Presented by:

This article appears in the E&P newsletter. Subscribe to the E&P newsletter here.

In a time of huge change for the industry, strategically approaching well completions and integrity issues is essential for sustainable oil and gas production. In order to achieve this, operators must consider the latest innovations, which often offer new methods and approaches to solve challenges experienced on their wells.

CannSeal believes every well should be looked at differently and puts developing bespoke solutions to integrity issues at the center of its operations. With scientists, engineers and innovators all under one roof, it has the capabilities to provide industry-leading solutions to operators across the globe.

As the industry focuses on extending the life of current wells, demand continues to grow for bespoke solutions that can overcome challenges for even the most difficult wells. CannSeal is working to lead the way in developing industry-first applications of epoxy technologies that solve the most complex integrity and zonal isolation issues.

The Challenge

Neptune Energy approached CannSeal for solutions to zonal isolation challenges it was experiencing on wells with both gravel pack and openhole completions in its Gjøa and Duva fields. To limit crossflow between two reservoir zones on Gjøa P1 well, CannSeal initially installed a successful gravel pack epoxy completion. As a result, Neptune Energy approached CannSeal for help replacing swell packers on one of its most complex openhole wells on Duva.

During initial completions on Duva, wellbore challenges were experienced. Unsuccessful swell packer installations had already been attempted when running the lower completion with large outside diameter (OD) packers and inflow control device (ICD) screens. Establishing zonal isolation completions of the open annulus remained an essential requirement of operations to enable the well to be completed and brought online. Neptune Energy saw the potential of CannSeal solutions to overcome these challenges.

The CannSeal solution

CannSeal works collaboratively with its clients throughout all operations to ensure that solutions are tailored for each individual well. The epoxy is tailored by its viscosity, rheology and density, before it goes through rigorous testing in scaled test wells. This means that the epoxy arrives on site ready for injection, with the correct properties to achieve the project goals. With Neptune Energy, this collaborative approach was integral to the realization of an industry-first application of an open-hole epoxy plug isolation during initial completion stages.

The outcome of the collaboration was the development of a solution that would replace the swell packers with CannSeal’s ZonalSeal annular plugs. The ZonalSeal epoxy solution was designed to fill and secure the open void, while also maintaining the full pipe interior diameter (ID). To do so, the CannSeal wireline tool was run to the target locations with Altus tractoring and casing collar locator (CCL) correlation. The tool then perforated the blank sections between the ICD screens. Ultra-high viscous epoxy sealant was then injected into the open void outside the 6 5/8 inch pipe to create an annular plug. This operation was completed with multiple wireline runs (one run per plug) to install four epoxy plugs, consisting of 38 liters of sealant at a coverage length of 2.64 m.

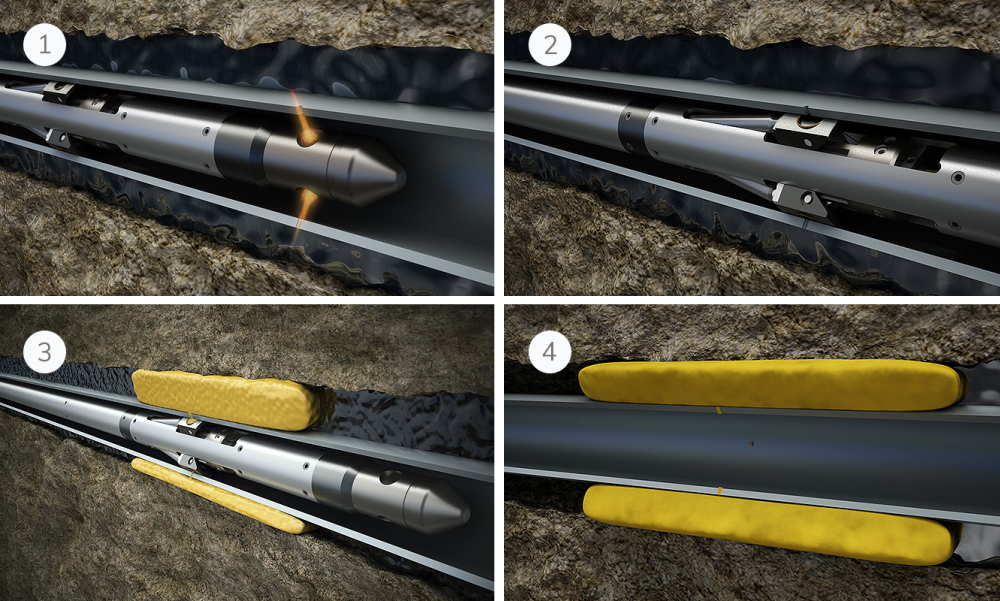

Step 1: The CannSeal tool is run downhole to perforate the liner and create an opening into the annulus.

Step 2: ZonalSeal epoxy is injected through the perforation into the open void.

Step 3: The epoxy creates an immediate barrier between production zones, before setting completely over an individual pre-determined period. Once set, both the open annulus and perforations are sealed off to provide full zonal isolation against both liquid and gas flows.

Step 4: The CannSeal tool is retracted clean from the well, with epoxy plugs remaining downhole.

The result: successful zonal isolation in an open void annulus and a ‘new normal’ in well completions

The four epoxy plugs were installed successfully—achieving zonal isolation objectives. Without a reliance on the OD swell packers, the lower completion was run and set at target depth in the open annulus while maintaining the full pipe ID. This solution enabled Neptune Energy to proceed to lower completions and start the well to plan. This was an industry-first application of CannSeal ZonalSeal technology during the initial completion stages.

Following the operation, Neptune Energy recognized CannSeal as a significant contributor to the success of the completion in the after-action review on the Duva development.

To maximize safe and efficient production as gas and oil supplies remain tight, operators must continue to seek out new technologies to overcome old problems. Bespoke epoxy solutions offer tailored pathways to these goals and are gaining significant traction in both the North Sea and globally.

Recommended Reading

TotalEnergies Starts Production at Akpo West Offshore Nigeria

2024-02-07 - Subsea tieback expected to add 14,000 bbl/d of condensate by mid-year, and up to 4 MMcm/d of gas by 2028.

E&P Highlights: Feb. 5, 2024

2024-02-05 - Here’s a roundup of the latest E&P headlines, including an update on Enauta’s Atlanta Phase 1 project.

CNOOC’s Suizhong 36-1/Luda 5-2 Starts Production Offshore China

2024-02-05 - CNOOC plans 118 development wells in the shallow water project in the Bohai Sea — the largest secondary development and adjustment project offshore China.

US Drillers Cut Oil, Gas Rigs for First Time in Three Weeks

2024-02-02 - Baker Hughes said U.S. oil rigs held steady at 499 this week, while gas rigs fell by two to 117.

Equinor Receives Significant Discovery License from C-NLOPB

2024-02-02 - C-NLOPB estimates recoverable reserves from Equinor’s Cambriol discovery at 340 MMbbl.