[Editor's note: This article originally appeared in the February 2020 issue of E&P magazine. Subscribe to the magazine here.]

An updated program is needed these days to identify the players and positions in the unconventional drilling arena. The driller is being recast as a process manager, robotics have replaced mangled fingers that once manhandled pipe on the drill floor, and directional drilling has morphed from an art to a science as sophisticated algorithms take over much of the responsibilities of highly prized directional drillers.

For sure, a contemporary U.S. onshore drilling ecosystem can perhaps best be described as an amalgamation of software driving hardware toward a wholesale recalibration of what was once considered optimum efficiency. As the sector takes more of a manufacturing approach to well construction, and with more operations transferred to the office, U.S. land has been ground zero for advances in automation and digitalization. That assessment was born out by the industry-funded Drilling Systems Automation (DSA) Roadmap, sponsored in part by the Society of Petroleum Engineers’ Drilling Systems Automation Technical Section and the International Association of Drilling Contractors’ Advanced Rig Technology Committee and Drilling Engineering Committee.

“The transformation [toward automation] is advancing the quickest in the USA land drilling environment, which will provide both a platform and an understanding for future developments and global adoption,” concluded the initiative’s final report released on June 1.

Optimum drilling efficiency was once described loosely as reaching programmed depth, at penetration rates as fast as safely possible and with minimum nonproductive time (NPT) along the way. The end result was handing off a usable wellbore to the completions team. While that definition still holds, the crowded subsurface environment of multiwell drilling pads has raised the stakes appreciably. Steering and well placement have taken on ultracritical roles as operators must avoid bumping into existing wells and putting the clamps on maximum reservoir drainage. Not surprisingly, directional drilling has taken top billing on the land-centric automation stage.

Variations in rotary walk and build, geologic target changes, anticollision considerations, costs associated with high tortuosity, and the risks of reduced production and EURs are among the myriad directional drilling anomalies that can cognitively tax even the most experienced and talented directional driller.

“There are too many variables for a human to consider in real time,” Bill Chmela, vice president of business development for H&P Technologies, said of the demands placed on directional drillers, magnified with the subterranean complexities of multiwell pads. “If automated cars can navigate our roads, automated directional drillers should be able to navigate the subsurface and land well locations defined by geologists, geophysicists and reservoir engineers.”

