Presented by:

This article appears in the E&P newsletter. Subscribe to the E&P newsletter here.

Advances in technology are leading to a transition in the oil and gas industry, increasing efficiency in operations and maximizing the utilization of subsurface data. Advanced materials and artificial intelligence have become paramount for the development of new wells and for acquiring an accurate understanding of the reservoir formation. "NanoTagging" is a technology that significantly improves the accuracy of cuttings depth determination to +/- 2 ft in wells that are thousands of feet long.

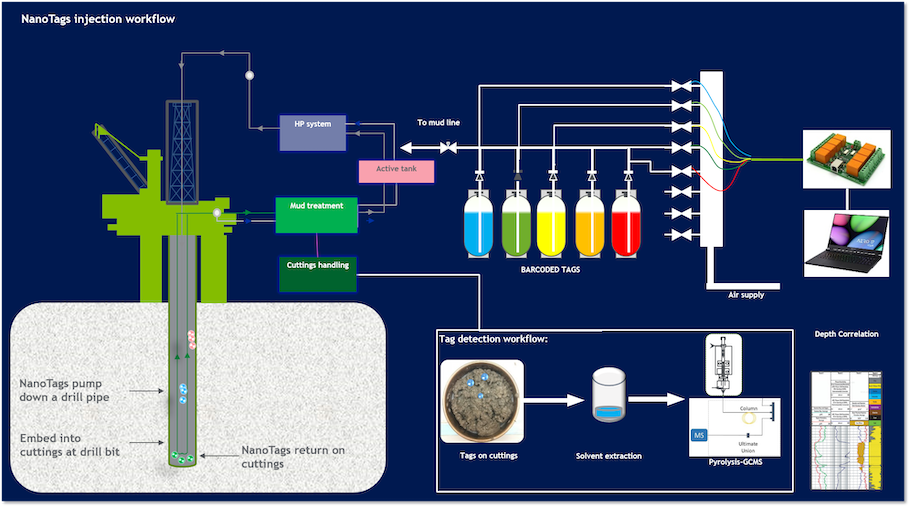

The NanoTagging method injects specially designed nanoparticle “tags” into drilling fluids, which generate a barcode signature upon cuttings analysis that precisely determines the original depth of the drill cuttings. This depth correlation system consists of barcoded NanoTags, an extraction process and a detection method for precisely and distinctively detecting the tags residing on the drill cuttings.

Saudi Aramco has successfully synthesized a small library of polymeric NanoTags using a simple, scalable emulsion polymerization method. Notably, the sizes of the as-made NanoTags are narrowly distributed in the range of 20 nm to 60 nm. These barcoded NanoTags are also compatible with drilling fluids and safe for handling and disposal due to their low toxicity and long shelf life.

Saudi Aramco also designed a solvent-extraction and thermal-separation workflow. The workflow extracts and separates the NanoTags from other small molecule additives and hydrocarbons on the cuttings and then subjects the NanoTags to pyrolysis—a process that thermally depolymerizes the NanoTags at elevated temperatures for identification by GCMS.

Case study

This technology was tested for the first time in December 2019 under realistic conditions in a Middle East gas well drilled in a carbonate formation. After demonstrating that the NanoTags, dispersed in aqueous fluids, have a negligible effect on the rheology of the drilling mud at a low-injection volume, Saudi Aramco injected three distinctly barcoded NanoTags at 5 and 10 ppm into the water-based drilling mud for three minutes at a point just upstream of the high-pressure mud pumps. The NanoTags traveled with the mud and marked the fresh cuttings at the drill bit when they were created at a known downward travel time after their injection time.

The company then collected cuttings off the shale-shakers and analyzed them to identify the NanoTags. A wide sampling window was defined based on the mud flow rate and modeling of all bottomhole assembly dimensions: the samples were collected in two-minute intervals starting from 15 minutes prior to 15 minutes after the calculated “optimal” arrival time (lag time). Scheme 1 illustrates the NanoTag technology demonstrated in the field and in the laboratory.

