Hart Energy’s E&P Meritorious Awards for Engineering Innovation program highlights new products and technologies that demonstrate innovation in concept, design and application. (Source: Shutterstock)

This year’s Meritorious Awards for Engineering Innovation (MEAs) recognize 17 technologies for engineering excellence in the upstream petroleum industry. Hart Energy’s MEA program highlights new products and technologies that demonstrate innovation in concept, design and application.

The expert panel of judges included engineers and scientists from operating and consulting companies worldwide. Judges were excluded from categories in which they or their companies have a business interest.

Artificial Lift: InfinityPL; Ambyint + AWS with CNX Resources

Category: Artificial Lift

Product: InfinityPL

Company: Ambyint + AWS with CNX Resources

Website: www.ambyint.com

Direct URL for more info: Ambyint InfinityPL

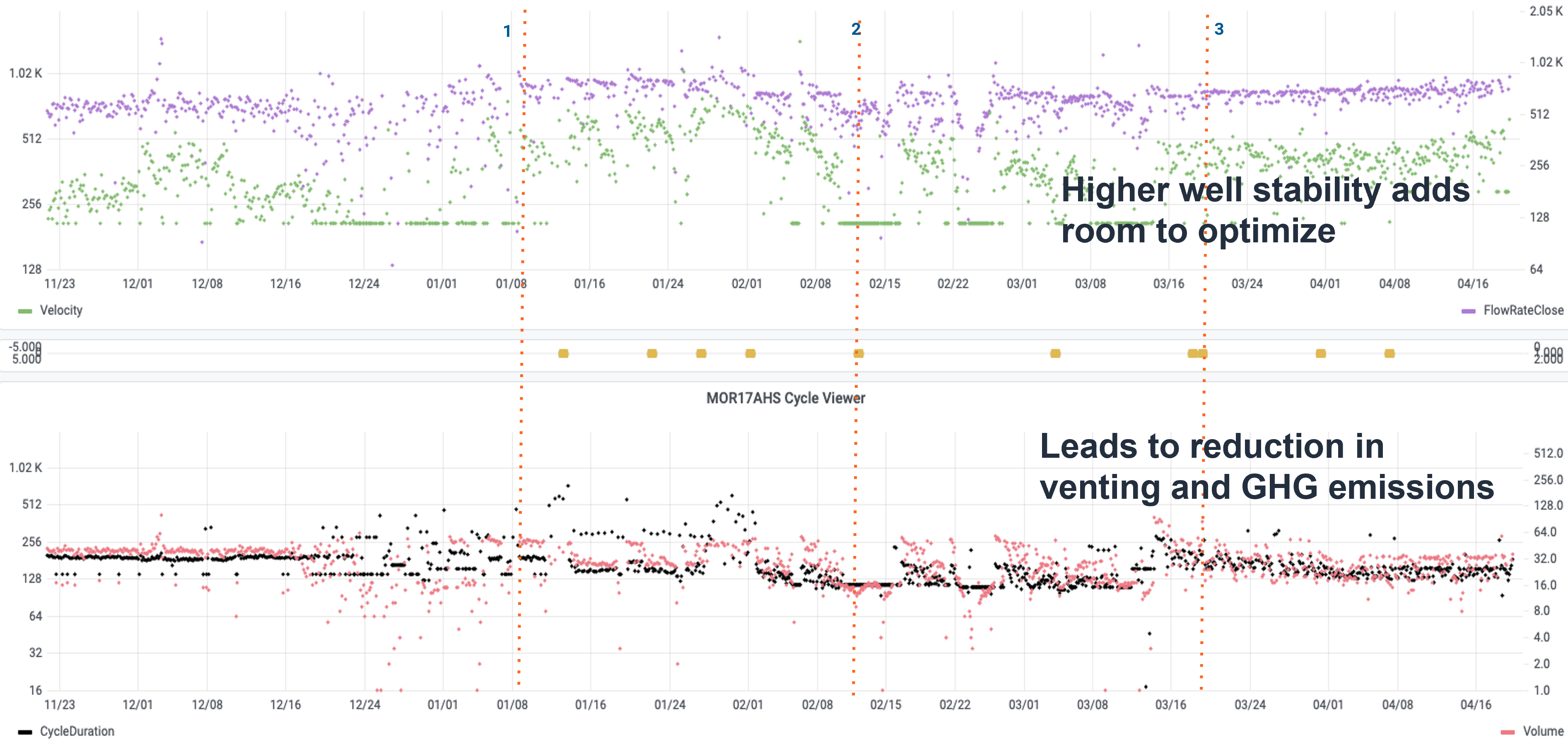

Ambyint’s InfinityPL, which runs on Amazon Web Services (AWS), helps increase production in wells. The data-driven, cloud-based solution combines advanced physics and subject matter expertise with artificial intelligence (AI) to automate operations and production optimization workflows.

The platform helps operators find setpoints likely to increase productivity and avoid unnecessary downtime across all types of artificial lift, including electric submersible pumps (ESP), plunger lift, rod lift and gas lift. While plunger lift systems are mechanically simple, they produce vast amounts of data that can be leveraged to optimize performance. Data analysis required to uncover insights can be time-consuming and manual.

CNX Resources sought to optimize production and reduce the number of liquid loading events across its horizontal Marcellus Shale plunger lift wells. The CNX operations team vented wells regularly to remediate liquid loading, which led to increased emissions and reduced productivity and efficiency. To overcome these challenges, CNX worked with Ambyint and AWS to deploy a solution that optimized well productivity through improved analytics and autonomous management.

Ambyint deployed InfinityPL to CNX’s plunger lift wells, leveraging the AWS cloud environment for data integrations with CNX’s existing SCADA and production accounting systems. Through automation and proactive management, CNX was able to improve well stability, which led to opportunities for performance optimization, and a reduction in venting events and greenhouse-gas emissions by 48%.

Predictive maintenance and autonomous management of control system settings also resulted in a 4% increase in gas production. Based on the success of the 26 pilot wells, CNX expanded the work to an additional 120 wells.

Carbon Management: Canrig nanO2 Fuel Enhancer; Nabors Industries

Category: Carbon Management

Product: nanO2 Fuel Enhancer

Company: Canrig

Website: www.canrig.com

Direct URL for product info: nanO2 fuel enhancer

The Canrig nanO2 fuel enhancer from Nabors Industries, when added to diesel, adds a combustion catalyst component that helps improve combustion while reducing emissions. Typical fuel enhancers and additives increase the cetane index and provide cleaning effects. Using a skid, nanO2 connects to the fuel tank using a precision dosing unit that measures and mixes the appropriate ratio of nanO2 during diesel refueling. The treated fuel is fed through the monitoring manifold, which records fuel consumption data, and then into the generators from the existing fuel system.

The nanO2 fuel enhancer has been deployed on onshore and offshore rigs and in completions operations using varying grades of diesel fuel. It has resulted in up to an 8% increase in fuel efficiency over the baseline. Canrig said its customers save more than $600 per day with the 8% increase in fuel efficiency, based on an average land rig using 2,200 gallons per day (gal/d) at $3.50 per gallon.

The nanO2 fuel enhancer was deployed on a drilling rig in East Texas. Canrig used kilowatt-hours per gallon (kWh/gal) as the standard to evaluate the rig’s efficiency, fuel usage and electrical power. Fuel usage was recorded daily using tank level readings and cross-checked against indicated fuel delivery. Engine power data and the number of online generators were captured by rig controls, and the data was analyzed.

Testing resulted in a 5% increase in fuel efficiency over the baseline, saving 5,425 gal of diesel over the 73 days that the rig used nanO2. The fuel savings equate to an estimated reduction of 55.6 metric tons of CO2 equivalent.

