Data analytics, machine learning, artificial intelligence and more are providing great value for the industry. (Source: huyangshu/Shutterstock.com)

Learn more about Hart Energy Conferences

Get our latest conference schedules, updates and insights straight to your inbox.

Editor’s note: The copy herein is contributed from service companies and does not reflect the opinions of Hart Energy.

_____________________________________________________________________________________________

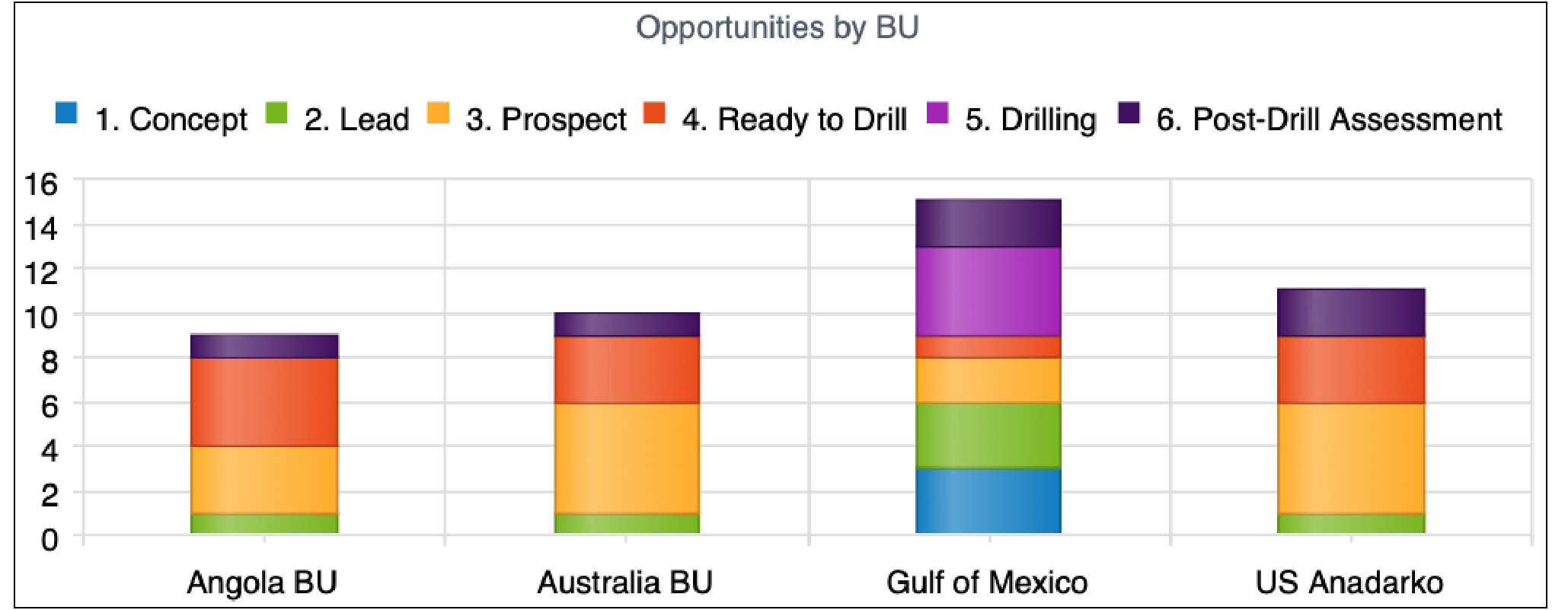

Improve analysis productivity of exploration opportunities

Geoscientists and reservoir engineers evaluate resource potential and the chance of success for their exploration plays and prospects through detailed analysis. They feed results into exploration portfolios for decision makers to consider. These processes are often time-consuming and fraught with error. Critical information and assumptions can be lost, out of sync or not timely delivered, which impacts decisions made on capital and resource allocation. Historically, these data have been managed in file libraries and complex spreadsheets. Rose & Associates and 3GiG have developed a web- or server-based application, Appra, that stores the evaluation data, applying version control through the play or prospect life cycles. Using new automation, Appra allows both scientists and leadership the ability to access, analyze and track exploration decisions, becoming the single source for the value capture of their exploration business. 3-gig.com, roseassoc.com

New backward compatible flow computer optimizes productivity

ABB’s Measurement & Analytics business unit for flow computers and controllers has released the new XSeries G5 backward compatible, extendable flow computer and remote terminal unit (RTU) for the upstream oil and gas industry. This will help provide more solutions to optimize the productivity of a company’s assets across its full life cycle. This new generation will offer low-power, high-reliable microprocessor-based units with a new Linux operating system, persistent memory and a secured wireless connectivity, combined with the same wide range of measurement, monitoring and alarm applications for remote gas or oil systems. It also will provide an upgrade path to new digital technologies, protocols such as message queuing telemetry transport and secured wireless connectivity (WiFi-Access Point or Bluetooth). A single flow computer or RTU can now be configured to support many control logics and alarms systems. It also would be able to perform up to 24 measurement runs for gas or liquid, utilizing preconfigure application or custom control logics developed using IEC 61131 programming language. new.abb.com