Automated directional drilling, sliding

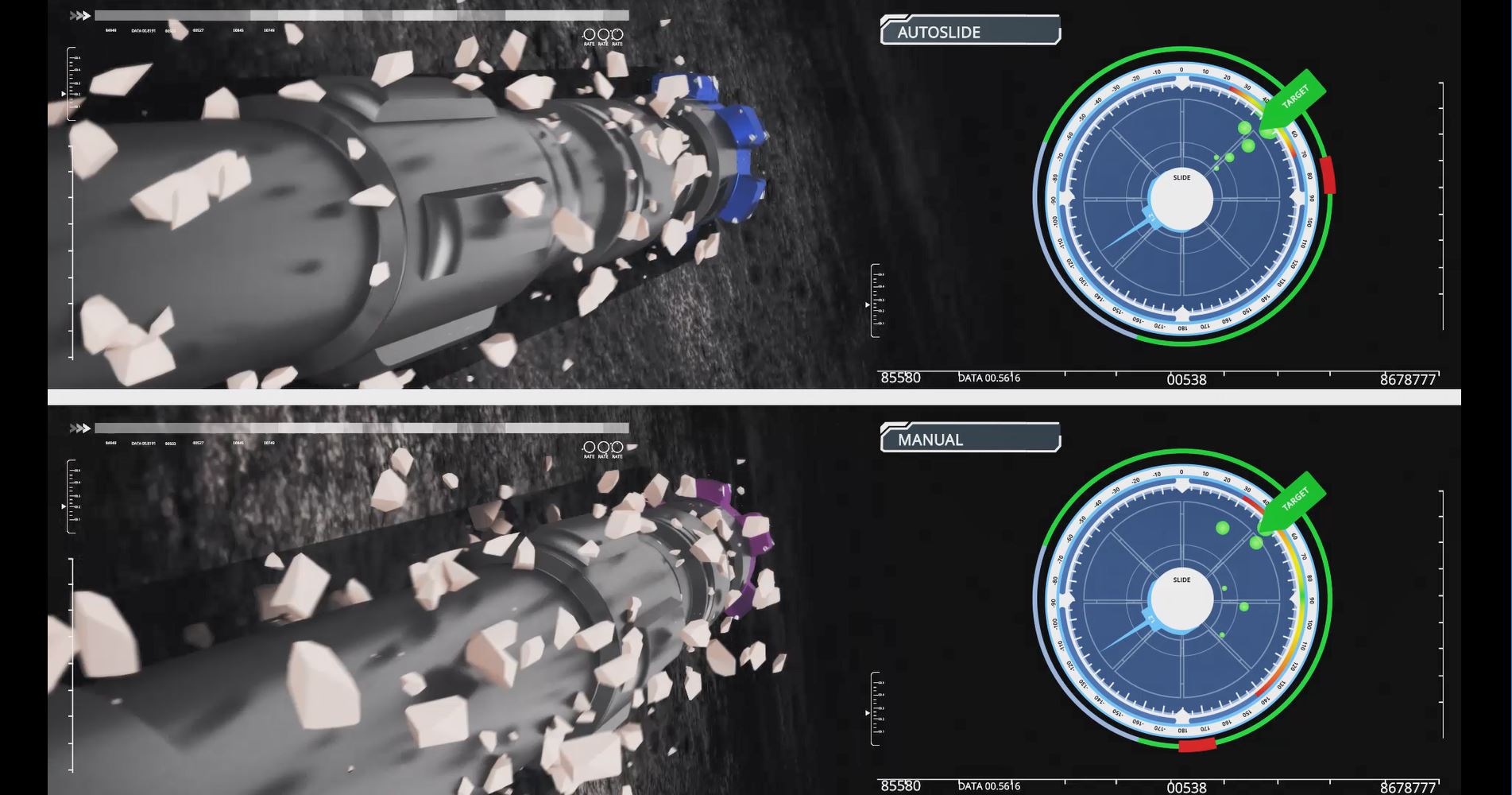

The wholly owned subsidiary of premier land drilling contractor Helmerich & Payne (H&P) Inc. took that proposition to heart with the development of an automated bit guidance system, which in early 2019, was expanded with the debut of automated sliding technology. While the bit guidance system automatically dictates when to slide or rotate, based on preprogrammed economic and production considerations, the auto slide implements those decisions.

“When you execute a slide, the driller must work the torque off the pipe, orient the tool and go to bottom where the bit sees some reactive torque,” Chmela said. “As you’re drilling, the toolface orientation wants to move, so the directional driller has to decide whether to add weight, take weight off or evaluate the flow rate to keep the toolface stable and maximize ROP. We developed an algorithm that does that automatically, so the system says when to slide.”

Unlike the rig-agnostic bit guidance system, the automated sliding component, for now, is reserved solely for H&P rigs. “Part of the reason is that interfacing the [sliding] decision-making tools to the rig control system is complex, and when you’re controlling the actual equipment on the rig, you want to make sure it’s done right and tested extensively,” he said.

The genesis of the closed-loop directional drilling technologies, and by extension H&P Technologies, can be traced to a small team within a Dallas independent, charged some eight years ago with investigating the glaring performance disparities between wells on a single pad.

“The drillers were saying ‘why are we drilling this well in 30 days and this well in 20 days?’ The production guys were saying ‘why is this well producing this much and the one right next door is producing 30% less?’ They were also asking why they were able to easily run casing in one well but couldn’t in an adjoining well,” Chmela said. “They came to the conclusion that the biggest factor in all these things was the skill of the directional driller, so we started looking at the tasks a directional driller does and how much of that we can improve through automation.”

Developers were moved to the rig site where they wrote and tested algorithms to replace manual calculations, such as motor yield when drilling a curve, the bottomhole assembly (BHA) tendencies while rotating and other cognitive decisions once made by the directional driller.

“We found that a computer could do all those calculations much, much faster and more reliably. After building the [bit guidance] system, we found we were making much better decisions,” he said. “The directional driller still has to do it, but everything that would be considered in decision-making is incorporated in the system.”