Digital Oil Field: Neuro Autonomous Solutions; SLB

Category: Digital Oil Field

Product: Neuro Autonomous Solutions

Company: SLB

Website: www.slb.com

Direct URL for more info: Neuro autonomous solutions

SLB’s Neuro Autonomous Solutions system creates a continuous feedback loop between the surface and downhole to increase the efficiency and consistency of E&P operations while reducing human intervention.

During well construction, Neuro Solutions employs advanced cloud-based software coupled with intelligent systems to deliver steering autonomy for directional drilling. Steering sequences are self-determined using AI with surface and downhole automation workflows to deliver the well trajectory on plan. As the well is drilled, a real-time continuous feedback loop between an intelligent downhole system and a surface advisory system automates downlinks, reducing control loop time. The instantaneous correlation between downhole and surface actions in accordance with the well plan reduce risk, refine precision and increase efficiency while reducing associated drilling emissions.

During well intervention, Neuro Solutions at the edge ensures safer, more efficient and dependable operational execution and connectivity, eliminating internet reliance for significantly higher execution performance at the wellsite. Furthermore, actionable insight from acquired log data is available within hours at the wellsite, shrinking the decision timeline.

An operator in the Middle East used Neuro solutions to autonomously drill a well from 22-degree to 90-degree inclination with a 2,500-ft curve section and a 5,400-ft lateral section. For both sections, the operator used autonomous-capable rotary steerable systems that contributed to the balance between surface and downhole autonomy, enabling a 36% reduction in downlinks compared with offset wells drilled in manual mode, while achieving a 13% increase in rate of penetration.

Drill Bits: Aegis 3D-printed Armor; SLB

Category: Drill Bits

Product: Aegis 3D-printed Armor

Company: SLB

Website: www.slb.com

Direct url for product info: Aegis 3D-printed Armor

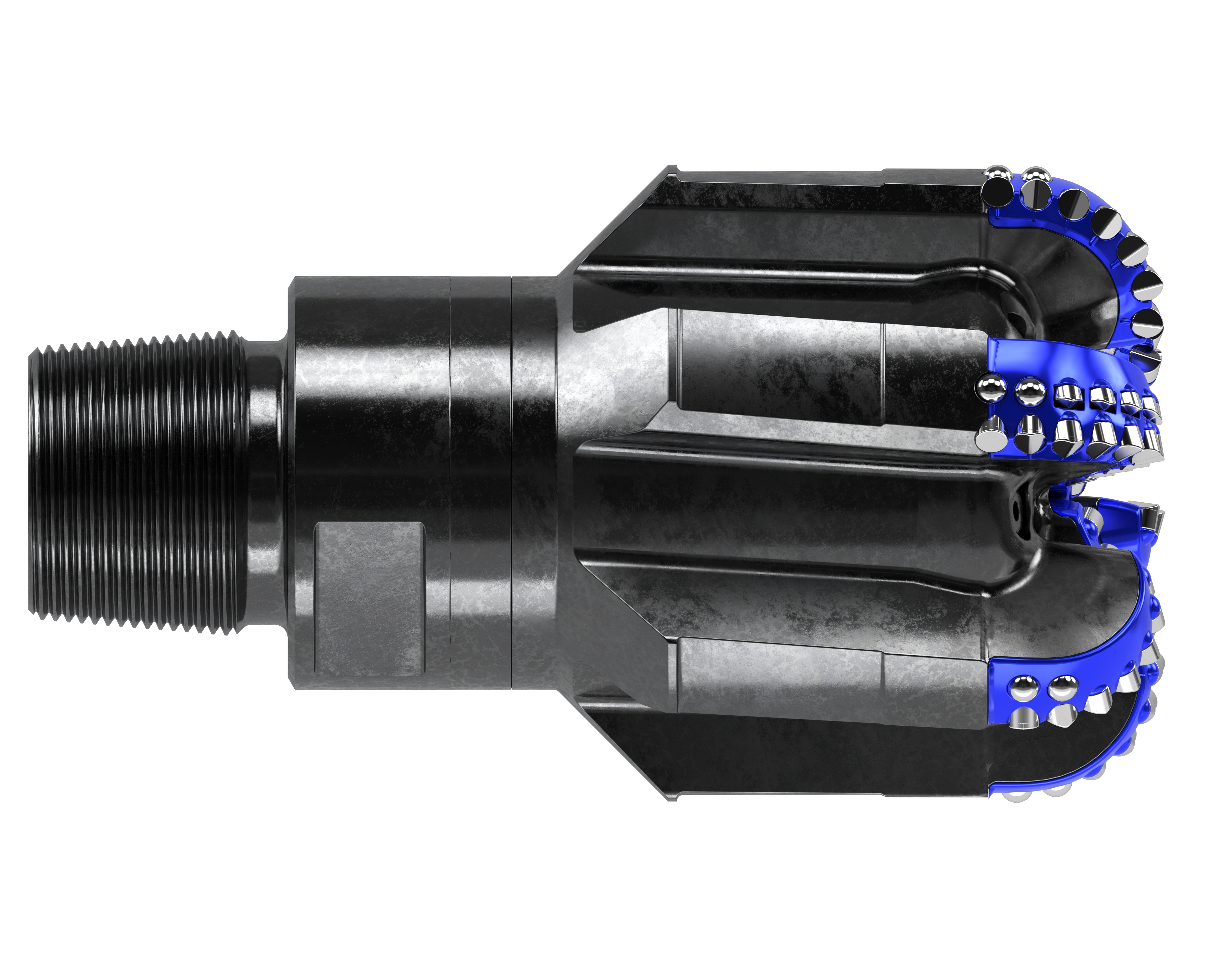

SLB’s Aegis 3D-printed armor is 400% more erosion resistant than traditional hard-facing metalwork and 40% stronger than matrix bit material. The armor comprises individual strips applied to the blade face of steel-bodied bits, replacing traditional hard facing and providing a shield against erosion from drilling fluid jetted from the bit’s nozzles. Aegis 3D-printed armor increases erosion resistance in the areas surrounding the cutter pockets, prolonging bit life and decreasing production cost and average cost per run.

The improved blade face and cutting element protection delivers more strength for aggressive bit designs to improve overall bit performance as well as better erosion resistance. This enables angling the bit nozzles toward the blades and cutting elements for more efficient cuttings evacuation enforced by drilling fluid flow, resulting in faster ROP, more footage, and increased bit durability.

An Alaska North Slope operator planned a well with a large-hole curve and extended lateral intermediate section. The interval traversed formations of soft, sticky shale mixed with silt and sandstone with a high tendency for bit balling, and the planned well profile required a 31-degree to 82-degree inclination for the curve. SLB recommended adding Aegis 3D-printed armor to the blades. The bottomhole assembly (BHA) included a Rhino XS2 reamer, the PowerDrive Xceed RSS, and a fusion-bodied bit with Aegis armor. The combination drilled an interval of 3,712-ft measured depth (MD) at an ROP of 81.2 feet per hour (ft/h) with an inclination that ranged from 24.3 degrees to 81.5 degrees and a maximum dogleg severity of 3 degrees per 100 ft in one run without bit balling.

