Oil and gas production field operations have transformed in the last 10 years. Historically, lease operators visited every well daily. While on location they would operate field equipment, check for pollution, check tank levels and gather readings from the production equipment. Calculating oil and gas is as important as producing it, so with the tank gauges and Barton meter readings the production totals collected in an operator’s tally book, which eventually showed up on the company’s production report. Visiting location was crucial in gathering data to calculate daily production. Even as telemetry became more commonplace and production totals were automated, operators were still expected to visit each location daily.

Enter the shale boom and the resulting commodity price fluctuation. With this challenge, companies had to become a little more unconventional in the way they operated, looking for better, smarter, faster ways to conduct manual and time-consuming activities—to evolve with the rest of the world into the digital workplace. The operate by exception model resulted.

Operate by exception challenged the status quo. Daily location visits became unnecessary for gathering production information. As a result of no longer being tethered to a route system, companies began prioritizing their wells based on production, operational complexity, safety, and environmental concerns. This allowed companies to focus the efforts of their field staff where production was higher and realize a higher return on investment by reducing the costs associated with visiting locations every day.

Ensign has taken the operate by exception model a step further into the future, by developing what it refers to as a dynamic routing operating model, which has three major objectives: translating business objectives directly to the efforts of the field in real-time, making use of shared resources and gathering and analyzing data for decision making based on profitability, not just production.

With dynamic routing, field activities are managed from a centralized control room connected to Scada. Field equipment is monitored in aggregate to allow prioritization of field operations in real-time and in direct alignment with business goals. This results in increased “wrench time” per operator and a better understanding of the headcount needed to effectively manage the field. By applying resources in this efficient manner, tied to actual activity, operational expenses decrease and the appropriate headcount becomes less ambiguous allowing headcount to be maintained despite the rise and fall of commodity price. Allowing the control room to prioritize daily tasks also allows field leadership to devote efforts to mentoring and developing competencies in their team. They can also manage more people, flattening out the organization with less levels of management and further reducing operational expenses.

Using a control room today is common, but Ensign has identified four minimum requirements for success:

- The control room must be in proximity to the engineering and leadership teams to effectively translate ongoing priorities and focus.

- Clear designation of production priorities through business processes and well profitability tiering is crucial to translate expectations between business unit stakeholders and field.

- Daily, face-to-face interaction between the control room and engineers is critical in bridging gaps between the calculated outcome intended by the engineering efforts and the reality when applying the process in the field.

- The control room operators must have strong field experience and field credibility to successfully direct the efforts of the field staff and to assist in troubleshooting techniques.

Ensign’s partnership with Sales Force, utilizing their scheduling software (Field Service Lightning), allows the control room to view the location and activities of field staff and direct activities in real-time as needed. Ensign’s behind-the-scenes calculation of revenue and expenses on a per well basis is integrated into the Sales Force system, which allows these dynamic decisions to be made while continually evaluating profitability. For example, when making the decision to route field staff to a lower production well to bring it back online versus optimizing a high production well, in seconds Ensign can determine which decision makes the most profit and then identify and deploy staff with the applicable skill set in proximity to work the job.

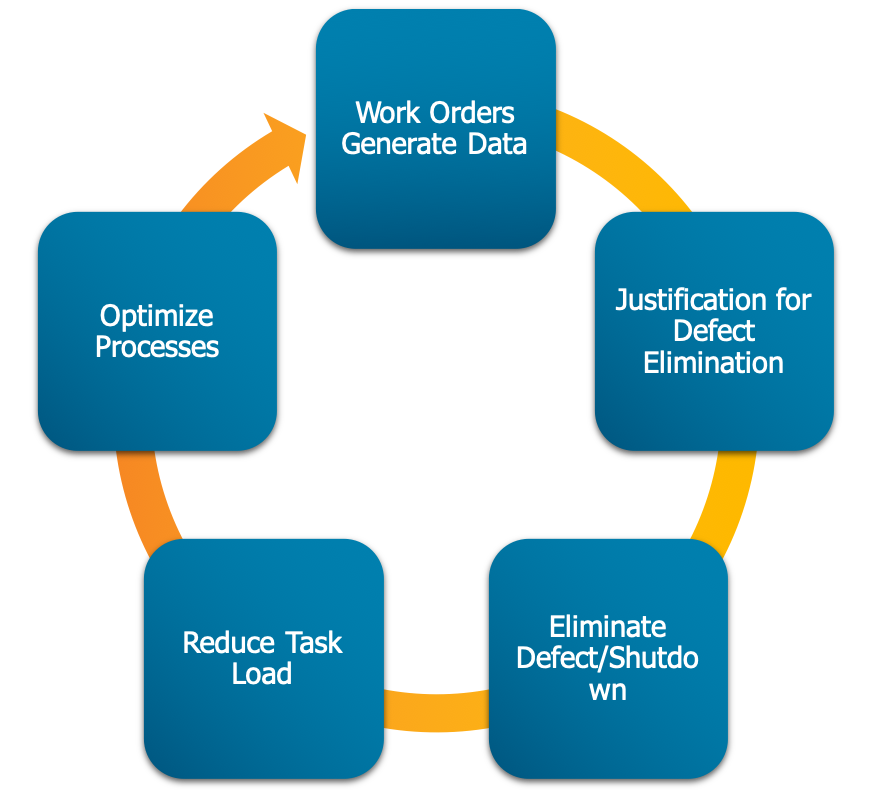

Further, use of this data creates a continuous optimization cycle. By capturing and analyzing multiple data points as work is completed including travel time, wrench time, task types, and costs, Ensign can justify curing defects based on profitability as opposed to continuing to treat the symptoms of the defect. For example, Ensign can determine the cost of addressing hydrates in pipelines—cost of lost production and cost of employee drive time and actual work time spent addressing the issue over time—and compare that with the cost to fix the defect on a permanent basis through installation of a gas dehydration unit. This data provides the business rationale for the work by identifying which course of action results in the most profitability for the company. After elimination of the issue, field employees have more time to address different issues. As this process repeats, the field is continually optimized.

Since implementation of dynamic routing, Ensign has seen safer operations, decreased operational expenses, and decreased production downtime. With improved routing Ensign has reduced driving incidents by 72%. Because dynamic routing facilitates wrench time, Ensign has seen 266% increase in work order completion and a 43% decrease in downtime impact, all with 54% less committed resources.

About the author: Chris Baker is production manager at Ensign Natural Resources.

Recommended Reading

Matador Stock Offering to Pay for New Permian A&D—Analyst

2024-03-26 - Matador Resources is offering more than 5 million shares of stock for proceeds of $347 million to pay for newly disclosed transactions in Texas and New Mexico.

Hess Corp. Boosts Bakken Output, Drilling Ahead of Chevron Merger

2024-01-31 - Hess Corp. increased its drilling activity and output from the Bakken play of North Dakota during the fourth quarter, the E&P reported in its latest earnings.

The OGInterview: Petrie Partners a Big Deal Among Investment Banks

2024-02-01 - In this OGInterview, Hart Energy's Chris Mathews sat down with Petrie Partners—perhaps not the biggest or flashiest investment bank around, but after over two decades, the firm has been around the block more than most.

Petrie Partners: A Small Wonder

2024-02-01 - Petrie Partners may not be the biggest or flashiest investment bank on the block, but after over two decades, its executives have been around the block more than most.

From Restructuring to Reinvention, Weatherford Upbeat on Upcycle

2024-02-11 - Weatherford CEO Girish Saligram charts course for growth as the company looks to enter the third year of what appears to be a long upcycle.