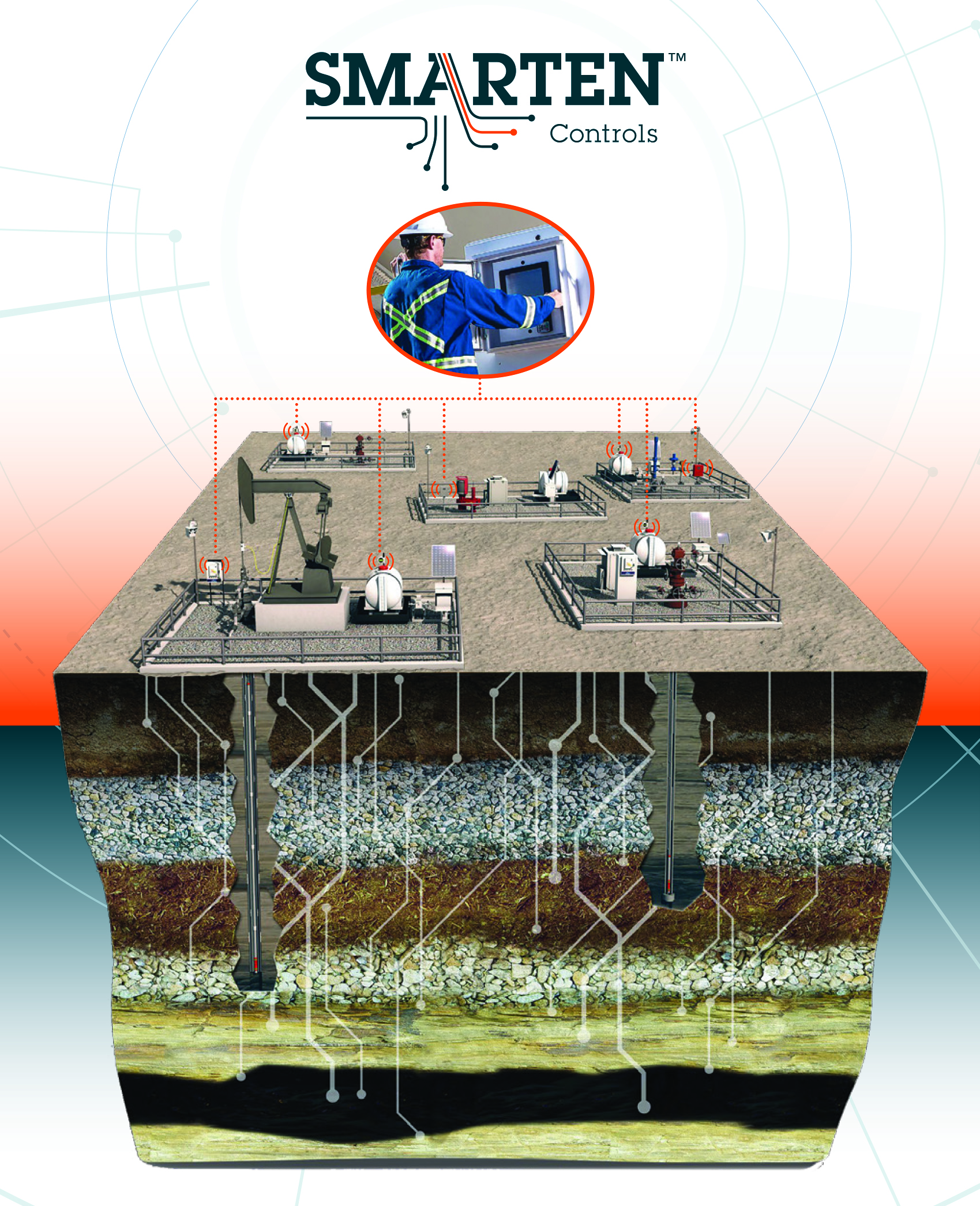

Asset management system controls multiple forms of artificial lift

SMARTEN is an asset management system developed by Apergy that can control and optimize multiple forms of artificial lift that are being classified as total asset managers. The new technology has the capability to control and optimize rod, hydraulic, electric submersible pump and gas-lift units. The SMARTEN controls asset manager is the industry’s first automated wellsite management system that is designed to deliver maximum performance and optimized production for wells. This technology provides a versatile, programmable platform, customizable to an operator’s unique pumping environment. Featuring an easy-to-use interface, the system provides remote, real-time diagnostics and alerts, allowing users to monitor changing well conditions. apergy.com

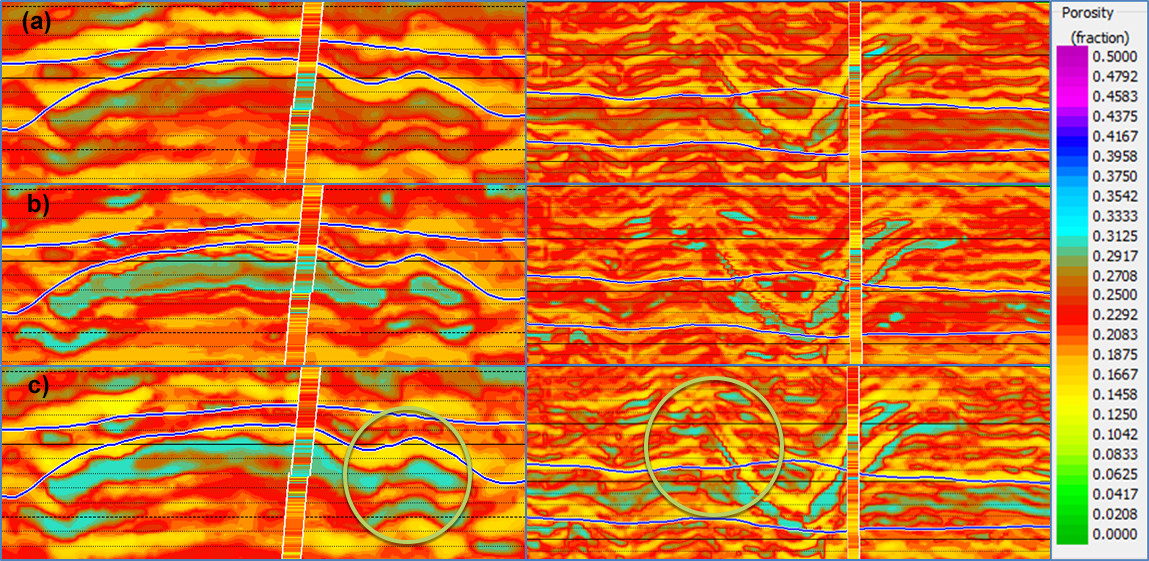

Deep learning powers more accurate prospect prediction

CGG GeoSoftware is expanding its machine learning technology to put the power of a new generation of analytic and prediction techniques into the hands of geoscientists in intuitive and accessible ways so they can more accurately characterize hydrocarbon reservoirs. Hampson-Russell Emerge software, part of the GeoSoftware portfolio, has added deep learning in the form of a deep feed forward neural network (DFNN), which offers new opportunities for predicting reservoir properties. The new technology is easy to implement in reservoir workflows thanks to flexible parameterization and the usual attention to user-friendliness. Deep learning in Emerge helps geophysicists predict reservoir property volumes from seismic attributes and well data with greater detail than conventional approaches by revealing more subtle variations than previously possible. cgg.com

