Emissions pose both a safety and environmental hazard. In some cases, burning emissions via flare is the best solution, while in other cases vapor recovery might be preferred. Environmental pollution legislation is—almost without exception—the driver behind the decision to install a vapor recovery unit to meet the permitting requirements and to provide cleaner local environmental emission controls and safer working environments.

Beyond the environmental and safety advantages, the potential economic benefit from the recovery of a highly valuable product cannot be ignored. In addition to wellsite waste gas, common fugitive emission points include tank vapors and vent lines on instruments.

The latest emissions regulations specify that emissions from compressor packing on reciprocating compressors must be controlled. With sales gas pipelines, compressor packages for collecting and compressing these gases can be employed. These packages recover and reroute gas emissions back into the gas pipeline. In stranded gas applications, gas-to-liquids packages recover valuable hydrocarbon liquids.

Combustion and environmental control companies can design a cost-effective combination vapor recovery flare package that allows producers to recover heavier gases as a liquid and safely flare lighter hydrocarbons like methane.

When processing combustible gases, a flare provides a safe means of disposal for gas releases. Instead of an accidental dangerous gas release into the atmosphere that could harm employees, the surrounding area or facility, potential release sources are collected and routed to a flare. At the flare, the gases are ignited by pilots and destroyed through controlled combustion in a designed-for-purpose system. While the fire visible from a flare might be alarming, the products of combustion—CO2 and water—are better for the environment, plant and people when compared to raw gases.

Design considerations

Zeeco’s experience in flare design has led to some adages and practical approaches for flare systems. In general, engineers work to minimize the size and diameter of a flare while still fully combusting gases. Using the smallest applicable diameter converts the potential energy of the gas (pressure) into kinetic energy (velocity). More velocity means a more erect flame, quicker air inspiration and less sweep gas—all lowering emissions.

Ultimately, designing the smallest possible tip while maintaining high destruction efficiencies lowers capital costs and extends the lifespan of equipment due to less destructive flame impingement (vs. a larger diameter flare tip). The evaluation of a flare’s combustion performance is predictable by comparing the flare tip exit velocity to the heating value of the flared gases.

To ensure the flare gas has ample opportunity to combust fully, there should be sufficient heating value to the gas. The velocity of the gas must be correct to prevent a separation of the combustible zone from the pilot ignition source at the flare tip; this phenomena is known as lift-off. A robust flame not detached from the flare tip and pilots demonstrates ample combustion efficiencies.

Meeting standards

Regulations are in place to ensure manufacturers and operators properly combust flare gases. In these regulations, the exit velocity of the tip is the primary operational consideration for the application of U.S. Environmental Protection Agency (EPA) standards.

With offshore platforms, flaring systems face challenges such as space availability, heat radiation, noise and environmental regulations. Offshore flares need to deliver high destruction efficiencies and stable flame patterns across a wide operating envelope and should be designed to meet the pressure, flow and gas composition ranges required. Reliable flare pilots are a critical component in maintaining safety and emission standards. Hurricane-proof pilots such as high-stability, low-flow, ballistic pellet ignition and monitoring systems help minimize common offshore flaring challenges.

Onshore production flares, wellsite flares and tank vent flares also are subjected to both climate challenges and remote areas. In the U.S., systems must be compliant with the EPA’s New Source Performance Standards OOOO (NSPS Quad O), National Emissions Standards for Hazardous Air Pollutants, Maximum Achievable Controls Technology and other applicable requirements. NSPS Quad O requires gases that would otherwise be vented during periods of flowback be routed to a completion control device (CCD) instead. The CCD must achieve a minimum of 95% volatile organic compounds (VOCs) reduction. A properly designed flare will achieve greater than 98% VOCs reduction.