Drilling Fluids/Stimulation: AquaShear Drilling Fluids Mixer; Johnson Specialty Tools

Category: Drilling Fluids / Stimulation

Product: AquaShear Drilling Fluids Mixer

Company: Johnson Specialty Tools

Website: https://johnsonst.net/

Direct URL for product info: AquaShear Drilling Fluids Mixer

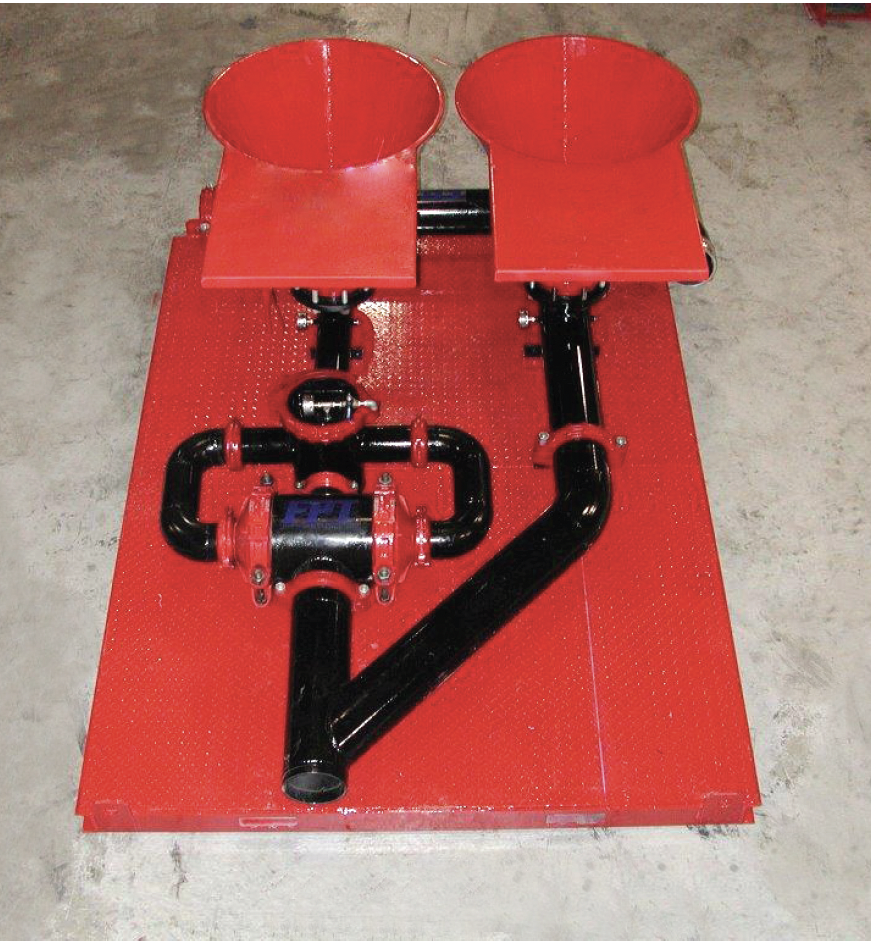

AquaShear drilling fluid mixing technologies from Johnson Specialty Tools have been applied in the Permian Basin to reduce the volume of additive products by up to 20% per well and to cut the rig time associated with mixing and equipment maintenance by 50%.

AquaShear mixers achieve near-instantaneous hydration, dispersion, mixing, blending, and shearing, which reduces additive product volumes and stabilizes drilling fluid properties. They also eliminate the sludge at the bottom of tanks, which lowers cleanout times and cost. Rig crews and mud engineers have reported that high volumes of lost circulation materials can be mixed without particle clogging, and there is no need to continuously adjust fluid properties to maintain viscosity levels for effective hole cleaning and high ROP. The units optimize powdered mud additive yield and oil mud and packer fluid emulsions, with no loss of undissolved materials across the shakers.

Customers using AquaShear reported the unit reduced their mixing time for a 300-bbl batch from two hours to half an hour and that drilling mud costs dropped by an average of 27% as a result of improved dispersion and hydration of all drilling fluid components.

One customer used the AquaShear unit to quickly add 800, 50-lb sacks of barite to a kill fluid that was needed on a well taking a high-pressure kick. The time saved was significant and there was no hopper plugging. In another field trial, a customer reported substantially reduced mixing times and no fisheyes.

Drilling Systems: GeoSphere 360; SLB

Category: Drilling Systems

Product: GeoSphere 360

Company: SLB

Website: www.slb.com

Direct URL for more info: GeoSphere 360

SLB’s GeoSphere 360 3D reservoir mapping-while-drilling service maps fluid volumes, bodies and faults at reservoir scale.

The GeoSphere 360 service maps the reservoir boundaries and features, which allows for enhanced completion designs and production using fewer, better wells. The service extrapolates shapes that are impossible to see at the wellbore scale for better reservoir understanding in heterogenous or complex reservoirs — and not just 3D structural delineation but also 4D fluid-movement evaluation.

GeoSphere 360 service acquires 360-degree tensor data and sends it uphole in real-time via mud pulse telemetry and wired drillpipe. Real-time cloud computing inverts the large datasets with a 2D azimuthal pixel-based algorithm. GeoSphere 360 service produces 3D-resistivity volumes that are filtered to understand the geometrical relationship of the resistive geobodies around the wellbore, calibrating the seismic data and feeding into reservoir modeling workflows.

Equinor used the GeoSphere 360 3D reservoir mapping-while-drilling service to provide a complete 3D structural understanding from the landing zone to inside the main section of the horizontal interval in a North Sea Paleocene field. By improving azimuthal geosteering decisions, Equinor extended the well inside the reservoir section and delivered nearly 100-m MD of extra net pay interval. Due to the complex nature of the reservoir, the capability to map structural and stratigraphic changes both vertically and laterally was crucial for the success of the well. Applying GeoSphere 360 enabled steering away from the planned trajectory toward the sweet spot, which was located sideways from the planned trajectory.

Exploration/Geoscience: BlendSeis: Advanced Seismic Data Aquisition; Saudi Aramco