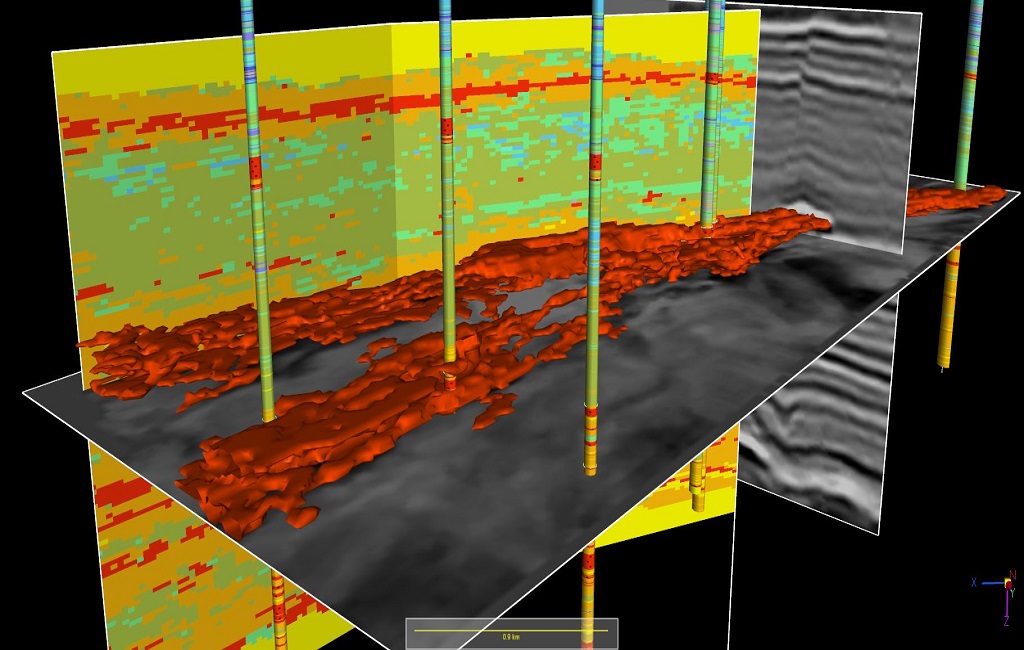

Machine learning techniques accelerate interpretation, reservoir characterization

Predicting facies and rock types from seismic data is traditionally done using deterministic or stochastic seismic inversion methods. When combined with rock typing and seismic facies classification, their outputs can be used to create subsurface facies models for prospecting or simulation. These methods, however, lack the resolution required to accurately predict thin beds or intermediate-type facies, and they frequently fail to model the heterogeneity that characterizes many reservoirs. Emerson E&P has developed a supervised machine learning approach called Democratic Neural Network Association (DNNA) that reconciles multiple datasets to predict reservoir lithofacies heterogeneities and distribution away from the wellbore. This process results in a probabilistic facies model description of the reservoir, prediction of the most probable facies distribution and associated maximum probability, and the probability of each facies. Results introduce valuable insights into reservoir presence uncertainty and are ready for simulation. The outcome is critical for a better understanding of reservoir behavior. Even with the sheer volume of available data, machine learning produces outputs in minutes or hours rather than months or years, and it is ideal for cloud implementation. emerson.com

