The Pearsall Shale play is emerging as another potential unconventional resource for the South Texas region. Geologically, the play lies several formations below the Eagle Ford Shale in the Lower Cretaceous and extends geographically from Maverick County near the Mexican border to Karnes County southeast of San Antonio.

To reach this shale zone, a deep vertical intermediate section is drilled through a hard carbonate sequence containing the Georgetown, McKnight, Edwards and Glen Rose formations. The production hole consists of a curve and a horizontal section through the Pearsall Shale.

The MultiSense dynamics mapping system, a bit-based vibration tool, was utilized to record downhole vibrations in the 97⁄8-in. intermediate hole section. The objective of the project was to measure, understand and mitigate vibrations at the bit and bottomhole assembly (BHA) in an effort to improve drilling performance. The operator saved a significant amount of drilling time through the elimination of downhole vibrations and improved ROP.

The analysis reported in this study was conducted to identify which types of downhole vibrations occurred while drilling the intermediate section within the lower Cretaceous leading to drilling inefficiencies and eventually damaged drillbits. Advancements in bit design and diamond-cutter technology have allowed polycrystalline diamond compact (PDC) bits to drill formations that were previously deemed non-PDC drillable.

As a result, operating parameters for PDC bits have shifted to higher weight-on-bit (WOB) ranges at reduced rpm to enhance drilling performance in harder rock types. Unfortunately for PDC bits, higher WOB and lower rpm initiate torsional instability that develops into stick/slip type vibration.

For this project several bit designs were equipped with the MultiSense module to record downhole vibrations to gain a better understanding of these drilling dynamics. Once the bit was pulled to surface, the vibration data were downloaded and correlated with time-based surface drilling data, which were downloaded at 5-sec data resolution.

MultiSense module

The MultiSense module is installed in the shank of the bit as shown in Figure 1. The module resides directly inside the drillbit shank to capture the true dynamic dysfunctions at the bit. It also can be positioned in subs and placed anywhere in the drillstring.

The module is a drilling dysfunction identification tool. The device comprises accelerometers in which axial, lateral and torsional vibrations are measured. Field-proven downhole algorithms convert raw g-root mean squared values to understandable drilling dysfunctions such as stick/slip, bit bounce and whirl. Several different accelerometers are used to measure rpm.

The module is capable of recording data in two different operational modes: background and burst. The background data calculate and store average values for axial and lateral accelerations in addition to maximum, minimum and average rotary speeds. Samples of high-frequency data, also known as “burst files,” are stored at consistent intervals.

Background, drilling challenges

The carbonate formations encountered in the lower Cretaceous presented various challenges for the operator drilling in Frio County. The project wells consist of a design with three casing strings, with a lateral section in the Pearsall Shale. The surface section begins with a 14¾-in. surface hole to about 1,189 m (3,900 ft) true vertical depth (TVD), where the 10¾-in. casing is set.

Next, the 97⁄8-in. intermediate section consists of a vertical hole with interval total depth (TD) ending at about 3,277 m (10,750 ft) TVD, where the 75⁄8-in. casing is placed. Last, the production section is drilled in 6¾-in. hole with a build and horizontal interval to well TD at about 4,695 m (15,400 ft) measured depth (MD).

For the 97⁄8-in. intermediate section, unconfined compressive strengths were evaluated from offset wells in the area for the formations in the lower Cretaceous. Rock strength values averaged nearly 15,000 psi within the Georgetown Limestone.

The underlying Edwards Formation also consists of a limestone with a harder unconfined compressive strength (UCS) ranging from 15,000 psi to 20,000 psi. The following McKnight Formation averages nearly 20,000 psi and contains both limestone and anhydrite.

Finally, the Glenn Rose Formation is composed of a thick limestone interval with a UCS range within 18,000 psi to 20,000 psi and lies above the Pearsall Shale pay zone.