With the downturn gaining traction in late 2014, the in-house development group—with the operator’s blessing—spun off into Motive Drilling Technologies. Contractor H&P acquired Motive and its algorithm-driven bit guidance system in June 2017, followed six months later with the acquisition of Denver-based Magnetic Variation Services LLC (MagVAR) and its proprietary technology for cleansing the errors and uncertainties from raw MWD data. As its name implies, the company corrects for magnetic variances and errors caused by metal interference with the drillstring and BHA within the directional drilling field.

“Survey corrections help operators get their spacing right,” said MagVar veteran George Colbert, now H&P Technologies’ director of business development. “When you try to space these wells, there’s an ellipse of uncertainty. The survey may say ‘here’s where your well is,’ but it’s somewhere between this 500-foot to 700-foot ellipse. What we do is reduce that level of uncertainty.”

In late 2018, H&P acquired software-based training and consultancy company Angus Jamieson Consulting Ltd. of Inverness, Scotland, rounding out the triumvirate, collectively rebranded as H&P Technologies.

Deployment cycle

Prior to deployment, the directional drilling team meets with the operator to analyze the programmed drilling parameters and primary objectives, with corresponding economic and production considerations inputted into the system.

“We sit down beforehand with a checklist. Where are your lease lines? Where are your other boreholes and how close can we get to those boreholes? If we go up or down, left or right, how will that affect your production? So all the directional drilling decisions have the influence of the reservoir engineer, geophysicist and geologist, which no one has consistently done before,” Chmela said.

In the first step of the deployment cycle, all real-time surface and downhole data are acquired on location and subsequently aggregated into a single medium. The MWD data are continuously streamed to H&P Technologies’ Denver hub, where it is scrubbed and returned for programming into the bit guidance system. At this point, automation takes control by orienting the corrected data to the real-time well conditions, followed by deciding and then executing where precisely to point the bit and when to rotate or slide.

“We first analyze all the data to just orient us as to what’s currently going on downhole,” Chmela said. “We calculate the motor yields, the BHA tendencies and the current position of the bit, but in a much more sophisticated way than a person can do it in real time.”

Described as the “next evolutionary step” in true drilling automation, AutoSlide enables immediate recognition and reaction to downhole changes.

“Once you get into the slide the system has told you to make, you may find, for instance, that you’re not getting the proper yield. Before we reach the end of the programmed slide, the system may either say we’re good to go or extend the slide by 1.5 feet or 2.7 feet, whereas a human might say we’ve done our [programmed] 10-foot slide, or else they may say we need to add 20 feet to the slide. The economic ramifications of that can be huge and you can even ruin a wellbore,” Colbert said. “The auto slide judges toolface precision, so the directional driller may be sliding faster, but the toolface is all over the place. What comes out of this man versus machine is that the technology is as good, if not better, than the best directional driller, but it performs consistently over and over again, and consistency wins out in the end.”

‘Sky’s the limit’

Metaphorically, having an active BHA at the surface that enables immediate recognition and reaction to changing downhole conditions would radically enhance the directional steering and wellbore placement exercise. So says Halliburton Sperry Drilling of its digital twin, which replicates “wellbore propagation in real time on the surface” and is the backbone of the LOGIX automated drilling director.

Using intricate physics-based models and machine learning to project the well path, LOGIX controls steering to accurately place the wellbore and avoid collisions, while at the same time managing vibration and pressure parameters. The steering recommendations based on those projections, in turn, are automatically downlinked to the modular iCruise intelligent rotary steerable system (RSS), which packs sophisticated algorithms, multiple sensors, advanced electronics, survey packages and high-speed processors that collectively deliver downhole measurement data at the rate of 1,000 times per second for toolface control.

Simply put, “iCruise tells us what’s happening [in real time], while LOGIX predicts where you’ll be in 500 feet or 1,000 feet and tells you the toolface and duty cycle you need to follow to be there,” said Global Drilling Automation Manager Julien Marck, pointing out the “consistent and reliable performance” of LOGIX integrated with the iCruise RSS effectively closes the once huge gap between theory and actual practice.

“If you combine the LOGIX recommendations at the surface, the downhole CruiseControl algorithms of the [iCruise] tool and the knowledge you get with the sensors, you can really close the loop,” he said. “First, you need toolface control [positioning] for perfect well placement, but you also need consistent performance and good steering decisions.”

