Presented by:

This article appears in the E&P newsletter. Subscribe to the E&P newsletter here.

Of the many challenges facing unconventional well production, sand production is one that is prone to draining drillers’ finances. As the sand motion goes through the tubing of the well, the sand wears it down, eliminating future use of the tubing, according to Josh Susmarski, business development manager of unconventional well completions with Schlumberger.

(Source: SPE)

“When you're producing sand in your well, you're sandblasting everything that's in its way,” he said. “So starting out from your ESP [electric submersible pump], it has to wear through in the sand motion that you're going to get. Then, as you get to surface, you have to worry about surface equipment—so chokes [and] the wellhead itself. They're all going to get eaten by the sand.”

Schlumberger’s Katherine Escobar, artificial lift domain champion, and Gocha Chochua, technical adviser for CFD modeling and simulation, joined Susmarski during SPE Live’s recent webinar “Sand Production from Unconventional Wells Using Artificial Lift Methods,” as they explained which technologies will help drillers in eliminating sand production.

“From top to bottom, it's got a lot of costs associated with it,” Susmarski said. “And it doesn't matter what type of lift method you're using. If you're [using an] ESP, the wear is apparent because you can see that it eats apart the internal workings of the ESP, the electric pump.”

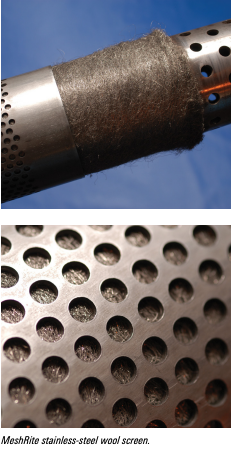

To help prevent the particles from disrupting production in unconventional wells, Chochua said 2D and, more recently, 3D sand screens help trap the sand in the pipes, making it easier to scoop out and dispose of it. Additionally, “centrifugal or vortex separators” can be used, which use “1,000 Gs of the acceleration to separate the sand from production fluid and keep it downfall,” he said.

In some cases, operators can combine both the filters and the vortex separator for more efficiency.

“The centrifugal separators [are] certainly efficient for larger particles and low-viscosity fluid,” Chochua said. “But when we come to the oil production, then efficiency of the separation by the vertical devices or centrifugal separations has to be a function of the operating conditions.”

Although 3D filters are the most recent, highest efficiency screens, according to Chochua, they have a few limitations. Escobar said wells moving a large volume of fluid also move a lot of sand, requiring a lot of moving parts for sand to get into and contaminate.

“Pretty much when you're talking about artificial assistance, you're talking about metal components and moving parts,” Escobar said. “You definitely want to keep your sand out of it, out of the rod and all those metal components.”

According to Escobar, the key to knowing which solution to use is first identifying what type or types of solids are being produced. Since different sized particles could require either a filter or vortex separator, or both, the first step is knowing what the technology will be used for.

“One thing we have been able to see with a couple customers is that when we combine MeshRite together with a chemical treatment, we actually get times fold results, for instance," she said. "You will likely need to identify, besides sand, what is coming from the fractures, if you're producing any type of scale. So if we combine the sand control method together with the chemical treatment of the well, that's something definitely you would want to look at.”

Susmarski added that operators should focus on how they want to control the sand and for how long.

If an operator is questioning if they need to control the sand, "Take a look at the whole business [and] look all the way down," Susmarski said. "Where is the disposal going? Are you able to reuse this equipment, but you're not reusing it because it's got holes in it? If you've got an ESP, if I can reuse that, I'd like to.”

Recommended Reading

Range Resources Holds Production Steady in 1Q 2024

2024-04-24 - NGLs are providing a boost for Range Resources as the company waits for natural gas demand to rebound.

EQT Sees Clear Path to $5B in Potential Divestments

2024-04-24 - EQT Corp. executives said that an April deal with Equinor has been a catalyst for talks with potential buyers.

Novo II Reloads, Aims for Delaware Deals After $1.5B Exit Last Year

2024-04-24 - After Novo I sold its Delaware Basin position for $1.5 billion last year, Novo Oil & Gas II is reloading with EnCap backing and aiming for more Delaware deals.

Matador Hoards Dry Powder for Potential M&A, Adds Delaware Acreage

2024-04-24 - Delaware-focused E&P Matador Resources is growing oil production, expanding midstream capacity, keeping debt low and hunting for M&A opportunities.

TotalEnergies, Vanguard Renewables Form RNG JV in US

2024-04-24 - Total Energies and Vanguard Renewable’s equally owned joint venture initially aims to advance 10 RNG projects into construction during the next 12 months.