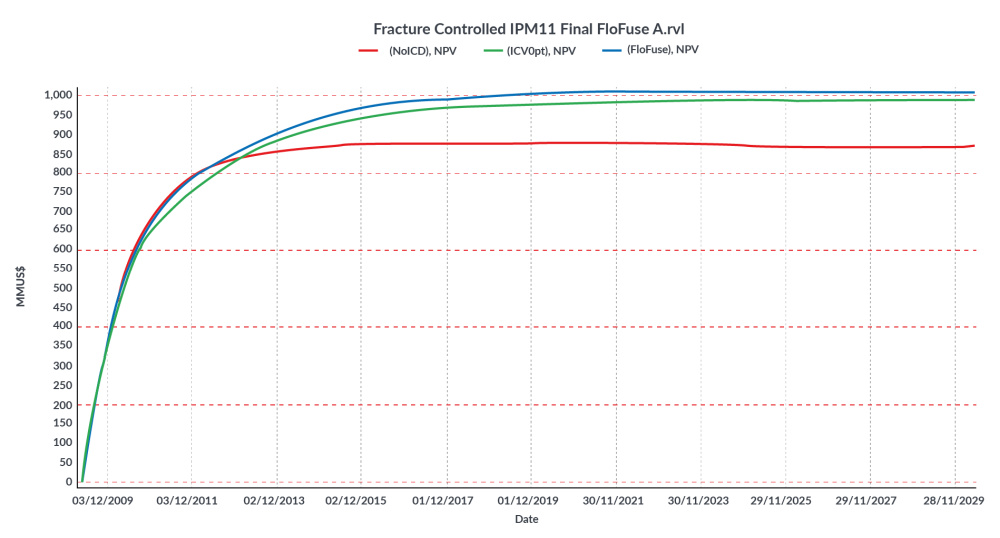

This reactive control on the injection fluid conformance for the studied cases resulted in an increased sweep and ultimate oil recovery (up to 20%) while reducing the total volume of injected fluid (by 30%), so significantly increasing delivered field net present value (Figure 4).

About the Authors: Mojtaba Moradi is a reservoir engineer at Tendeka, which he joined in 2017. He performs reservoir simulation studies as well as performing integrated well & reservoir modelling, in particular, for wells equipped with flow control technologies. He holds a BSc from Iran and a PhD (2016) from Heriot-Watt University. He worked as a Consultant Reservoir Engineer in the Centre of Enhanced Oil Recovery and CO2 Solutions before joining Tendeka. He is a reservoir engineer with ten years’ experience and a member of the European Association of Geoscientists and Engineers (EAGE), and SPE.

About the Authors: Mojtaba Moradi is a reservoir engineer at Tendeka, which he joined in 2017. He performs reservoir simulation studies as well as performing integrated well & reservoir modelling, in particular, for wells equipped with flow control technologies. He holds a BSc from Iran and a PhD (2016) from Heriot-Watt University. He worked as a Consultant Reservoir Engineer in the Centre of Enhanced Oil Recovery and CO2 Solutions before joining Tendeka. He is a reservoir engineer with ten years’ experience and a member of the European Association of Geoscientists and Engineers (EAGE), and SPE.

Steve Todman is Petroleum Experts’ principal developer for reservoir simulation software REVEAL, which is designed to capture additional reservoir such as geo-mechanics and thermal rock fracturing, polymers, surfactants, chemical and biological reactions. He gained a degree in Mathematical Physics from Edinburgh University in 1988 and worked for 10 years in the nuclear industry, concentrating on mass and heat transfer in fast reactor sodium to steam heat exchangers. He joined Petroleum Experts in 1998.

Steve Todman is Petroleum Experts’ principal developer for reservoir simulation software REVEAL, which is designed to capture additional reservoir such as geo-mechanics and thermal rock fracturing, polymers, surfactants, chemical and biological reactions. He gained a degree in Mathematical Physics from Edinburgh University in 1988 and worked for 10 years in the nuclear industry, concentrating on mass and heat transfer in fast reactor sodium to steam heat exchangers. He joined Petroleum Experts in 1998.

References:

Al Shemaili, Sultan Ibrahim, Fawzy, Ahmed Mohamed, Assreti, Elamari, El Maghraby, Mohamed, Moradi, Mojtaba, Chaube, Prabodh, and Tawheed Mohammed. "The New Generation of Outflow Control Devices Autonomously Controlling the Conformance of Water Injection Well- A Case Study with ADNOC Onshore" Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, UAE, Nov 2021. https://doi.org/10.2118/207647-MS

Al Harrasi, Ameera, Maskari, Muna, Urdaneta, Gerardo, Al-Jumah, Ali, Badi, Salim, Busaidi, Iman, Harthy, Khalfan, Abazeed, Osama, and Mojtaba Moradi. "Autonomous Outflow Control Technology AOCD in New Water/Polymer Injectors in Heavy Oil Fields from South Sultanate of Oman." Paper presented at the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, UAE, November 2021. doi: https://doi.org/10.2118/207361-MS

Moradi, Mojtaba, and Michael R Konopczynski. "The New Flow Control Devices Autonomously Controlling the Performance of Matrix Acid Stimulation Operations in Carbonate Reservoirs." Paper presented at the SPE Annual Technical Conference and Exhibition, Dubai, UAE, September 2021. doi: https://doi.org/10.2118/205975-MS

Recommended Reading

TechnipFMC Eyes $30B in Subsea Orders by 2025

2024-02-23 - TechnipFMC is capitalizing on an industry shift in spending to offshore projects from land projects.

Air Products Sees $15B Hydrogen, Energy Transition Project Backlog

2024-02-07 - Pennsylvania-headquartered Air Products has eight hydrogen projects underway and is targeting an IRR of more than 10%.

Air Liquide Eyes More Investments as Backlog Grows to $4.8B

2024-02-22 - Air Liquide reported a net profit of €3.08 billion ($US3.33 billion) for 2023, up more than 11% compared to 2022.

Some Payne, But Mostly Gain for H&P in Q4 2023

2024-01-31 - Helmerich & Payne’s revenue grew internationally and in North America but declined in the Gulf of Mexico compared to the previous quarter.

Kimmeridge Fast Forwards on SilverBow with Takeover Bid

2024-03-13 - Investment firm Kimmeridge Energy Management, which first asked for additional SilverBow Resources board seats, has followed up with a buyout offer. A deal would make a nearly 1 Bcfe/d Eagle Ford pureplay.