It all began with what Marck described as the “perfect digital twin,” which demonstrated precisely how the tool would behave in the face of ever-changing operational and geological conditions and at a challenging 15-degree/100-ft dogleg severity. The digital twin enabled iCruise designers to determine exactly how the tool would react under various operational factors, such as weight on bit, flow rates and bit selection.

The next step was to leverage that behavioral insight into a predictive platform that could make immediate recommendations during a directional drilling operation. Enter LOGIX, which began as an advisory system, computing downhole trends and the resulting steering behavior. It has evolved into a full suite of software with an expanding portfolio of services.

The iCruise RSS was engineered at the onset with the aim of tying into LOGIX and eventually providing a fully automated directional drilling system, with vertical, inclination and azimuth steering controls built into the tool. “When we began designing iCruise, we asked what can we do to get the data we’ll need in a few years to enable automation. The tool was built from the start for automation,” Marck said.

The RSS comes with multiple sensors that, along with surveys, take numerous dataset measurements, including gamma, vibration, pressure-while-drilling and three sets of inclination/azimuths, which are critical for steering control. “When you’re collecting data at 1,000 times per second downhole, there is no way to send all those data to surface, so we focused on putting some of the advanced technologies and control algorithms right into iCruise,” he said. “With all the sensors, you can almost perfectly know what kind of reliable and consistent performance you’ll get.”

By using data internally, the tool immediately identifies and reacts if it starts to deviate from the programmed well path. “The tool automatically senses that trend and adapts to bring the tool back to the target,” Marck said.

Importantly, he said, the modularity of the iCruise enables Sperry Drilling to collaborate with operators to customize a solution that addresses their specific well plan and objectives. Adapting the modular geometry of the RSS enables numerous plug-and-play functionalities and consistently predictable performance, Marck said. All pertinent data from the operator’s well program, including the landing point, inclination and lateral length, are inputted into LOGIX, along with nearby wellbore information for anticollision measures.

“Between the sensors and the sophisticated downhole control algorithms of iCruise and the coupling at the surface with LOGIX, I would say the sky’s the limit,” Marck said. “Because all applications are web-based, we can be in Houston and automatically land a well in the Permian Basin or in the Middle East.”

As for the suggestion that push-button directional steering, with zero human involvement at the well site, is on the near-horizon, Marck said, “I’d argue we’re almost, if not already, there, but safety must always come first. So I would say that even though we can, [it] doesn’t mean we should. We can drill wells now with very little human interaction, but from a safety perspective, you have to keep humans in the loop.”

Under-budget 3-mile lateral

In July 2019, the iCruise intelligent RSS drilled what is believed to be a Permian Basin record 15,382-ft lateral in two runs with sustained ROP averaging 110 ft/hr. Matched with a Halliburton GeoTech (GTi) drillbit and NitroForce high-flow, high-torque motor, the iCruise tool eliminated a planned third run, reaching target depth below the authorization for expenditure in 140 rotating hours.

By maintaining optimal drilling parameters, activating the tool’s internal CruiseControl and using LOGIX at the surface, the major operator reduced well time and achieved the required dogleg to accurately steer within the programmed geological target, thereby helping increase production and maximize asset value.