Category: Exploration / Geoscience

Product: BlendSeis: Advanced Seismic Data Acquisition and Processing

Company: Saudi Aramco

Website: https://www.aramco.com/

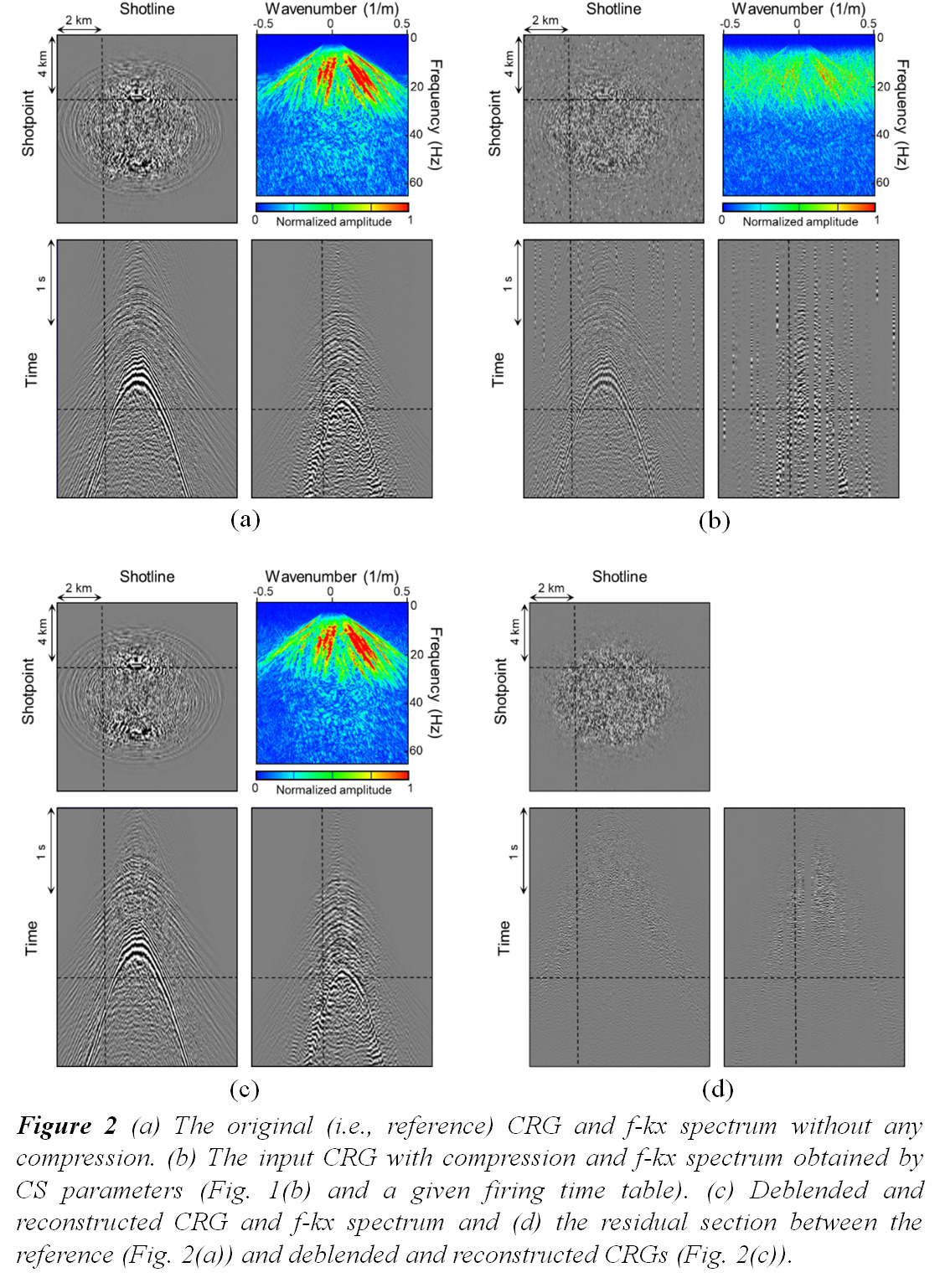

Saudi Aramco’s BlendSeis integrated seismic acquisition and processing technology yields high-resolution subsurface images for accurate geologic interpretation and reservoir characterization. BlendSeis employs compressive sensing of seismic data in time by combining simultaneous sources and continuous recording and in space by non-uniform undersampling of source and/or receiver locations or concurrently in both domains.

Aramco used a source blending approach to develop a joint deblending and wavefield reconstruction via sparsity-promoting inversion algorithm. During an onshore field survey acquisition, Aramco reported achieving three times higher productivity obtaining superior 3D subsurface images than a conventional seismic crew.

Aramco demonstrated the concept of compressive sensing in time and space on a seismic survey covering 100 sq km acquired with eight simultaneous sources and 50% of the originally designed sources points. The optimal non-uniform sampling of the original source points was determined by minimizing the mutual coherence. During repeated random realization, a jittered undersampling scheme that supplements random undersampling to avoid nonexistent local information raised by unnecessarily large intervals is applied with the whole survey area divided into a number of small 2D windows for local optimization of the sampling operator.

The data can be examined in a common receiver gather domain, with blended shooting of sparsely deployed sources at optimally sparsified locations. To obtain the results, an underdetermined system of equations is solved by a joint deblending and reconstruction algorithm using an l2-norm objective function with additional constraints. These results demonstrate that the proposed algorithm effectively handles noisy and partially sampled seismic data.

Floating Systems and Rigs: MPD-Ready Jack-Up Riser; Oil States Industries

Category: Floating Systems and Rigs

Product: MPD-Ready Jack-Up Riser

Company: Oil States Industries

Website: oilstates.com

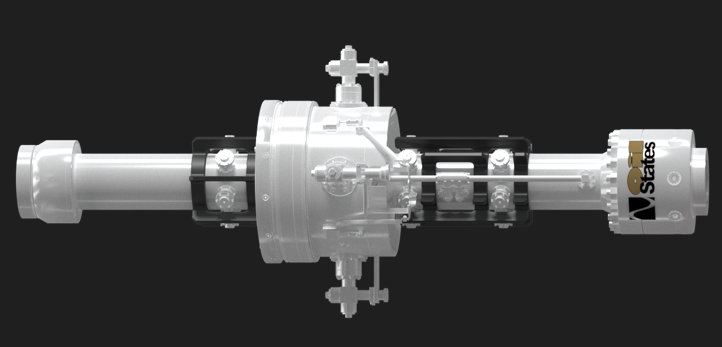

Oil States’ MPD-Ready Jack-Up Riser System has built-in automation capabilities along with a package of controls, umbilical and topside equipment.

With downhole pressure control drilling in managed pressure drilling (MPD) mode, mud is less likely to be lost into the formation and formation fluid is less likely to enter the riser. The MPD system features an 18 3/4-inch thru-bore MPD joint and dedicated, quick-closing annular packers for unplanned bearing change-out, eliminating the need to rely on the BOP annular.

The MPD joint runs through the rotary table from the drill floor to the BOP stack, during which it locks into the hands-free flowline connector. Avoiding reliance on the BOP annular allows the MPD-Ready Jack Up Riser to reduce costs, safety risks and nonproductive time.

The MPD-Ready Jack-Up Riser is rated for temperatures ranging from -29 C to 121 C. The system can withstand up to 3,000 pounds per square inch (psi) for the MPD section above the BOP and up to 15,000 psi for the BOP and components below.

Formation Evaluation: StrataStar Deep Azimuthal Resistivity Service; Halliburton

Category: Formation Evaluation

Product: StrataStar® Deep Azimuthal Resistivity Service

Company: Halliburton

Website: https://www.halliburton.com/

Direct URL for product info: StrataStar® Deep Azimuthal Resistivity Service

The StrataStar deep azimuthal resistivity service from Halliburton provides high fidelity maps of the reservoir in real-time.

With a spacing of 12 ft, the StrataStar service combines the largest electromagnetic signal deployed on a single collar with a sophisticated processing algorithm to reveal, while drilling, the positions, thicknesses and resistivities of interbedded rock and fluid layers up to 30 ft away from the wellbore. With more than 5,000 electromagnetic measurements acquired from a 24-ft long collar every 12 seconds, it provides a detailed image of the surrounding formations and fluids as well as accurate petrophysical evaluation of the reserves in place, including electrical anisotropy.

Real-time visualization of the surrounding geology and fluids allows operators to accurately lock onto geological bodies from far away and precisely steer the well while maintaining the desired distance from unproductive water flooded or shale zones. The StrataStar service also provides shallower multi-frequency measurements to enable petrophysical analysis across a range of fluids and rocks.

Halliburton deployed the StrataStar service alongside an existing azimuthal resistivity tool in a 6 3/4-inch BHA to steer a 10,000-ft horizontal section of an Alaska North Slope well with a goal to verify comparable, if not better, downhole data. The StrataStar service trial demonstrated perfect alignment of inversion data with the established independent tool. It also provided additional high-value details, such as multiple resistivity boundaries and a clear, easy-to-understand representation of the geology. The new mapping capability revealed variations in sand thickness and lateral variability in the formations consistent with the depositional environment.

HSE: Digital Gas Monitoring Ecosystem; Shepherd Safety Systems

Category: HSE

Product: Digital Gas Monitoring Ecosystem

Company: Shepherd Safety Systems

Website: https://shepherdsafetysystems.com/

Direct URL to product info: Digital Gas Monitoring Ecosystem

The Digital Gas Monitoring Ecosystem from Shepherd Safety Systems is a digital toxic gas detection solution that integrates multigas sensors, wearable personal monitors, and a field communications and command platform that allows onsite and offsite personnel to monitor crew safety and emissions from any location. The equipment can detect CH4, H2S, LEL, CO, SO2 and O2. On request, sensor packages for ClO2, HCl, HCN, NO, NO2, O3, and PH may be integrated into the Shepherd Digital Gas Monitoring Ecosystem system.

One E&P company deployed the Shepherd Digital Gas Monitoring Ecosystem as a way to manage multiple tasks. The company wanted to monitor, manage and reduce methane emissions; increase the depth of monitoring levels; and protect the health and safety of team members. The monitoring system pinpointed methane releases in a production location. Gas leaks were discovered and reported in ppm in real-time, enabling the E&P’s team to quickly verify and repair emissions of ~100,000 standard cubic feet per day.

