A robotics company applied space flight communication fundamentals to the problem of how to control an untethered robot in real time during a subsea mission.

But that wasn’t the only issue the company saw with the traditional choices of AUV or ROV for subsea oil and gas inspection, maintenance and repair (IMR) work. Without a tether, a hydraulics-based manipulator was impossible, so an electric manipulator was necessary. And to ensure the robot could complete its mission, it needed plenty of power and the ability to communicate over long distances.

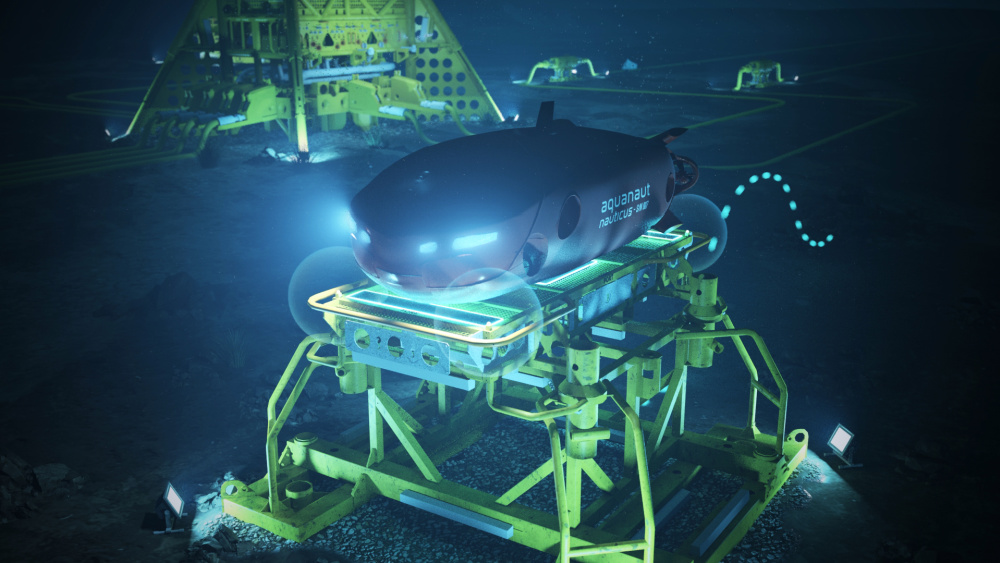

Nauticus Robotics Inc., newly listed on NASDAQ, designed something of a hybrid between the AUV and the ROV but started the initial design from the perspective of creating an underwater robot. In April, the company announced plans to create the Nauticus Fleet, composed of 20 Hydronaut-Aquanaut pairs. Over the course of 2022 and early 2023, three of the flagship Aquanauts will become available, with robots headed to Norway, Scotland and the Gulf of Mexico. Five more are set to be manufactured next year.

In early August, Nauticus announced a Hydronaut-Aquanaut pair was entering the qualification phase for Shell Plc.

The Hydronaut is an 18-m optionally crewed autonomous surface vessel (ASV) that ferries Aquanauts to and from the work site and supports battery recharges and the communications link from the local remote operations center for supervised autonomous operations.

The Aquanaut is a fully electric, free-swimming subsea robot, controlled through acoustic communication networking and can perform data collection and inspection. With Nauticus’ all-electric Olympic Arm work-class manipulators, it can carry out a host of underwater maintenance and repair tasks.

“We focus on activities where you need to interact with the water column, the seabed, do physical manipulation,” said Nicolaus Radford, Nauticus Robotics founder and CEO.

Todd Newell, Nauticus’ senior vice president for business development, said the Aquanaut isn’t an enabling technology.

“They can get the work done today, but with our offering, they’ll be able to get it done so much more efficiently,” he said.

The Aquanaut isn’t designed for heavy construction or campaigns that require an ROV tethered to a large boat for days on end. The Aquanaut is intended for the IMR market and can support light intervention work.

The tandem pairing of the Hydronaut and Aquanaut makes it possible to eliminate ROVs and the larger vessels needed to support ROVs at a work site. Newell said an estimated 80% of costs associated with ROV operations are for the boat, not the subsea vehicle. At the same time, the majority of the emissions are also associated with the vessel, he noted.

“The most value creation comes from eliminating the large surface vessel or eliminating the vessels altogether,” Newell said.

A fresh design approach

Creating an underwater robot that could carry out IMR activities without a tether required a major rethink in design.