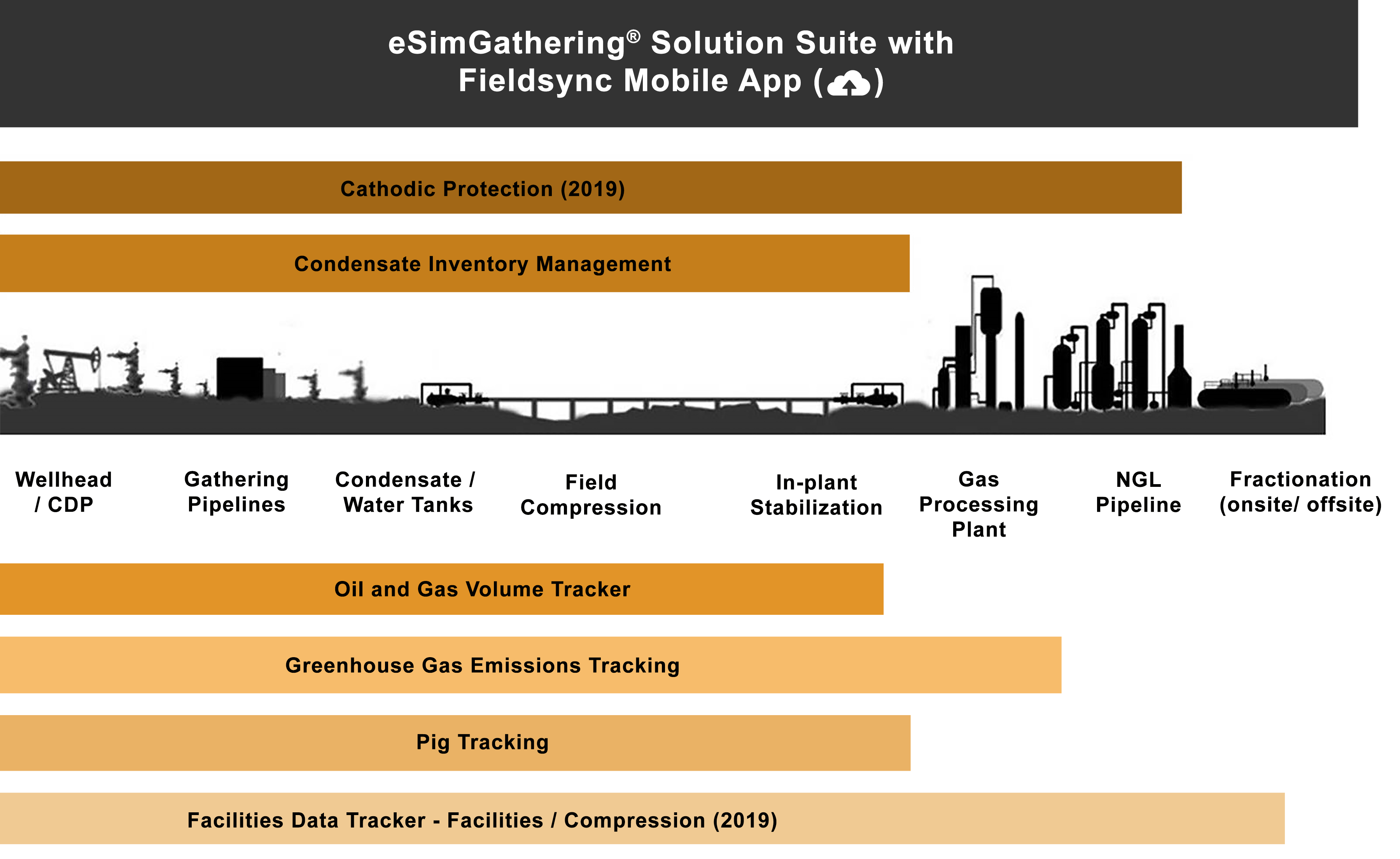

Apps allow operators to capture data while in the field

In 2018 eSimulation released the eSimGathering 2.0 and FieldSync 2.0 mobile app, which enable operators to capture data while in the field. These data are automatically uploaded to a cloud database for use by other business groups. Updates include condensate inventory management that tracks condensate and water hauling at each facility accounting for production, sales, transfers and losses; pig tracking; greenhouse gas emissions tracking (tracks vents and blowdowns); and an oil and gas volume tracker that calculates volume, energy and component losses/gains across the system. The technologies reduce the manpower required to manage field gathering businesses by 20% to 30%. They also help HSE personnel identify and mitigate permit limit exceedances and avoid costly penalties. The apps standardize calculations and create mathematical integrity for ease of auditing. Field data capture and cathodic protection modules are planned for this year. esimulation.com

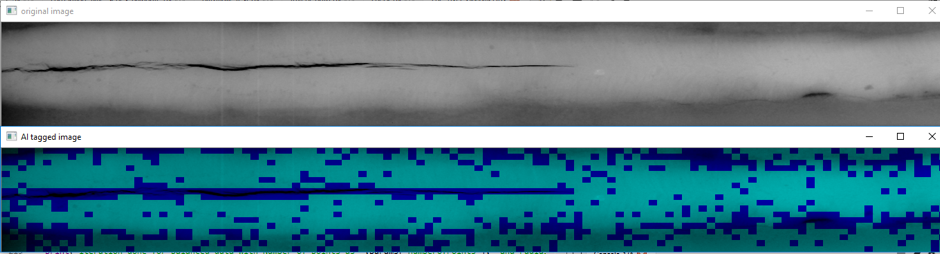

AI apps target specific industry challenges

Flutura’s upstream artificial intelligence (AI) apps target specific industry problems (i.e., fracking AI apps provide early detection warning signals from fracking pumps, top drive AI apps help reduce downtime and drilling efficiency AI apps reduce invisible loss time). In addition, many mission critical systems used in upstream operations are welded together. These assets must be tested for reliable performance as degradation can be found in joints. Flutura’s deep learning diagnostic app diagnoses poor weld conditions by looking at radiology data. This app can foresee and prevent catastrophic incidents especially on welded oil pipelines. Another technology assists with the changing oil and gas industry, as many of the people with experience troubleshooting upstream problems are retiring. Flutura’s industrial bot can codify this knowledge and offer newer employees help in troubleshooting equipment. To optimize costs, Flutura ensures drilling and production efficiency using downhole and surface-level sensor data streams and helps heavy equipment manufacturers provide value-added digital diagnostics and prognostics as a service for early detection of failures. fluturasolutions.com