For a drilling location, $150,000 in nonproductive time was eliminated by reducing the number of false alarms when traditional H2S sensors showed high readings when pressure washed by the rig crew. Because Shepherd sensors are named by location, the incidents of false alarms and stop work orders dropped from the previous year’s levels.

Hydraulic Fracturing/Pressure: ClearVision; EV

Category: Hydraulic Fracturing / Pressure Pumping

Product: ClearVision™

Company: EV

Website: www.evcam.com

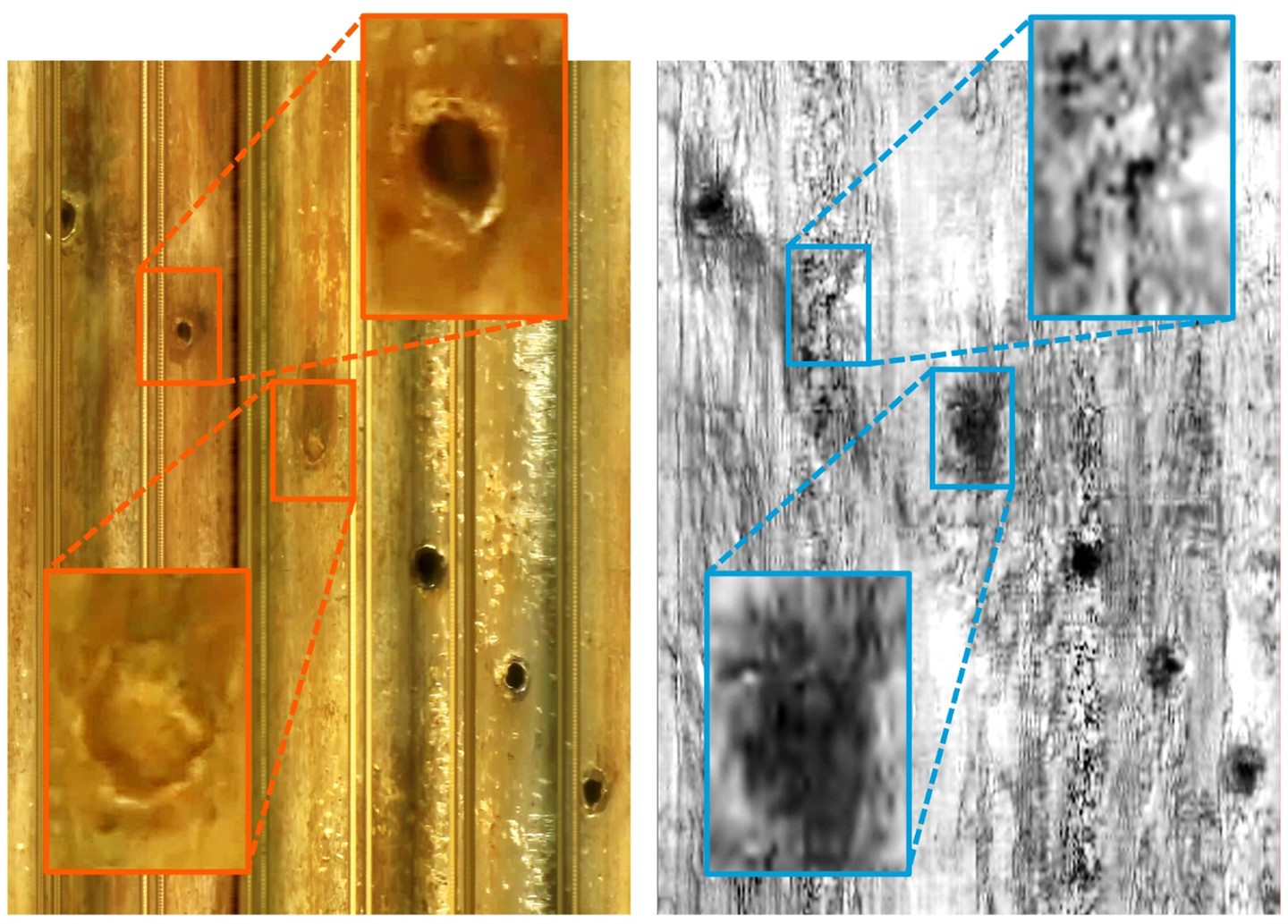

EV’s ClearVision integrated array video and phased array ultrasound scanning tool combines 360-degree video and phased array ultrasound technologies for 4D evaluation of wellbores. ClearVision enables operators to see and measure 100% of perforations—including small dimension perforations and those plugged with sand. The tool delivers unambiguous information regarding perforation erosion and proppant placement trends, empowering engineers to improve frac designs for better well performance and increased hydrocarbon production.

For a well in the Permian Basin, the tool string was deployed on coil tubing and data was acquired for the 3,000 ft and 16 stages of the lateral section closest to the heel. The well included some untreated base holes, providing in-situ dimensions used as a reference to calculate the eroded area of the treated perforations. The previous technology used by the operator resulted in 56% of the 16 stages missing perforations from two or more clusters, which invalidated the data for analysis purposes. In contrast, when the operator used ClearVision, 100% of the perforations were measured, delivering valid data for all stages to ensure accurate analysis.

ClearVision enabled the operator to identify the best-performing stage design and apply it to all the stages of the next well, which improved reservoir stimulation and delivered an additional $1.4 million of production revenue for a single well in its first year of production. This economic gain was further enhanced by the resulting increase in stage length and subsequent reduction in operating time, which yielded $350,000 in savings.