Putting data to work

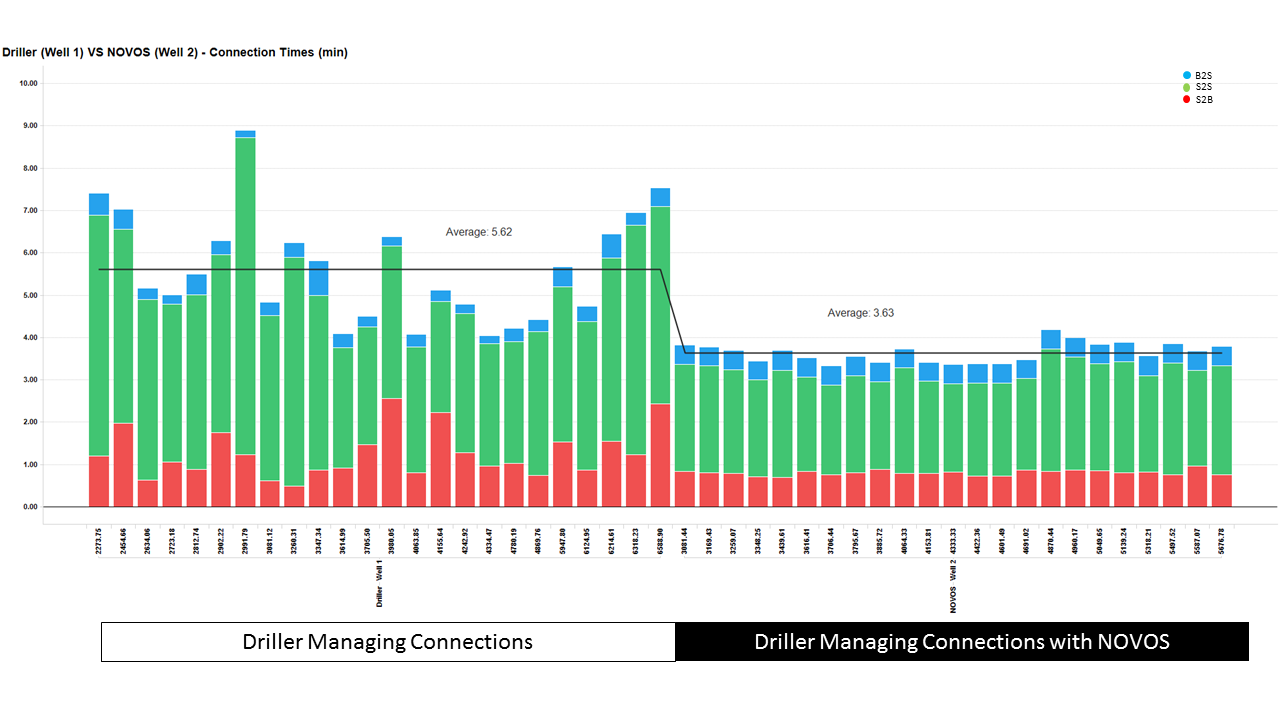

Much of the earliest work on automation centered on the more repetitive and hazardous rig floor activities, like transferring pipe from slips to subsurface engagement and back. While automating the slip-to-slip process remains the core of the National Oilwell Varco (NOV) NOVOS reflexive drilling system, the massive volume of downhole data now being generated has spawned a host of tie-in applications, according to Matt Jackson, NOVOS product development supervisor. Typically integrated with the company’s wired drillpipe technology, the NOVOS platform is being expanded from more than 300 channels to nearly 1,000 data-collecting tags.

“Since we’re now automating all of the [rig] processes, we have a plethora of datapoints that tell us everything from whether we’re in a reaming process or in the friction test process. It shows us the datapoints we’re extracting from torque and drag, pickup and slack-off values,” he said. “We see NOVOS as kind of a hub where more advanced systems, like ROP optimization and wired drillpipe applications, can be tied into the rig control systems. Of course, pipehandling and multimachine control are integrated into the system as well.”

Illustrative of the evolution of the automation platform, NOV (as of late July 2019) had successfully completed a series of field trials, orchestrated to test the feasibility of integrating managed pressure drilling (MPD) into the NOVOS system. “Now we have a very large backlog of new features and functionality, so we’re prioritizing what’s important,” Jackson said.

The NOVOS system debuted in the Permian Basin in October 2016 as part of an integrated program that included wired drillpipe and other data collection technologies, and it demonstrated its capacity to consistently and expeditiously pick up pipe, drill down the stand and return to the slip with no hands-on involvement.

The process includes engaging the formation “in a controlled way,” Jackson said, pointing out that NOVOS picks up formation vibration signals, for instance, enabling the system to maintain vibrations in a normal range for 78% of tag bottom events, some 42% better than that achieved manually. Corralling vibrations, in turn, reduces NPT and unnecessary trips, and it reduces wear on bits, drillpipe and other downhole tools.

“Since we have those downhole vibration measurements at our fingertips, we’re able to tag the formation much more intelligently,” Jackson said. “We like to say that we’re trying to elevate the driller’s view from essentially an advanced crane operator to more of a process manager.”

