When it comes to deepwater developments, speed is the name of the game.

The faster a job offshore is completed the safer and more environmentally friendly it is. It could also save money as day rates for drillships can exceed $400,000/day.

Baker Hughes understands this.

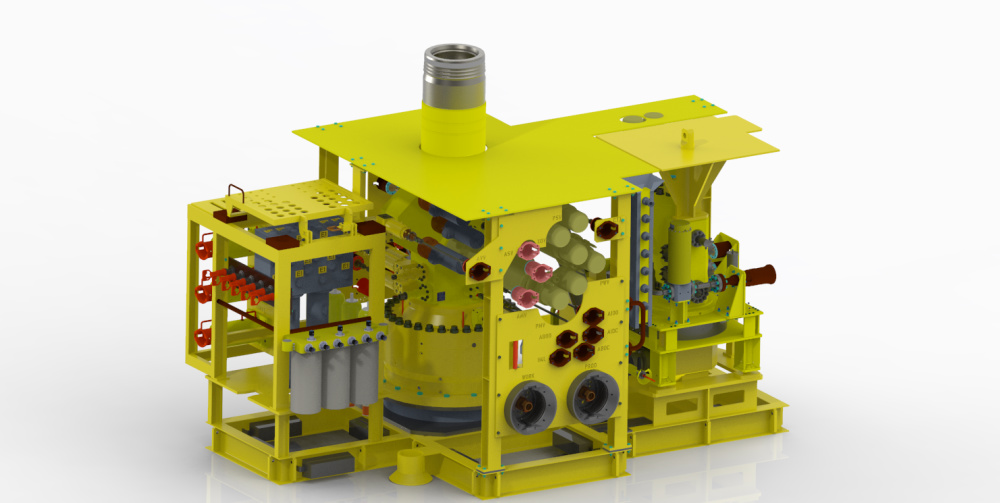

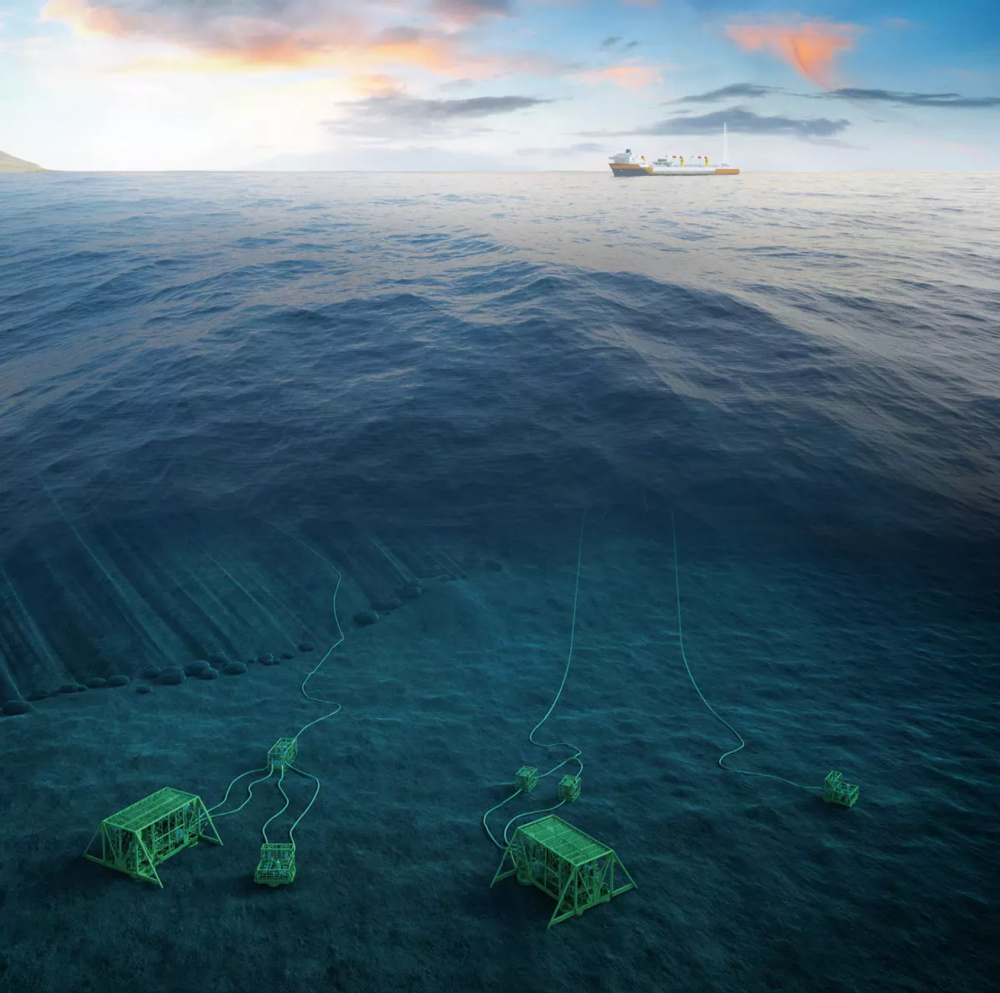

Earlier this year at Offshore Northern Seas 2022, Baker Hughes unveiled their brand new fast all-electric subsea tieback solution. This new tieback drives cost efficiencies while reducing topside footprint, and delivering environmental benefits for subsea operations.