IOR/EOR/Remediation: Welltec Puncher 218; Welltec

Category: IOR/EOR/Remediation

Product: Welltec Puncher 218

Company: Welltec

Website: https://welltec.com

Direct URL for more information: Welltec Puncher 218

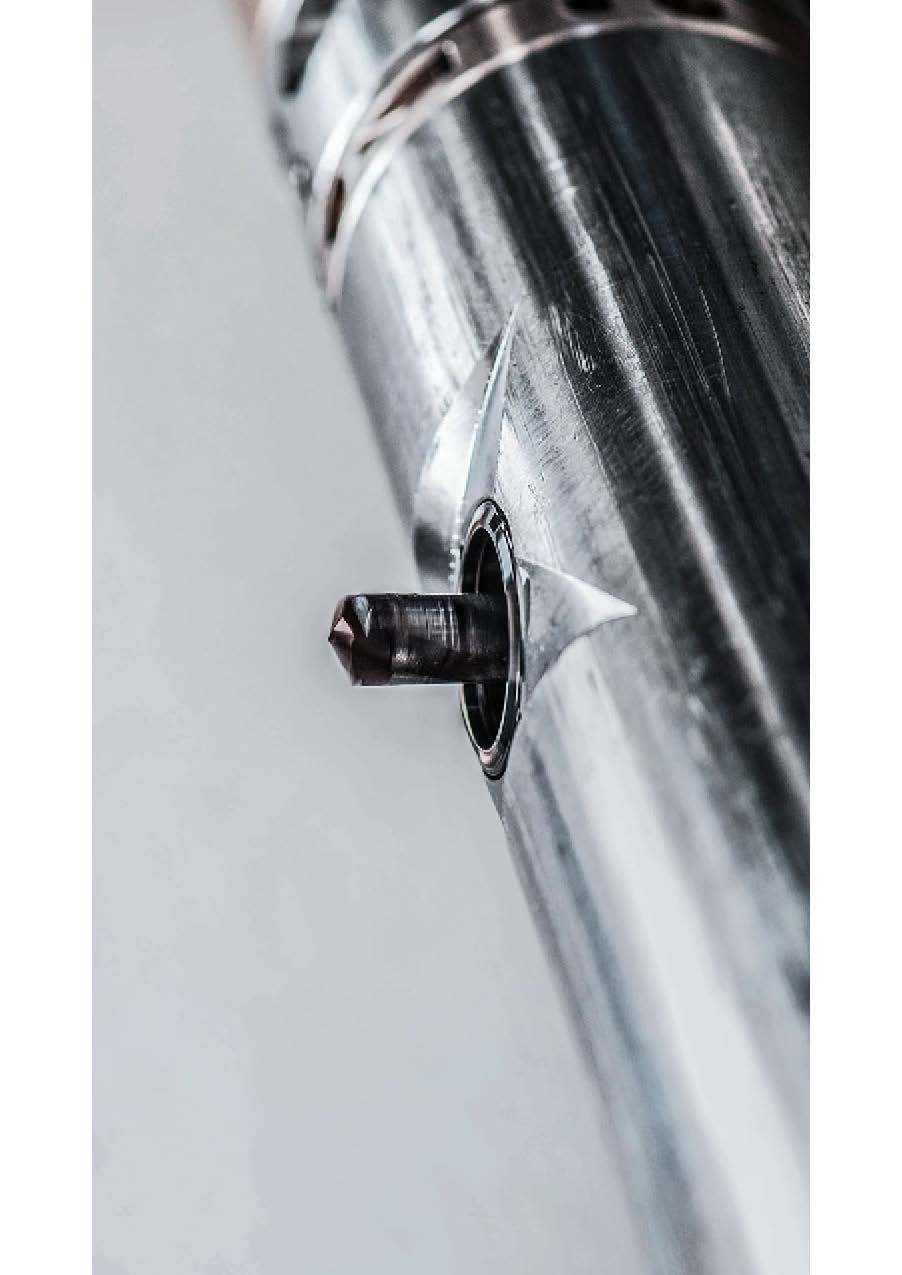

The Welltec Puncher 218 provides an e-line conveyed, non-explosive method for equalizing pressures between tubular strings. It is available with an outer diameter of 2.125 inches. The slim non-explosive puncher is capable of creating multiple perforations on a single run. Using a fast, drilling technique, the Welltec Puncher produces a precise, uniform hole. The puncher can be run slick to any depth in the well or equipped with a “no-go” for a hole punch at an exact depth. Multiple holes can be drilled in a single run, and it can be deployed independently or with other tools. It can combine with the Well Tractor for punching in highly deviated or horizontal wells.

During plug and abandonment preparation offshore Denmark, TotalEnergies wanted to circulate trapped gas from a well by creating multiple perforations in the 4 ½-inch tubing. The chosen solution had to be capable of creating a predetermined number of uniform holes in the 28Cr alloy tubing chosen for the completion due to its resistive qualities in a sour well environment with a high concentration of hydrogen sulfide (H2S).

Welltec deployed a mechanical tool suite including the ultra-slim Welltec Puncher 218 using a fast, surface-controlled drilling technique to produce precise and uniform holes with depth control to avoid damaging the casing behind. The plan was to create five, 12-mm uniform perforations below the production packer.

The Welltec Puncher 218 was run in hole and created all five perforations within a 3 ft interval on a single run without damaging the casing behind.

Machine Learning and AI: LOGIX Autonomous Drilling Platform’s Auto Steer Module; Halliburton

Category: Machine Learning and AI

Product: LOGIX Autonomous Drilling Platform’s Auto Steer Module

Company: Halliburton

Website: https://www.halliburton.com/

Direct URL to product info: LOGIX Autonomous Drilling Platform’s Auto Steer Module

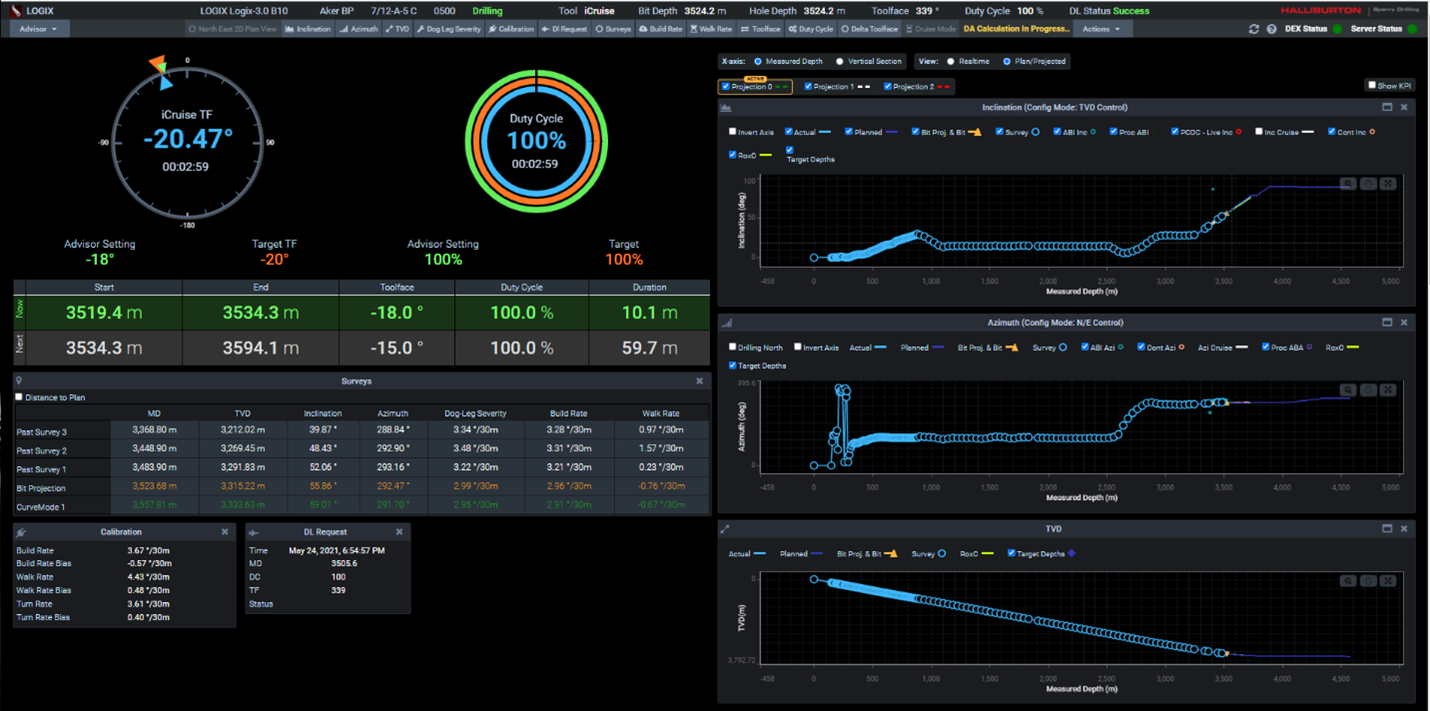

The LOGIX autonomous drilling platform from Halliburton combines physics-based 3D modeling, machine learning (ML) techniques, and digital twin technologies. The LOGIX platform is composed of several modules, including the Auto Steer autonomous directional drilling module.

The module uses ML to generate real-time adjustments to steer the well according to the well plan while also automatically incorporating reservoir target changes based on real-time formation evaluation and reservoir mapping geosteering data. To date, more than 6 million ft were drilled autonomously on the LOGIX platform in more than 2,500 runs, reducing well delivery times by up to 25% and personnel on board requirements by up to 60%.

LOGIX Auto Steer’s first autonomous job to land a well with geosteering integration was performed in Ecuador. The well profile was a complex 3D well with a build interval, followed by a tangent and then a build-and-turn interval to get to the reservoir section. The well had to maintain a dogleg severity of less than 1 degree per 100 ft in the 300-ft tangent section where the ESP would be placed and achieve the landing target based on real-time geosteering interpretation to maximize reservoir exposure. Using LOGIX Auto Steer, the team drilled the curve and tangent, maintaining 0.85-degree dogleg severity or less.