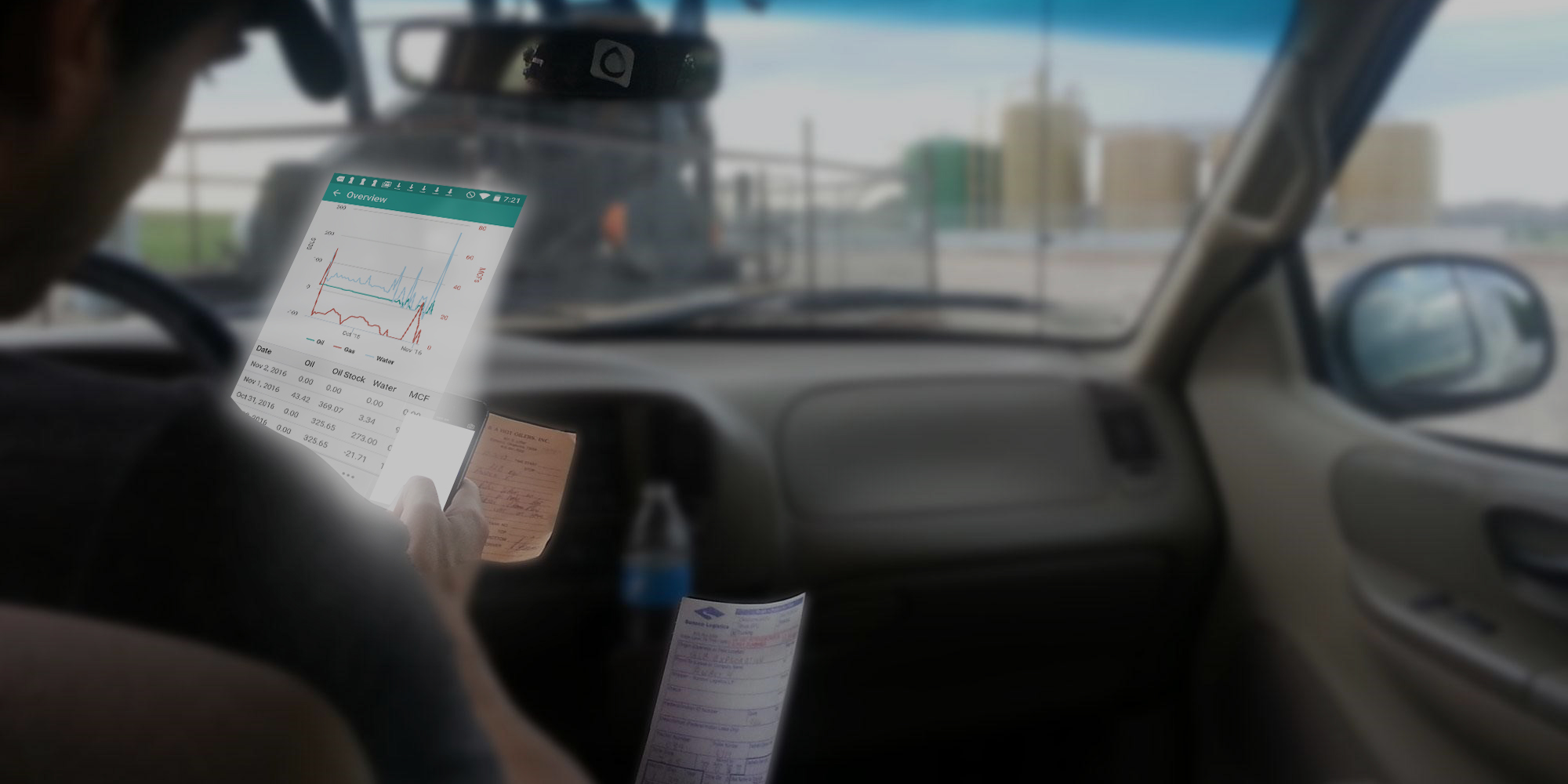

App replaces spreadsheet, gauge sheet workflows from pumpers in the field

GreaseBook is a simple, mobile-first oil and gas production app specifically designed to replace spreadsheet and gauge sheet workflows from pumpers in the field. The app provides timely data from the field increasing the accountability of one’s pumpers, correct data from the field helping to alleviate minutiae from the back office and a centralized place from which an operator’s entire team can work. In addition to releasing Android and Microsoft Surface apps to complement its iOS app, the cost-effective app has recently rolled out a powerful well-testing, allocations and downtime tracking suite. GreaseBook continues to maintain a strong risk-reversal policy: no contracts, no training fees, no setup fees, free help desk calls and a 60-day 100% money back guarantee. greasebook.com

Automation platform delivers consistent fracture treatment across stages

In 2018 Halliburton launched the Prodigi Intelligent Fracturing service as a hydraulic fracturing automation platform with the goal of delivering a consistent fracture treatment across stages. The first iteration of the platform, Prodigi AB Service, focuses on automatically controlling pump rate to breakdown all perforation clusters in a stage. To date, more than 2,000 stages have been pumped with the Prodigi AB Service, improving cluster efficiency, lowering treating pressures, reducing screenouts and resulting in faster treatment times. In East Texas, by using Prodigi to improve cluster breakdown, Halliburton was able to achieve a significant increase in treating rate, which lead to a 10% reduction in stage pumping time. This ultimately led to cost savings for the operator and reduced risk to screenout in the target basin. Moreover, this year Halliburton will introduce several other automation elements to Prodigi that continue to focus on stimulation consistency and improved well performance. halliburton.com