“In this industry, they talk about subsea vehicles. We thought that was completely wrong. We thought they were robots,” said Radford, who led several robotics efforts at NASA. “We started with that foundation. We were developing an underwater robot.”

As such, he said, the design from the outset was based on an underwater robot, and the overall result was a bit of a hybrid between ROVs and AUVs.

There were several issues at play. The underwater robot needed an electrical manipulator because hydraulics would require a tether. Without the tether, power became a factor, as well. Perhaps even trickier was that communications between the controller and the subsea vehicle typically happens via fiber optics in the tether, so a different communications method was necessary.

First, Nauticus tackled the manipulation side of the problem, seeking to replicate the function of hydraulic manipulation underwater but electrically to remove the need for the tether.

An electric manipulator is “more delicate in operation and can control its forces better,” Radford said. “Hydraulic manipulators can damage things more easily. We’ve heard not great feedback on that.”

Nauticus’ Olympic arm, released earlier this year, has absolute position sensing, direct cartesian control and subsea tool changing. Additional features include environmental perception, autonomous behavior with checks and tetherless operation.

Without a tether, the subsea robot needed a battery pack.

Newell said the Aquanaut carries twice as much battery power as its competitors so they can remain on mission long enough to complete a task.

“Everyone’s robot is going to run out of power when not plugged in,” he noted.

But the Aquanaut’s battery pack will last 24-36 hours, depending on how demanding the work is, before needing to recharge, he said. That can be done through the Hydronaut or at a nearby platform, he said.

Communications inspired by space

Historically, subsea vehicles have been controlled by communications through a tether. Without that tether, other communications systems fell short, Newell said.

“If you cut the cable, you have only a couple of options available,” Radford said.

Cell phones can send a signal and stream video, but seawater absorbs the radio frequency, making it impossible to communicate the same way underwater as topside, he said.

Light travels fast, but is limited to a couple hundred meters because it diffuses as it travels through the water, he said. While sound travels far, it’s slow, he added. Most teleoperators can withstand about 750 milliseconds of latency between the control and the action, so whatever communication method was chosen had to meet a number of requirements, he said.

“There’s an entire framework of how to control robots in faraway locations with very little data,” Radford said. “It’s part of how we were developing control of robots in NASA.”

Working from the architecture inspired by NASA’s long-range control and communication systems for robots in space, Nauticus adapted the method for the subsea environment.

“We had to create machine intelligence that Nauticus could control over a latent network,” Radford said. “We had to make these robots really smart. We spent years developing the machine intelligence and self-directed control and self-sufficient behavior.”

As such, the Aquanauts respond to high-level commands, rather than needing to have the operators control the robot’s every action, he said. The operator might double click on a valve on the on-computer dashboard and the remote robot mobilizes to turn that valve, he said.

“We developed some complex autonomy so they do not have to be communicated with at the rate that tethered [robots] do,” he said.

Radford said Nauticus has demonstrated the Aquanaut has all the autonomy needed to make the concept a reality. After the success of several pre-production prototypes, Nauticus kicked off production of the fleet.

Newell said there is no current expectation that an operator is ready to have any robot operate fully autonomously from a risk management standpoint.

“We are getting them to come around on supervised autonomy,” or teleoperations with a human in control, he said. “Technology is going down that path.”

Recommended Reading

NGL Growth Leads Enterprise Product Partners to Strong Fourth Quarter

2024-02-02 - Enterprise Product Partners executives are still waiting to receive final federal approval to go ahead with the company’s Sea Port Terminal Project.

After Megamerger, Canadian Pacific Kansas City Rail Ends 2023 on High

2024-02-02 - After the historic merger of two railways in April, revenues reached CA$3.8B for fourth-quarter 2023.

Enbridge Advances Expansion of Permian’s Gray Oak Pipeline

2024-02-13 - In its fourth-quarter earnings call, Enbridge also said the Mainline pipeline system tolling agreement is awaiting regulatory approval from a Canadian regulatory agency.

Canadian Natural Resources Boosting Production in Oil Sands

2024-03-04 - Canadian Natural Resources will increase its quarterly dividend following record production volumes in the quarter.

Shell’s CEO Sawan Says Confidence in US LNG is Slipping

2024-02-05 - Issues related to Venture Global LNG’s contract commitments and U.S. President Joe Biden’s recent decision to pause approvals of new U.S. liquefaction plants have raised questions about the reliability of the American LNG sector, according to Shell CEO Wael Sawan.