The original well plan was followed until the geosteering team confirmed a change in the geology, resulting in a new landing target. LOGIX Auto Steer steered to the new well path autonomously and successfully landed the well. A total of 87.4% of the lenght was autonomously drilled using LOGIX Auto Steer.

Non-Fracturing Completions: Fuzion-EH electro-hydraulic downhole wet-mate connector; Halliburton

Category: Non-Fracturing Completions

Product: Fuzion-EH electro-hydraulic downhole wet-mate connector

Company: Halliburton

Website: www.halliburton.com

Direct URL to product info: Fuzion-EH electro-hydraulic downhole wet-mate connector

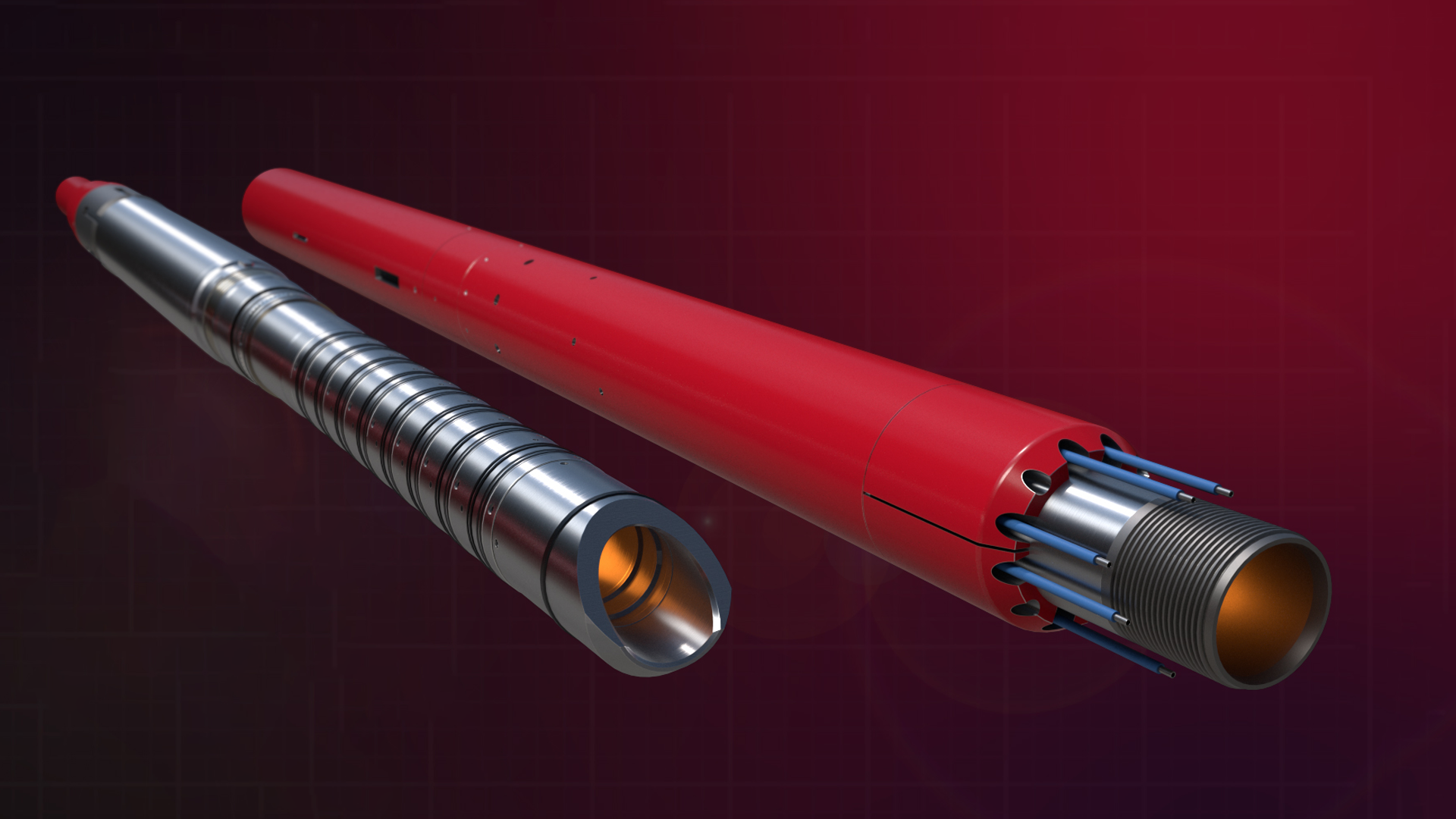

Halliburton’s Fuzion-EH electro-hydraulic downhole wet-mate connector makes it possible to disconnect and reconnect the upper completion and retain complete control over interval control valves and communication with electrical gauges below the production packer. The Fuzion-EH wet-mate connector reduces the complexity of removing failed upper completion equipment, such as electric submersible pumps, subsurface safety valves, and gas lift mandrels.

Fully compatible with the SmartWell intelligent completion systems, Fuzion also enables efficient lower completion deployment on drill pipe without the need for flatpacks when running SmartWell completions in extended reach wells or in wells with high fluid losses.

The Fuzion-EH downhole wet-mate connector is run with the completion above the production packer and is equipped with seven independent hydraulic control lines and one electric line. Once the packers are set, the upper portion of the tool (male) can be removed from the lower portion (female) multiple times with full isolation of the tubing to the annulus and each individual control line.

The Fuzion-EH wet-mate tool was successfully installed in two deepwater wells offshore Brazil in 2022. Using the tool’s single-trip configuration, it was possible to replace a failed subsurface safety valve (SSSV) later without the need to cut and release the three zonal production packers or lose the ability to control and monitor the SmartWell completion. Without this tool, the operator would have to curtail production if a SSSV failed and would have to plan a multi-trip deepwater workover operation.