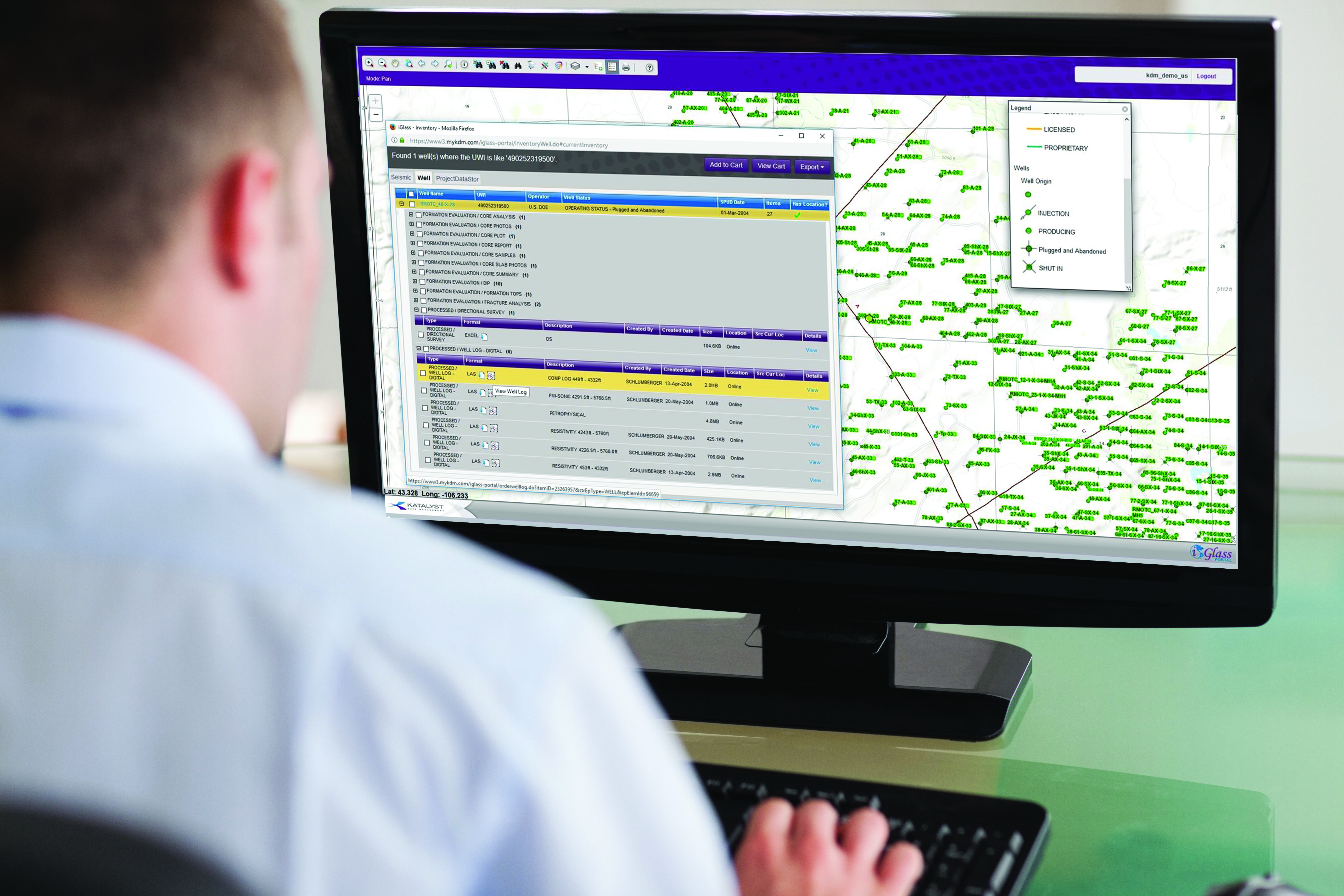

Electronic well file for E&P data analytics

Oil and gas companies moving toward Big Data analytics are missing a critical dataset in their analytic data pool by keeping information locked up inside paper logs and well files. In 2018 Katalyst Data Management launched a well file and well log scanning service for the oil and gas industry. Scanning “paper to digits” is the first step in the company’s initiative to create a complete electronic well file to enable analysis of the data. The electronic well file contains data that are already in digital format, such as LAS, DLIS and other well logs, XLS spreadsheets and other digital data, along with the “paper to digits” data that have been scanned. Digital and paper data are packaged into an electronic well file and stored in Katalyst’s cloud-based storage solution iGlass, a PPDM 3.8 database for subsurface data. Once the well file is in iGlass, clients can view and download their well data files and metadata alongside their seismic data volumes from a single GIS map portal. The data management software includes tools that are specific to the life cycle of seismic, well and interpretation data types. katalystdm.com/wells

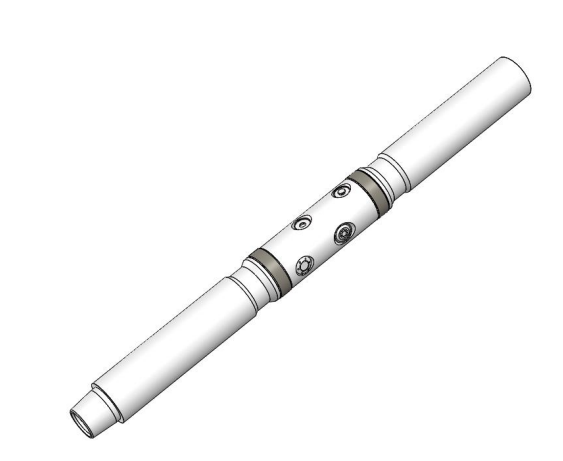

Tool samples high-frequency dynamics data at 1,500 Hz

NOV has released the BlackBox HF memory-mode tool that samples high-frequency dynamics data at 1,500 Hz and load measurements at 100 Hz to the ReedHycalog portfolio of drilling dynamics measurement tools. The tool features advanced internal memory to record a full dataset for 175 hours, providing data for weight on bit, torque on bit, three-axis vibration, annular pressure, internal pressure, temperature and rpm. Due to the high memory capacity of the BlackBox HF tool, all of the high-speed, sampled data are stored and delivered to the surface, where it can be further analyzed in the office. The first 6¾-in. prototype BlackBox HF tool recently went downhole for a West Texas operator, and the tool collected high-frequency data without issue for seven runs. The BlackBox HF tool was made commercially available at the end of the first quarter of the year, with the initial rollout taking place in the North American market. nov.com

Tool allows users to stop typing and start importing

Allez from Peloton is a workflow tool for importing, visualizing and reporting drilling and completions data. Allez is designed to revolutionize how users work in WellView. Users will experience a drastic reduction in the amount of manual data entry required by providing a series of import tools and integrations with vendors and third-party systems, including Pason WellView DataLink, WVXML and WITSML. peloton.com