Control options

Portable open and enclosed wellhead and well pad flares that do not require a pre-poured foundation can be the solution to completing wells quickly and effectively while complying with oil and gas gathering field environmental regulations. The Zeeco enclosed wellhead flare system, for example, is a simple, low-maintenance flare providing smokeless, high-efficiency combustion without field operator attendance or adjustment requirements.

Often used with tank batteries, heater treaters, vapor recovery towers and other field equipment, the system’s advantages include no visible flame, quiet operation and no moving parts. Due to a proprietary tip that inspirates air, this wellhead flare achieves up to 99% or greater destruction removal efficiency and comes preassembled on two small skids with pre-spooled interconnecting wiring to minimize installation time and expense.

In some cases, selecting a high-pressure/low-pressure (HP/LP) system, also known as dual flares, will allow an operator to effectively handle the HP wellhead separator/heater treater flows and LP tank battery vent gases that are common on most well pad locations. Solar energy-powered flare igniters also are available for remote locations where electricity is unavailable, as is often the case in remote fields.

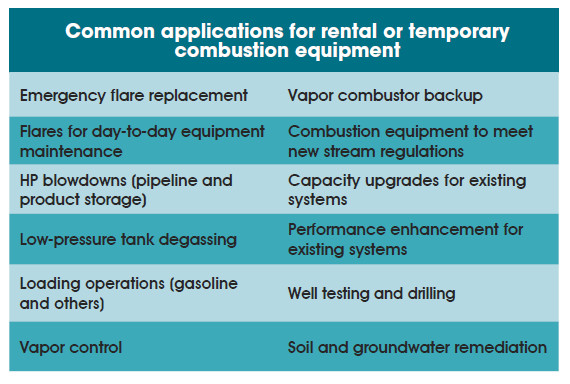

Upstream and midstream operators sometimes choose rental or mobile systems to control emissions, which are typically trailer-mounted or skidmounted. Many of these systems feature a hydraulic lift system for ease of installation. Open-flare, enclosedflare, thermal oxidizers and vapor combustor systems are available and can be used to effectively destroy waste gases. Systems that can automatically control combustion and quench air along with fuel gas (in low-Btu applications) to maintain precise chamber temperatures for destruction and removal efficiencies of up to 99.9% will meet or exceed the most stringent clean-air standards.

Regardless of the type of flare system used, a properly engineered flare will include investment castings for the critical components in the heat-affected zones to minimize the potential for field failure. A continuous, monitored pilot that meets or exceeds American Petroleum Institute 537 design criteria for performance under high wind and rain conditions means fewer operations and maintenance issues in the field and ensures environmental performance.

Open-flaring equipment can range from small skid- and trailer-mounted flares to 91-m- (300-ft-) tall elevated systems. Enclosed vapor combustor, incineration and flare systems can dispose of anywhere from very small process vent streams to 1.4 MMcm/d (50 MMscf/d) emergency releases.

Recommended Reading

Report: Freeport LNG Hits Sixth Day of Dwindling Gas Consumption

2024-04-17 - With Freeport LNG operating at a fraction of its full capacity, natural gas futures have fallen following a short rally the week before.

Permian NatGas Hits 15-month Low as Negative Prices Linger

2024-04-16 - Prices at the Waha Hub in West Texas closed at negative $2.99/MMBtu on April 15, its lowest since December 2022.

BP Starts Oil Production at New Offshore Platform in Azerbaijan

2024-04-16 - Azeri Central East offshore platform is the seventh oil platform installed in the Azeri-Chirag-Gunashli field in the Caspian Sea.

US Could Release More SPR Oil to Keep Gas Prices Low, Senior White House Adviser Says

2024-04-16 - White House senior adviser John Podesta stopped short of saying there would be a release from the Strategic Petroleum Reserve any time soon at an industry conference on April 16.

Core Scientific to Expand its Texas Bitcoin Mining Center

2024-04-16 - Core Scientific said its Denton, Texas, data center currently operates 125 megawatts of bitcoin mining with total contracted power of approximately 300 MW.