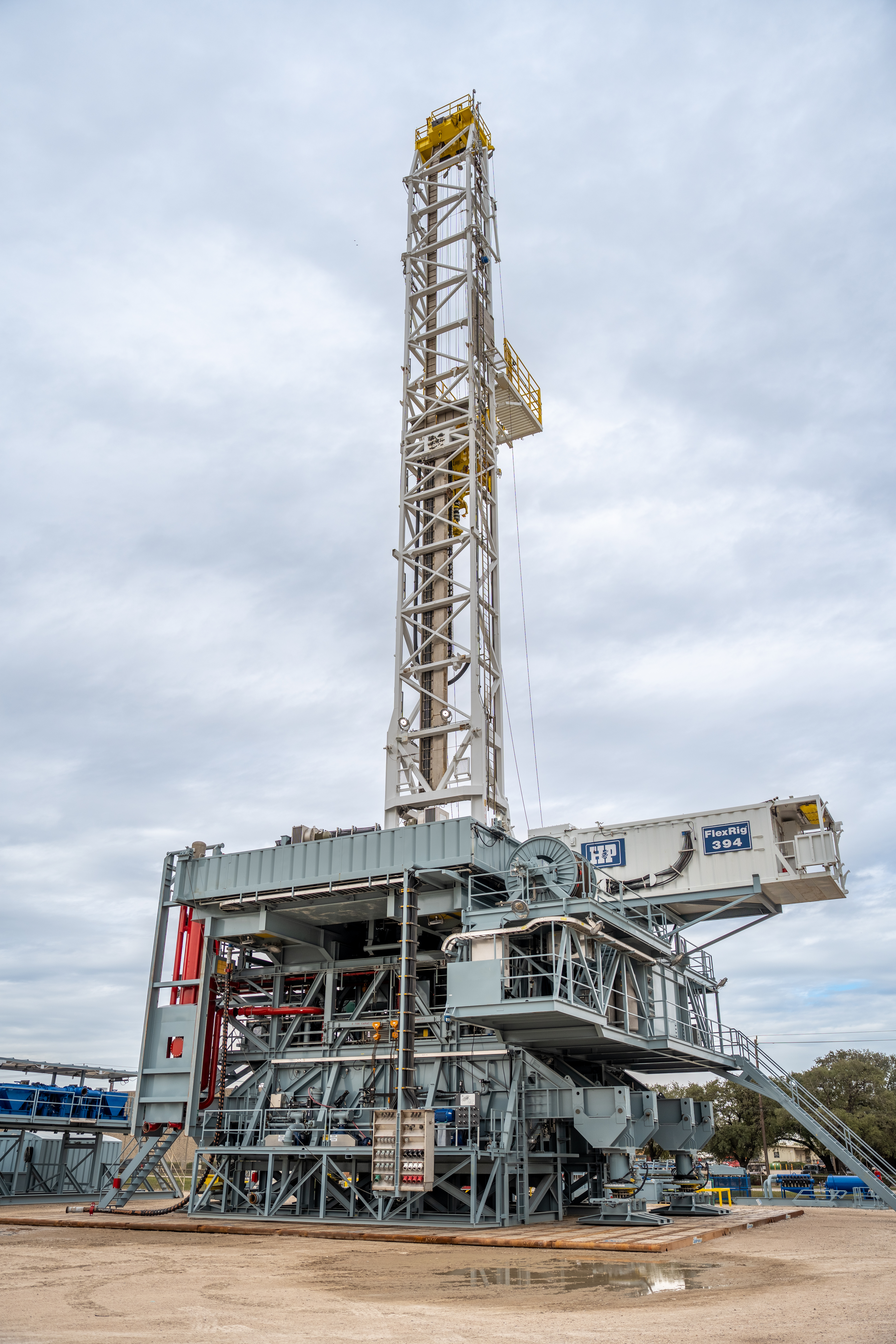

Onshore Rigs: FlexRig Flex3 Walking Rig Million Pound Mast; Helmerich & Payne

Category: Onshore Rigs

Product: FlexRig Flex3 Walking Rig Million Pound Mast

Company: Helmerich & Payne

Website: http://www.helmerichpayne.com

Helmerich & Payne’s (H&P) FlexRig Flex3 Walking Rig Million Pound Mast is customized for mobility and agility in Middle East terrain for unconventional pad drilling.

Unlike most conventional rigs, the Flex3 walking rig is a side-saddle configuration to reduce flat time during common rig activities: drilling, pad-to-pad rig moves and well-to-well rig walks. A hookload of 1 MMlb, a 720,000-lb setback capacity, and the capacity to set almost 24,000 ft of 5 ½-in. Drill pipe in the racking board equips the rig for complex lateral wells. It can walk 500 ft in a straight line or multiple rows within a 200 ft by 50 ft box. With the H&P BoomBox, the rig can remain energized during the walks because there is no need to break electrical connections.

The introduction of the new rig design has contributed to reducing cycle times by more than 35% from 2016 to 2022. What was once a three-to-five-hour release to spud skid, is now as low as an hour and a half through the use of walking technology. The accumulator skid relocation away from inside the rig substructure ensured compliance with standards without giving up mobility and modularity. Expanded substructure and BOP handling capabilities enabled handling larger Middle East BOP equipment and complied with well control standards.

Subsea Systems: REACH Wireline-retrievable Safety Valve; Baker Hughes

Category: Subsea Systems

Product: REACH wireline-retrievable safety valve

Company: Baker Hughes

Website: https://www.bakerhughes.com/

Baker Hughes’ REACH wireline-retrievable safety valve (WRSV) makes it possible to bring ultra-deepwater wells with failed tubing-retrievable safety valves (TRSV) back online faster, safer, and more economically than through a deepwater workover. The surface-controlled REACH WRSV is capable of operating at the low pressures required in subsea wells.

It has the ability to operate within the limitations of the existing hydraulic system, which eliminates the need to pull the upper completion to replace the failed TRSV. As such, control lines or smart completion accessories remain intact and operable when the intervention is complete.

The REACH WRSV requires a riserless lightwell intervention (RLWI) vessel to perform the job, which avoids the high cost of a workover and can expedite schedules as RLWI can typically be deployed more quickly.

Building on the design principles of the existing REACH TRSV, the REACH WRSV is rated to 12,500 psi at 300 F and exceeds API 14A requirements. The company estimates using the REACH WRSV can save operators $50 million per well compared to a major workover.

A client in the Gulf of Mexico (GoM) was operating an ultra-deepwater well with a nitrogen-charged tubing retrievable safety valve (TRSV). When the TRSV failed, Bureau of Safety and Environmental Enforcement regulations required the well to be shut-in until the TRSV could be repaired or replaced. The client approached Baker Hughes about deploying a REACH WRSV via light well intervention. It was tested in February 2023 at Baker Hughes’ test rig in Tomball, Texas, and will be installed in the GoM well in August.

Water Management: Zero Liquid Discharge (ZLD) Produced Water; Saudi Aramco

Category: Water Management

Product: Zero Liquid Discharge (ZLD) Produced Water Management Project

Company: Saudi Aramco

Website: https://www.aramco.com

Saudi Aramco’s Zero-Liquid Discharge (ZLD) produced water management solution desalinates produced oilfield water by transforming its ionic properties that can be injected into the reservoir for pressure maintenance and increase the efficiency of oil recovery.

ZLD water can also be used as frac-water for tight gas and unconventionals, wash water for crude oil desalting and in other applications including the irrigation. ZLD uses a pretreatment system to remove residual hydrocarbons and H2S plus a dynamic vapor compression (DyVaR) unit for salt removal from hypersaline oilfield produced water. The pretreatment system uses a vent gas scrubber and chemical scavenger to lower the dissolved H2S from produced water, while dissolved gas floatation with nitrogen gas removes dispersed hydrocarbons.

The pretreated produced water is then processed in DyVaR to effectively remove salts from produced water. The DyVaR unit is equipped with "cyclones" to accomplish water evaporation at a temperature of about 175 F. The water vapor is then condensed to generate the low salinity water. The reject brine is continuously recycled to mix with feed pretreated produced water to achieve up to 80% to 90% water recovery. The concentrated salts obtained from ZLD technology were processed further to recover purified salts or directly used to formulate drilling fluids, which results in zero waste discharged into the environment.

The ZLD pilot unit has a 225 bbl/d capacity and was able to remove the residual hydrocarbons and dissolved H2S to less than 1 ppm and lower the salinity of produced water from 90,000 ppm total dissolved solids to less than 100 ppm to 200 ppm total dissolved solids to essentially generate fresh water with a consistent recovery factor of about 80%.

Recommended Reading

Daniel Berenbaum Joins Bloom Energy as CFO

2024-04-17 - Berenbaum succeeds CFO Greg Cameron, who is staying with Bloom until mid-May to facilitate the transition.

Equinor Releases Overview of Share Buyback Program

2024-04-17 - Equinor said the maximum shares to be repurchased is 16.8 million, of which up to 7.4 million shares can be acquired until May 15 and up to 9.4 million shares until Jan. 15, 2025 — the program’s end date.

Mexico Pacific Appoints New CEO Bairstow

2024-04-15 - Sarah Bairstow joined Mexico Pacific Ltd. in 2019 and is assuming the CEO role following Ivan Van der Walt’s resignation.

Global Partners Declares Cash Distribution for Series B Preferred Units

2024-04-15 - Global Partners LP announced a quarterly cash dividend on its 9.5% fixed-rate Series B preferred units

W&T Offshore Adds John D. Buchanan to Board

2024-04-12 - W&T Offshore’s appointment of John D. Buchanan brings the number of company directors to six.