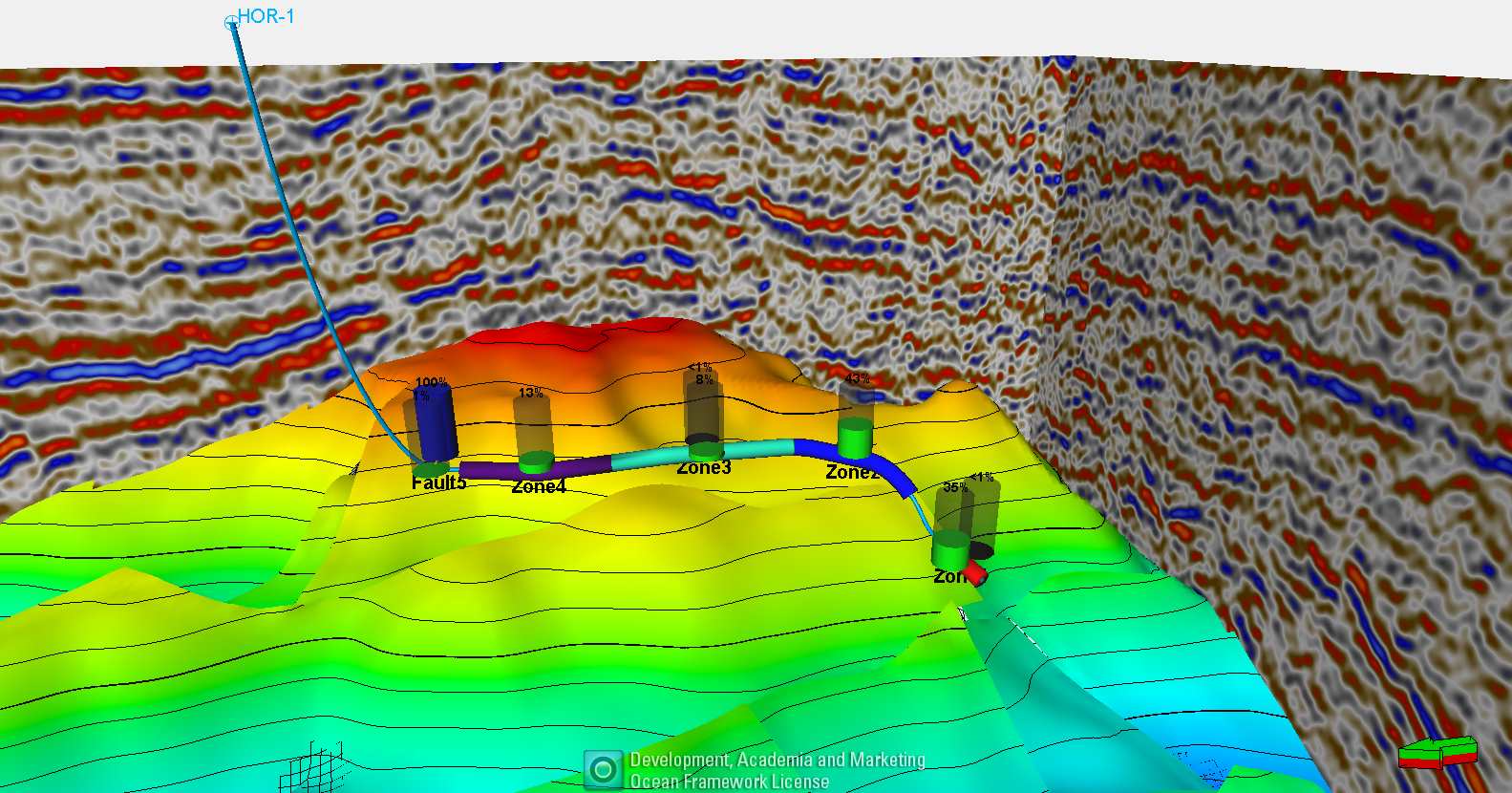

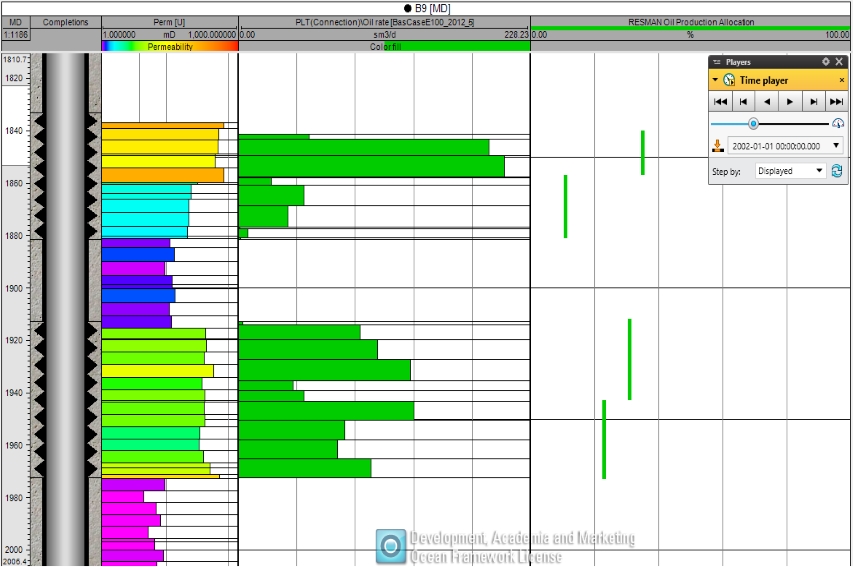

Digitizing inflow tracer interpretation

Inflow tracer systems enable years of continuous well and reservoir monitoring, where the signal trends can be cross-correlated with production data, complementing existing data workflows used for production optimization and reservoir surveillance. In this way, value can be extracted when inflow tracer data are digitized and uploaded into an operator’s existing database system and software platforms. Over the past decade, RESMAN has been delivering thousands of inflow tracer interpretation reports. To facilitate data integration and the resulting visualization within existing software and data workflows, RESMAN has developed a software plug-in called RES•ViZ. The tool is designed to import qualitative and quantitative interpretations into Schlumberger’s Petrel reservoir modelling software. Inflow tracer data (e.g., location) and interpreted results (e.g., inflow contribution) are integrated with other subsurface data, facilitating operations analysis, well event processing and history matching. Furthermore, if multiple quantifications have been performed in the same well, inflow changes over time can be animated. Through this reservoir engineering tool, static and dynamic models can be kept up to date by the asset team with the latest inflow tracer interpretations and operational insight. resman.no

In-chassis flow computer reduces costs, complexity of well pad automation

In an effort to cut costs and increase efficiencies, oil and gas producers are transitioning from single-well pad fields to multiwell pad sites. These more complex operations have greater data and control requirements, making measurement more difficult and creating additional engineering, operating and maintenance costs for producers. The Logix chassis-based oil and gas flow computer was developed by ProSoft Technology to reduce the cost and complexity of well pad automation systems. The solution seamlessly integrates with Rockwell Automation Logix controllers to help oil and gas producers avoid the obstacles and high cost of traditional remote terminal unit based solutions on multiwell sites. Utilizing this flow computer allows producers to have one architecture for control and measurement, helping reduce hardware, software and licensing costs, optimize operations and simplify deployment and scalability. Additionally, it utilizes a single high-speed connection to SCADA systems, improving data integrity and data accuracy. rockwellautomation.com, prosoft-technology.com

Digital twin allows companies to increase efficiency, reduce costs

The digital twin offers many potential benefits to the oil and gas industry. It describes an extensive collaborative approach that allows companies to plan, design, build, operate and maintain an asset using an integrated parametric data model and a single set of interoperable and reusable data. SNC-Lavalin has been delivering brownfield digital twins in a very rapid and low-cost way. The company follows a three-step process: 1) Digitally capture an environment using a variety of sensors, reality capture and digital scanning devices; 2) Create a digital version, or digital twin, of the captured reality—with this twin enriched with additional asset information and data where required; and 3) Explore and interact with the created digital twin using, for example, immersive technologies. The digital twin allows companies to increase efficiency and reduce costs across the entire life cycle of a project by identifying clashes during design, enabling more effective design and risk reviews, delivering more effective training and planning activities, and simulating dismantling and demolition. snclavalin.com