An overarching goal of this project was to “make the oilfield more efficient,” said Gareth Davies, executive director of systems and technology – oilfield equipment at Baker Hughes.

“What this is, is an electrified tree system that we’ve tried to minimize the infrastructure overhead for,” he said. “If we’re going to supply power to the tree system, then if we can help it, we don’t really want to supply anything else like hydraulic fluid or chemicals. So, what we tried to do is to put all of those functionalities into the tree system so that we can eliminate all of the other infrastructure supports.”

“We bring a lot of that different sort of mindset and we’re going to do a lot more of it too, but it allows us to start to think about different problems like grid style electrification for the offshore environment.”—Gareth Davies, Baker Hughes

The idea for this new tieback originally began with Baker Hughes trying to limit the amount of CO₂ that was produced in the manufacturing process. To do that, they began eliminating unnecessary components in an effort to make everything light and cheap. From there, they began to eliminate things like the hydraulic lines and chemical storage.

Despite the obvious benefits an all-electric subsea tieback could have on the offshore industry, this product is the first of its kind. Developing this wasn’t a particularly easy task, especially in an industry that is heavily ruled by the old guard.

“The biggest thing we’ve had to overcome in the process is actually mindsets—traditional thinking mindsets,” Davies said. “That’s something that even though we’ve ended up with a semi-traditional looking product, it’s got a lot of functions and services on it that you would never have got if you'd started in a traditional sort of way.”

Development

Along with waiting for mindsets to evolve, Davies also noted that they had to wait for technology to evolve as well.

Baker Hughes’ product has been in development for 18 months, before then technology wasn’t advanced enough to even fathom this project. In early trials, they weren’t even able to remove the hydraulic support infrastructure, as they kept it as a backup plan in case things went wrong.

“A lot of the interventions, if you talk to [our operators], that they do at the moment result from valve issues or hydraulic issues,” said Davies. “So, it’s a really positive thing for us to think about; less interventions, which means less trips, which means less cost and higher reliability as well.”

The lack of hydraulic support within the umbilical is just an example of one benefit of the all-electric tieback.

Reducing the amount of direct lines that need to go to each well can take the umbilical down from 14 inches to 8 inches, significantly reducing cost. By reducing one of the subsystems the “umbrella becomes a lot smaller” and capital expenditure can be reduced by 15% or more.

Electric driven system is also more reliable, according to Davies, and allows customers to take a hands-off approach once the equipment is in place and keep operators out of harm’s way.

Next Steps

While the product’s current version is not installed anywhere, Davies assures that the technologies are “pretty mature.”

“They’re all independently qualified, so as a system, it’s not a TRL 7 (technology readiness level 7) system as we would traditionally think about it, but each of the elements has been installed for significant amounts of time,” he said.

Even though this tieback is extremely innovative, it’s not the last step. Baker Hughes envisions a “fully electrified offshore environment” with a cheaper and more environmentally-friendly umbilical-less tieback.

“You’ll see quite a few product introductions from us in the next couple of years that are very much around rethinking traditional mindsets and rethinking different problems associated with a very mature industry,” Davies said. “We bring a lot of that different sort of mindset and we’re going to do a lot more of it too, but it allows us to start to think about different problems like grid style electrification for the offshore environment.”

Recommended Reading

Deep Well Services, CNX Launch JV AutoSep Technologies

2024-04-25 - AutoSep Technologies, a joint venture between Deep Well Services and CNX Resources, will provide automated conventional flowback operations to the oil and gas industry.

EQT Sees Clear Path to $5B in Potential Divestments

2024-04-24 - EQT Corp. executives said that an April deal with Equinor has been a catalyst for talks with potential buyers as the company looks to shed debt for its Equitrans Midstream acquisition.

Matador Hoards Dry Powder for Potential M&A, Adds Delaware Acreage

2024-04-24 - Delaware-focused E&P Matador Resources is growing oil production, expanding midstream capacity, keeping debt low and hunting for M&A opportunities.

TotalEnergies, Vanguard Renewables Form RNG JV in US

2024-04-24 - Total Energies and Vanguard Renewable’s equally owned joint venture initially aims to advance 10 RNG projects into construction during the next 12 months.

Ithaca Energy to Buy Eni's UK Assets in $938MM North Sea Deal

2024-04-23 - Eni, one of Italy's biggest energy companies, will transfer its U.K. business in exchange for 38.5% of Ithaca's share capital, while the existing Ithaca Energy shareholders will own the remaining 61.5% of the combined group.