Results, conclusions

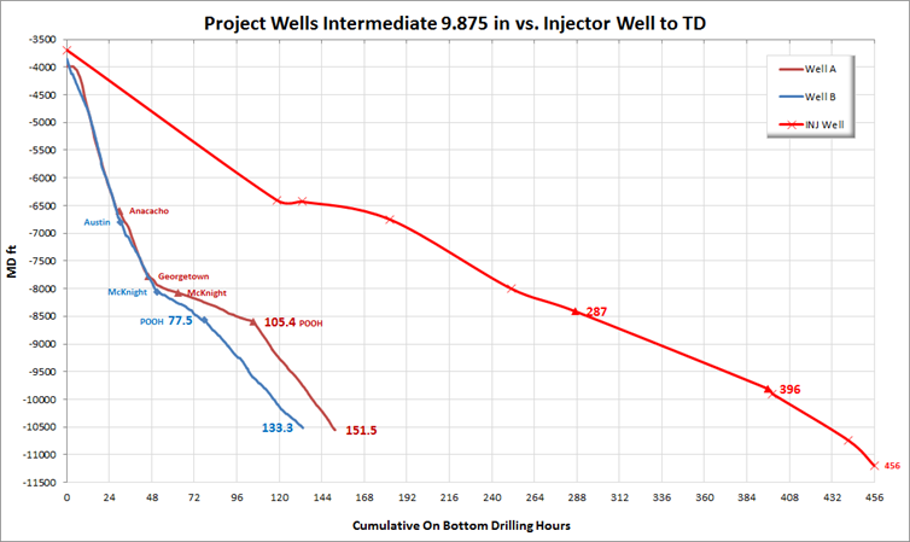

Prior to the project wells, an offset injector well was drilled with a 12¼-in. vertical hole down to 2,564 m (8,409 ft) MD, allowing a pre-well analysis. Although the injector well was constructed with a different casing design, it required five bit runs and 287 drilling hours to reach this depth. Multiple BHAs were tripped due to slow ROP where the PDC bits exhibited impact damage

indicative of downhole vibrations. For the project wells, the operator redesigned the casing string and reduced hole size from 12¼ in. to 97⁄8 in.

Also with the utilization of the MultiSense module, a better understanding of drilling dysfunctions could be attained by reviewing torsional and lateral vibration data and then correlating these data with time and depth. From this correlation the operator would then be able to optimize the drilling BHA and select the proper bit design to maximize drilling efficiency through the various formations.

The use of a downhole motor and a modified bit design on well B increased overall ROP by 37% to the base of the McKnight Formation. Drilling to a depth of 2,610 m (8,562 ft) MD on well B saved 27.9 hours of rig time compared to well A.

Comparing project well B to the offset injector well showed savings of an estimated 209.5 hours or 8.7 days to reach this similar depth (Figure 2). The utilization of the MultiSense module allowed the operator to gain a better understanding of the drilling dynamics occurring downhole at the bit.

This investigation revealed that stick/slip was the most common downhole vibration for the rotary BHA and was responsible for the damaged PDC bit. Incorporation of a downhole motor and a durable PDC bit in the BHA eliminated stick/slip in the carbonate formations and enhanced ROP. The lessons learned were implemented in sequential wells to improve drilling performance for the intermediate hole section.

Recommended Reading

Hess Corp. Boosts Bakken Output, Drilling Ahead of Chevron Merger

2024-01-31 - Hess Corp. increased its drilling activity and output from the Bakken play of North Dakota during the fourth quarter, the E&P reported in its latest earnings.

The OGInterview: Petrie Partners a Big Deal Among Investment Banks

2024-02-01 - In this OGInterview, Hart Energy's Chris Mathews sat down with Petrie Partners—perhaps not the biggest or flashiest investment bank around, but after over two decades, the firm has been around the block more than most.

Some Payne, But Mostly Gain for H&P in Q4 2023

2024-01-31 - Helmerich & Payne’s revenue grew internationally and in North America but declined in the Gulf of Mexico compared to the previous quarter.

Petrie Partners: A Small Wonder

2024-02-01 - Petrie Partners may not be the biggest or flashiest investment bank on the block, but after over two decades, its executives have been around the block more than most.

BP’s Kate Thomson Promoted to CFO, Joins Board

2024-02-05 - Before becoming BP’s interim CFO in September 2023, Kate Thomson served as senior vice president of finance for production and operations.