Automated tool quickly develops dynamic, accurate models

The benefits of predictive maintenance for oil and gas operators is well-known, but traditional approaches to building a predictive model take time to design and implement, struggle to scale across large operations and are limited by edge cases. SparkCognition’s Darwin automated model building product creates dynamic, accurate models that take far less time to develop. Darwin has been used to create predictive artificial intelligence for a major oil and gas company. The company wanted a single, scalable solution that could monitor all assets, despite the differing behaviors and life cycles of machines within the gas system. An unsupervised approach was used to build a model that could identify normal versus anomalous behavior in real time and track anomalies to downtime events. The model was able to successfully identify anomalies and track them to production downtime events, giving advanced warning to engineers of potential issues and providing leading indications for root cause analysis. This proof of concept was so successful that the company has decided to go forward with a full deployment. sparkcognition.com

Automated storage tiering and scalability

The oil and gas industry processes large amounts of data on a regular basis (e.g., seismic data, charts, research documents and process reports). These data accumulate over time and grow continuously making it a challenge for IT environments to effectively store, manage, control and use these data. StoneFly’s Super Scale Out (SSO) network attached storage (NAS) appliance, with its latest addition of automated storage tiering, enables IT environments to set up scalable data storage infrastructure that can accommodate petabytes of continuously growing, unstructured data and facilitate IT administrators to manage and control these data under a single global namespace and a centralized management interface. Automated storage tiering enables IT administrators to configure policies that automatically move data based on the data of creation or the usage frequency. This practice reduces the need to constantly manage the storage infrastructure and makes the process efficient. The integration of an automation-enabled storage infrastructure in the IT environments of oil and gas industries simplifies data storage and management, consuming lesser resources and enhancing productivity. stonefly.com

Cloud-based automated seismic metadata capture

Released in January, the SeisConnect system establishes a data model that connects data in ways not possible by human review by creating main categories within the model using connectors, data phrases, sentiments, topic modeling and languages. Using the Tape Ark SeisConnect engine, users can create logical and ranked groups of data that indicate the relevance (i.e., topic models through connectors related to the data) and much more. For examples, users can ask, “Show me all seismic data that have a copyright notice in the header of the seismic file and has a license document that references that survey name.” SeisConnect addresses concerns over data ownership and licensing, creates textual connections from all metadata inputs and develops content risk profiles. tapeark.com

Tool minimizes safety risks and validates well integrity

Weatherford’s Vero automated connection integrity is the most disruptive technology ever introduced in the tubular running space, according to the company. Vero applies artificial intelligence (AI) to minimize safety risks and validate well integrity with absolute certainty. In applications ranging from conventional land to complex deep water, the technology provides operators with previously unobtainable consistency and accuracy. The solution employs two proprietary features: AutoMakeup technology, which precisely controls connection makeup, and AutoEvaluate software, which continually assesses torque against original equipment manufacturer criteria. By applying AI at every stage from pipe manufacturing to well installation, Vero can remove the uncertainty of human judgment from the connection process. In so doing, the tool can minimize the chance of catastrophic well failures associated with poorly made up connections as well as reduce the total cost of well ownership, minimize safety risks and protect corporate reputation. Vero goes beyond tubular running to minimize the associated risks, both onshore and offshore, and builds wells that last a lifetime. weatherford.com

Chemical management platform ensures target concentrations are maintained

WellAware, an Industrial Internet of Things company for oil and gas, released an enhancement to its chemical management platform with the launch of Proportional Dosing. According to WellAware data, average chemical injection variance is 37%, with variances strongly skewed toward underinjection. The lack of accurate chemical dosage leads to lost production revenue due to workovers and shutdowns as well as increased maintenance costs. The WellAware Proportional Dosing technology guarantees real-time injection rates match recommendations on production and water management assets, ensuring target concentrations are maintained. By making real-time injection rate changes correlated to actual production flow levels, the required injection rate to achieve the target dosage levels can be assured and monitored for compliance. WellAware provides the source of truth for both operators and chemical service providers, and it provides the basis for the establishment of service level agreements and optimized production. Field results indicate a 30% reduction in downtime and cost savings of nearly $45,000 per well with implementation. WellAware’s product is designed for high-rate applications with various production rates, measuring flow rates every second and updating corresponding injection rates every minute. wellaware.us

Software collects and integrates data from a variety of sources

Recent years have seen technology adoption move from purchasing and repurchasing software, upon the release of new versions, to subscription-based software as a service (SaaS), which supplies incremental updates on a fluid basis. Expanding on that concept, Zedi has recently released Zedi Automation as a Service (ZAaaS). ZAaaS integrates automation hardware, software, analytics and service combined with expert engineering and design into best practice solutions to collect and integrate data from a variety of sources, making data and information available to decision makers on smart devices across the company, anywhere and anytime. ZAaaS uses industry standard hardware, combined with Zedi’s purpose-built platform, to present a curated experience requiring less upfront engineering and investment, getting E&P companies the most cost-effective results faster. zedisolutions.com

Recommended Reading

Mexico Pacific Appoints New CEO Bairstow

2024-04-15 - Sarah Bairstow joined Mexico Pacific Ltd. in 2019 and is assuming the CEO role following Ivan Van der Walt’s resignation.

Global Partners Declares Cash Distribution for Series B Preferred Units

2024-04-15 - Global Partners LP announced a quarterly cash dividend on its 9.5% fixed-rate Series B preferred units

W&T Offshore Adds John D. Buchanan to Board

2024-04-12 - W&T Offshore’s appointment of John D. Buchanan brings the number of company directors to six.

73-year Wildcatter Herbert Hunt, 95, Passes Away

2024-04-12 - Industry leader Herbert Hunt was instrumental in dual-lateral development, opening the North Sea to oil and gas development and discovering Libya’s Sarir Field.

Riley Permian Announces Quarterly Dividend

2024-04-11 - Riley Exploration Permian’s dividend is payable May 9 to stockholders of record by April 25.