Intelligently tagging the formation includes the capacity to automatically make adjustments as downhole conditions warrant, said Andrew Macleod, North America sales manager for the NOV eVolve integrated optimization service. “In shale you want high ROP and low weight to tag bottom, so with NOVOS you can change it foot by foot. If, for example, you see pressure going up and surge and swab becoming a problem, you can tell NOVOS to make the necessary adjustments. NOVOS allows us to digest massive amounts of data and automate those in a repeatable process,” he said.

While consistency remains the primary driver for automation, the downturn forced operators to squeeze out efficiencies to reduce drilling costs and the HSE footprint. “There are also some hidden benefits in consistency,” said Chris Christopher, NOV drilling automation advisor. “With the tag bottom app, for instance, maybe you’re tagging bottom at the same speed of the driller on average, but what’s hidden is that with NOVOS you’re protecting the bit every time you tag bottom. Now, you get one bit run instead of three. And, of course, you’re controlling the process to take humans out of the risk zones, and the ability to control surge and swab leads us to better well control.”

Furthermore, automatically cleaning tremendous downhole data streams replaces tedious and time-consuming manual cleansing and delivers data that are sufficiently filtered into a usable format. Exporting and processing raw data through the NOV analytical dashboard to connected rigs enables customers to customize how they wish to visualize the data.

“Clients don’t want more data; they want usable data that help them do their jobs. As everything that’s recorded on the rig is streamed through NOVOS, you can write an app to control anything on the rig,” Macleod said.

Crucial to that end has been a keen industrywide focus on preventing “dirty data” from making its way into an automated or digitally enhanced process, according to Pradeep Ashok, senior research scientist at the multidisciplinary Rig Automation and Performance Improvements in Drilling (RAPID) group at the University of Texas at Austin.

“The quality [of data] has definitely improved, not necessarily because of the [rig] sensors, but the companies supplying the data are putting a little more effort into cleaning the data before it gets to the end user,” he said. “Not a lot has been done on the surface sensor side over the past two to three years to improve data quality. Downhole [sensors] are not necessarily better than surface sensors; they’ve just improved much more over the past two to three years.”

Digital health check

While those data have been used consistently to reduce NPT downhole (one of the primary drivers for drilling automation), the exorbitant costs associated with unexpected failures of critical surface equipment cannot be understated. A single failure on the top drive on a land rig, for instance, can shut down drilling for a day or longer and cost upward of $120,000 to restore service, according to the RAPID group.

Typically, the scheduled-based maintenance programs devised by the original equipment manufacturers fail to take into account factors such as specific operating and environmental conditions and human errors. Attaching instrumentation to surface equipment to continuously monitor the useful life remaining and provide immediate alerts for any operational upsets can eliminate the budget-draining NPT of incurring a breakdown while drilling a well, according to Chris Harshbarger, vice president of digital technology for Forum Energy Technologies Inc. Harshbarger heads up the company’s neoteric AMPIX predictive maintenance and condition monitoring systems, which were rolled out, respectively, in 2018 and earlier this year.

The initiative to engineer a suite of digital technologies to monitor the health of rig surface equipment began two years ago, initially with an analysis of the sensors and controls on catwalks, iron roughnecks and other equipment in Forum’s portfolio.

“Predictive maintenance has models running in the background that are based on the physical design [of the equipment], so we use physics in the beginning and then we mesh in operating conditions. We combine physics models and data-based models to create this machine learning algorithm that learns how the equipment is going to operate and identifies the failure modes,” he said.

The plug-and-play capabilities of the preventative maintenance system enable customization to any piece of surface equipment the operator so desires, with individual rigs now fitted with anywhere from 20 to 100 sensors. The dashboard for the predictive maintenance platform is equipped with a “health meter” that, depending on the specific equipment, visualizes the hours, cycles or strokes remaining before major maintenance is required.

“They can plan ahead to fix something, be it a bearing, motor, gear box on a top drive, a valve, a piston, a fluid end in a mud pump or other equipment, rather than having it go out in the middle of a well,” Harshbarger said. “By pinpointing exactly when something is going to fail, you can plan whether to start the next well or shut down for maintenance.”