In the laboratory, the NanoTags were first separated from the cuttings via solvent extraction and thermal evaporation to remove the polymers and small molecule additives normally present in the mud. The NanoTags were pyrolyzed and analyzed using a Triple-Quad GCMS linked to a pyrolyzer. The results demonstrated the unambiguous detection of NanoTags extracted from carbonate cuttings recovered from the water-based mud containing NanoTags at a concentration of a few ppm.

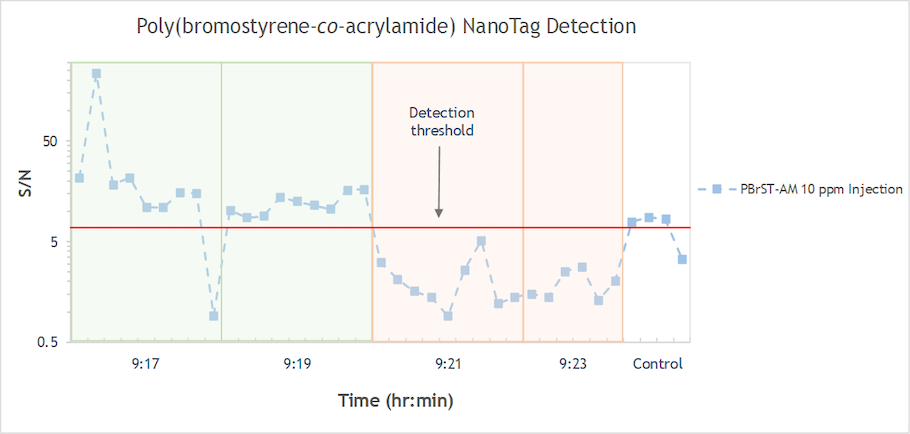

Scheme 2 shows a sample of the distribution of the tag signals over the time window of the cutting collections. Here, NanoTags were detected close to the optimal arrival time, and they were not detected several minutes earlier or later, where not expected.

The distribution of the NanoTags versus time was compared with the modeled arrival times, including the mud-logger’s software corrections for variations in mud flow by counting actual pump-strokes. The depth determined using the tags was consistent with the depth assigned by the mud logging service.

Elsewhere, Saudi Aramco also discovered a systematic difference between depths estimated from the downward NanoTags travel times and the depths calculated from mud-logger’s compensated upward travel times. These differences could potentially show evidence of hole enlargement or other systematic errors that this invention aims to eliminate.

Conclusion

The NanoTags for drill cuttings depth correlation technology improves the current mud logging process and is cost-effective, straightforward and environmentally friendly. This technology allows oil and gas operators to improve the quality of lithological and petrophysical analyses, enhance formation evaluation and geosteering practices, and control well placement with mud logging, thus helping to maximize oil recovery.

Looking toward the future, Saudi Aramco is working on automating the field dispensing of the different NanoTag barcodes into the mud and automating the laboratory extraction and detection workflow. Automation of each step of this technology could make the tagging process a routine operation available for improving mud-logging data quality.

View E&P's 2021 'Meritorious Awards for Engineering Innovation' Winning Technologies

Recommended Reading

Thanks to New Technologies Group, CNX Records 16th Consecutive Quarter of FCF

2024-01-26 - Despite exiting Adams Fork Project, CNX Resources expects 2024 to yield even greater cash flow.

Cheniere Energy Declares Quarterly Cash Dividend, Distribution

2024-01-26 - Cheniere’s quarterly cash dividend is payable on Feb. 23 to shareholders of record by Feb. 6.

Marathon Petroleum Sets 2024 Capex at $1.25 Billion

2024-01-30 - Marathon Petroleum Corp. eyes standalone capex at $1.25 billion in 2024, down 10% compared to $1.4 billion in 2023 as it focuses on cost reduction and margin enhancement projects.

Humble Midstream II, Quantum Capital Form Partnership for Infrastructure Projects

2024-01-30 - Humble Midstream II Partners and Quantum Capital Group’s partnership will promote a focus on energy transition infrastructure.

Hess Corp. Boosts Bakken Output, Drilling Ahead of Chevron Merger

2024-01-31 - Hess Corp. increased its drilling activity and output from the Bakken play of North Dakota during the fourth quarter, the E&P reported in its latest earnings.