Meanwhile, the sister condition monitoring system sends an immediate alert upon identifying an operational hiccup that signifies an impending failure. Also included beneath the AMPIX umbrella, the condition-based monitoring component is largely reserved for critical surface equipment, such as the top drive, drawworks and mud pumps, where specialized instrumentation primarily measures temperature and vibration levels as well as pressure and oil quality values.

As for top drives specifically, researchers in the RAPID group exploit data collected from existing rig sensors to signal when a failure is approaching. The data were incorporated in a recently developed physics-based thermal model, used in combination with a fault detection algorithm, to enable condition-based monitoring to head off costly failures.

Harshbarger said AMPIX condition monitoring alerts have come up for everything from looming deteriorations of a gear box or bearings in a top drive to loose connections. “Another thing we monitor is the air conditioner in the doghouse and power house. If we see the temperature rise, we let the rig know immediately, because if the power house gets too hot, those drives will overwork and shut down, and then you’re not drilling. There may be something wrong with the compressor, but usually when they check it out, someone has either left a door open or something has gotten disconnected.

We’ve saved a ton of NPT that way.”

He cited one operator that conservatively saved more than $1.5 million in a single year by eliminating failure-induced NPT across its multirig fleet.

Field to office

Hand in hand with its role in the steady progression of automated drilling, meteoric advancements in telemetry have likewise helped accelerate the transfer of key personnel from the field to remote operating centers. Bolstered by improved rig connectivity, MWD hands and directional drillers are among the latest to replace exposure to sweltering West Texas summers and sub-freezing North Dakota winters with the comforts of an office and regular work hours, according to Baker Hughes.

“The decoding of the telemetry we now get from MWD to surface is much more reliable and stable, so we can handle control of it at the end of the communications link, rather than having someone on location,” said John Macpherson, chief consulting scientist in the company’s Drilling Technology group in Celle, Germany. “That’s allowed us to facilitate de-manning at the rig site.”

Dean McCoy, who at the time of this interview was operations manager for North America Land Remote Field Operations Centers, said Baker Hughes began looking at establishing remote operations centers to handle MWD services around 2007, but at the time, communications between rigs and offices were unacceptably slow. Given the rapid advancements in rig-to-office communications networks, the company revisited the concept in 2011. “We asked every area across North America to make it work, which they did. So we brought people into offices to run MWD services remotely,” he said.

However, given area-specific practices and communication protocols, every location was working on a different wavelength, creating an operational gap. “Everyone had different connectivity rates; some of it was due to communications and some was rig procedures. People were doing things differently. Granted, you need some fluctuation, depending on where you’re drilling, but we needed to standardize across our North America Land region,” he said.

The company did just that in August 2015 by consolidating all of the areas’ remote centers into a centralized remote operations center in Houston with standardized procedures, communication protocol and documentation. The remote MWD business “exploded” in 2018, which McCoy attributes to clients’ push for improved per-rig drilling efficiency, safety and cost. “We basically did more work in 2018 than we did through August 2015 to December 2017 combined. That forced us in July 2018 to open a second remote operations center in Oklahoma City,” he said.

The directional drilling side followed suit, as operators requested directional drillers be moved into their offices where they could interact with peers as well as the geologists and other operator personnel. As opposed to having a single directional driller at the rig site, assembling a number of directional drillers in one room sharing insight on different hole sections, for instance, has helped drill wells faster with better quality wellbores. “Anything you can do from a [rig site] cabin, you can do remotely,” McCoy said.

H&P Technologies, for one, has relocated a number of experienced directional drillers to command centers in Dallas, Denver and Calgary to provide oversight of ongoing field operations and ensure consistency is being met. In the current setup at the Dallas headquarters, six work stations, or pods, equipped with vertical screens are each capable of constantly monitoring eight rigs simultaneously.

“We’re kind of like air traffic control, as we watch the guidance that the bit guidance system comes up, as well as that of the auto slide system,” said Dave Simpson, manager of the Dallas center. “We watch them execute the slides and make sure it’s doing things that are not going to get us into trouble. It minimizes the mistakes made by human error to maximize the on-bottom time and minimize the off-bottom time.”

Operators in the Marcellus-Utica Shale play in the Appalachian Basin were early movers in displacing directional drillers from the rig site to offices. “In the northeast [U.S.], we’ve been working with rotary steerable systems, which are automated to a degree that enables us to move the directional driller from the well site to a remote center,” Baker’s Macpherson said. As of December, more than 5 MMft of hole have been drilled unmanned across U.S. basins without a directional driller on site.

“The MWD people are in our remote centers, while the directional drillers are with the geologists in the clients’ remote centers, which enables faster decision-making and allows us to get really high performance out of these wells,” Macpherson said. “Having the communication infrastructure and the software that enables it really moves us closer to factory-style drilling and getting these wells down faster and faster.”

With directional drillers and MWD personnel validating that operations can be carried out effectively from remote locations, it’s only a matter of time before other subject matter experts (SMEs) are brought into the fold. “If I have a drilling optimization engineer sitting next to the directional drillers and geologists, the whole process is streamlined,” McCoy said. “Then you include reservoir navigation and wireline so you can start looking at future portions of the well, including the completions. It can be a totally different way of doing business.”

Macpherson pointed out that the field-to-office movement does not so much represent a wholesale cultural change but rather an organizational shift. “If you look at it from a manufacturing perspective, you’re basically moving the SMEs up the decision-making tree and using that expertise to properly improve the efficiency of the operation,” he said. “The SMEs have become extremely valuable in automation, for example, by helping develop algorithms and roll out training. When we develop these automation pieces, they take them to the field to make sure they can actually use what we produce.”

He added, “Your job’s not disappearing; you’re just changing roles.”

Furthermore, one of the more enduring challenges facing the industry as the automation wave sweeps across the unconventional landscape is dealing with the human factor, in particular, convincing humans that automation is not a threat to their livelihoods.

The angst factor

The emergence of robotics and algorithms as preferable to humans for repetitive and highly inflexible tasks has generated an understandable measure of angst among rig floor hands. While the DSA Roadmap conceded automation, by intent, is meant to decrease the human population on the rig, automation will not, in and of itself, be responsible for the wholesale tossing of rig crews into unemployment lines.

“Most industrial automation experts agree that a completely autonomous system without direct human interaction is not a practical goal. This means that the role of humans at the well site will not disappear but will change dramatically as tasks and responsibilities are systematically shifted to automated machines and remote operating centers,” the final report concluded.

Nevertheless, introducing any automated technology instantly sends up alarms that can make engaging operational personnel more than a little bit challenging. “When you talk about automation in the oil field, people envisage robots taking their jobs,” says NOV’s Macleod. “So you have to explain and demonstrate that this is a system to assist you in the things you already do. You’re in charge of the system; it just makes your life easier.”

As H&P Technologies discovered, telling veteran directional drillers that a significant portion of their job is being taken over by computers can be an especially tough sell. “The field guys will say ‘I’m not letting a box tell me how to do my job.’ They’ll deny at first that it can even work. Once they see it in operation, they begin accepting it,” H&P’s Chmela said.

Halliburton’s Marck added, “You don’t automate jobs; you automate tasks. When you automate the steering, this allows the directional driller to concentrate on ROP optimization, without having to be concerned with the survey or steering direction.”

He concluded, “Some tasks can be automated easily, but new tasks are also being created.”

Read E&P's other "Drilling Innovations" cover stories from the February issue:

Hardware evolution moving rigs toward automation revelation

Innovation grows exponentially for downhole drilling tools

Multilaterals provide an unconventional approach to shale reservoirs

Recommended Reading

Shell Brings Deepwater Rydberg Subsea Tieback Onstream

2024-02-23 - The two-well Gulf of Mexico development will send 16,000 boe/d at peak rates to the Appomattox production semisubmersible.

Stena Evolution Upgrade Planned for Sparta Ops

2024-03-27 - The seventh-gen drillship will be upgraded with a 20,000-psi equipment package starting in 2026.

Shell Taps TechnipFMC for 20K System for Sparta

2024-02-19 - The deepwater greenfield project in the Gulf of Mexico targets reserves in the high-pressure Paleogene reservoir.

Rystad: More Deepwater Wells to be Drilled in 2024

2024-02-29 - Upstream majors dive into deeper and frontier waters while exploration budgets for 2024 remain flat.

E&P Highlights: April 1, 2024

2024-04-01 - Here’s a roundup of the latest E&P headlines, including new contract awards.